Table of Contents

-3-

1 Introduction......................................4

1.1 Before Using the Product ..................... 4

1.2 Over View of the Product ..................... 4

1.3 System Configuration........................... 5

2 Safety Precautions........................... 6

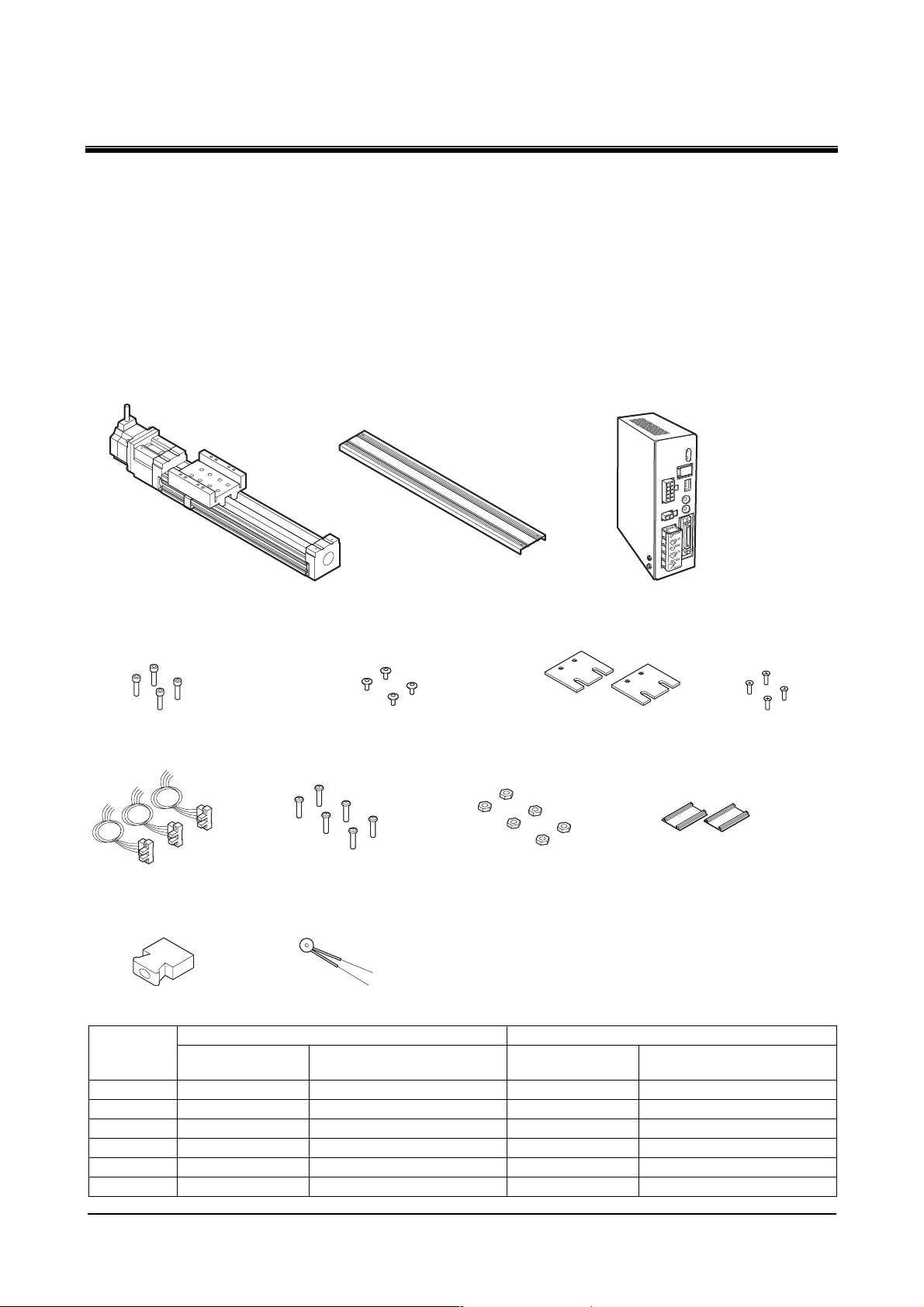

3 Preparation ....................................... 8

3.1 Checking the Product........................... 8

3.2 Product Number Code ......................... 9

3.3 Motorized Slider and Driver

Combinations ....................................... 9

3.4 Names of the Parts and

Main Functions ................................... 10

4 Installation ...................................... 12

4.1 Location for Installation ...................... 12

4.2 Motorized Slider Installation ............... 12

4.3 Installing the Load .............................. 17

4.4 Install the Driver ................................. 18

5 Connections ................................... 21

5.1 Connection Example for a

Standard Type .................................... 21

5.2 Connection Example for an

Electromagnetic Brake Type .............. 24

5.3 Connecting to the Power supply ........ 26

5.4 Grounding the Motorized Slider

and Driver........................................... 27

5.5 Noise Elimination Measure ................ 27

5.6 Connecting the Electromagunetic

Brake .................................................. 28

5.7 Connecting Control Input/Output........ 29

5.8 Input Signals....................................... 30

5.9 Output Signals.................................... 33

5.10 Connecting the Photosensor .............. 35

5.11 Timing Chart ....................................... 36

6 Setting.............................................37

6.1 Resolution Selector Switch................. 37

6.2 Pulse-Input Mode Selector Switch ..... 37

6.3 Current Setting Switch........................ 38

6.4 Speed Filter Setting Switch ................ 39

7 Running ..........................................40

7.1 Return to Mechanical Home

Operation............................................ 40

7.2 Positioning Operation ......................... 40

7.3 Operating the Electromagnetic

Brake Type ......................................... 44

8 Maintenance ...................................46

9 Troubleshooting and Remedial

Actions............................................47

9.1 Protective Functions........................... 47

9.2 Troubleshooting.................................. 48

10 Appendix.........................................49

10.1 Specifications ..................................... 49

10.2 Acceleration Setting Curve................. 53