2

Operation

yUse a motor and driver only in the specied combination. An incorrect combination

may cause a re.

yProvide an emergency-stop device or emergency-stop circuit external to the

equipment so that the entire equipment will operate safely in the event of a system

failure or malfunction. Failure to do so may result in injury.

yBefore supplying power to the driver, turn all input signals to the driver to OFF.

Otherwise, the motor may suddenly start when the power is turned on, leading to

injury or damage to equipment.

yWhen moving the moving part manually, put the motor into a non-excitation state.

Continuing the work while the motor is in an excitation state may result in injury.

yUse a 24 VDC power supply that has been given reinforced insulation between the

primary side and secondary side. Failure to do so may cause electric shock.

yImmediately when a problem occurred, stop operation and turn o the driver power

supply. Failure to do so may result in re, electric shock, or injury.

yUse only an insulated screwdriver to adjust the driver’s switches. Failure to do so may

result in electric shock.

Maintenance and inspection

yDo not touch the terminals while conducting the insulation resistance measurement

or dielectric strength test. Doing so may result in electric shock.

Precautions for use

This chapter covers restrictions and requirements the user should consider when using

the product.

•Be sure to use our cable to connect the motor and driver.

Check the USER MANUAL for the cable models.

•When conducting the insulation resistance measurement or the

dielectric strength test, be sure to separate the connection between the

motor and the driver.

Conducting the insulation resistance measurement or dielectric strength test with the

motor and driver connected may result in damage to the product.

•Motor excitation at power ON

Simply turning on the power will not excite the motor. To excite the motor, always turn

the C-ON input ON. It is possible to set the motor to be excited automatically after the

power has been turned on, by changing the applicable driver parameter using the

support software MEXE02 or our data setter OPX-2A.

•Preventing electrical noise

Refer to the USER MANUAL for measures with regard to noise.

•Preventing leakage current

Stray capacitance exists between the driver’s current-carrying line and other current-

carrying lines, the earth and the motor, respectively. A high-frequency current may

leak out through such capacitance, having a detrimental eect on the surrounding

equipment. The actual leakage current depends on the driver’s switching frequency, the

length of wiring between the driver and motor, and so on. When providing a leakage

current breaker, use the following products, for example, which have high-frequency

signal protection:

Mitsubishi Electric Corporation: NV series

•Saving data to the non-volatile memory

Do not turn o the main power supply or 24 VDC power supply while writing the data to

the non-volatile memory and also do not turn o for 5 seconds after the completion of

writing the data. Doing so may abort the writing the data and cause an alarm of EEPROM

error to generate. The non-volatile memory can be rewritten approximately 100,000

times.

•When an alarm of overvoltage protection is generated

If vertical drive (gravitational operation) such as elevator applications is performed or if

sudden start-stop operation of a large inertial load is repeated frequently, an alarm of

overvoltage protection may be detected. If an overvoltage protection alarm is detected,

adjust the driving condition or use our regeneration resistor RGB100.

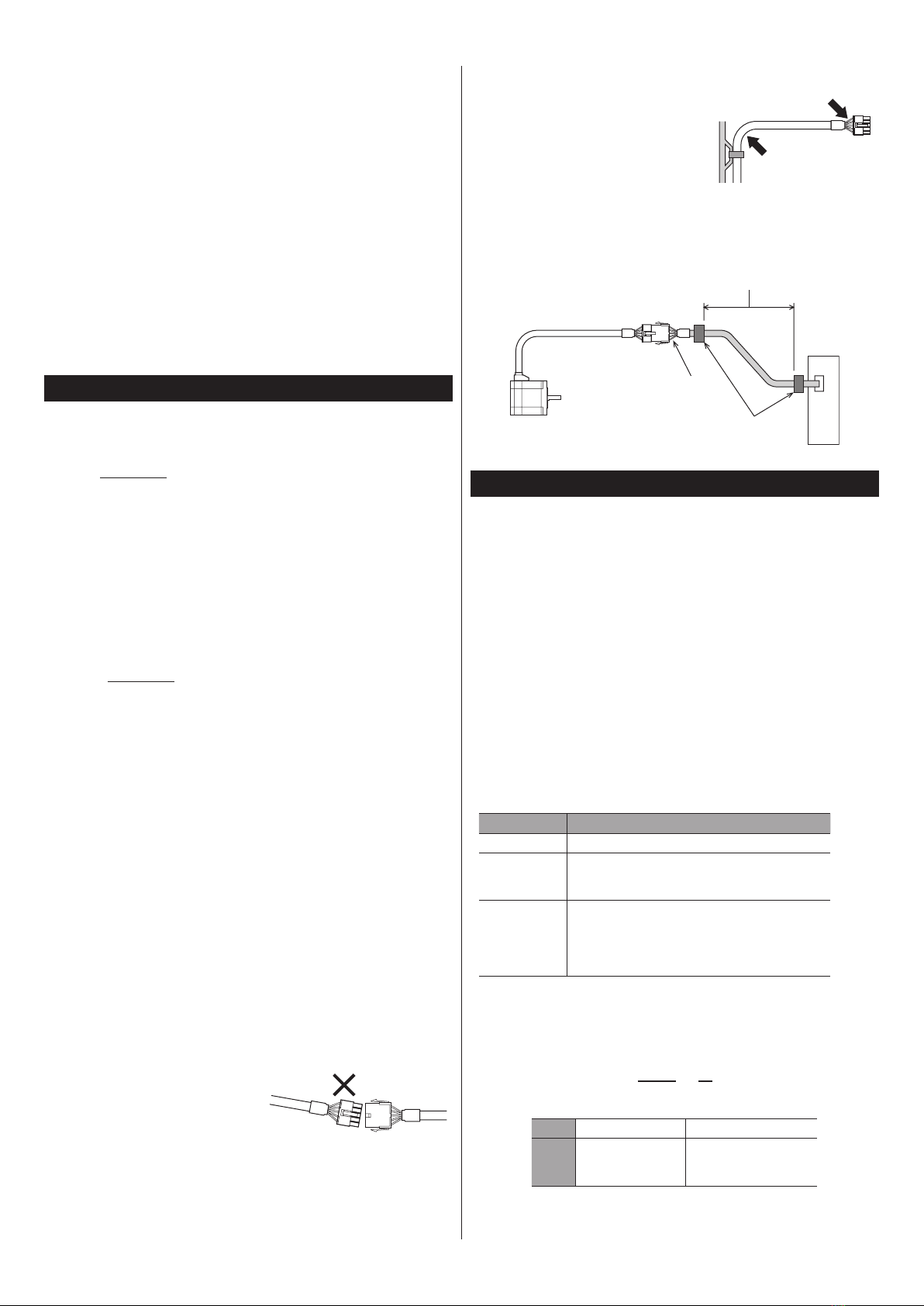

Notes when the connection cable is used

Note the following points when our cable is used.

•When inserting the connector

Hold the connector main body, and insert it

in straight securely. Inserting the connector

in an inclined state may result in damage to

terminals or a connection failure.

•When pulling out the connector

Pull out the connector in straight while releasing the lock part of the connector. Pulling

out the connector with holding the cable may result in damage to the connector.

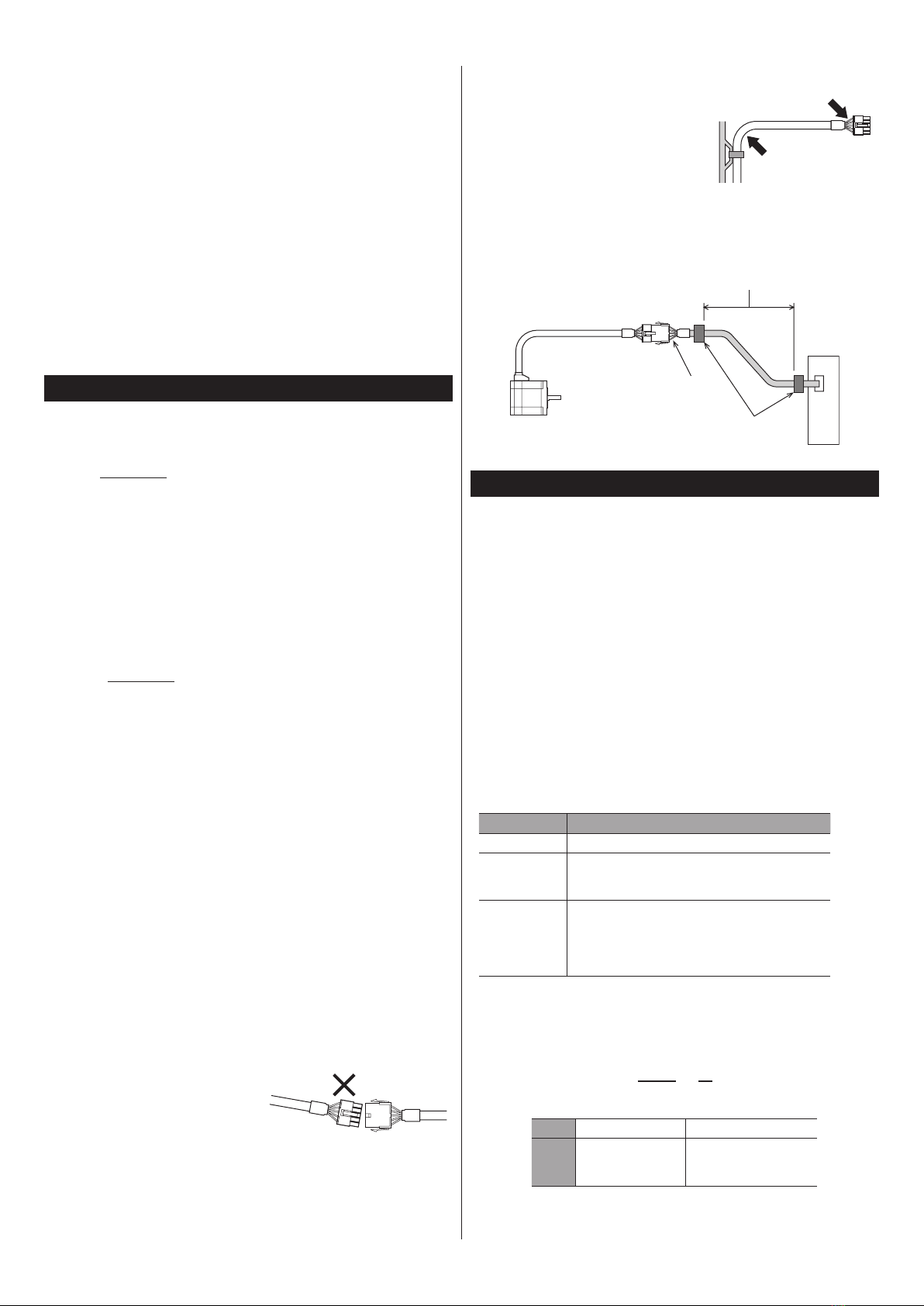

•Bending radius of cable

Use the cable in a state where the bending

radius of the cable is more than six times of

the cable diameter.

Do not bend the lead wires part or x it

with a clamp. Doing so may cause damage

to the connector. More than 6 times

of cable diameter

Do not bend the lead wires part

•How to x the cable

Fix the cable near the connector so that stress is not applied to the connector part.

Use a wide clamp or x the connector at two places to prevent stress from being applied

to the connector.

In the case of a exible cable,

this area is a movable range.

Fix

Driver

Motor

Do not bend the lead wires

part or x with a clamp

Preparation

Checking the product

Verify that the items listed below are included. Report any missing or damaged items to

the Oriental Motor sales oce from which you purchased the product.

yDriver...................................................................1 unit

yCN1 connector (6 pins).................................1 pc.

yCN3 connector (5 pins).................................1 pc.

yCN5 connector (36 pins) ..............................1 pc.

yConnector wiring lever (for CN3)..............1 pc.

ySeal (for CN5)....................................................1 pc. *

yOPERATING MANUAL Driver Edition.......1 copy (this document)

* To distinguish from connectors of other series, put the seal on the CN5 connector to

use.

Included connector model

There are two types of CN3 connectors made by WAGO Corporation and Molex

Incorporated.

There are two types of CN5 connectors made by 3M Company and Molex Incorporated.

Either one of them is included with the product. Check the manufacturer name with the

connector case.

Type Model number (Manufacturer)

CN1 connector MC1,5/6-STF-3,5 (PHOENIX CONTACT GmbH & Co. KG)

CN3 connector

721-205 (WAGO Corporation)

or

54928-0570 (Molex Incorporated)

CN5 connector

Case: 10336-52A0-008 (3M Company)

Connector: 10136-3000PE (3M Company)

or

Case: 54331-1361 (Molex Incorporated)

Connector: 54306-3619 (Molex Incorporated)

How to identify the product model

Verify the model number of the purchased product against the number shown on the

nameplate.

ARD - C

1 2

1 Series name ARD: AR Series driver

2 Power supply input

A: Single-phase 100-115 V

C: Single-phase 200-230 V

S: Three-phase 200-230 V