yUnauthorized reproduction or copying of all or part of this manual is

prohibited.

yOriental Motor shall not be liable whatsoever for any problems relating

to industrial property rights arising from use of any information, circuit,

equipment or device provided or referenced in this manual.

yCharacteristics, specications and dimensions are subject to change without

notice.

yWhile we make every eort to oer accurate information in the manual,

we welcome your input. Should you nd unclear descriptions, errors or

omissions, please contact your nearest Oriental Motor sales oce.

yis a registered trademark or trademark of Oriental Motor

Co., Ltd., in Japan and other countries.

© Copyright ORIENTAL MOTOR CO., LTD. 2018

Published in June 2019

echnical Support Tel:(800)468-3982

A.M. to 5:00 P.M., P.S.T. (M-F)

A.M. to 5:00 P.M., C.S.T. (M-F)

.orientalmotor.com

Schiessstraße 44, 40549 Düsseldor

f, Germany

echnical Support Tel:00 800/22 55 66 22

.orientalmotor.de

el:01256-347090

.oriental-motor.co.uk

el:01 47 86 97 50

.orientalmotor.fr

el:02-93906346

.orientalmotor.it

el:+55-11-3266-6018

.orientalmotor.com.br

• Please contact your nearest Oriental Motor oce for further information.

4-8-1Higashiueno

,Taito-ku,Tokyo 110-8536

el:03-6744-0361

.orientalmotor.co.jp

Tel:0800-060708

www.orientalmotor.com.tw

Singapore

Tel:1800-8420280

www.orientalmotor.com.sg

Tel:1800-806161

www.orientalmotor.com.my

Korea

Tel:080-777-2042

www.inaom.co.kr

Tel:1800-888-881

www.orientalmotor.co.th

Tel:400-820-6516

www.orientalmotor.com.cn

Tel:+91-80-41125586

www.orientalmotor.co.in

Hong Kong Branch

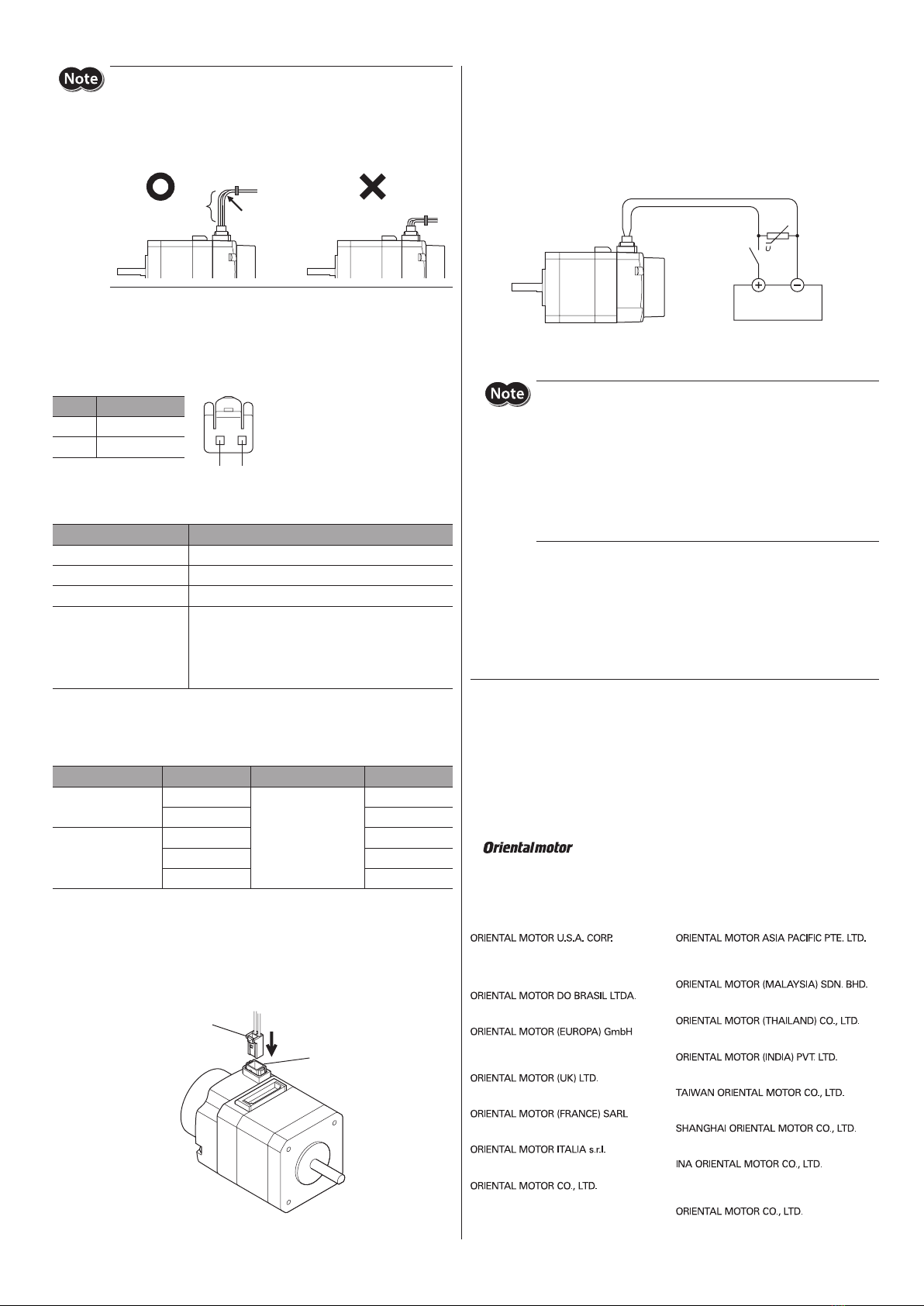

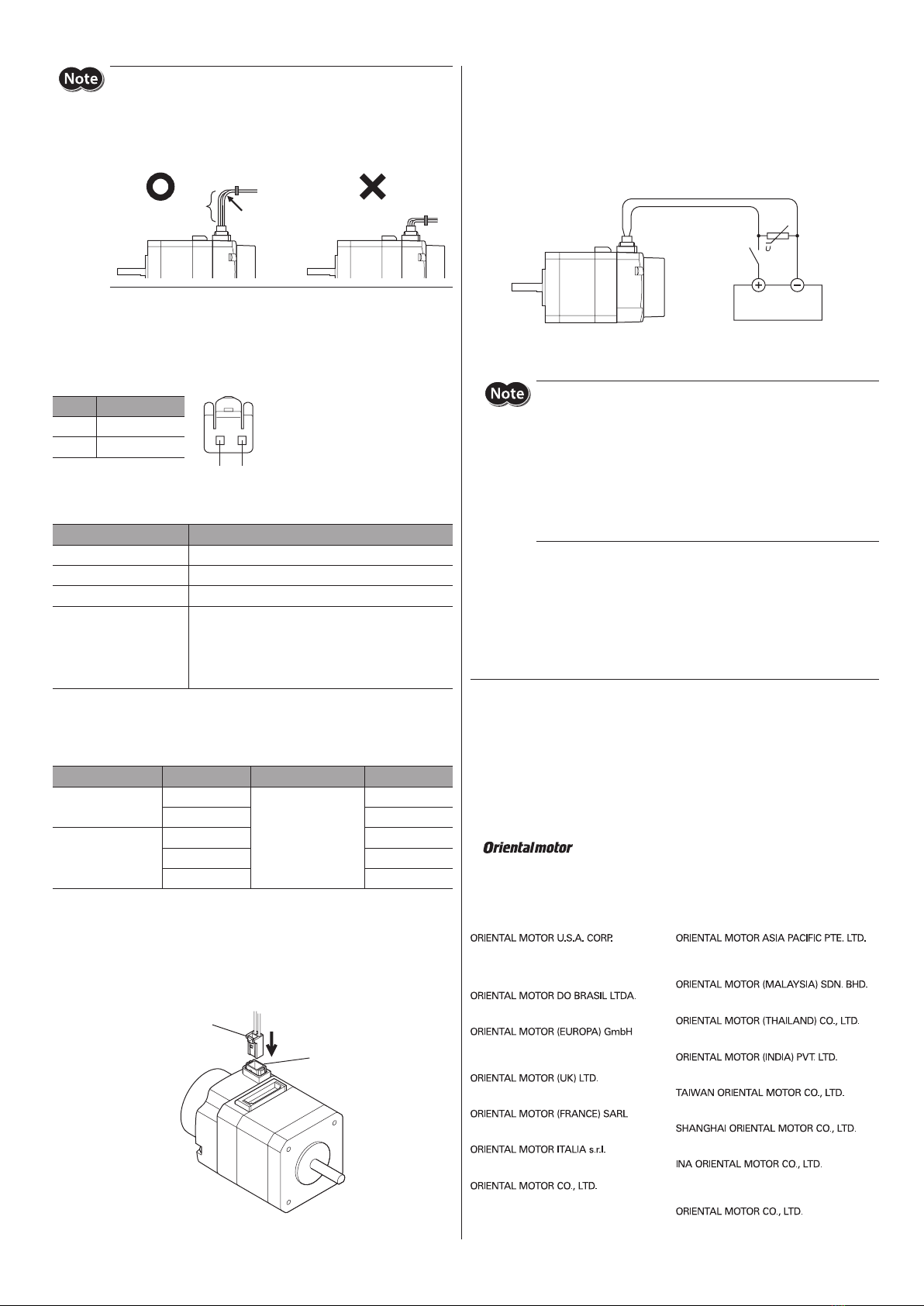

Secure the lead wires at the connection part to prevent the

connection part from receiving stress due to the exing of the lead

wires or the lead wires’ own mass. Also, do not excessively bend the

lead wires near the connection part of the connector. Applying stress

on the lead wires may cause poor contact or disconnection, leading to

malfunction or heat generation.

Bend excessivelyHave length

allowances More than 4 times

of the diameter of

the lead wire.

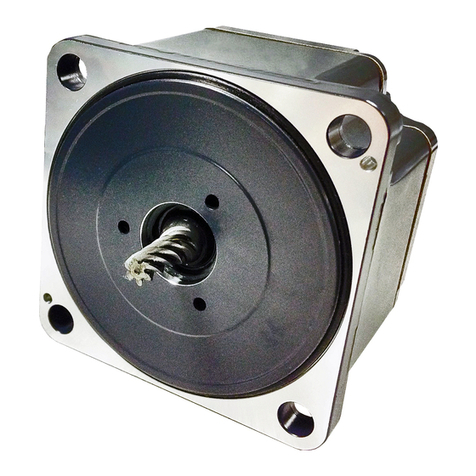

Specications for electromagnetic brake connection

cable

•Connector pin assignments

Pin No. Lead wire color

1 Red

2 Black

•Applicable connector and lead wire

Type Model

Connector housing DF62C-2S-2.2C (HIROSE ELECTRIC CO., LTD.)

Contact DF62-22SCA (HIROSE ELECTRIC CO., LTD.)

Designated crimping tool HT801/DF62-22(10) (HIROSE ELECTRIC CO., LTD.)

Applicable lead wire

AWG22 (0.3 mm2)

Outer sheath diameter:

ø1.2 to 1.5 mm (ø0.05 to 0.06 in.)

Stripping length of wire insulation:

1.8 to 2.3 mm (0.07 to 0.09 in.)

Specications of a power supply for

electromagnetic brake

Model Motor type Power supply voltage Current capacity

A (connector type) PKP24

24 VDC±5%

0.07 A or more

PKP26 0.18 A or more

B (lead wire type)

PKP22 0.05 A or more

PKP23, PKP24 0.07 A or more

PKP26 0.23 A or more

Connecting a power supply for electromagnetic

brake and releasing the electromagnetic brake

1. For the Model A (connector type), connect the electromagnetic brake

connection cable to the electromagnetic brake connector.

Elec

brake connector

tromagnetic brake

tion cable *

* This cable is provided as our product.

2. Connect the varistor (included) in parallel between the 24 VDC terminal

and GND terminal.

The varistor does not have polarity.

3. Connect the electromagnetic brake lead wires to the 24 VDC power

supply.

Connect the red lead wire to 24 VDC terminal, and the black lead wire to

GND terminal.

Va

Switch

Motor

24 VDC

power supply

Black Red

4. Turn on the 24 VDC power supply.

The electromagnetic brake is released.

yDo not apply the voltage beyond its specications. Doing so may

increase heat generation in the electromagnetic brake, resulting in

damage to the motor. Conversely, insucient voltage may prevent

the brake from releasing.

yBe sure to connect the varistor to protect the contact of the switch

or to prevent electrical noise.

yThe electromagnetic brake lead wires have polarities, so connect

them in the correct polarities. If the lead wires are connected with

their polarities reversed, the electromagnetic brake will not operate

properly.