−2−

1 Introduction

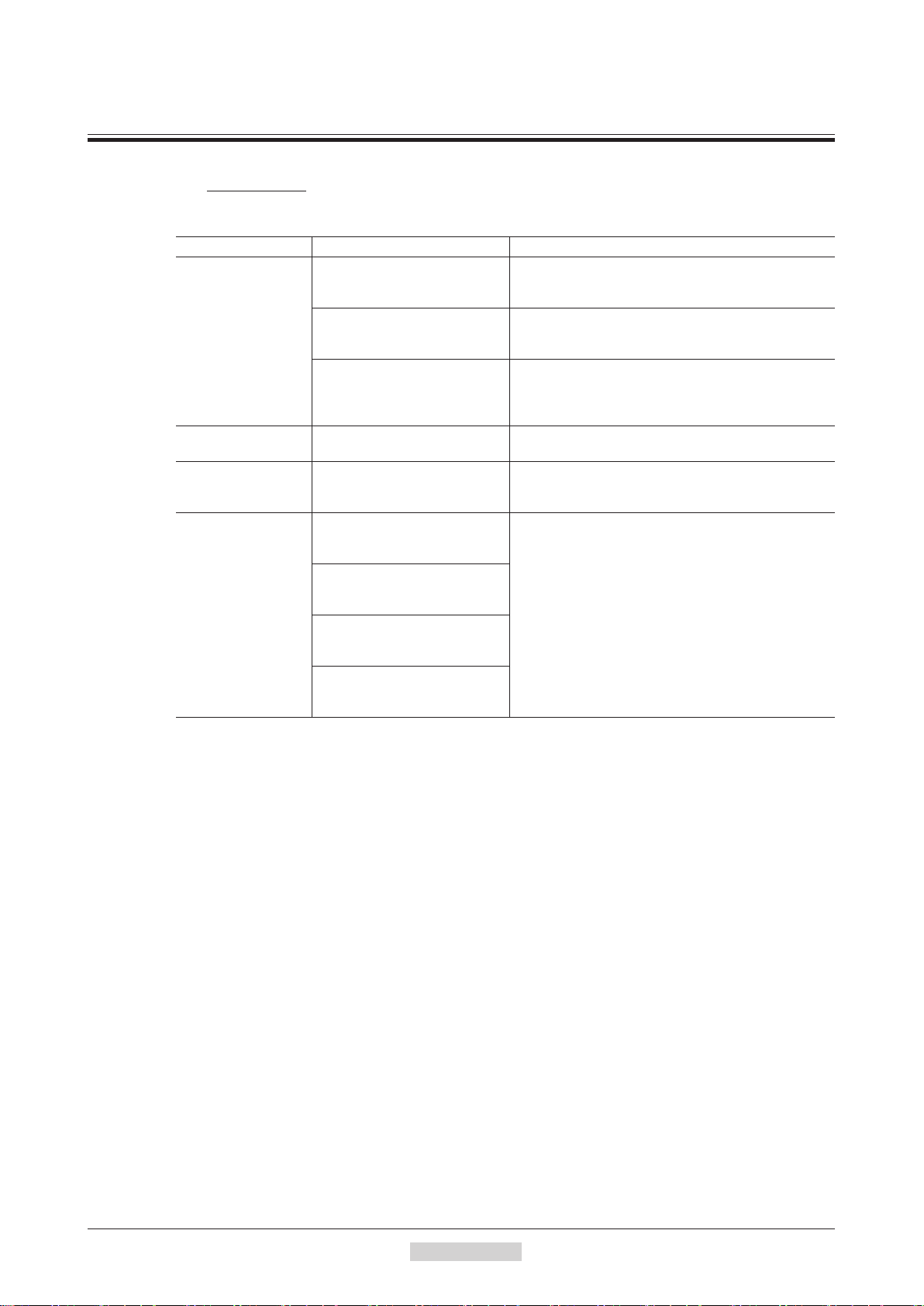

1 Introduction ................................................... 8

2 Operating Manuals for the AR Series .......... 9

3 Overview of the product ............................. 10

4 System conguration .................................. 12

5 Safety precautions ...................................... 13

6 Precautions for use ..................................... 16

7 General specications ................................ 18

8 CE Marking ................................................... 19

9 Preparation .................................................. 20

9.1 Checkingtheproduct................................... 20

9.2 Howtoidentifytheproductmodel............... 20

9.3 Combinationsofmotorsanddrivers............ 21

9.4 Namesandfunctionsofparts...................... 22

2 Installationand

connection

1 Installation ................................................... 26

1.1 Locationforinstallation................................ 26

1.2 Installingthemotor...................................... 26

1.3 Installingaload............................................ 27

1.4 Permissibleradialloadand

permissibleaxialload.................................. 28

1.5 Installingthedriver...................................... 29

1.6 Installingthebattery.................................... 30

1.7 Installingandwiringincompliancewith

EMCDirective.............................................. 30

2 Connection ................................................... 32

2.1 Connectionexample

(electromagneticbrakemotor)..................... 32

2.2 Groundingthemotoranddriver................... 36

2.3 Connectingthedatasetter.......................... 36

2.4 ConnectingtheRS-485communication

cable............................................................ 37

2.5 Connectingandchargingthebattery........... 38

3 Explanation of I/O signals .......................... 39

3.1 AssignmentofdirectI/O.............................. 39

Assignmenttotheinputterminals.....................39

Changingthelogiclevelsettingofinput

signals...............................................................40

Assignmenttotheoutputterminals...................41

3.2 AssignmentofnetworkI/O.......................... 43

Assignmentofinputsignals...............................43

Assignmenttotheoutputterminals...................45

3.3 Inputsignals................................................ 47

3.4 Outputsignals.............................................. 52

3.5 Sensorinput................................................ 56

3.6 Generalsignals(R0toR15)........................ 57

3 Operationtypeandsetting

1 Adjustment and setting .............................. 60

1.1 Resolution.................................................... 60

1.2 Operatingcurrent......................................... 61

1.3 Standstillcurrent.......................................... 61

1.4 Acceleration/decelerationrateand

acceleration/decelerationtime..................... 61

1.5 Smoothdrive............................................... 62

1.6 Speedlter.................................................. 62

1.7 Movingaveragelter................................... 63

1.8 Speederrorgain.......................................... 63

1.9 Controlmode............................................... 63

1.10 Positionloopgain,speedloopgain,

speedloopintegraltimeconstant................ 64

1.11 Absolute-positionbackupsystem................ 64

2 Operation ..................................................... 65

2.1 Positioningoperation................................... 66

Operationdata...................................................66

Startingmethodofpositioningoperation...........67

Operationfunction;Single-motion.....................71

Operationfunction;Linked-motionoperation.....72

Operationfunction;Linked-motionoperation2...73

Operationfunction;Push-motionoperation.......75

2.2 Return-to-homeoperation........................... 79

Additionalfunction.............................................79

Parametersrelatedtoreturn-to-home

operation............................................................80

Operationsequence..........................................81

Positionpreset...................................................86

2.3 Continuousoperation.................................. 86

Operationdata...................................................86

Startingmethodofcontinuousoperation...........87

Variablespeedoperation...................................89

2.4 Otheroperation............................................ 91

JOGoperation...................................................91

Testoperation....................................................92

Automaticreturnoperation................................92

Stopoperation...................................................93

Positioncoordinatemanagement......................93

Wrapfunction....................................................94

3 Operation data ............................................. 96

4 Parameter ..................................................... 97

4.1 Parameterlist.............................................. 97

4.2 I/Oparameter.............................................. 98

4.3 Motorparameter.......................................... 99

4.4 Operationparameter................................. 100

4.5 Return-to-homeparameter........................ 100

4.6 Alarm/warningparameter.......................... 101

4.7 Coordinationparameter............................. 101

4.8 Commonparameter................................... 101

4.9 I/Ofunctionparameter............................... 102

4.10 I/Ofunction[RS-485]parameter............... 103

4.11 Communicationparameter........................ 104