8 Installation General Instructions

transforma.organic

IG-234-EN version 01; 30/12/2015

4 INSTALLATION

4.1 Receipt of the transformer

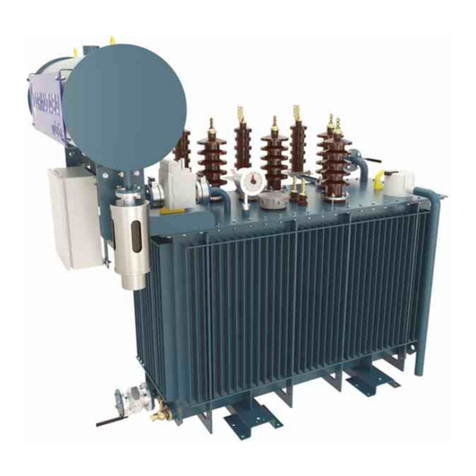

transforma.organic is supplied prepared for its connection

to Medium Voltage (MV) and Low Voltage (LV) lines. Some

elements, such as the rollers and / or the thermometer,

may be supplied unassembled for shipping.

When the transformer is received (at the customer

warehouse or at the transformer’s final location), it must be

carefully inspected, paying special attention to the

following aspects:

►The characteristics of the transformer, as indicated

on the "Name Plate", must coincide with those in

the "Test Protocol"; and these must correspond with

those specified in the corresponding order.

►Verify the general condition of the transformer and

check for absence of dents, especially on the

cooling equipment and on the Medium Voltage

(MV) and Low Voltage (LV) bushing insulators.

►Verify that the transformer has all of its accessories

(rollers, thermometer, etc.), ensuring they are not

damaged.

If any accessory is missing or damaged,

immediately notify the carrier and Ormazabal.

►The transformer seals must be unbroken and

untouched.

Fig. 4.1: Transformer seal

Manipulating or breaking the seal cancels the

transformer warranty as well as Ormazabal's

liability.

If any anomaly is detected upon receipt of the

transformer, inform Ormazabal immediately. If,

after a 15 day period, the manufacturer has not

received a report of anomalies or defects found, it

is assumed the transformer arrived in perfect

conditions and Ormazabal will not be responsible

for any future anomalies or their consequences.

4.2 Transformer site

The transformer site for both exterior and interior

installations, must allow for adequate cooling.

Both the technical conditions and the personal and

property safety requirements of the transformer's design

and site are defined in the applicable legislation and

standards.

If the transformer is installed indoors, prepare a horizontal

base that supports the transformer. Take into account the

total weight of the transformer, which is indicated on its

"Name Plate".

Lock the rollers to prevent the transformer from moving

during its operation.

CAUTION

Natural esters have higher freezing points than those

of mineral oil. The liquid may freeze during prolonged

exposure to temperatures below -5 ºC. In these

cases, the transformer can be powered without

affecting its physical - chemical properties. However,

the transformer should be protected from low

temperatures during prolonged storage periods.

Poor ventilation of the transformer may cause it to

overheat.