L

Lifting the machine ....................................................................................................................................... 18

Lifting the pile driver..................................................................................................................................... 19

Lifting the truck............................................................................................................................................... 18

Long out-of-use periods.............................................................................................................................. 52

Lubricant comparison table ....................................................................................................................... 62

Lubrication diagram...................................................................................................................................... 56

M

Machine cleaning........................................................................................................................................... 61

Main parts ............................................................................................................................................................5

Maintenance register..................................................................................................................................101

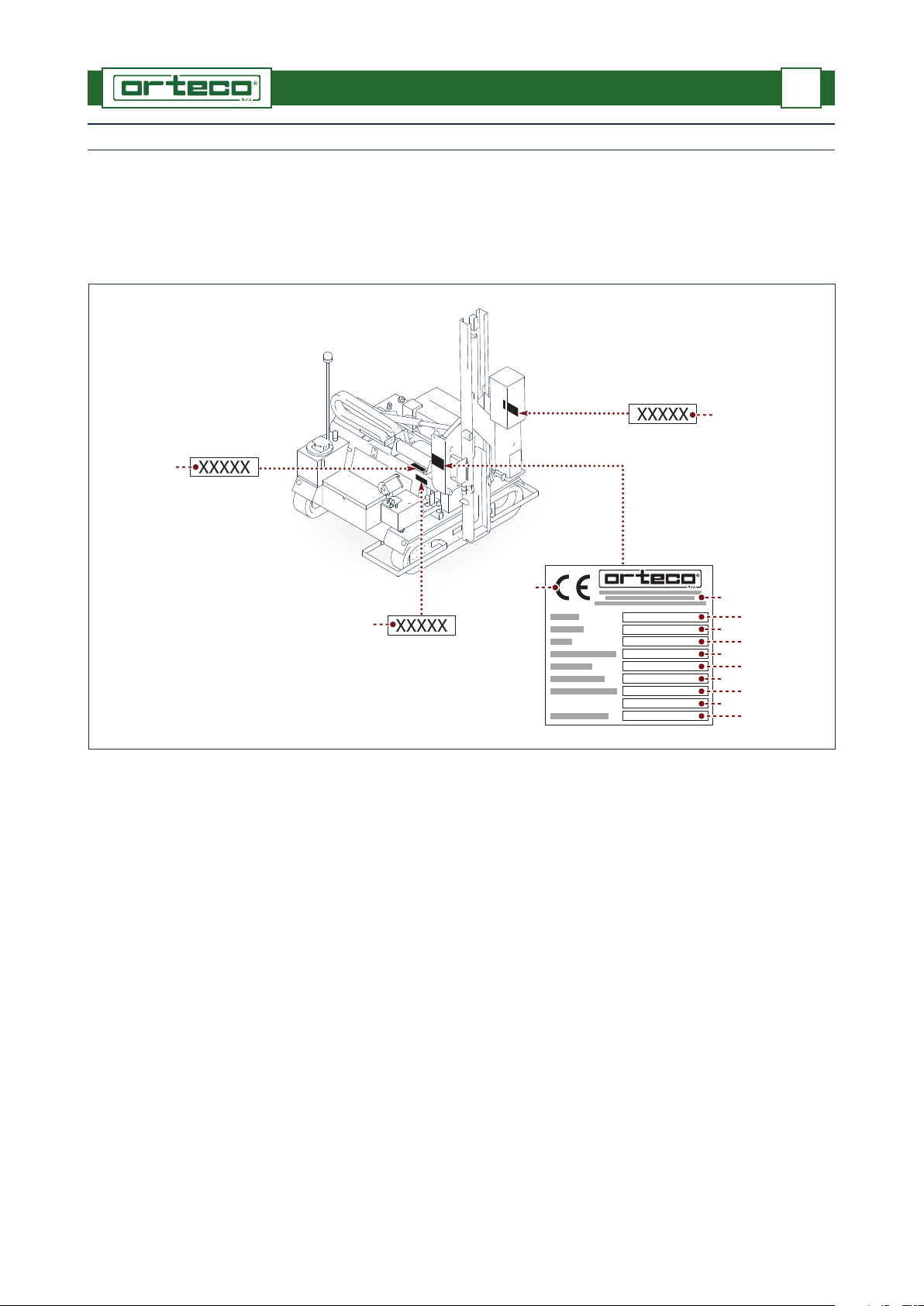

Manufacturer and machine identification details.................................................................................2

Metal pile extraction procedure ............................................................................................................... 38

N

Night-time work or poor visibility conditions...................................................................................... 54

Nut and bolt check ........................................................................................................................................ 57

Nuts and bolts tightening torques chart............................................................................................... 62

O

Operational stop............................................................................................................................................. 53

Operation controls......................................................................................................................................... 30

Operator training...............................................................................................................................................6

Overall dimensions........................................................................................................................................ 10

P

Pile driving procedure .................................................................................................................................. 36

Procedure for getting on and off the transport means.................................................................... 19

Procedure to make holes using the boring device ............................................................................ 42

Procedure to make holes using the corer.............................................................................................. 40

Procedure to make holes using the drill ................................................................................................ 47

R

Radio control.................................................................................................................................................... 69

Re-commissioning......................................................................................................................................... 52

Refuelling .......................................................................................................................................................... 52

Replacing hosing............................................................................................................................................ 66

Replacing supplementary air filter cartridges ..................................................................................... 65

Replacing the chain....................................................................................................................................... 67

Replacing the delivery line filter cartridge (high pressure)............................................................. 65

Replacing the discharge filter cartridge (low pressure) ................................................................... 64

Replacing the stroke plate .......................................................................................................................... 67

Replacing the track reduction gear oil ................................................................................................... 66

Residual risks.......................................................................................................................................................6

S

Safety advice concerning use.................................................................................................................... 27

Safety advice for maintenance.................................................................................................................. 55

Safety advice for the adjustments............................................................................................................ 22

Safety advice in case of faults .................................................................................................................... 63

Safety advice in case of replacements.................................................................................................... 64

Safety devices.....................................................................................................................................................7

Safety instructions for handling and transportation......................................................................... 16

Scrapping the machine................................................................................................................................ 68

Shifting on slopes procedure..................................................................................................................... 35

Shifting procedure......................................................................................................................................... 34

Sound emissions............................................................................................................................................. 10

Starting the engine........................................................................................................................................ 32

Starting the engine with the auxiliary battery .................................................................................... 33