OSAKA –AD 10 –OPERATING INSTRUCTIONS –V1 –PAG. 3

installation of equipment, eventually using the right filters if is

needed.

In case of failure or malfunction of measuring and control

equipment that can create dangerous situations or damage to

persons, things, animals or products (defrost food or changes in

their ideal state), it is recalled that the facility should be equipped

with electronic devices or electromechanical safety and warning

system.

They should be placed outside the measuring and control

equipments, possible protective devices, responding to specific

safety requirements that are covered by the norm of the product or

suggest the common sense.

For your own safety, is highly recommended fulfilling the

instructions provided above.

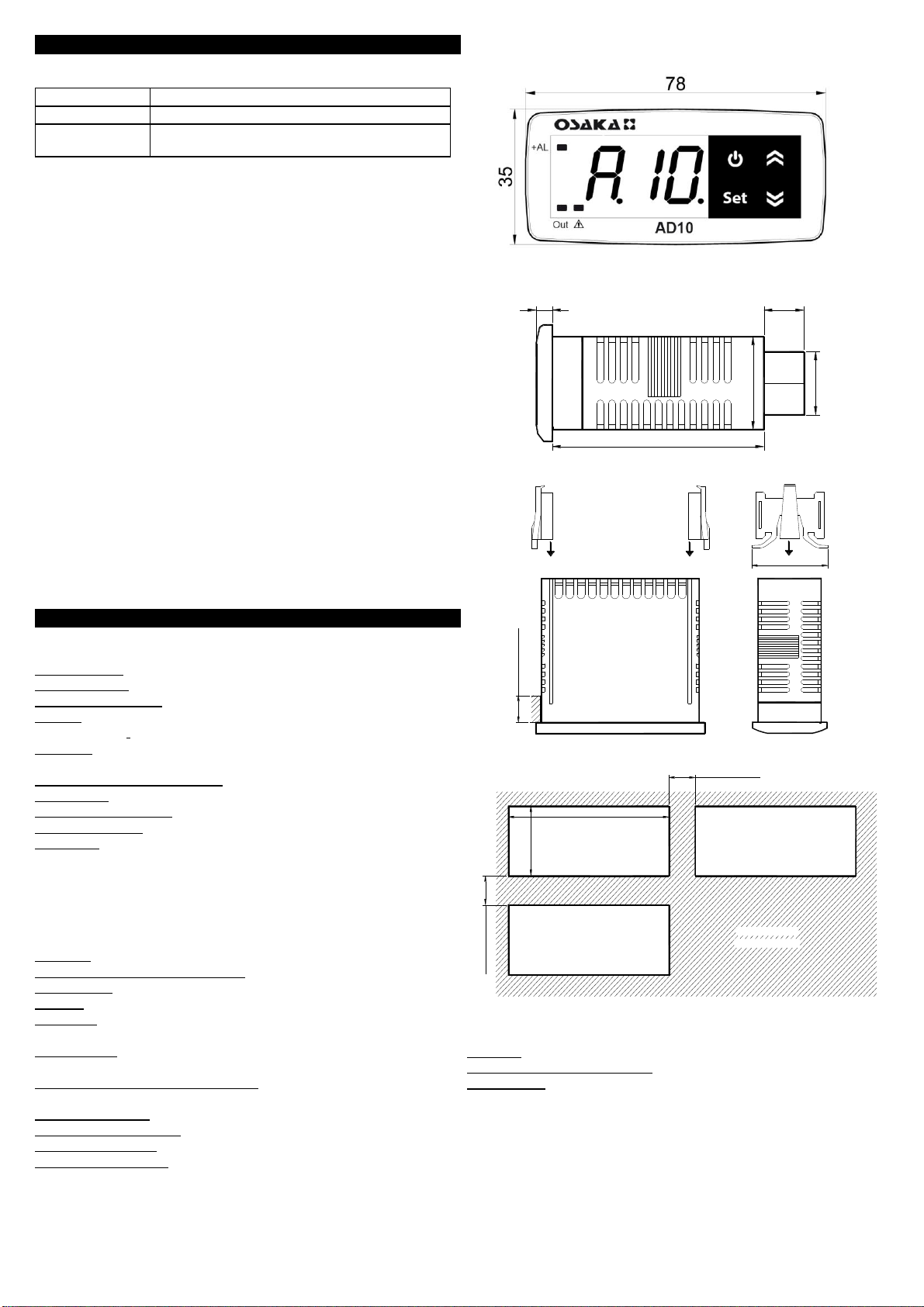

3.2 - MECHANICAL MOUNTING

The instrument, in case 78 x 35 mm, is designed for flush-in panel

mounting. Make a hole 71 x 29 mm and insert the instrument, fixing

it with the provided special brackets. We recommend that the

gasket is mounted in order to obtain the front protection degree as

declared. Avoid placing the instrument in environments with very

high humidity levels or dirt that may create condensation or

introduction of conductive substances into the instrument. Ensure

adequate ventilation to the instrument and avoid installation in

containers that house devices which may overheat or which may

cause the instrument to function at a higher temperature than the

one permitted and declared. Connect the instrument as far away as

possible from sources of electromagnetic disturbances such as

motors, power relays, relays, solenoid valves, etc.

3.3 - ELECTRICAL CONNECTION

Carry out the electrical wiring by connecting only one wire to each

terminal, according to the following diagram, checking that the

power supply is the same as that indicated on the instrument and

that the load current absorption is no higher than the maximum

electricity current permitted. As the instrument is built-in equipment

with permanent connection inside housing, it is not equipped with

either switches or internal devices to protect against overload of

current: the installation will include an overload protection and a

two-phase circuit-breaker, placed as near as possible to the

instrument, and located in a position that can easily be reached by

the user and marked as instrument disconnecting device which

interrupts the power supply to the equipment. It is also

recommended that the supply of all the electrical circuits connected

to the instrument must be protect properly, using devices (ex.

fuses) proportionate to the circulating currents. It is strongly

recommended that cables with proper insulation, according to the

working voltages and temperatures, be used. Furthermore, the

input cable of the probe has to be kept separate from line voltage

wiring. If the input cable of the probe is screened, it has to be

connected to the ground with only one side. We recommend that a

check should be made that the parameters are those desired and

that the application functions correctly before connecting the

outputs to the actuators so as to avoid malfunctioning that may

cause irregularities in the plant that could cause damage to people,

things or animals.

3.4 - ELECTRICAL WIRING DIAGRAM

Inputs for Free voltage contacts model version.

19

7

O U T

161413 15

CNO

17

NC

18

21 3 4 5 6

IN P U T S

222120 2423

108 9 1211

S U P P L Y

di1 di2 di3 di4 di5 di6 di7 di8 di9 di10

O u t: 8 A -A C 1 (3 A -A C 3 )/2 50 V A C B U Z Z E R

IN T E R N AL

X 31 L

Inputs for voltage signal (24 VAC/VDC) model version

di4

O u t: 8 A -A C 1 (3 A -A C 3 )/2 50 V A C

NC

16

O U T

431 2

13

X 31 L

1514

C

di1 di2 di3

S U P P L Y

di10

11

23

98 1065 7

1817

NO

19

IN P U T S

2120 22

di6di5 di7 di8 di9

12

24

IN T E R N A L

B U Z Z E R

2 4 V A C /V D C

(V D C : + -)

4.1 - INPUTS CONFIGURATION

Each signal is detected by the status change of an input that can

be configured to work through the following parameters:

“1.d” , “2.d”, “3.d” etc: determine the letter preceding the number

for that inputs must be reported as active signal. These parameters

are used to distinguish messages of some inputs like report alarms

(eg, A.01, A.02) from others that may signal errors (eg E.03, ""

E.04) or others who may signal functions in progress (eg F.05 ","

F.06)

“1.L” , “2.L”, “3.L” etc: determine the logic operating of the digital

inputs. If the input signal the event should contact closure

connected to the parameter should be programmed = no, vice

versa if you must report it to the opening of the contact connected

to the parameter should be programmed = nc.

“1.t” , “2.t”, “3.t” etc: allow to delay (up to a maximum of 99min

and 50sec.) the action of each inputs

“1.o” , “2.o”, “3.o” etc: Can establish whether the event should

turn on the internal buzzer or other alerts through output relay.

These parameters allow the buzzer to tie the activation and / or

relay output to some reports only considered serious (eg. alarms or

errors) that do not require other reports (eg. reports of functioning

or minor anomalies).

Parameters can be programmed:

= 0 - no signal

= 1 - signal only by buzzer

= 2 - signal only by output

= 3 - signal by buzzer and by output

“1.A” , “2.A”, “3.A” etc: Can establish whether the reporting on

the event should be memorized and therefore remain active even

when the digital input is deactivated. When an event is memorized

the label signal is flashing to indicate the condition of memorized

event.

4.2 - DISPLAY OPERATION

Through par. "t.dS" it’s possible to set the standard display

visualization with no Alarms/events signal.

If programmed = oF, the display visualization with no Alarms/events

signal is off except the separationled between letter and number.

If programmed = no.A display in the absence of Alarms/events

signal showing the label “no.A”.

If one event is active, the display always shows only the message

scheduled to report.

If more events are active led +AL is lit to indicate that there are

more alerts the operator and the display shows either all labels with

interval programmed at par. "t.td”.

By pressing and releasing key it’s possible to skip time "t.td" and

and quickly view all active alerts.