OSO SC 150 User manual

11002265-146015-07 - 02-2023

Manufactured by OSO Hotwater AS

Industriveien 1 - 3300 Hokksund - Norway

www.osohotwater.com

Saga Coil - SC

150-200-300 l.

EN

SAFETY INFORMATION

O&M INFORMATION

INSTALLATION MANUAL

TDS - TECHNICAL DATA SHEET

2

CONTENTS

1. Safety instructions....................................................... 3

1.1 General information........................................... 3

1.2 Safety instructions for users........................... 4

1.3 Safety instructions for installers................... 4

2. Product description.................................................... 5

2.1. Product identification........................................ 5

2.2. Intended use......................................................... 5

2.3 CE marking............................................................. 5

2.4 Technical data ....................................................... 5

2.5. ErP data (TDS)........................................................ 5

3. Installation instructions........................................... 6

3.1. Products covered by these instructions.. 6

3.2. Included in delivery............................................ 6

3.3. Product dimensions......................................... .. 6

3.4. Requirements for installation location ... 7

3.5. Pipe installation .................................................... 8

3.6. Electrical installation......................................... 10

4. Initial commissioning................................................ 12

4.1. Filling with water................................................ 12

4.2. Turning on the power..................................... 12

4.3. Setting the mixer valve................................... 12

4.4 Control points...................................................... 12

4.5. Emptying of water............................................. 12

4.6. Handover to end-user.................................... 12

5. User Guide....................................................................... 13

5.1. Settings ................................................................... 13

5.2. Maintenance........................................................ 13

6. Troubleshooting......................................................... 14

6.1. Faults and fixes.................................................... 14

7. Warranty conditions................................................ 15

7.1. Warranty and registration............................. 15

7.2. Customer service............................................... 15

8. Removing the product........................................... 15

8.1. Removal.................................................................. 15

8.2. Returns scheme.................................................. 15

3

1. SAFETY INSTRUCTIONS

1.1 General information

• Read the following safety instructions

carefully before installing, maintaining or

adjusting the water heater.

• Personal injury or material damage may

result if the product is not installed or

used in the intended manner.

• Keep this manual and other relevant doc-

uments where they are accessible for fu-

ture reference.

• The manufacturer assumes compliance

(by the end-user) with the safety, oper-

ating and maintenance instructions sup-

plied and (by the installer) with the fitting

manual and relevant standards and regu-

lations in effect at the date of installation.

Symbols used in this manual:

!

WARNING Could cause serious injury or death

!

CAUTION Could cause minor or moderate injury or damage to property

DO NOT

!

DO

!

This document should be kept in a suitable place where it is accessible for future reference.

!

4

1.3 Safety instructions for installers

!

WARNING

The overflow from the safety valve must NOT be sealed or plugged.

!

Any overflow pipe from the safety valve shall be in a suitable dimension and must be

uninterruptable, undamaged and frost-free with a fall to a suitable drain or gulley.

!

Fixed electric fittings should be used for installation in new homes or when changing an

existing electrical setup in accordance with regulations. A mains cable with plug for wall

socket can be used when replacing the product without changing the electrical setup.

!

The mains cable should withstand 90°C. A strain reliever must be fitted.

!

The product should be filled with water before the power is switched on.

!

The relevant regulations and standards, and this installation manual, must be followed.

1.2 Safety instructions for users

!

WARNING

The overflow from the safety valve must NOT be sealed or plugged.

The product must NOT be covered over the cover on the front.

The product must NOT be modified or changed from its original state.

Children must NOT play with the product or go near it without supervision.

!

The product should be filled with water before the power is switched on.

!

Maintenance/settings should only be carried out by persons over 18 years of age, with sufficient

understanding

!

CAUTION

The product must not be exposed to frost, over-pressure, over-voltage or chlorine treatment.

See warranty provisions.

Maintenance/settings should not be carried out by persons of diminished physical or mental capac-

ity, unless they have been instructed in the correct use by someone responsible for their safety.

!

CAUTION

!

The product should be placed in a room with a gully/drain, in accordance with current local

regulations. Alternatively, fit an automatic stop valve with sensor and overflow from safety

valve to drain. Liability for consequential damage will only apply if this is followed.

!

The product should be properly aligned vertically and horizontally, on a floor or wall suitable for

the total weight of the product when in operation. See type plate.

!

The product must have a clearance for servicing of 40 cm in front of the cover / 10 cm over the

highest point.

5

2.4 Technical data

2.5 ErP data - Technical Data Sheet

NRF no. Product code: Capacity

persons Weight

kg. Dia. x Height

mm. Freight

vol. m³ Heating time

hours Dt 65°C Heat

loss W

8000962 SC 150 - 3 kW/1x230V+HX 0.8m² 3.0 34 ø570 x 1010 0.37 -52

8000963 SC 200 - 3 kW/1x230V+HX 1.0m² 3.5 42 ø570 x 1260 0.47 -64

8000964 SC 300 - 3 kW/1x230V+HX 1.1m² 5.5 54 ø570 x 1710 0.62 -84

Brand Model-no. Model name ErP

profile

ErP

Rating

Energy

eff. % AEC - kWh/a

Thermo-

stat set-

ting °C

Volume

40°C

water

OSO Hotwater AS

11009722

Saga Coil - SC 150 - B - - 75 251

OSO Hotwater AS

11009723

Saga Coil - SC 200 - C - - 75 355

OSO Hotwater AS

11009724

Saga Coil - SC 300 - C - - 75 539

Regulation: 2017/1369/EU - Regulation: EU 812/2013 Directive: 2009/125/EC - Regulation: EU 814/2013

Heat loss tested acc. to standard: EN 12897

2. PRODUCT DESCRIPTION

2.1 Product identification

Identification details for your product can be found

on the type plate fixed to the product. The type

plate contains details of the product in accordance

with EN 12897:2016 and EN 60335-2-21, as well as

other useful data. See Declaration of Conformity at

www.osohotwater.com for more information.

OSO products are designed and manufactured in

accordance with:

• Pressure vessel standard EN 12897:2016

• Safety standard EN 60335-2-21

• Welding standard EN ISO 3834-2

OSO Hotwater AS is certified for

• Quality ISO 9001

• Environment ISO 14001

• Work environment ISO 45001

2.2 Intended use

Saga Coil is designed to supply homes with hot

running water. The product can be used with alter-

native energy sources.

2.3 CE marking

The CE mark shows that the product complies

with the relevant Directives. See Declaration of

Conformity at www.osohotwater.com for more

information.

The product complies with Directives for:

• Low voltage LVD 2014/35/EU

• Electromagnetic compatibility EMC 2014/30/EU

• Pressurised equipment PED 2014/68/EU

Any safety valve(s) used should be CE-marked

and comply with the PED 2014/68/EU.

This product has IP classification IP21

6

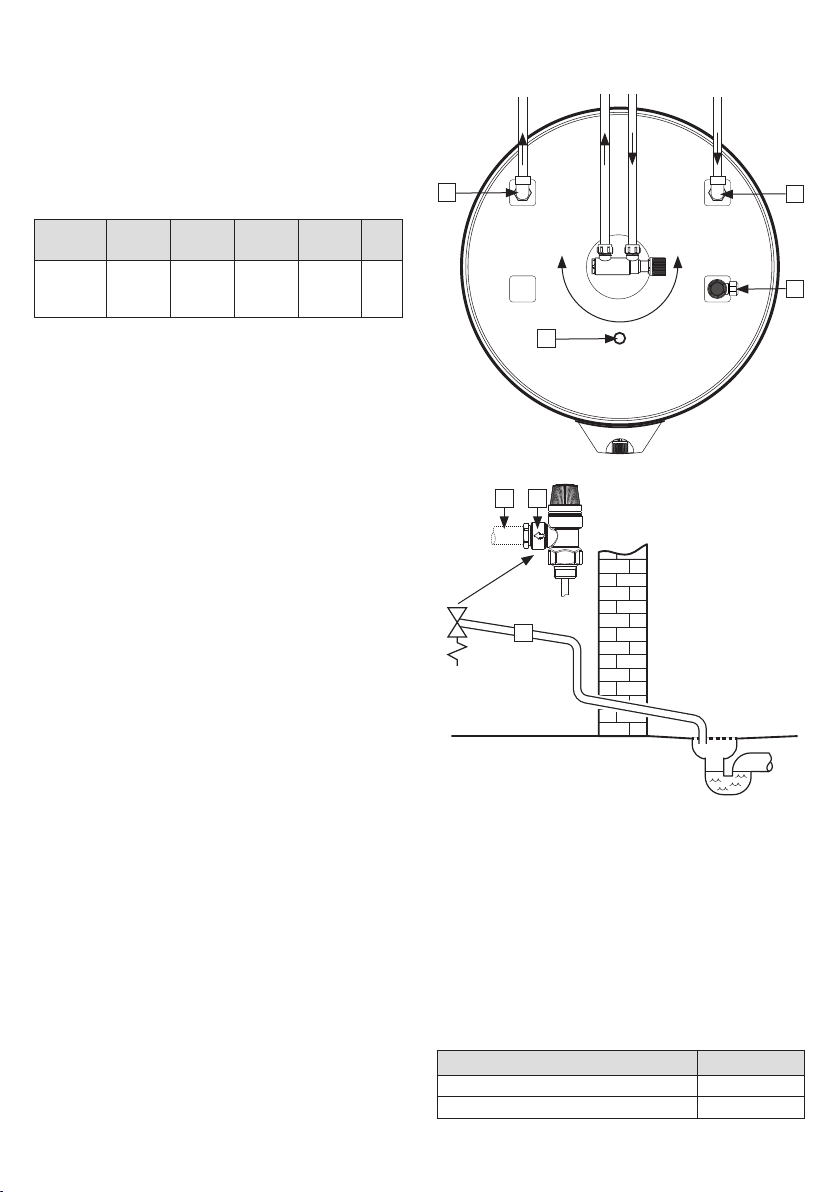

3.3 Product dimensions

All dimensions in mm.

Product AB C D E ø

SC 150 0-40 1010 960 125 655 570

SC 200 0-40 1260 1210 125 655 570

SC 300 0-40 1710 1660 125 655 570

Tolerance +/- 5 mm (not dimension A).

3. INSTALLATION INSTRUCTIONS

3.1 Products covered by these instructions

800 0962 Saga Coil - SC 150

800 0963 Saga Coil - SC 200

800 0964 Saga Coil - SC 300

3.2 Included in delivery

Ref no. Antall Beskrivelse

1 1 Insulated top cover (factory-fitted)

2 1 Mixer valve (factory-fitted)

3 2 Elbow brass for coil (included)

4 1 Tube for temperature sensor

5 1 Safety valve PT (factory-fitted)

6 1 Installation manual (this document)

7 1 Hot water heater with built-in coil

8 1 Thermostat

9 1 Heating element 3 kW 1x230V

10 1Drain valve (factory-fitted)

11 3Feet (factory-fitted)

AD

B C

ø

E

6

2

3

5

4

1

7

10

8

9

11

7

3.3.1 Delivery

The product should be transported carefully as

shown, with packaging. Use the handles in the

box.

!

CAUTION

Pipe stubs, valves etc. should not be used to lift

the product as this could cause malfunctions.

3.4 Requirements for installation location and

positioning

!

CAUTION

!

The product should be placed in a room with a gully/drain, in accordance with current local

regulations. Alternatively, fit an automatic stop valve with sensor and overflow from safety

valve to drain.

!

The product should be placed in a dry and permanently frost-free position.

!

The product should be placed on a floor or wall suitable for the total weight of the product

when in operation. See type plate.

!

The product must have a clearance for servicing of 40 cm in front of the cover / 10 cm over the

highest point.

!

The product should be easily accessible in the home for servicing and maintenance.

Min. 10 cm

Min. 40 cm

Min.

40 cm

8

Component

Torque

Ring clamp connection to CW/HW (ø15)

40 Nm (+/- 3)

Ring clamp connection to cylinder (ø22)

60 Nm (+/- 5)

Product CW HW Overflow

(2) Sensor

(3) Coil

(4)

SC 150 - 300 1/2” / ø15

mm ring

clamp

1/2” / ø15

mm ring

clamp

1/2” / ø15

mm ring

clamp

ø10 / 1/2”

internal ø22

3.5.5 Torque settings

3.5 Pipe installation

3.5.1 Incoming water pressure

The efficiency of the product depends on the in-

coming cold water pressure. The water pressure

should be min. 2 bar and max. 6 bar throughout

the day. Excessive water pressure can be adjusted

by installing a pressure reduction valve.

3.5.2 Fitting cold and hot water pipes (CW-HW)

and overflow pipes

A) Turn the mixer valve to the desired position.

• Tighten ring clamp to the cylinder (see

3.5.3)

B) CW/HW pipes of suitable size run to mixer

valve and tightened (see 3.5.3)

• With larger pipes, a reducer with 1/2"

internal thread may be used.

C) Overflow pipe (1) in a suitable dimension

can be run to safety valve

• Connects to the 1/2” / ø15 mm outlet (2)

on the safety valve

• Must be fitted uninterruptable, undamaged

and frost-free with a fall to the drain.

3.5.3 Connection to coil

The product is equipped with pipe elbow con-

nectors to the coil (4). The elbows has a 3/4”

ring clamp connection for flow/return pipes.

Fit pipes of suitable material/quality and tight-

en the ring clamps.

3.5.4 Connection to solar heating/hot water/

HW circulation/sensor tube

SC comes with a sensor tube (ø10 mm internal)

factory-fitted (3). This is intended for a tem-

perature sensor to control any external heat

source connected to the coil. The sensor slot

can be removed if the connector is to be used

for a different function.

The product is designed to be permanently con-

nected to the mains water supply. Approved pipes

of the correct size should be used for installation.

The relevant standards and regulations must be

followed.

The product can be heated with water from

solar collectors. OSO can supply a kit to utilise

alternative energy sources, which prioritises

solar heat over the electric heating element.

The product is equipped with a factory fitted

P&T 10 bar/90-95°C pressure and temperature

valve (5).

360°

4

3

5

4

1

1 2

9

RECOMMENDATION

-Allow clearance to the floor. Screw the feet out a minimum of 15 mm from the bottom of the

product.

-Mains cable for wall socket (2) should be hidden under the channels in the bottom of the

product.

-If a non-return valve is fitted a reduction valve and expansion vessel should be fitted (to stop

dripping from the safety valve).

-If the maximum water pressure exceeds 6 bar in a 24-hour period, a reduction valve and expansion

vessel shall be fitted.

-

For installation in a rooms which does not conform to the wetroom standard, a watertight

drip tray with overflow pipe > 18 mm. inside diameter should be fitted under the product, in

addition to an automatic stop cock with sensor. This will prevent possible material damage.

3.5.6 Fitting instructions

3.5.7 Installation recommendation

!

CAUTION

!

The product shall be placed in a room with a gully/drain, in accordance with current local

regulations. Alternatively, fit an automatic stop valve with sensor and overflow from safety

valve to drain.

!

The product shall be properly aligned vertically and horizontally, on a floor or wall suitable for

the total weight of the product when in operation. See type plate.

!

The product must have a clearance for servicing of 40 cm in front of the cover / 10 cm over the

highest point.

!

WARNING

!

The product shall be filled with water before the power is switched on.

!

Any overflow pipe from the safety valve shall be in a suitable dimension and must be

uninterruptable, undamaged and frost-free with a fall to a suitable drain or gulley.

2

3.5.8 Pressure drop table coil

Product information:

Pressure drop (mbar) at volume flow: Cw value (m³/t):

Product

Coil sur-

face m²

540 L/h

(0,15L/s)

900 L/h

(0,25 L/s)

1800 L/h

(0,50 L/s)

2700 L/h

(0,75 L/s)

3600 L/h

(1,00L/s)

4500 L/h

(1,25 L/s)

5400 L/h

(1,50 L/s)

Volume flow @

1 bar pressure drop

SC 150 0.8 26 65 220 457 775 1160 1620 4.15

SC 200 1.0 35 82 283 586 1000 1520 2130 3.60

SC 300 1.1 37 91 284 590 1015 1530 2140 3.59

10

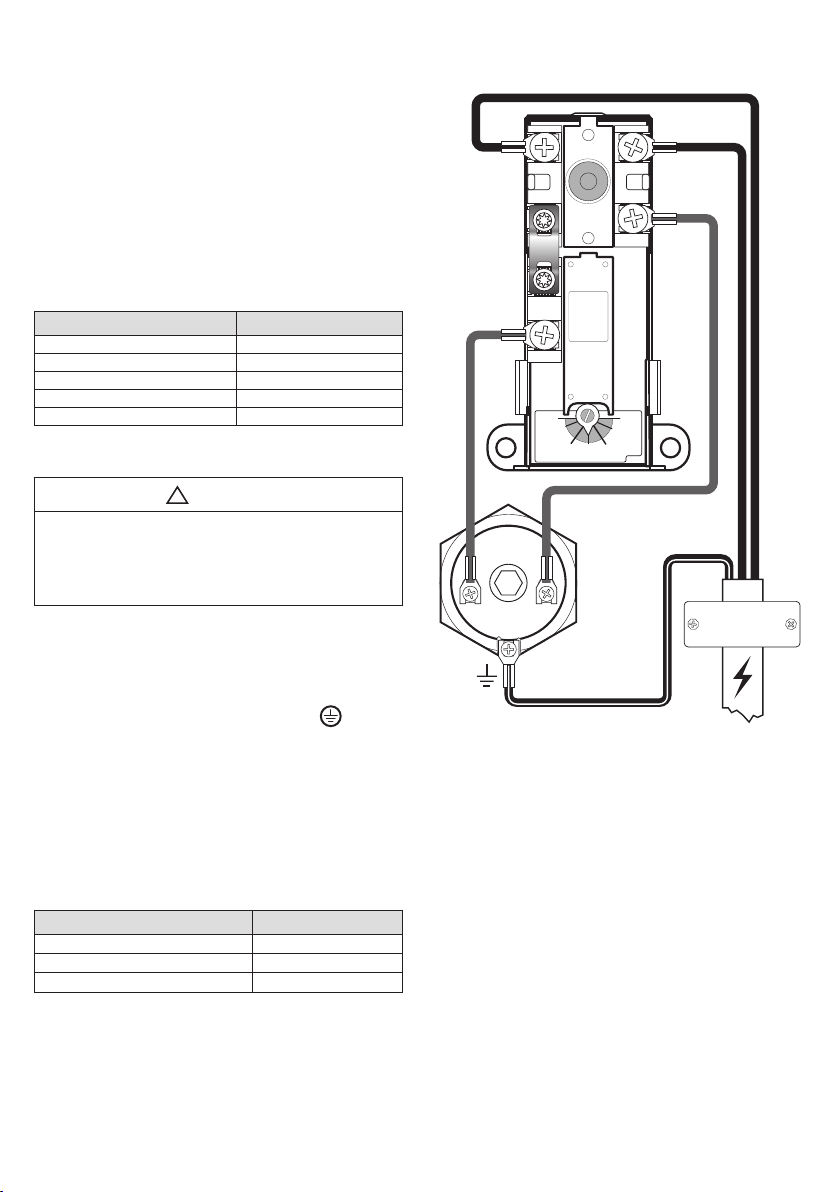

3.6.3 Torque settings

!

WARNING

Constant voltage present at terminals L and N.

Before any electrical work is done, the power

supply must be disconnected and secured

against activation while the work is in progress.

Component Torque

G1 1/4” heating element 60 Nm (+/- 5)

Thermostat screws 2 Nm (+/- 0.1)

Screw on the element head 2 Nm (+/- 0.1)

A) Live wire (L) connected to point ‘1’ on the

safety thermostat.

B) Neutral wire (N) connected to point ‘3’ on the

security thermostat.

C) Earth, yellow wire with green stripe

connected to terminal on the heating element

(hexagonal brass)

D) Internal wires from the element to the ther-

mostat are connected to point ‘4’ on the

safety thermostat and point ‘2’ on the work

thermostat. See illustration.

3.6 Electrical installation

3.6.1 Electrical components

Component Note

Safety thermostat 85°C thermal cut-out

Work thermostat 50-75°C adjustable

Heating element 2,8 kW 1-phase 230 V

Mains cable with plug Heat-resistant

Internal wires Heat-resistant

Fixed electric fittings should be used for installa-

tion in new homes or when changing an existing

electrical setup in accordance with regulations. A

mains cable with plug for wall socket can be used

when replacing the product without changing the

electrical setup. Any fixed electric fittings must be

installed by an authorised electrician. The relevant

standards and regulations must be followed.

3.6.2 Electrical connections in the junction box

Electrical connection, diagram

R

E

S

E

T

R

E

S

E

T

M2

1

2

3

4

THERM-O-DISC

60°C90°C

80°C 70°C

1

2

L N

11

RECOMMENDATION

-The mains cable supplied should be used with fixed electric fittings by removing the plug for the

wall socket. (Heat-resistant)

-Mains cable for wall socket/wall box should be hidden under one of the channels in the bottom of

the product.

-For products with ≤ 2kW capacity, a > 10A fuse / > 1.5# wire should be used*.

For products with ≤ 3kW capacity, a > 15A fuse / > 2.5# wire should be used (230V).

3.6.4 Fitting instructions

3.6.5 Fitting recommendation

!

WARNING

!

The product should be filled with water before the power is switched on.

!

Fixed electric fittings should be used for installation in new homes or when changing an existing

electrical setup in accordance with local regulations. A mains cable with plug for wall socket can

be used when replacing the product without changing the electrical setup.

!

The mains cable should withstand 90°C. A strain reliever must be fitted.

!

CAUTION

!

The product must have a clearance for servicing of 40 cm in front of the cover / 10 cm over the

highest point.

!

In case of damage to the mains cable and plug, it should be replaced with a specially adapted

mains cable from the manufacturer.

12

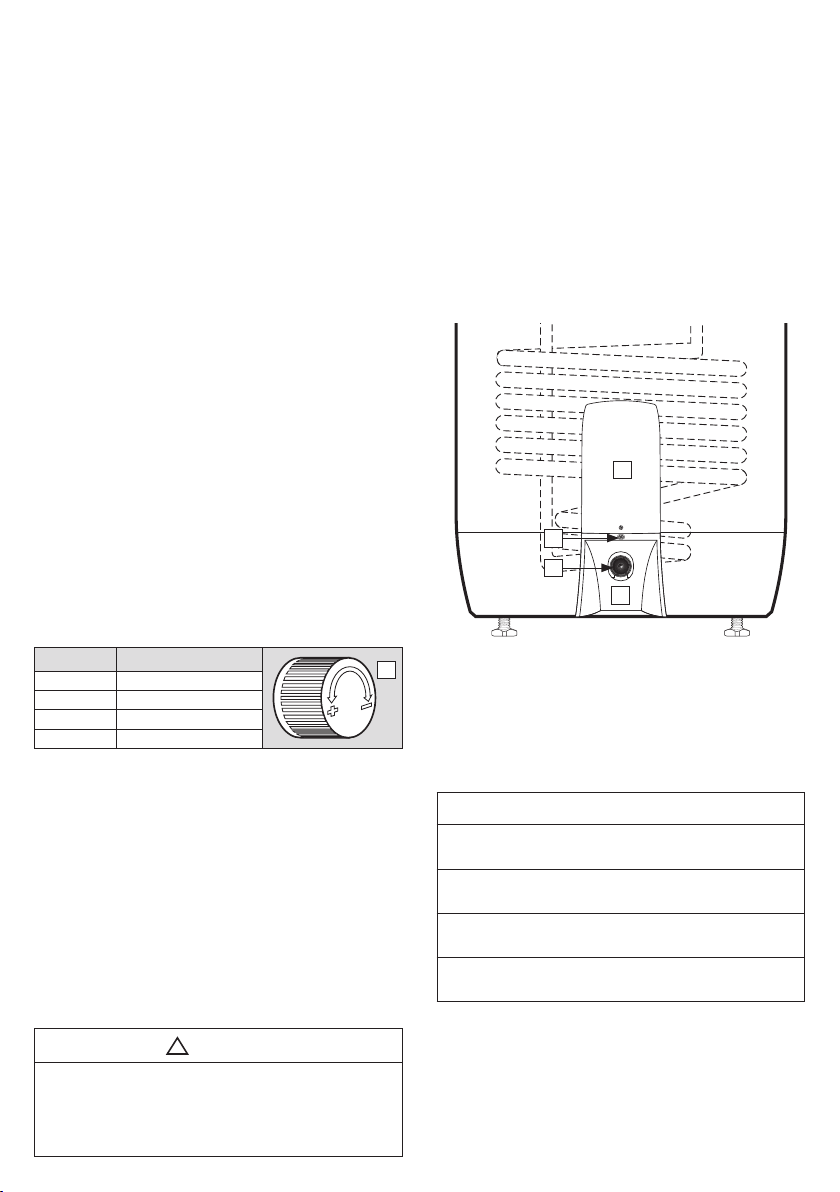

4.1 Filling with water

First check that all pipes are connected correctly.

Then proceed as follows:

A) Open a hot tap – leave it open

B) Turn the adjustable knob on the mixer valve all

the way to ‘+’.

C) Open the cold water supply to the product.

Check that the water from the open hot water tap is

flowing freely, without any air locks. Close hot tap.

Filling/emptying coil:

Follow the instructions for an

external heat source.

4.2 Turning on the power

When the cylinder has been filled with water, the

power can be switched on.

A) Insert plug into specified wall socket or turn on

on switch/fuse.

4.3 Setting the mixer valve

The outgoing hot water temperature from the

product to the taps in the home can be adjusted

with the knob on the mixer valve. Adjusting the

mixer valve does not affect the temperature of the

hot water in the product.

To adjust the temperature:

A) Turn the adjustable knob (1) all the way to ‘+’

B) Then turn the knob towards ‘-’ to the desired

temperature.

4.6 Handover to end-user

4. INITIAL COMMISSIONING

THE INSTALLER MUST:

Brief the end-user on safety and maintenance

instructions.

Brief the end-user on settings and emptying the

product.

Hand this installation manual over to the end-

user.

Enter contact details on the type plate on the

product.

4.4 Control points

A) Check that all pipe connections to/from the

product are tight and not leaking.

B) Check that the power supply to the product is

not at risk of exposure to mechanical, thermal

or chemical damage.

C) Check that any overflow pipe from the safety

valve is clear, undamaged and frost-free with

a fall to the drain.

D) Check that the product is standing firmly

vertically and horizontally.

!

WARNING

The water temperature in the product is 70°C and

could cause scalding. Before emptying, a hot tap

should be opened to the max. pressure/temper-

ature for min. 3 minutes.

After emptying, close the drain valve. Close all

open taps. Adjust the mixer valve to its original

setting. Refit the drain valve cover (2).

Turns Temperature

0 Approx. 70°C

1/4 Approx. 60°C

1/2 Approx. 50°C

3/4 Approx. 40°C

1

2

3

5

4

A) Disconnect the power supply.

B) Shut off incoming cold water supply.

C) Open a hot tap to the maximum

– leave open (prevents vacuum).

D) Open the mixer valve all the way to ‘+’.

E) Remove the cover over the drain valve (2) by

loosening the screw (5).

F) Open the drain valve (3). The product

empties.

4.5 Emptying of water

13

!

WARNING

Constant voltage present in the junction box. Be-

fore any electrical work is done, the power supply

must be disconnected and secured against acti-

vation while the work is in progress.

Turns Temperature

0 Approx. 70°C

1/4 Approx. 60°C

1/2 Approx. 50°C

3/4 Approx. 40°C

1

5.2 Maintenance

5.1 Settings

5.1.1 Thermostat setting

The thermostat on the product is adjustable from

50-75°C. The thermostat should not be set lower

than 65°C to prevent bacteria growth. To adjust

the temperature:

A) Disconnect the power supply.

B) Remove the cover (4) low down on the front of

the tank with a screwdriver.

C) Adjust the temperature on the thermostat (7)

with a screwdriver.

Fit the cover (4) before connecting the power

supply. Changing the temperature setting on the

thermostat only changes the temperature of the

water in the tank. Temperature to the taps is ad-

justed on the mixer valve.

5.1.2 Resetting the safety thermostat

The safety thermostat on the product cuts out

when there is a risk of overheating. This is reset

by removing the cover (4) and pressing the red

‘RESET’ button (6). If the thermostat cuts out re-

peatedly, contact the installer.

5.1.3 Adjusting the feet

The product is equipped with three factory-fit-

ted feet, adjustable from 0-40 mm. Screw the

feet out a minimum of 15 mm from the bottom

of the product. Adjust the feet individually un-

til the product is standing firmly vertically and

horizontally.

5.1.4 Setting the mixer valve

The outgoing hot water temperature from the

product to the taps in the home can be adjusted

with the knob on the mixer valve. To adjust the

temperature:

A) Turn the adjustable knob (1) all the way to ‘+’

B) Then turn the knob towards ‘-’ to the desired

temperature.

5. USER GUIDE

MAINTENANCE INSTRUCTIONS

!

Maintenance should be carried out by persons over 18 years of age, with suf-

ficient understanding.

!

Annual inspection of safety valve:

-Open valve for 1 min. by turning the knob (3) approx. 90 degrees to the open

position.

-Visually check that the water is flowing freely to the drain.

-YES = OK. Close the valve by turning the knob (3) a further 90 degrees to the

closed position.

-NO = NOT OK. Disconnect power supply / shut off water supply. Contact in-

staller.

60°C90°C

80°C 70°C

2

R

E

S

E

T

R

E

S

E

T

M2

1

2

3

4

1

7

6

3

14

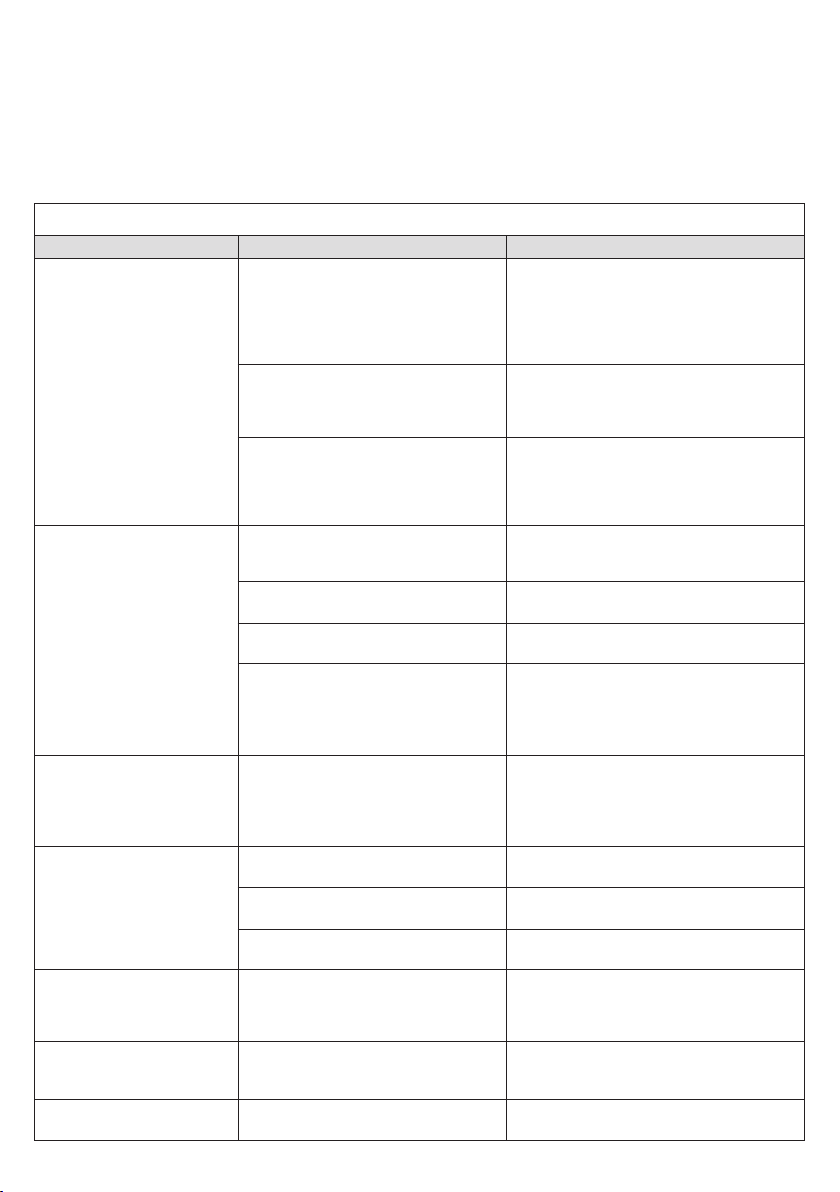

6.1 Faults and fixes

If problems arise when the product is in use,

check for possible faults and fixes in the table. If

the problem is not shown in the troubleshoot-

6. TROUBLESHOOTING

ing table or you are unsure what is wrong, con-

tact the installer (see type plate on the product)

or OSO Hotwater AS - see section 7.2.

TROUBLESHOOTING

Problem Possible cause of fault Possible solution

There is leakage/dripping

from the safety valve/

there is often water on the

floor by the cylinder in the

morning

Pressure reduction valve, water meter or

blocked non-return valve on the water

intake.

Water pressure into the home is too

high.

Fit AX expansion vessel with absorbs expan-

sion during heating, and fit pressure reduc-

tion valve for stable water pressure inside

the home. The pressure reduction valve is

adjusted in according to the pressure in the

expansion vessel. Contact auth. installer.

The safety valve is worn or there are par-

ticles stuck between the membrane and

the valve seat because the water is dirty

Try to flush with water through the safety

valve. Open valve for approx. 1 minute. See

section 5.2. If the valve still leaks, it must be

replaced. Contact auth. installer.

Leak from heating element.

Verify as follows: a) cut the electric supply, b)

unscrew the cover, c) visually check whether

there is a leak from the heating element. If so,

replace the gasket/heating element. Contact

auth. installer.

No hot water

Power supply interrupted. Verify that the fuse is on / the plug is

plugged in to the wall contact / the earth

breaker has not tripped.

Thermostat has cut out. Press the ‘RESET’ button on the safety ther-

mostat; see ‘User guide’.

Heating element is defective. Replace heating element. Contact auth. in-

staller.

Leak in hot water pipe

Verify as follows: a) close the mixer valve,

b) wait 2-3 hours, c) feel the mixer valve to

see whether it is hot. If so, there is a leak

in the hot water pipe or elsewhere. Contact

auth. installer.

Not enough hot water High consumption in the home.

Raise the temperature on the thermostat to

85°C; see ‘User guide’.

Switch to a larger OSO water heater. Con-

tact auth. installer.

Not high enough tem-

perature

The mixer valve is set for low tempera-

tures. Raise the temperature on the mixer valve;

see ‘User guide’.

The thermostat is set for low tempera-

tures. Raise the temperature on the thermostat to

85°C; see ‘User guide’.

Change from cold to hot water in taps. Contact auth. installer.

Fuse/earth breaker trips

repeatedly

Possible fault in the heater’s electrical

system.

Verify as follows: a) cut the electric supply, b)

unscrew the cover, c) visually check the junc-

tion box for any problems. If so, contact auth.

installer to check. Fit the cover.

Long time before the

water reaches the tap

Long stretch of pipe from water heater

to tap.

Fit circulation wire or heating cable to HW

pipe. Or fit an auxiliary heater by the tap.

Contact auth. installer.

Knocking in the pipes

when the hot tap is closed

Large pressure increase when the tap

is closed quickly. Completely normal. Fit AX expansion ves-

sel if troublesome. Contact auth. installer.

15

7.1 Customer service

In case of problems that cannot be resolved

with the aid of the troubleshooting guide in

this installation manual, contact either:

7. WARRANTY CONDITIONS

8. REMOVING THE PRODUCT

8.1 Removal

A) Disconnect the power supply.

B) Shut off incoming cold water supply.

C) Empty the product of water – see section 4.4.

D) Disconnect all pipes.

E) The product can now be removed.

1. Scope

OSO Hotwater AS (hereinafter called OSO) warrants for 2 years

from the date of purchase, that the Product will: i) conform to

OSO specication, ii) be free from defects in materials and

workmanship, subject to conditions below. All components carry

a 2-year warranty.

The warranty is voluntarily extended by OSO to 5 years for the

stainless steel inner tank. This extended warranty only applies

to Products purchased by a consumer, that has been installed

for private use and that has been distributed by OSO or by a

distributor where the Products have been originally sold by OSO.

The extended warranty does not apply to Products purchased by

commercial entities or for Products that have been installed for

commercial use. These shall be subject only to the mandatory

provisions of the law. The conditions and limitations set out below

shall apply.

2. Coverage

If a defect arises and a valid claim is received within the statutory

warranty period, at its option and to the extent permitted by law,

OSO shall either; i) repair the defect, or; ii) replace the product

with a product that is identical or similar in function, or; iii) refund

the purchase price.

If a defect arises and a valid claim is received after the statutory

warranty period has expired, but within the extended warranty

period, OSO will supply a product that is identical or similar in

function. OSO will in such cases not cover any other associated

costs.

Any exchanged Product or component will become the legal

property of OSO. Any valid claim or service does not extend the

original warranty. The replacement Product or part does not carry

a new warranty.

3. Conditions

The Product is manufactured to suit most public water supplies.

However, there are certain water chemistries (outlined below)

that can have a detrimental eect on the Product and its life

expectancy. If there are uncertainties regarding water quality, the

local water supply authority can supply the necessary data.

The warranty applies only if the conditions set out below are met

in full:

• The Product has been installed by a professional installer,

in accordance with the instructions in the installation

manual and all relevant Codes of Practice and Regulations

in force at the time of installation.

• The Product has not been modied in any way, tampered

with or subjected to misuse and no factory tted parts have

been removed for unauthorized repair or replacement.

• The Product has only been connected to a domestic mains

water supply in compliance with the European Drinking

Water Directive EN 98/83 EC, or latest version. The water

should not be aggressive, i.e. the water chemistry shall

comply with the following:

- Chloride < 250 mg / L

- Electric Conductivity (EC) @25°C < 750 uS / cm

- Saturation Index (LSI) @80°C > - 1,0 / < 0,8

- pH level > 6,0 / < 9,5

• The immersion heater has not been exposed to hardness

levels exceeding 10°dH (180 ppm CaCO3). A water

softener is recommended in such cases.

• Any disinfection has been carried out without aecting

the Product in any way whatsoever. The Product shall be

isolated from any system chlorination.

• The Product has been in regular use from the date of

installation. If the Product is not intended to be used for 60

days or more, it must be drained.

• Service and/or repair shall be done according to the

installation manual and all relevant codes of practice. Any

replacement parts used shall be original OSO spare parts.

• Any third-party costs associated with any claim has been

authorized in advance by OSO in writing.

• The purchase invoice and/or installation invoice, a water

sample as well as the defective product is made available

to OSO upon request.

Failure to follow these instructions and conditions may result in

product failure, and water escaping from the Product.

4. Limitations

The warranty does not cover:

• Any fault or costs arising from incorrect installation,

incorrect application, lack of regular maintenance

in accordance with the installation manual, neglect,

accidental or malicious damage, misuse, any alteration,

tampering or repair carried out by a non-professional, any

fault arising from the tampering with or removal of any

factory tted safety components or measures.

• Any consequential damage or any indirect loss caused by

any failure or malfunction of the Product whatsoever.

• Any pipework or any equipment connected to the Product.

• The eects of frost, lightning, voltage variation, lack

of water, dry boiling, excess pressure or chlorination

procedures.

• The eects of stagnant (de-aerated) water if the Product

has been left unused for more than 60 days consecutively.

• Damage caused during transportation. Buyer shall give the

carrier notice of such damage.

• Costs arising if the Product is not immediately accessible

for servicing.

These warranties do not aect the Buyer’s statutory rights.

8.2 Returns scheme

This product is recyclable and should be taken

to the environmental recycling centre. If the

product is to be replaced with a new one, the

installer can take the old cylinder away for re-

cycling.

A) The installer who supplied the product.

B) OSO Hotwater AS: Tel.: +47 32 25 00 00

OSO Hotwater AS

Industriveien 1

3300 Hokksund - Norway

Tel: + 47 32 25 00 00

www.osohotwater.com

© This installation manual and all its content is protected by copyright and

may be reproduced or distributed only with written consent from the manufacturer.

We reserve the right to make changes without notice.

This manual suits for next models

5

Table of contents

Other OSO Water Heater manuals

Popular Water Heater manuals by other brands

State Water Heaters

State Water Heaters 184671-000 instruction manual

Airxcel

Airxcel SW5EA Operating, installation and service manual

3P Technik

3P Technik 3P Barrique instruction sheet

GE

GE 50T06AAG Energy guide

Bradford White

Bradford White ECO-DEFENDER U130T*FRN Service manual

HTP

HTP SSU-10DB Installation, operation, maintenance, & troubleshooting

Bradford White

Bradford White Magnum D75T125E3N Installation & operation manual

Drazice

Drazice OKHE ONE20 OPERATING AND INSTALLATION Manual

onsen

onsen 14L manual

Modena

Modena EI 3D Series manual

Argo

Argo Technibel TANK 200L Usage and maintenance manual

ThermoBar

ThermoBar 130 Installation, user instructions and care