OSO Dualstream Technical document

TECHNICAL AND INSTALLATION MANUAL

HOT WATER

CAPACITY

120 - 380 LITRES

BY

OSO HOTWATER (UK) LIMITED

This manual gives detailed advice for installation and should be read

carefully prior to fitting the OSO Dualstream. Where components are

supplied only for indirect units, this is clearly shown.

The OSO Dualstream must be installed by a competent person and in

accordance with current Building Regulations including Guidance

Document G3.

Drawings on pages 1-18 show

22mm valves on cold water supply.

For 28mm see page 19.

IM/OD/1

1

CONTENTS

INTRODUCTION 1

1-1 Introduction .......................................................... 2

1-1.1 How the OSO Dualstream System Works.2

1-1.2 System Contains.................................................. 2

1-1.3 System Features.................................................. 2

1-1.4 Central Heating System.................................... 3

1-1.5 Models Available .................................................. 3

OPERATOR CONTROLS 2

2-1 Hot Water Temp. ............................................... 4

2-1.1 Hot Water Control - Heating System .......... 4

2-1.2 Hot Water Control - Immersion Heater ...... 4

2-2 Hot Water Overheating................................... 6

2-2.1 Water Heated by Heating System................ 6

2-2.2 Water Heated by Immersion Heater............ 6

2-3 Shut Off Valves................................................... 6

2-3.1 Stop Cock................................................................ 7

2-3.2 Double Check Valve ........................................... 7

2-3.3 Cold Water Shut Off Valve............................... 7

2-3.4 Supply Water Shut Off Valve .......................... 7

2-3.5 Hot Water Shut Off Valve ................................. 7

2-4 Pressure Relief ................................................... 7

2-5 Servicing ................................................................ 7

TECHNICAL INFORMATION 3

3-1 System Components....................................... 8

3-2 Specifications...................................................... 8

3-2.1 Cylinder .................................................................... 8

3-2.2 Accumulator .......................................................... 8

3-2.3 Pipes.......................................................................... 8

3-2.4 Electrics.................................................................... 8

3-3 Wiring....................................................................... 9

3-3.1 Immersion Heater ................................................ 9

3-3.2 Wiring Layout S Plan .........................................10

3-3.3 Wiring Layout Y Plan..........................................11

INSTALLATION 4

4-1 Building Control ................................................12

4-1.1 Regulations ............................................................12

4-1.2 Electrical Regulations........................................12

4-2 Installation ............................................................12

4-2.1 Positioning ..............................................................12

4-2.2 Unvented Hot Water Cylinder ........................12

4-2.3 Accumulator ...........................................................13

4-2.4 Tundish.....................................................................13

4-2.5 Discharge Pipe .....................................................13

4-2.6 Scale Protection...................................................14

4-2.7 Pipework..................................................................14

4-2.8 OSO Dualstream Components .....................14

4-2.9 Connections to OSO Dualstream.................14

4-3.0 Direct Cylinders....................................................14

COMMISSIONING 5

5-1 Commissioning Checks................................15

5-1.1 Commissioning Procedure ..............................15

5-2 Handing Over ......................................................15

SERVICING 6

6-1 Routine Service..................................................16

6-1.1 Service Procedure...............................................16

SPARE PARTS 7

7-1 Spare Parts...........................................................17

SECONDARY RETURN 8

8-1 Secondary Return.............................................17

OSO DUALSTREAM 9

9-1 OSO Dualstream................................................18

CONNECTIONS 10

10-1 28mm Connections..........................................19

FAULT DIAGNOSIS 11

11-1 Fault Diagnosis ..................................................19

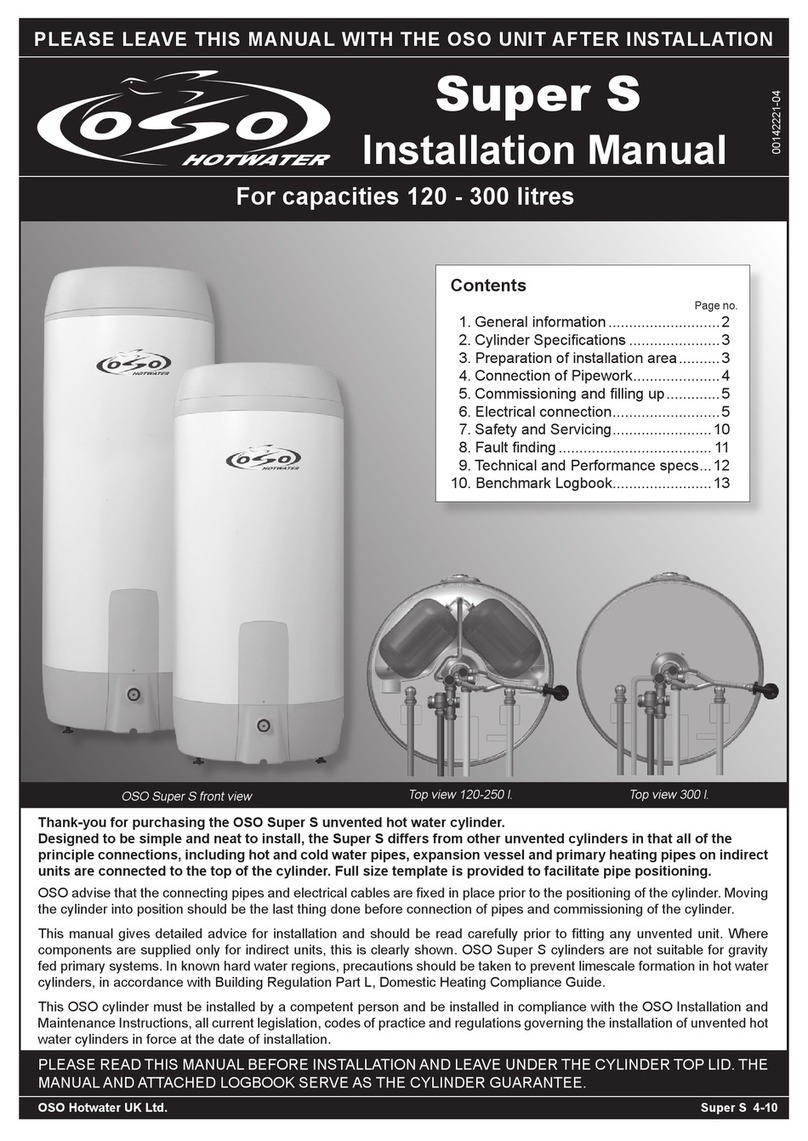

1-1 INTRODUCTION

This Handbook has been compiled to assist in the Installation and Operation of the OSO Dualstream domestic hot and cold

water system. The Installer of the system should give full operating instructions to the householder for the OSO Dualstream

System.

1-1.1 How the OSO Dualstream system works

Fig.1-1 is a schematic illustration of a typical OSO Dualstream system showing how it works.

Option A is used when the accumulator is installed remotely from the unvented cylinder and requires an accessory pack

containing pressure reducing valve, expansion relief valve expansion vessel and bracket, available at additional cost and

should be ordered with the system.

1-1.2 System Contains

1. An unvented hot water cylinder pre-plumbed with all valves and controls with easy access pipe connections for quick,

trouble-free installation.

2. Cylinder Thermostat and High Limit Thermostat.

3. An Accumulator (cold water storage) and associated fittings.

4. One two port motorised valve for connection to heating system flow to cylinder (Indirect only).

5. The OSO Dualstream is supplied with an adjustable pressure reducing valve. This means pressure to all mains water

outlets can be adjusted between 0.5 bar to 5 bar.

1-1.3 System Features

1. All Taps and Showers are at maximum ‘Mains Pressure’.

2. Equal pressure at Hot and Cold Taps.

3. No pressure drop when more than one Tap is in use.

4. More than 25% less pipework than traditional systems.

5. No loft storage tank.

6. Completely sealed system - all Cold Taps are classed as wholesome water.

2

INTRODUCTION 1

Fig. 1-1 Schematic illustration

(Indirect unit)

Rubber expanding

bladder inside vessel.

Pressure is maintained

at maximum

‘Mains Pressure’.

Pressure relief valve

vents excess pressure

from Hot Water System.

Hot Water Cylinder is at

‘Mains Pressure’ due to

incoming cold.

Cylinder with immersion

heater. Water can be heated

by any conventional method.

Existing

Mains Supply

Hot Supply

Option A

Non-return valve. As

water is used system

is equalised to

maximum ‘Mains

Pressure’.

Boiler Return

Secondary Return

Boiler Flow

Air Pressure

Diaphragm

Accumulator

Mains Water

3

INTRODUCTION 1

1-1.4 Central Heating System

The OSO Dualstream system does not affect the Central Heating installation. However consideration has to be

given to the best method of connection and control of the heating system to the indirect cylinder.

1-1.5 Models Available

Below is a typical selection of the systems available, other combinations can be tailored to suit requirements.

Model Accumulator (Cold Water Storage)

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

Hot Water Cylinder (Direct RD Indirect RI)

20 R

120

120

160

580

720

All sizes are nominal

Very low mains flow rates may require larger or multiple accumulators

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type 19608

100

86

440

890

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R

120

120

160

580

720

20 R

150

150

190

580

900

20 R

200

200

250

580

1150

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type 18891

170

150

535

995

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R

200

200

250

580

1150

20 R F1

200

250

310

580

1400

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type 18892

240

205

540

1220

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R F1

250

250

310

580

1400

20 R F1

300

300

365

580

1600

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type 18893

310

255

540

1500

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R F1

300

300

365

580

1600

20 R F1

380

380

462

580

2100

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type 18894

450

385

665

1550

2-1 HOT WATER TEMPERATURE

2-1.1 Hot Water Control - Heating System (Indirect only)

When the hot water is heated by the heating system the temperature of the hot water at the taps is controlled by the Cylinder Thermostat.

This controls a Motorised Valve that opens and closes the flow from the heating system.

The temperature range is 45°C to 75°C.

Recommended setting is between 50°C minimum and 70°C maximum.

1 Indirect Units

Motorised valve

To comply with regulations governing the installation of indirect unvented

cylinders, a motorised valve must be fitted in the primary flow. Your OSO unit has

been supplied with a two port motorised valve, which will act as a positive energy

cut-out should the safety cut-out operate. The motorised valve will also control the

temperature of the domestic stored water via the cylinder thermostat, which is

located in the electrical box. The unit should be installed on an “S’’ or “Y’’ plan

system. Please follow the instructions carefully. All electrical connections must

conform to current IEE wiring regulations. The working thermostat which controls

the temperature of the domestic hot water (see fig. 2) is adjustable between 45°C

to 75°C. A safety cut out is also incorporated within the thermostat and will

operate at 85°C ± 3°C. Should the safety cut out be brought into operation, the

motorised valve will operate and close down the primary flow to the cylinder. To

reset the safety cut out and the motorised valve the reset button must be pressed

in (see fig. 2). If using a 6-wire 28mm or 1’’ BSP V4043H on either circuit the white

wire is not needed and must be made electrically safe.

2-1.2 Hot Water Control - Immersion Heater

When the hot water is heated by the electric Immersion Heater, the temperature

of the hot water at the taps is controlled by the Immersion Heater Thermostat.

This is located under the electrical box cover, left hand thermostat.

2 Direct units

Wiring instructions for the water heaters are located on the reverse side of the lid.

Follow the wiring instructions connecting the live, neutral and earth as

indicated. All internal wiring is factory mounted. Each immersion heater has

a working thermostat adjustable between 45°C to 75°C. A safety cut-out is

also incorporated within the thermostat and will operate at 85°C ± 3°C.

Should this happen, press the reset button.

Important: Before resetting the safety cut-out or altering the thermostat

setting, isolate electrical supply to the unit prior to removal of the lid.

Ensure the lid to the electrical box is replaced correctly and the

retaining screw is fitted.

The lower immersion heater should be connected to the off peak supply

(if available) whilst the top immersion heater can be connected to the day

tariff. The immersion heater can be connected to the mains supply through a

water heater controller (Contact your local electricity company if in doubt).

WARNING: When the cover is removed electrical live terminals are

exposed.

ALWAYS TURN OFF THE ‘WATER HEATER’ SWITCH BEFORE

REMOVING COVER.

The temperature range is 45°C to 75°C.

Recommended setting is between 50°C minimum and 70°C maximum.

The electrical connection to the immersion heater must conform to

current IEE wiring regulations. The unit must be permanently connected

to the electrical supply through a double-pole linked switch with a

minimum break capacity of 13 amps.

4

OPERATOR CONTROLS 2

Fig. 2-1a Hot Water Control

Adjustment

Screw

LN

Fig. 2-1b Immersion Heater Thermostat

Return to Boiler

Motorised valve

Flow from Boiler

Pole Switch

5

OPERATOR CONTROLS 2

IMPORTANT HEALTH AND SAFETY INFORMATION FOR INSTALLERS AND SERVICE ENGINEERS

HEALTH AND SAFETY AT WORK ACT 1974

CONSUMER PROTECTION ACT 1987

COSHH REGULATIONS 1988

MANUAL HANDLING OPERATIONS REGULATIONS 1992

The regulations set no specific requirements such as weight limits. However common sense still has to be used

based on an ergonomic approach for each individual.

The following information is given as a requirement of the above legislation.

Great care is taken to ensure that OSO Dualstream systems are designed and manufactured to meet general

safety requirements when properly used and installed as recommended in this manual.

It is the responsibility of Users and Engineers to ensure that adequate protective clothing and glasses are worn

when working with the OSO Dualstream system.

SEALS AND INSULATION

Insulation and sealing materials are used in the construction of the OSO Dualstream cylinders. Units are sealed

and when used in the manner for which they are intended the insulating and sealing materials do not present any

known hazard. However always observe the following recommendations:-

1. Avoid inhalation of fibres or dust, wear face mask.

2. Avoid eye contamination by fibres or dust – wear eye protection.

3. As far as possible avoid any skin contact with Fibreglass Insulation, Glass Rope, Mineral Wool, Insulation

Pads and Ceramic Fibre.

OTHER MATERIALS

SEALANTS, ADHESIVES AND PAINTS

Sealants, Adhesives and Paints are used in the construction of the OSO Dualstream components. When used in

the manner for which they are intended they do not present any known hazard.

ELECTRIC

All Cylinders have electrical supply of 240v (enough to endanger life) connected to the Immersion Heater. Always

isolate during adjustment, servicing and repair.

OSO (UK) will not accept responsibility for any damage or personal injury caused by not giving due

consideration to the above safety recommendations.

All replacement parts must be supplied by OSO HOTWATER (UK) LIMITED.

To obtain the address of a local stockist contact:

OSO HOTWATER (UK) LIMITED

E15 Marquis Court, Team Valley Trading Estate, Gateshead, Tyne & Wear, NE11 0RU.

Tel: (0191) 482 0800 Fax: (0191) 491 3655

Email : technical.uk@oso-hotwater.com - spareparts.uk@oso-hotwater.com - sales.uk@oso-hotwater.com

www.oso-hotwater.com

6

OPERATOR CONTROLS 2

Fig. 2-2a High Limit Thermostat

Hot Supply

Option A Cylinder with immersion heater.

Water can be heated by any

conventional method.

Pressure relief valve

vents excess pressure

from Hot Water System.

Hot Water Cylinder is

at ‘Mains Pressure’

due to incoming cold.

Rubber expanding

bladder inside vessel.

Pressure is maintained

at maximum ‘Mains

Pressure’

Air Pressure

Diaphragm

Accumulator

Mains Water

Existing

Mains Supply

Non-return valve. As

water is used system is

equalised to maximum

‘Mains Pressure’.

(Indirect unit)

2-2 HOT WATER OVERHEATING

2-2.1 Water Heated by Heating System

When the hot water is heated by the heating system a High Limit

Thermostat prevents the water within the Cylinder overheating.

In the event of the water temperature within the Cylinder reaching

85°C the thermostat will trip and close the Motorised Valve shutting

off the flow from the heating system - see fig. 2-2a.

The High Limit Thermostat is a manual reset type, this means that

it has a button that pops out when the thermostat has been tripped

by overheating - see fig. 2-2a.

To reset the system after overheating allow time for the water to

cool, or run off some hot water, then remove the electrical box cover

and press the High Limit Thermostat manual reset button.

If the High Limit Thermostat trips more than once, switch off the

heating system and Immersion Heater and contact your installer.

2-2.2 Water Heated by Immersion Heater

A safety cut-out is also incorporated within the thermostat and will operate at 85°C ± 3°C. Should this happen,

press the reset button.

WARNING: When the cover is removed electrical live terminals are exposed.

ALWAYS TURN OFF THE ‘WATER HEATER’ SWITCH BEFORE REMOVING COVER.

Note: The High Limit temperature of 85°C is factory set and cannot be changed.

2-3 SHUT OFF VALVES

The OSO Dualstream installation will

have a number of shut off valves, the

location of these will be dependent on

the installation - fig. 2-3a shows a

typical layout.

IMPORTANT:

Before closing ANY valve:-

1. Switch OFF the Electric

Immersion Heater.

2. Turn OFF the Heating System.

Note: When operating the stop cock

turn the valve fully open then close

1⁄2turn, this prevents the valve

sticking.

Fig. 2-3a Typical Shut Off Valve Locations

High

Limit

Adjustment

screw

Cylinder thermostat located

in electrical box

2-3.1 Stop Cock

Normally located at the point where the mains supply enters the dwelling.

Shuts off the mains water supply to the dwelling.

2-3.2 Double Check Valve

Normally located after Stop Cock.

Shuts off the mains water supply to the dwelling and prevents Backflow.

2-3.3 Cold Water Shut Off Valve

Normally located in the cold feed close to the Cylinder.

Shuts off the cold water to the taps.

2-3.4 Supply Water Shut Off Valve

Normally located where the cold supply connects to the combination valve on the Cylinder.

Shuts off the cold supply to the Dualstream system.

2-3.5 Hot Water Shut Off Valve

Normally located where the Domestic Hot Water feed comes from the Cylinder.

Shuts off the hot water to the taps.

2-4 PRESSURE RELIEF

The OSO Dualstream installation has a Pressure Relief Valve normally mounted on the cylinder. In the event of the

pressure within the system becoming too high, the Expansion Relief Valve will open, venting the pressure.

A tundish will be fitted in the system, this should be located in a position where it can be seen. This device gives

a visual warning that pressure is being vented as water.

In the event of water being seen at the tundish do the following:-

1. Turn ON a hot tap to relieve the pressure.

2. Turn OFF the Electric Immersion Heater.

3. Turn OFF the Heating System.

4. Investigate possible cause for high pressure e.g:-

i Cylinder Thermostat is set too high.

ii Mains water is not on or fully on.

iii Restriction in hot water pipework.

5. Contact the installer before restarting the system.

2-5 SERVICING

It is recommended that the system is inspected by an approved engineer

once per year.

The service procedure is included in section 6-1.1.

7

OPERATOR CONTROLS 2

CLOSED

OPEN

Fig. 2-3b Valves

Fig. 2-4 Tundish

Note: The Tundish should remain

in view do not box it in or cover it up.

Hot Supply

Option A

7

12 6

10

A

J

B

3

14

5

4

9

2

8

TECHNICAL INFORMATION 3

3.1 SYSTEM COMPONENTS TYPICAL LAYOUT AND CONNECTIONS

3.2 SPECIFICATIONS

3-2.1 Cylinder

Maximum Water Supply Pressure..........................6.0 Bar

Operating Pressure .......................................................3.5 Bar

Pressure and Temperature Relief Valve....10 Bar/90°C

Maximum Temperature.....................................................75°C

Cylinder Thermostat............................range 45°C to 75°C

Recommended Setting...................50°C min - 70°C max

High Limit Thermostat .....................................fixed @ 85°C

Immersion Heater

Voltage ..............................................................................240v

Power .................................................................................3kW

Motorised Valve.............................................................V4043H

3-2.2 Accumulator

Membrane .................................Butyl for wholesome water

Maximum pressure .........................................................10 Bar

Factory set pressure.........................................................2 Bar

3-2.3 Pipes

All pipes should be sized to suit application.

3-2.4 Electrics

All systems are supplied for 240V SINGLE PHASE.

1. Accumulator (Cold Water Storage)

2. Unvented Cylinder

3. Cylinder Thermostat (Indirect)

4. Immersion Heater Thermostat

5. Immersion Heater

6. Expansion Relief Valve

7. Pressure Reducing Valve

9. Pressure Relief Valve & Temperature

Relief Valve

10. Tundish

12. Cold Main Shut Off Valve

14. Cylinder Drain Cock

15. Tee Connection

A. Water from system

B. Accumulator Drain Cock

C. Controlled action diaphragm

D. Gas charge

E. Gas charge valve

F. Internal clench ring

G. Threaded nut for pum stand installation

H. Air flow design to reduce condensation

I. Diffuser directs flow up and out

Note: All items numbered are supplied.

The accumulator must be set at between 1 and 1.5

bar below the pressure reducing valve setting.

Minimum accumulator pressure 0.5 bar (7 PSI).

If there is an incoming pressure of 3.5 bar or over DO

NOT adjust the accumulator pressure. You should only

take air out of the accumulator and not pump it up on

installation.

3.1a SCHEMATIC LAYOUT

(Indirect unit)

Accumulator

H

F

D

E

C

1

G

15

9

TECHNICAL INFORMATION 3

3-3 WIRING

3-3.1 Immersion Heater and Thermostat

The immersion heater must be permanently connected

to the electrical supply through a double-pole linked

switch with a minimum break capacity of 13 amps.

Please use the cable glands supplied to protect and fix

electrical cables at cable entry points.

Immersion Heater 240 V - 1 phase

WARNING: Isolate from main electricity supply before

any adjustments are made.

IMPORTANT!

1. WATER IN BEFORE POWER ON.

2. All internal wiring is factory mounted. Please do

not touch.

3. Regulations require competent person.

4. Check wiring is in accordance with diagram.

5. The safety cut-out operates if:

- Wiring is incorrect

- The immersion heater is defective

- Thermostat is set too high or is defective.

Reduce thermostat setting and press the reset button.

If still out of operation, contact competent person.

Immersion heater, part no. 71255.

Thermostat, part no. 80020.

Fig. 3-3a

IMMERSION HEATER THERMOSTAT

(LEFT HAND THERMOSTAT)

WIRING DIAGRAM

10

TECHNICAL INFORMATION 3

3-3.2 S Plan Wiring Layout (Indirect only)

For Other Boilers Refer To Boiler Manufacture

Immersion Heater

Thermostat

(Left Hand)

CylinderThermostat

(Right Hand)

11

TECHNICAL INFORMATION 3

3-3.3 Y Plan Wiring Layout (Indirect only)

For Other Boilers Refer To Boiler Manufacture

Immersion Heater

Thermostat

(Left Hand)

Cylinder Thermostat

(Right Hand)

12

INSTALLATION 4

4-1 BUILDING CONTROL

To install an OSO Dualstream System the installer must be fully competent, suitably qualified and possess any

applicable licence that may be required by the local inspectorate for installation of an unvented hot water storage

system.

In some areas the Local Authority may require notification by means of a building notice or by the submission of

full plans for the proposed installation of an unvented hot water storage system.

4-1.1 Regulations

The Water Byelaws and Current Building Regulations should be considered when installing an OSO

Dualstream System.

4-1.2 Electrical Regulations

All wiring must be to current lEE Wiring Regulations.

4-2 INSTALLATION

4-2.1 Positioning

It is the responsibility of the installer to ensure the safe handling of the OSO Dualstream components in accordance

with current Health and Safety Legislation (See page 3 for weights).

If the unit is sited where it could be subjected to frost i.e. in an outhouse or garage, adequate frost protection must

be provided, this should include an overriding frost stat wired so that the system is heated in the event of low

temperature.

The floor must give adequate support to the unit when full. (See page 3 for weights).

For maintenance purposes leave at least 500mm at the front of the unit.

The installer must ensure the space available is adequate for the cylinder and accumulator being fitted.

Note: Consult the Building Regulations for safe floor loadings.

4-2.2 Unvented Cylinder

The unvented cylinder can be sited anywhere within the thermal envelope of the dwelling. If the unit is to be sited

in an outhouse or garage, adequate frost protection must be provided; this should include an overriding frost stat

so that the system is heated in the event of low temperature.

The floor must give adequate support to the cylinder when full (See page 3 for weights). Consult the Building

Regulations for safe floor loadings.

For maintenance purposes adequate access must be available around the cylinder. Access of at least 100mm is

required above the cylinder. The cylinder must be installed vertically.

13

INSTALLATION 4

4-2.3 Accumulator

The accumulator must be installed in any convenient location within the dwelling. If the accumulator is to be sited

in an outhouse or garage, adequate frost protection must be provided; this should include an overriding frost stat

so that the system is heated in the event of low temperature.

The accumulator must be installed vertically. Legs and self-tapping screws are supplied for floor fixing.

100mm minimum access is required at the top of the accumulator for adjusting the air charge above or below the

pre-set charge.

Do not fit a non-return valve between the accumulator and the unvented cylinder.

IMPORTANT: The Accumulator must be set between 1 and 1.5 bar below the pressure reducing valve

setting. Minimum accumulator pressure is 0.5 bar (7PSI). If there is an incoming pressure of 3.5 bar or

over DO NOT adjust the accumulator pressure. You should only take air out of the accumulator and not

pump it up on installation

Note: As OSO Dualstream is a sealed system the pressure at the

taps is not affected by the height of the cold water storage.

4-2.4 Tundish

The Tundish must be installed so that it is clearly visible to the householder.

A typical arrangement for the Tundish discharge is shown in fig. 4-2a. Refer to the applicable Building Regulations

for specific details of Tundish installation.

4-2.5 Discharge Pipe

WARNING: Scalding water and steam can be blown out of the discharge pipe. Position the discharge so that

it is not a hazard to property or people (especially children). Refer to Building Regulations G3.

Downward discharges at low level, i.e. up to 100mm above external surfaces such as car parks, hard standings,

grassed areas etc, are acceptable providing that where children may play or otherwise come into contact with

discharges, a wire cage or similar guard is positioned to

prevent contact, whilst maintaining visibility.

Discharge at high level, i.e. into a metal hopper and metal

down pipe with the end of the discharge pipe clearly visible

(tundish visible or not) or onto a roof capable of withstanding

high temperature discharges of water and 3m from any

plastics guttering system that would collect such discharges

(tundish visible).

Where a single pipe serves a number of discharges, such as

in blocks of flats, the number served should be limited to not

more than 6 systems so that any installation discharging can

be traced reasonably at least one pipe size larger than the

largest individual discharge pipe to be connected. For further

information contact your Building Control Office. Maximum

permitted length of 22mm pipework is 9m. Each bend or

elbow is equivalent to 0.8m of pipework.

As the OSO Dualstream Accumulator acts as the system expansion vessel, an independent expansion vessel

system is not normally required.

However if an independent expansion vessel is specified it should be fitted to the domestic hot water system. It

may be installed in any position within the dwelling. The vessel must always be open to the system with no shut

off valve in the line. The expansion vessel should be connected between the cold inlet and the pressure reducing

valve.

Fig. 4-2a Typical Tundish Arrangement

14

INSTALLATION 4

4-2.6 Scale Protection

IMPORTANT: All installations should have a scale protection device fitted and in areas known to have

hard water, a water softening device is strongly recommended.

The location and position of the Scale Protection Device or Water Softener should be as the manufacturers

recommendations.

4-2.7 Pipework

When all pipework has been installed, disconnect from the OSO Dualstream components and flush all pipework

thoroughly. When connecting to existing pipework remove all unwanted components, create new pipe runs then

flush thoroughly before connecting to the OSO Dualstream components.

Due to vibration in transport it will be necessary to check for leaks after filling and pressurising system.

4-2.8 OSO Dualstream Components

All OSO Dualstream components and pipework are checked at the factory prior to dispatch, however always check

the connections for leaks on commissioning as transportation and installation can cause joints to move.

4-2.9 Connections to OSO Dualstream

It is recommended that any additional valves supplied by the installer should be lever operated full flow type.

4-3.0 Direct Cylinders

Direct cylinders except 120 litres are supplied with 2 - 3Kw single phase immersion heaters and are suitable for all

off peak tariffs.

5-1 COMMISSIONING CHECKS

It is the responsibility of the installer to ensure that the OSO Dualstream System is properly commissioned.

5-1.1 Commissioning Procedure

1. Check Accumulator pressure is between 1 and 1.5 bar below the pressure reducing valve setting

(Minimum 0.5 bar 7 PSI).

2. Check that the Tundish is correctly installed to conform to the Building Regulations.

3. Check that all pipe connections are tight and that no joints have been left unsoldered.

4. Check that ALL drain cocks are closed.

5. Check that ALL wiring connections have been made.

6. Check that the required earth continuity conductors have been fitted.

7. Check that the Immersion Heater has its cover fitted.

8.

Check that a Scale Protection device or Water Softener has been fitted according to manufacturers instructions.

9. Open all shut off valves.

10. Turn on Mains Stop Cock and allow the system to fill.

11. Open all domestic taps in turn to purge air.

12. Check the system for leaks including around the Immersion Heater.

13. Check that no water is passing through the Expansion Relief Valve or the Pressure and Temperature Relief

Valve, this will be evident at the Tundish.

14. Test the operation of the Pressure and Temperature Relief Valve by turning the Cap to the left and ensure that

the water flows freely and safely to waste.

15. Test the operation of the Expansion Relief Valve by turning the Blue Cap to the left and ensure that the water

flows freely and safely to waste.

16. Set Cylinder Thermostat at required temperature between 50°C and 70°C.

The Boiler and heating system should be checked before continuing.

17. Set Motorised Valve to manual, open and allow the heat coil to fill.

18. Set the Motorised Valve to Auto.

19. Switch on the heating system.

20. Wait for the system to heat up.

21. Check temperature of tap water.

22. Check operation of Cylinder Thermostat. When turned down below tank temperature the Motorised Valve

should close. When turned up above tank temperature the Motorised Valve should open.

23. Check for leaks again when the system is up to temperature.

5-2 HANDING OVER

Having filled in the Guarantee Form, this should be sent to OSO Hotwater (UK) Ltd. The Installer should next

recheck the system and ensure it is completely satisfactory before demonstrating to the householder. The

householder should be aware of the following:

1. How to set the temperature of the tap hot water.

2. The function of the Pressure and Temperature Relief Valve and Expansion Relief Valve and that overpressure

may cause steam and scalding water to be emitted from the discharge pipe.

3. The Tundish is supplied as a visual identification for overpressure or temperature relief.

4. The procedure to follow in the event of overpressure. Refer to 2-4.

This manual and supplements must be left with the householder.

15

COMMISSIONING 5

16

SERVICING 6

6-1 ROUTINE SERVICE

The OSO Dualstream system should have a routine service at least once in 12 months.

IMPORTANT: Always turn off the heating system and electricity supply to the OSO Dualstream before

working on the System.

6-1.1 Service Procedure

1. Turn the Heating System OFF.

2. Turn the electrical supply to the OSO Dualstream OFF.

3. Close the Stop Cock.

4. Open the hot taps.

5. Attach a hose to the Cylinder Drain Cock and empty the Cylinder.

6. Remove Immersion Heater, remove limescale and examine the element.

In hard water areas it is probably better to replace the Immersion Heater if heavily scaled.

7. Replace Immersion Heater ‘O’ Ring.

8. If heavy scaling is evident then descaling the system is recommended.

9. Clean and check the line strainer in the Pressure Reduction Valve - replace if required.

10. Check and clean the expansion relief valve - replace if required.

11. Flush the system if descaling has been carried out and refill the system.

12. Open the cold tap to empty the accumulator.

13. Check Accumulator pressure is 1-1.5Bar below the set pressure of pressure reducing valve.

14. Check the system for leaks including accumulator and around the Immersion Heater.

15. Test the operation of the Pressure and Temperature Relief Valve by turning the Cap to the left and ensure that

the water flows freely and safely to waste.

16. Test the operation of the Expansion Relief Valve by turning the Blue Cap to the left and ensure that the water

flows freely and safely to waste.

17. Check that no water is passing through the Expansion Relief Valve or the Pressure and Temperature Relief

Valves, this will be evident at the Tundish.

18. Switch on the heating system.

19. Check operation of Motorised Valve by setting heating system to call for hot water. The valve should open.

Then turn hot water off - the valve should close.

20. Wait for the system to heat up.

21. Check temperature of tap water.

22. Check operation of Cylinder Thermostat. When turned down below tank temperature the Motorised Valve

should close. When turned up above tank temperature the Motorised Valve should open.

23. Check for leaks again when the system is up to temperature.

17

SPARE PARTS 7

7-1 SPARE PARTS

8-1 SECONDARY RETURN (Direct or Indirect)

Accumulator Nominal

Capacity (Litres) Part No

Unvented Cylinder See page 3 for unvented cylinder details

80030

71255

92000

Cylinder Thermostats

Immersion Heater

Motorised Valve

Pressure Reducing Valve

3/4’’

510508

1’’

300129

Combined

5550803

219002

1’’

225002

1’’

102207

3/4’’

510505

Check valve

Expansion relief valve

Temperature and

Pressure Relief Valve

Tundish

Hot Water Shut Off Valve

Cold Water Shut Off Valve

Cold Supply Shut Off Valve

22mm

021-16935

28mm

021-18047

100

19608

170

18891

240

18892

310

18893

450

18894

1 Secondary Return Fitting

2 Non Return Valve

3 Circulation Pump

4 Secondary Return Line

4

32

1

FIGURE 8.1a

OSO DUALSTREAM

9.1 THE OSO DUALSTREAM

The OSO DUALSTREAM utilises all the benefits of traditional unvented cylinders with standard controls;

temperature / pressure relief valve and pressure reducing valve set at 3.5 bar and the accumulator at 2 bar.

The system also uses an accumulator vessel, this stores mains water at the main pressure in a special butyl

diaphragm, and is the driving force to the hot / cold supplies. Delivering a substantial increase in water volume to

both Hot & Cold outlets within the building.

If the accumulator is sized correctly it will allow any number of baths or showers to be used simultaneously,

irrespective of the incoming main flow rate and will function even if the mains are turned off, regardless of the mains

water pressure. OSO DUALSTREAM systems can be fitted close together or remote from each other offering

flexibility in installation.

18

Hot Supply

Option A

7

12 6

10

A

J

B

3

14

5

4

9

2

1. Accumulator (Cold Water Storage)

2. Unvented Cylinder

3. Cylinder Thermostat (Indirect)

4. Immersion Heater Thermostat

5. Immersion Heater

6. Expansion Relief Valve

7. Pressure Reducing Valve

9. Pressure Relief Valve & Temperature

Relief Valve

10. Tundish

12. Cold Main Shut Off Valve

14. Cylinder Drain Cock

15. Tee Connection

A. Water from system

B. Accumulator Drain Cock

C. Controlled action diaphragm

D. Gas charge

E. Gas charge valve

F. Internal clench ring

G. Threaded nut for pum stand installation

H. Air flow design to reduce condensation

I. Diffuser directs flow up and out

The accumulator must be set at between 1 and 1.5

bar below the pressure reducing valve setting.

Minimum accumulator pressure 0.5 bar (7 PSI).

If there is an incoming pressure of 3.5 bar or over DO

NOT adjust the accumulator pressure. You should only

take air out of the accumulator and not pump it up on

installation.

9.1a SCHEMATIC LAYOUT

(Indirect unit)

Accumulator

H

F

D

E

C

1

G

15

OSO Hotwater (UK) Limited

E15 Marquis Court, Team Valley Trading Estate, Gateshead, Tyne & Wear, NE11 0RU • Tel. (0191) 482 0800 • Fax. (0191) 491 3655

Email. technical.uk@oso-hotwater.com • sales.uk@oso-hotwater.com • spareparts.uk@oso-hotwater.com

Web www.oso-hotwater.com

19

28mm CONNECTIONS

10.1 28mm Connections

OSO Dualstream units with hot water capacities from 250 litres to 380 litres are available with 28 mm hot and cold

connections. The combination valve supplied will incorporate an adjustable pressure reducing valve, line strainer, non-return

valve, balanced cold take off and connection for expansion vessel.

Hot water connection is 1" BSP.

11.1 Fault Diagnostic

PROBLEM

1. Poor flow rate at taps

2. Good volume for short time then tails off.

Or performance the same no difference.

Water not entering accumulator

3. Mains water discoloured

4. Water leaking from beneath accumulator

5. Water condensation running down accumulator

6. Noise from accumulator when filling water hammer noise

CHECK

Line Strainer

Isolation valves fully open

No check valves online

Size of pipework

Accumulator pressure charge

Accumulator pressure

Incorrect setting re-set

1.5 bar differential between accumulator and reading on

combination valve min setting 0.5 bar.

Drain down accumulator refill, if persists check mains

supply. Redish taint to water. Check air in accumulator, no

air present only water, diaphragm faulty replace

accumulator.

Drain down accumulator, tilt back and check compression,

fitting may be loose from transit.

Check pipework lagged, air movement or change within

confined space.

Normal situation expansion of diaphragm, check valves,

check jumpers in stop cock.

SERVICEABLE 1" PRESSURE

REDUCING CARTRIDGE AND LINE

STRAINER (SET AT 3.5 BAR)

EXPANSION RELIEF VALVE

(SET AT 8 BAR)

28mm COLD

MAINS IN

28mm TO

CYLINDER

1" BALANCED COLD WATER TAKE OFF

WITH NON-RETURN VALVE

3/4" B.S.P. CONNECTION

FOR EXPANSION VESSEL

Table of contents

Other OSO Water Heater manuals

Popular Water Heater manuals by other brands

Lochinvar

Lochinvar AMP 200-9 Installation, commissioning, user & maintenance instructions

State Water Heaters

State Water Heaters EDT662ORT instruction manual

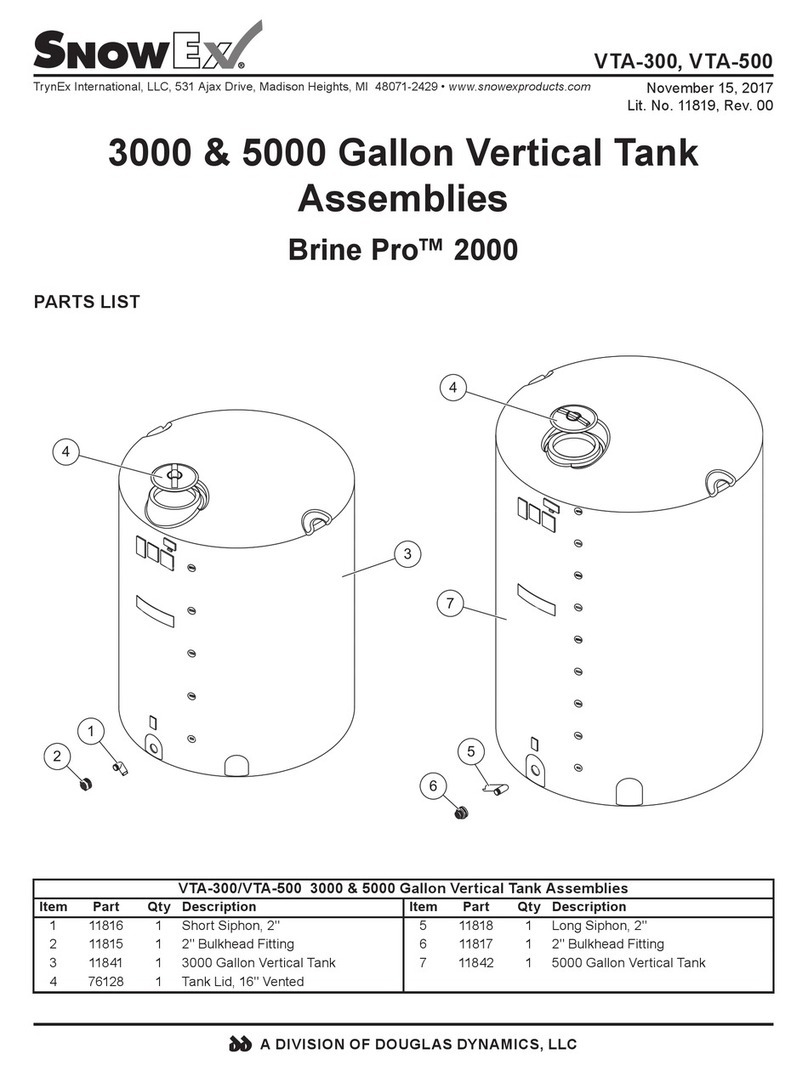

SnowEx

SnowEx Brine Pro 2000 VTA-300 quick start guide

DAXOM

DAXOM UKDAX-11ST Installation and operating manual

Keston

Keston qSpa Installation and servicing instructions

Modena

Modena EI 3D Series manual

EemaX

EemaX PA018208T2T Installation guide and owner's manual

clage

clage CEX-U Operating instructions for the user

Heatrae Sadia

Heatrae Sadia Multipoint 30 Installation and user instructions

Pentair

Pentair SEP 100 installation guide

Nibe

Nibe ES 24 Series Installation and maintenance instructions

Rinnai

Rinnai EHP32-HPST265 installation manual