OTS XB-OTS-VIKA10 User manual

VICAT SOFTENING POINT TEMPERATURE TESTER

OPERATION MANUAL

XB-OTS-VIKA10

Thank you for your esteemed company to buy our products.

The operation is simple to use, but the wrong operation will cause the accidents and shorten the life of the

device or reduce its performance. Therefore, please be sure to familiarize yourself with this manual before use.

Please keep this manual.

Security Marks

In this manual, there are following marks for security in operation. To avoid accidents and hazard,

please obey the following precautions, warnings and notes:

Danger

This mark means workers may be hurt if he does not comply it.

Warning

This mark indicates the machine is possible to be damaged if it is not used

by the right instructions.

Attention

The test quality and result might be effected.

This item shows the auxiliary statement of this product in operation.

Warning marks are showed in the following:

Warning

The mark suggests the operating place

shall take this manual as reference.

Danger voltage

This symbol says be aware of high voltage pressure.

Ground protection

wire

It shows the cable of ground wire.

!

Note

!

!

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

3

I

、

Hardware overview

1.1 Main purpose and scope of application

Thermal deformation and Vicat softening point temperature tester is mainly used for thermal

deformation analysis of non-metallic materials such as plastics, rubber, nylon, electrical insulating

materials and the determination of Vicat softening point temperature. It is used by chemical companies,

scientific research institutions, colleges and universities. Ideal testing tool for other departments.

1.2 Meet the standards

This instrument satisfies the determination of the Vicat softening point temperature of

thermoplastic plastics in GB/T1633-2000 "Determination of the Vicat Softening Point Temperature of

Thermoplastics", referring to the plastic bending load in GB1634-79 "Plastic Bending Load Thermal

Deflection Temperature Test Method" Heat distortion temperature test method. Please read this

manual carefully before using this instrument.

1.3 Structure introduction:

1

2

3 4

5

6 7

8

9

10

Remarks:

1. Dial indicator

2. Stirring motor

3. Manual handle

4. Dial indicator support rod

5. Touch screen controller

6. Chassis

7. Mechanical over-temperature protection

8. Power switch

9. Stirring motor speed controller

10. Foot

1.4 Main technical parameters:

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

4

①Temperature control range: room temperature~300℃

②Rising rate: (120±10)℃/h [(12±1)℃/6min]

(50±5)℃/h [(5±0.5)℃/6min]

③The maximum temperature indication error: ±0.5℃

④Maximum deformation indication error: ±0.01mm

⑤Deformation measurement range: -0.1mm~1.1mm

⑥Number of sample racks: 3

⑦The weight of the load rod and the tray: 56g The weight of the meter rod: 12g

⑧Heating medium: methyl silicone oil or transformer oil

⑨Cooling method: natural cooling above 150℃, water cooling or natural cooling below 150℃

(high-efficiency instrument is equipped with rapid cooling device)

⑩Heating power: 3.5kW

1.5 Working principle

1.5.1 Determination of the Vicat softening point temperature of thermoplastics: When the temperature

is increased at a constant rate, the temperature at which a standard indenter penetrates the surface of

the thermoplastic sample to a depth of 1 mm under a certain load condition is measured.

1.5.1 Plastic bending load thermal deformation temperature test method: Determine the plastic sample

immersed in a suitable liquid heat transfer medium with constant heating, and under the action of

simply supported beam static bending load, the bending deformation of the sample reaches the

specified value The temperature at the time.

1.6 Working conditions

1. Ambient temperature: within the range of 10℃~40℃;

2. The relative humidity of the environment is within 30%—80%;

3. In an environment without vibrations and corrosive media;

4. Install and adjust to the level correctly on a stable foundation;

5. There is no strong magnetic field interference when working, and no strong convection in the

surrounding air;

1.7 Electrical requirements

Power supply: 220VAC-15%~240VAC+10%

1.8 Dimensions: length 500mm wide 400mm high 1400mm

1.9 Instrument weight: 100Kg

II.Install

2.1 Instrument unpacking inspection

2.1.1 Avoid violent vibration and mechanical damage during the transportation of the instrument. If

the instrument is damaged due to damage to the packaging box, please contact the relevant

transportation department and notify our company in time, and the operator should not dispose of it by

himself.

2.1.2 Check the attached accessories one by one according to the packing list. If the attached

accessories do not match the packing list, please contact our company in time.

2.2 Hardware installation:

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

5

2.2.1 Take out the instrument. The host machine should be placed on a dry, ventilated, non-vibrating

horizontal ground to make the instrument stable.

2.2.2 The computer and printer should be placed on the workbench, and the signal cable and power

cord should be connected.

2.2.3 Connect the inlet of the cooling water pipe with the inlet water pipe, and the outlet water pipe

with the sewer.

2.2.4 Pour methyl silicone oil (or transformer oil) into the oil groove and check whether there is oil

leakage in the oil discharge nozzle and other parts.It is strictly prohibited to power on the instrument

before adding heating medium in the medium box.

2.2.5 Add about 10 liters of methyl silicone oil (or transformer oil), and the oil level is about 50 ~

60mm from the upper plane of the tank.

2.2.6 Put the three sample racks into the oil groove and connect the connection of the deformation

sensor. There is only one temperature sensor on the testing machine, which has been installed at the

factory without user installation. Check whether the load rod movement up and down smoothly.

2.2.7 Check whether the connection is correct and connect the mainframe power supply. At this time,

the stirring motor should run and whether it is sensitive and reliable.

III

、

Calibration

3.1. After the thermal deformation and VEKA softening point temperature detection equipment is

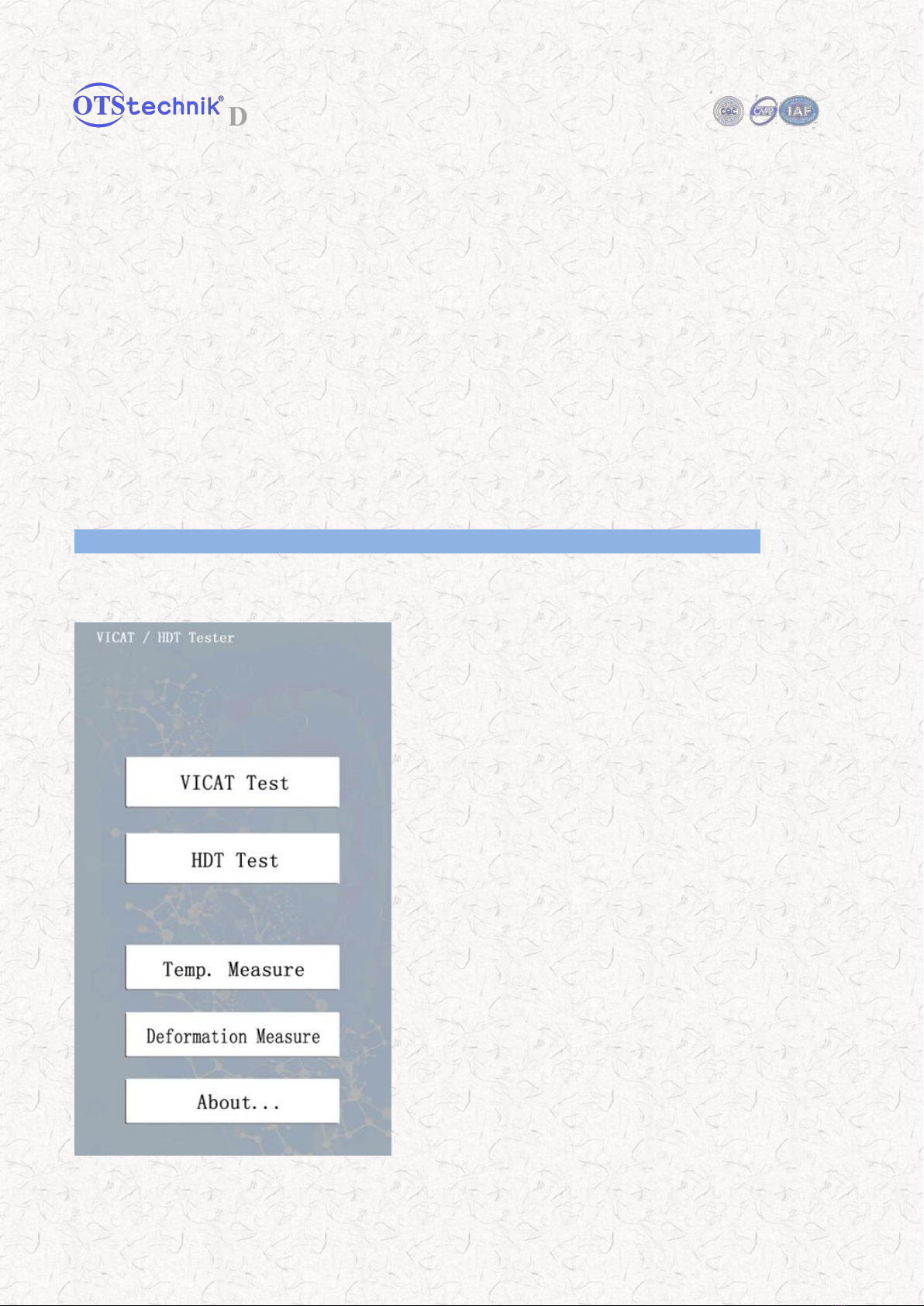

powered on, the test system enters the following figure after completing the self-test:

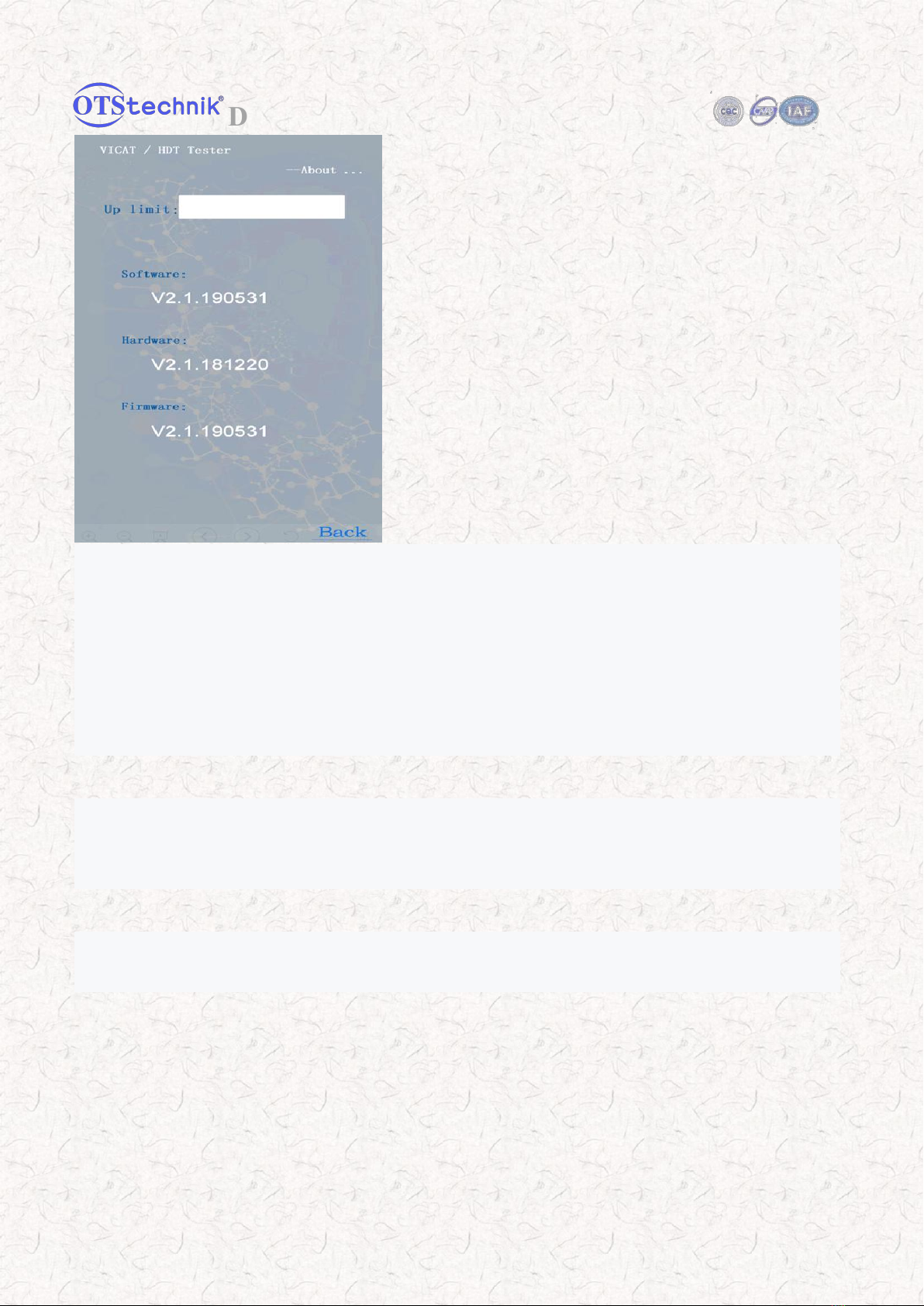

Click on "About..."Button to enter the system information interface, as shown in the figure below

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

6

Upper limit temperature: flash point temperature of medium oil. When temperature is controlled, the

temperature of oil tank reaches this temperature, the system stops temperature control for protection to

prevent fire.

Software version: software version number of touch screen

Hardware version: thermal deformation, VEKA temperature control board version number

Firmware version: Software version number for thermal deformation, VEKA temperature control

board internal

3.2 Instrument measurement

The measurement of the instrument includes the measurement of deformation, temperature and

heating rate. When measuring the instrument, please follow the steps below to ensure the accuracy of

the instrument.

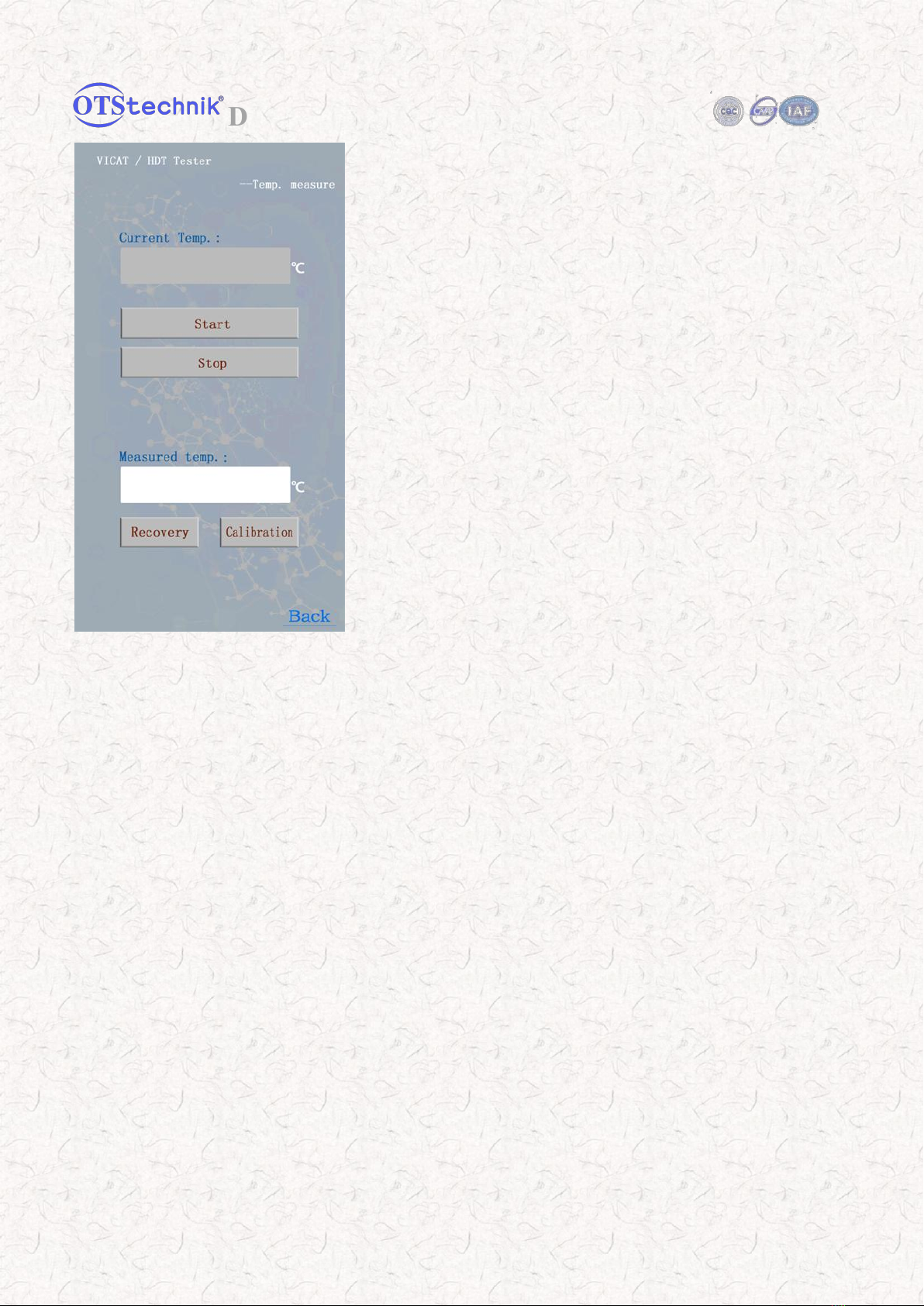

3.3 Temperature measurement

Temperature calibration needs to use temperature measuring instruments, click "temperature

measurement" to enter the calibration interface, as shown below:

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

7

Click the "Start Temperature Control" button to start temperature control and input the corresponding

calibration temperature at the calibration temperature, such as 50. When the measuring instrument just

displays 50 ° C, click the "Calibration" button twice successively, and the system will indicate that the

calibration is successful and the current point calibration is completed. Then enter "100" and wait for

the calibration of the next point.

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

8

Repeat the above operations until the corresponding temperature point calibration is completed. The

temperature correction points are: 50, 100, 150, 200, 250 ℃; it must be noted that the calibration

temperature cannot exceed the flash point temperature of the medium oil.

Click the "Stop Temperature Control" button to stop the heating control and complete the calibration,

and click the "Back" button to return to the main interface.

Note: The upper limit protection temperature should be set before heating up.

3.4 Deformation measurement

The measurement of the deformation measurement system requires a micrometer. Before

measurement, please make sure that the dial indicator and the standard measurement instrument for

measurement have been correctly installed on the instrument stand. Please refer to the instrument

manual for the installation method. Click the "Deformation Measurement" button to enter the

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

9

following:

The interface shows the current deformation of the dial indicator on each shelf. If the difference

between the dial gauge data and the standard displacement measuring instrument exceeds the standard

regulations, the dial gauge should be replaced.

3.5 Heating rate measurement

The measurement of heating rate needs to start a new test, such as: Vicat measurement, select 50℃/h

or 120℃/h rate, and then keep the displacement stable to ensure that the test does not end due to the

arrival of deformation, click the "start test" button to start heating control. After 12 minutes, record the

temperature difference at every 6-minute interval, and the error is within ±0.5℃to be qualified.

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

10

IV. Testing method

4.1 Vicat determination

Thermoplastic Vicat softening point temperature measurement: When the temperature is increased at a

constant rate, the temperature at which a standard indenter penetrates 1mm deep into the surface of the

thermoplastic sample under a certain load is measured.

According to GB/T1633 or ISO306:1994 test method standard cut sample. The thickness of the

sample should be (3~6.5)mm, a square sample with a side length of 10mm, or a round sample with a

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

11

diameter of 10mm; the thickness of the molded sample should be (3~6.5)mm; the thickness of the

plate sample should be the original thickness of the plate, But when the thickness exceeds 6.5mm, the

thickness of the sample is reduced to (3~6.5)mm through single-sided machining. If the thickness of

the plate is less than 3mm, directly stack up to three specimens together so that the total thickness is

between 3mm and 6.5mm, and the thickness of the top piece is at least 1.5mm.

The supporting surface and side of the sample should be parallel, and the surface should be flat and

smooth, without bubbles, no sawtooth marks, dents or flashing and other defects. The stacking surface

of the sample should be kept flat and there should be no gaps between the stacks. There are at least 2

samples in each group.

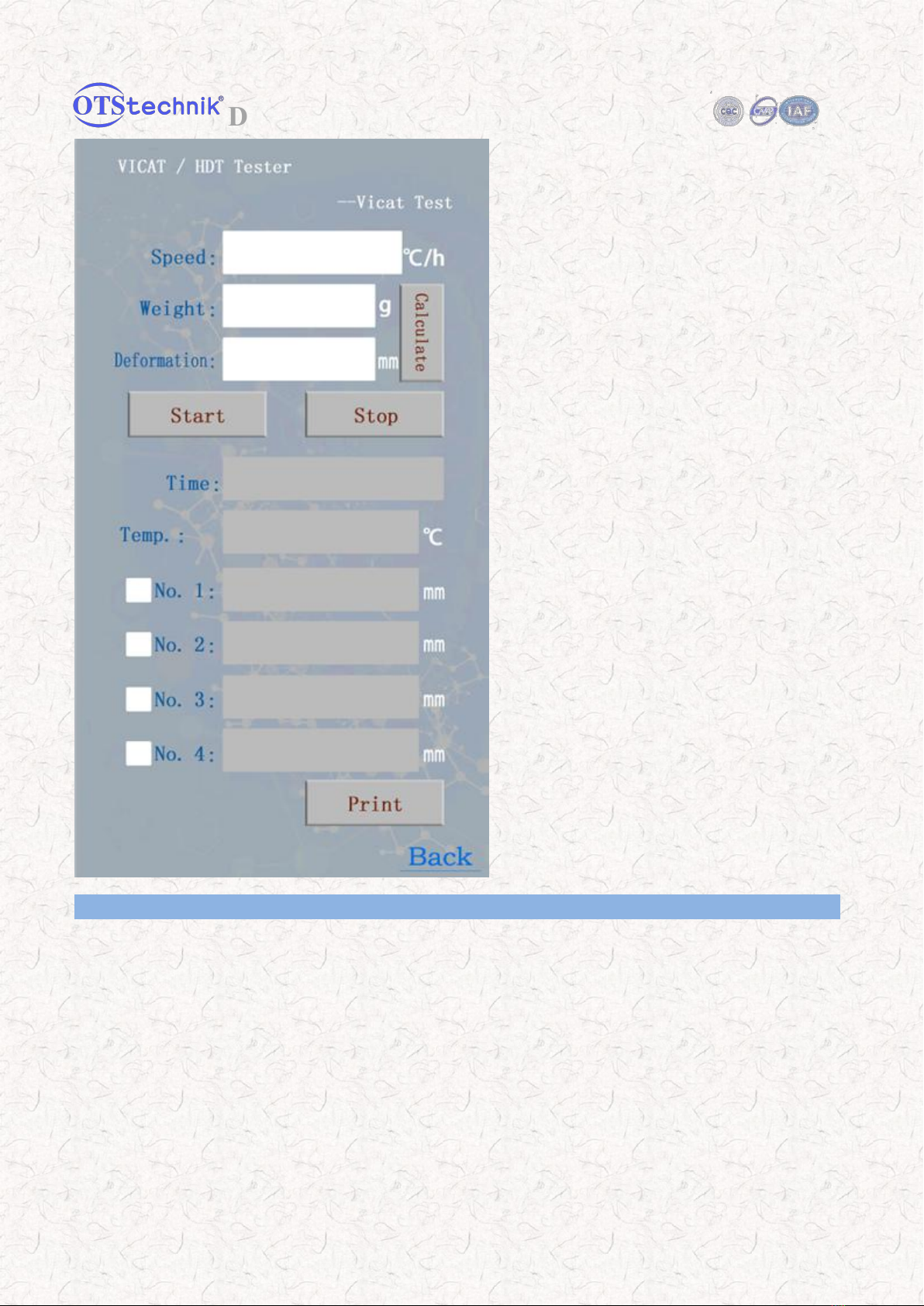

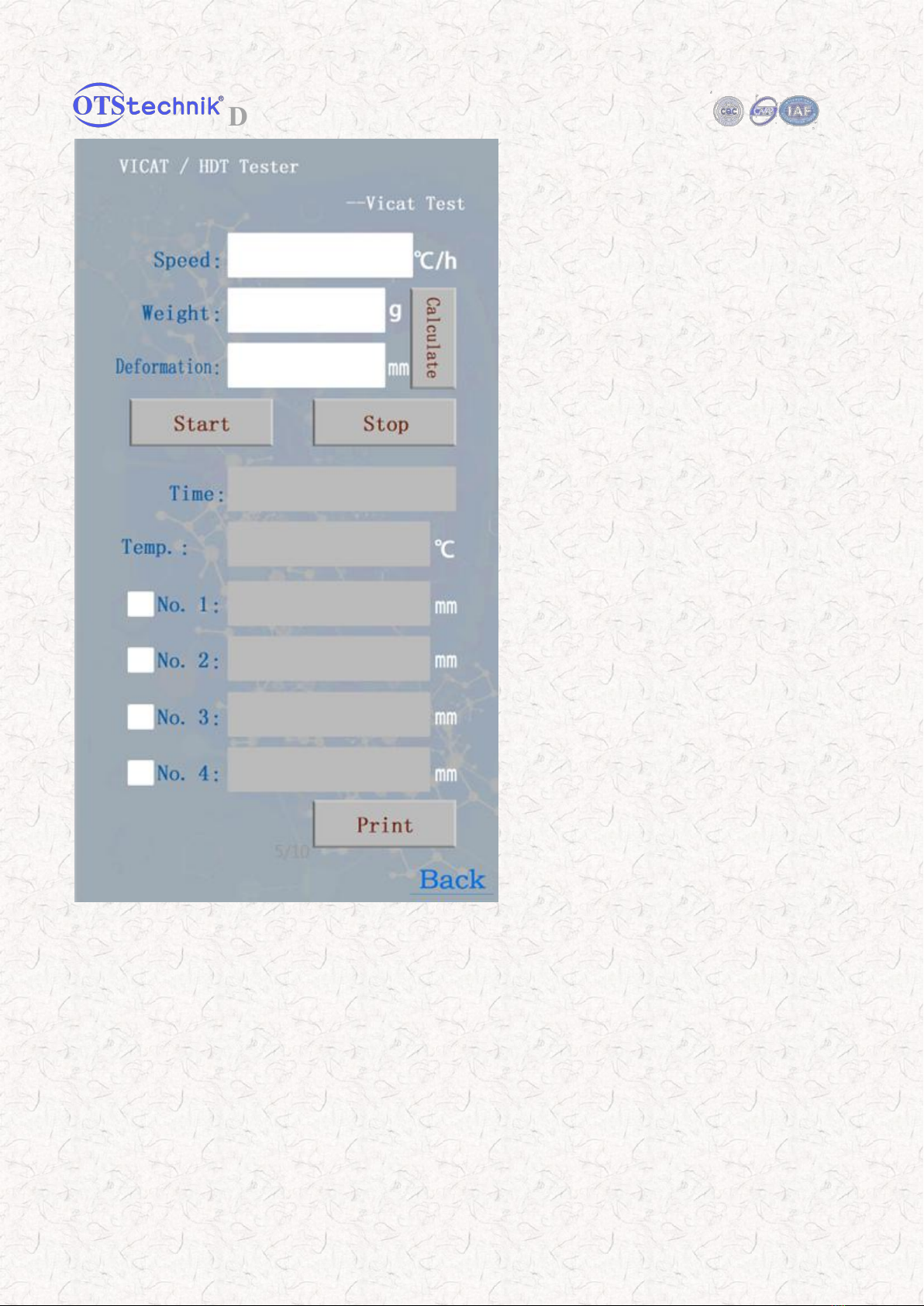

Before measuring the Vicat softening point temperature, please prepare the sample, perform

pretreatment, measure the size of the sample, then install the sample, click the "Vicat determination"

button to enter the interface as shown in the figure below

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

12

According to the test requirements, enter the appropriate heating rate, directly enter the mass of the

loaded weight, or click the "Calculate" button to enter the interface as shown in the figure below:

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

13

Enter the number of layers, thickness and load of the sample. The additional weight is the total mass

of the load bar, the pressure needle and the weight tray (68g); click the "Calculate" button again, and

the corresponding weight weight will be displayed; click the "Back" button Return to the test

interface.

Testing method

total weight(N)

Need to add weight(g)

Method A

10N

10*1000/9.81 - 68= 951

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

14

Method B

50N

50*1000/9.81 - 68= 5029

Weight calculation formula:

F1=

R

F

81.9

1000

F1—The mass that needs weight

F-Two types of loads in accordance with A or B

R-load bar + tray + pressure needle (pressure head) + sensor shaft (68g)

Check the sample holder used in this test. If it is three sets of samples, check the three deformations

corresponding to the installed samples, and click "Start test" to start temperature control;

At the end of the test, it will automatically stop heating up, click the "Print" button to take out the test

report.

4.2. Thermal deformation measurement

Plastic bending load thermal deformation temperature test method: Determine the temperature at

which the plastic sample is immersed in a suitable liquid heat transfer medium with a constant

temperature rise, and under the action of a static bending load of a simple beam type, the sample

bending deformation reaches the specified value .

The heat deformation test sample is prepared to cut the sample according to the GB/T1634 or ISO75

test method standard. The conventional test size is (80×10×4) mm and (120×4×10) mm.

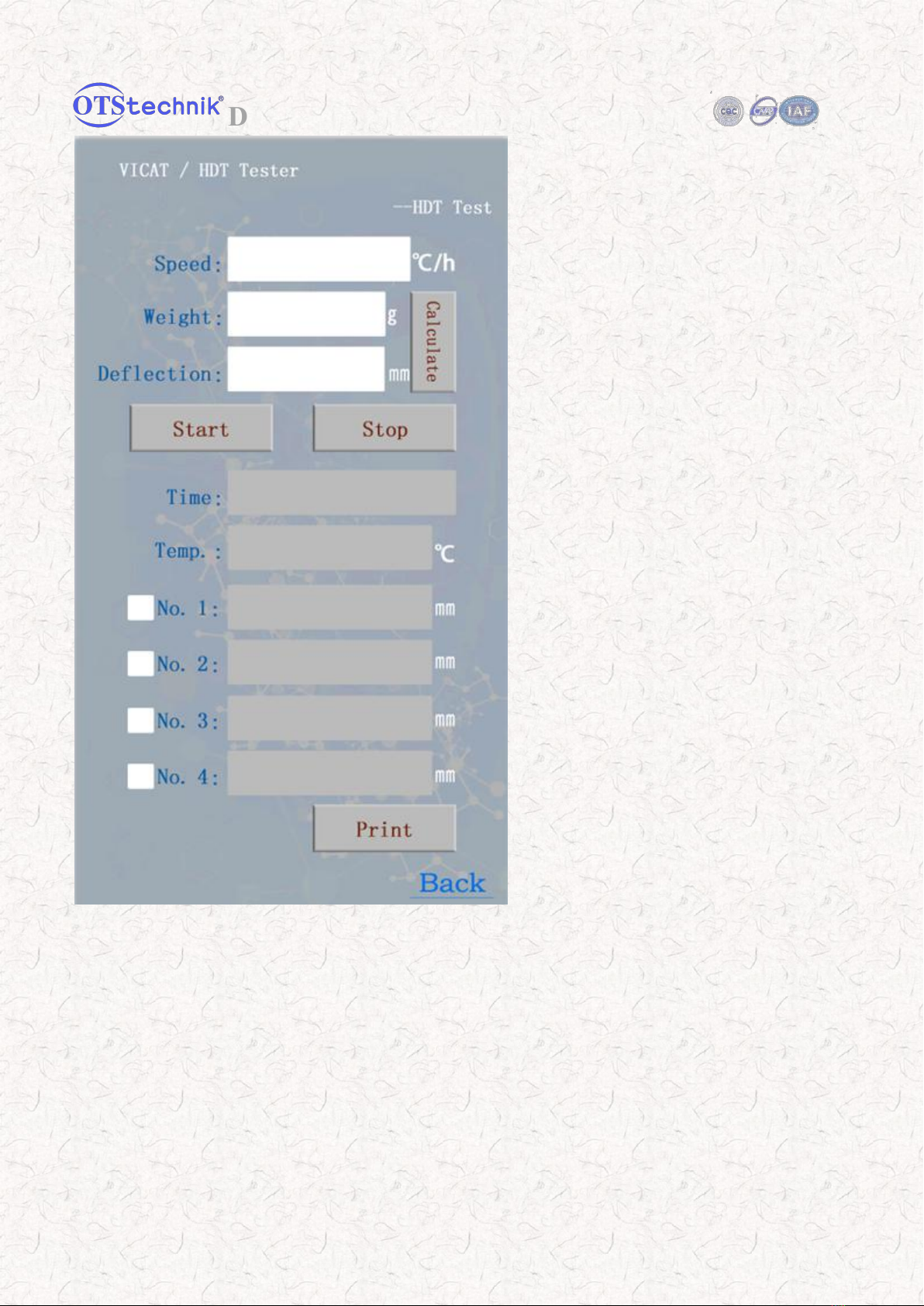

Before measuring the thermal deformation temperature, please prepare the sample, perform

pretreatment, measure the specifications and dimensions of the sample, then install the sample, click

the "thermal deformation measurement" button to enter the thermal deformation measurement

interface, as shown in the following figure:

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

15

Enter the appropriate heating rate; click "calculate" to enter the corresponding sample size, select

"flat" or "side stand", enter the corresponding bending stress, click the "calculate" button again, and

the corresponding weight will be displayed. Enter the span and deflection, click "Back" to return;

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

16

The calculation of load is carried out according to GB1633-2000 and GB1634-2004. The following

table lists the load corresponding to the common sample size:

placement

method

Testing

method

Sample size(l×b×h)

pressure,MPa

Load,N

Need to add weight

F1,g

Lay flat

(recommended)

A

80mm×10mm×4mm

1.80

3

(3/9.81) ×1000-68 =

238

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

17

B

0.45

0.75

(0.75/9.81)

×1000-68= 8

C

8.00

13.33

(13.33/9.81×1000-68

= 1291

Side stand

A

120mm×10mm×4mm

1.80

4.8

(4.8/9.81)×1000-68

= 421

B

0.45

1.2

(1.2/9.81) ×1000-68

= 54

C

8.00

21.33

(21.33/9.81)

×1000-68 = 2106

Note: The subtracted number 68 in the column of the weight to be added in the table represents the

weight of the load bar + tray + indenter (or indenter) + sensor axis. The calculation of the weight to be

added is based on g = 9.81 m/s2 calculation.

For sample sizes not in the table, the required load can be calculated by the following formula:

F=2 ×δ×b × h × h / (3 × L) ……………………(1)

F1 = F × 1000 / 9.81 – R ………………………………(2)

In the formula: F—the load to be applied to the sample, in N

F1—The mass to be added with weight, unit g

δ-Standard bending normal stress (A method 1.80MPa; B method 0.45MPa; C method 8.0MPa)

b—sample width, unit: mm

h—sample height, unit: mm

L—The distance between two pivots, 100mm/64mm

R—load bar weight + pallet weight + pressure needle (indenter) + sensor axis (70g)

If there are two sets of sample holders, check the two deformations corresponding to the installed

samples, and click "Start Test" to start temperature control;

Dongguan Xin Bao Instrument Co., Ltd

Add: The 3rd Industrial Zone, Chashan Town, Dongguan. Tel: 0769-33365786 www.ots-testequipment.net

18

At the end of the test, it will automatically stop heating up, click the "Print" button to take out the test

report.

V

、

Notice

1. Heating is strictly prohibited when methyl silicone oil is not added to prevent dry burning from

damaging the heating tube

2. After each test is completed, be sure to take out the tested sample to prevent the next repetitive

heating to dissolve or decompose and increase the nail

The viscosity of the base silicone oil causes uneven heating.

3. The over-temperature protection should be adjusted to 250℃during the test (you can set it

according to your needs)

4. When the cooling water pipe is connected to the water, the pressure should not be too high, so that

the water pipe can be broken by explosion-proof, while saving water

5. During the high temperature test, a small amount of volatile smoke will appear (most obvious above

200℃), please do a good job of ventilation and smoke exhaust.

Table of contents

Popular Test Equipment manuals by other brands

Agilent Technologies

Agilent Technologies InfiniiVision 3000 X- Series Advanced training guide

Keysight Technologies

Keysight Technologies N5990A-301 user guide

Industrial Fiber Optics

Industrial Fiber Optics IF-FOM Operator's manual

Hioki

Hioki 3159 instruction manual

Elektro-Automatik

Elektro-Automatik ELR 9000 operating manual

Meatest

Meatest M505D Operation manual