ii

_____________________________________________________________________________________________

______________________________________________________________________________________________

DANGER

This product is designed to conform to IEC 61010 Safety Standards, and

has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as

damage to the product. Be certain that you understand the instructions

and precautions in the manual before use. We disclaim any

responsibility for accidents or injuries not resulting directly from

product defects.

Safety Symbols

The symbol printed on the product indicates that the user should

refer to a corresponding topic in the manual (marked with the

symbol) before using the relevant function.

In the manual, the symbol indicates particularly important

information that the user should read before using the product.

Indicates that dangerous voltage may be present at this terminal.

Indicates a fuse.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Indicates a protective conductor terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

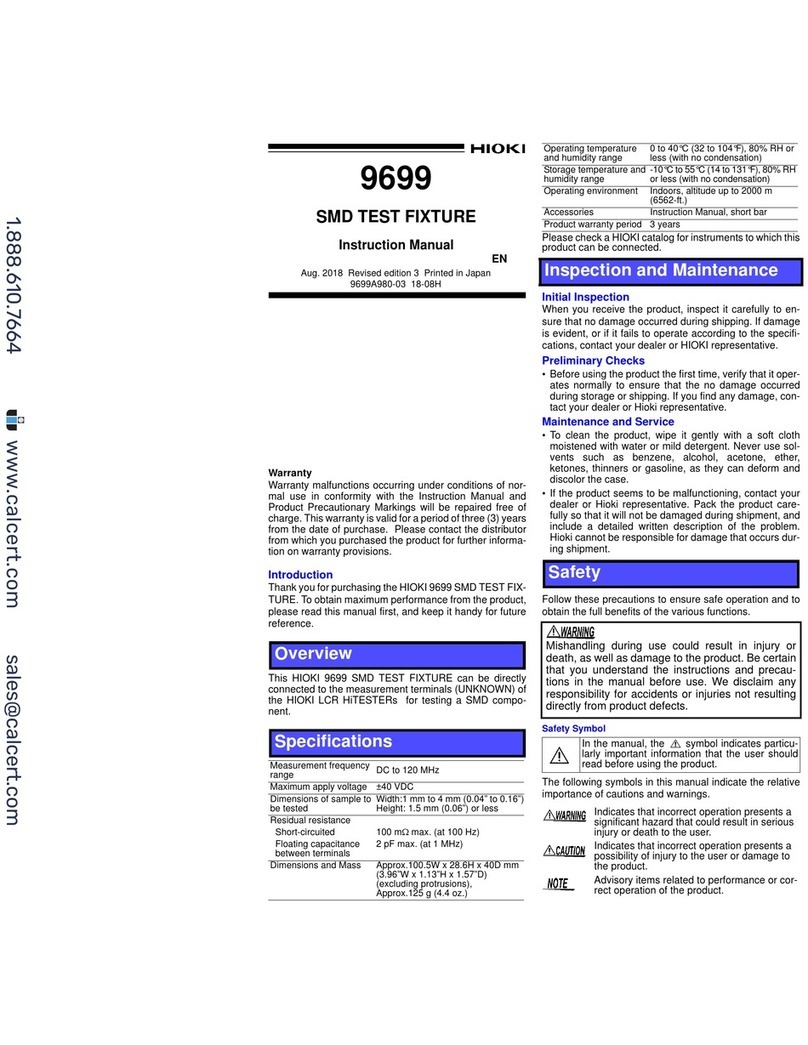

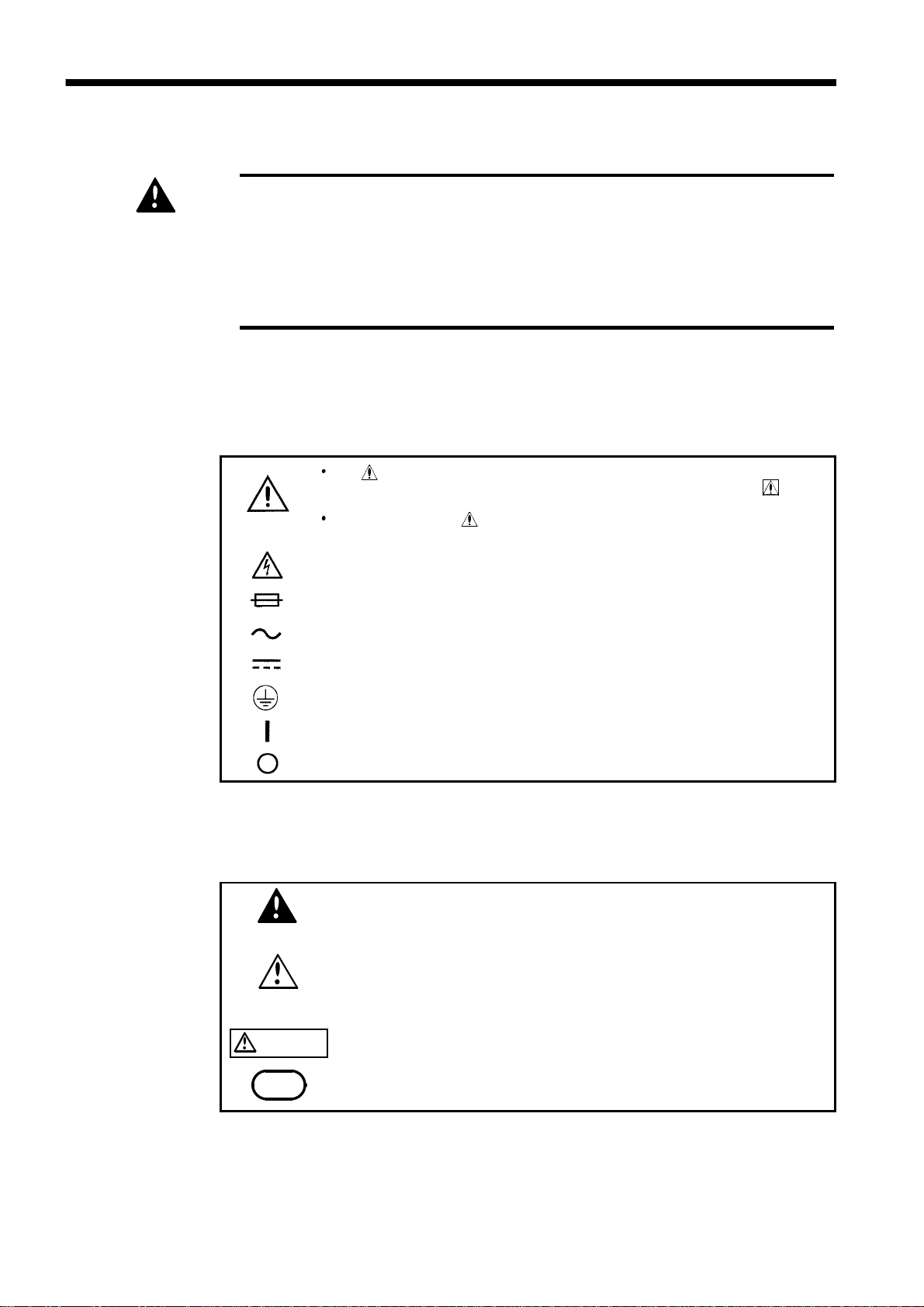

DANGER

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

WARNING

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

CAUTION Indicates that incorrect operation presents a possibility of injury to

the user or damage to the product.

NOTE Advisory items related to performance or correct operation of the

product.

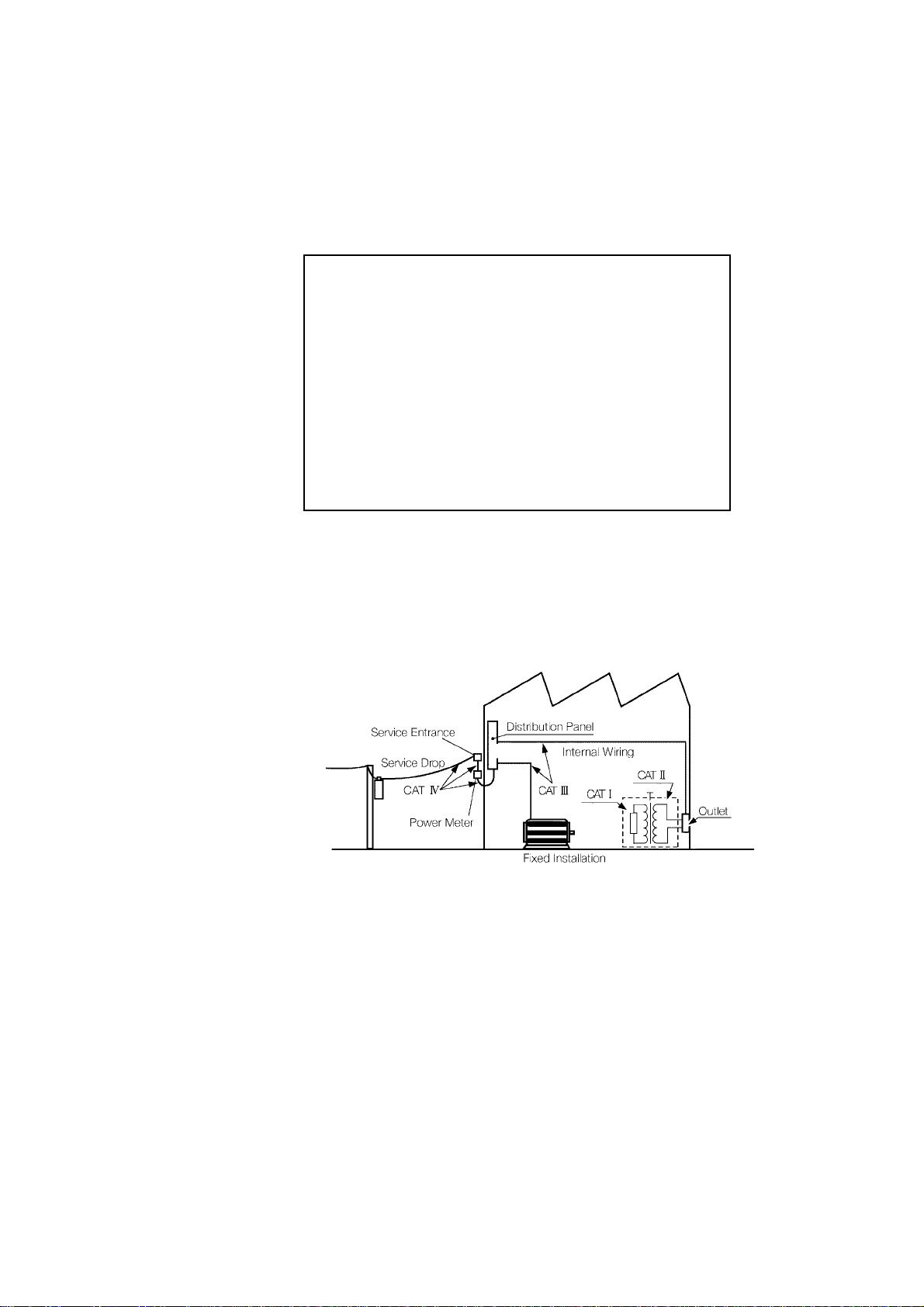

Safety Notes

This manual contains information and warnings essential for safe operation

of the product and for maintaining it in safe operating condition. Before

using the product, be sure to carefully read the following safety notes.

The following symbols in this manual indicate the relative importance of

cautions and warnings.