1 Introduction

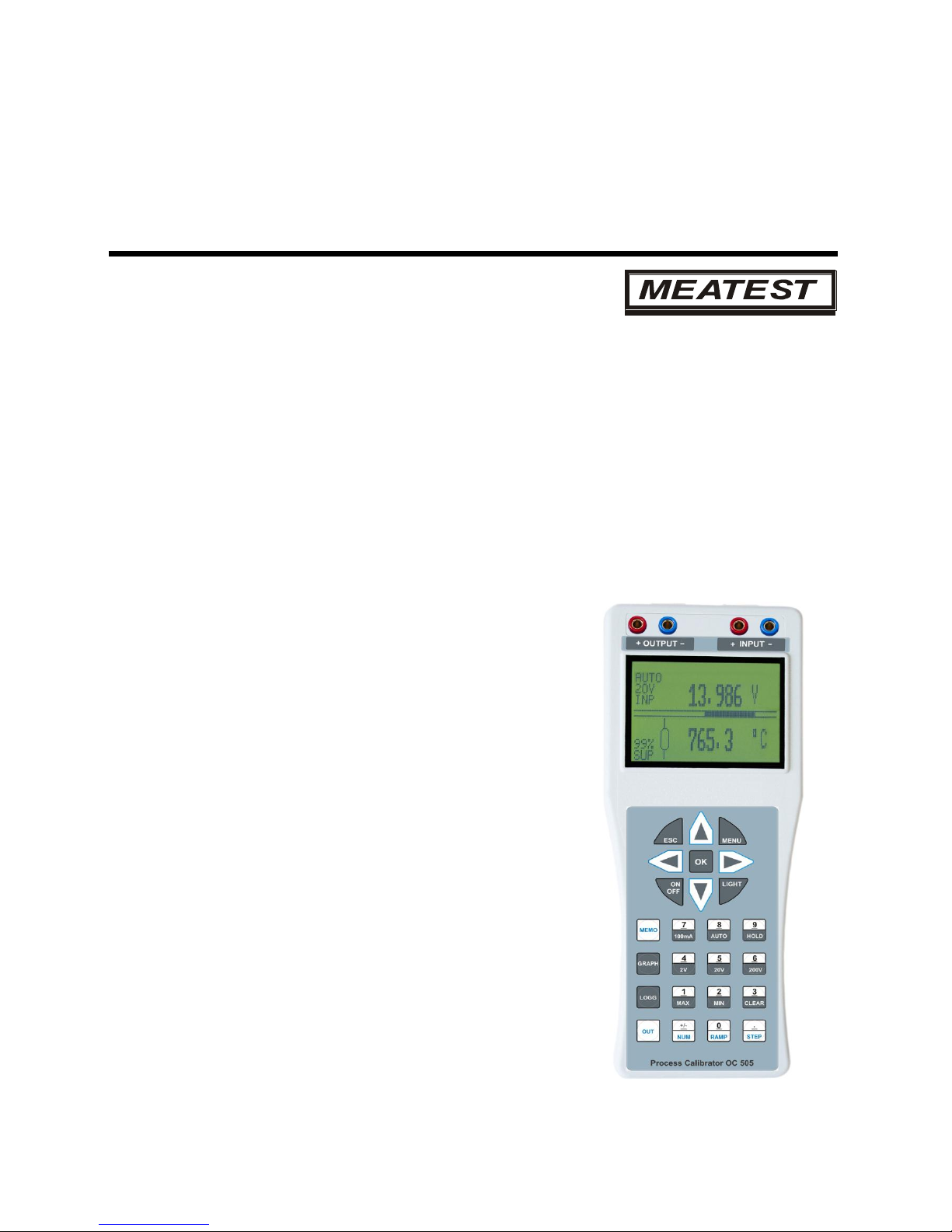

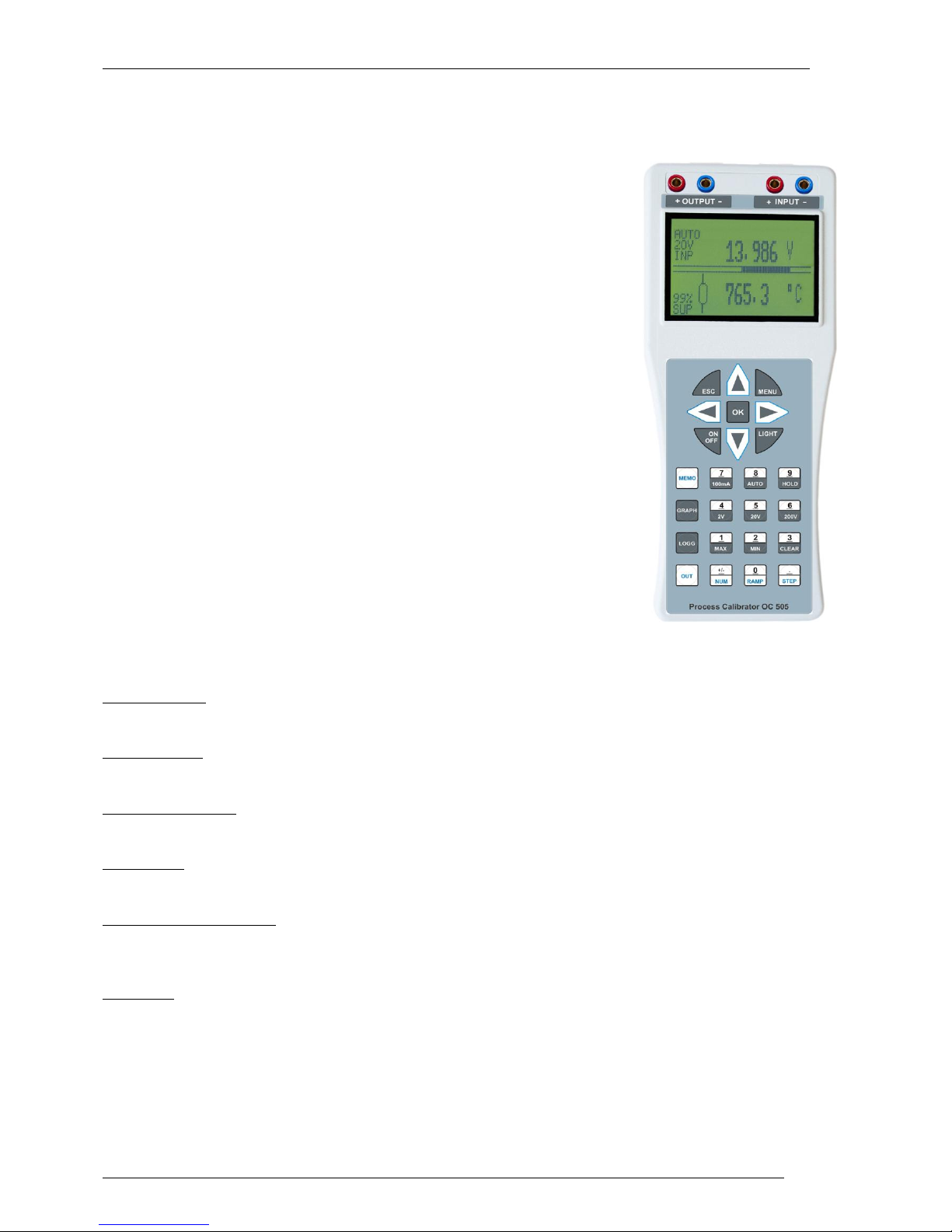

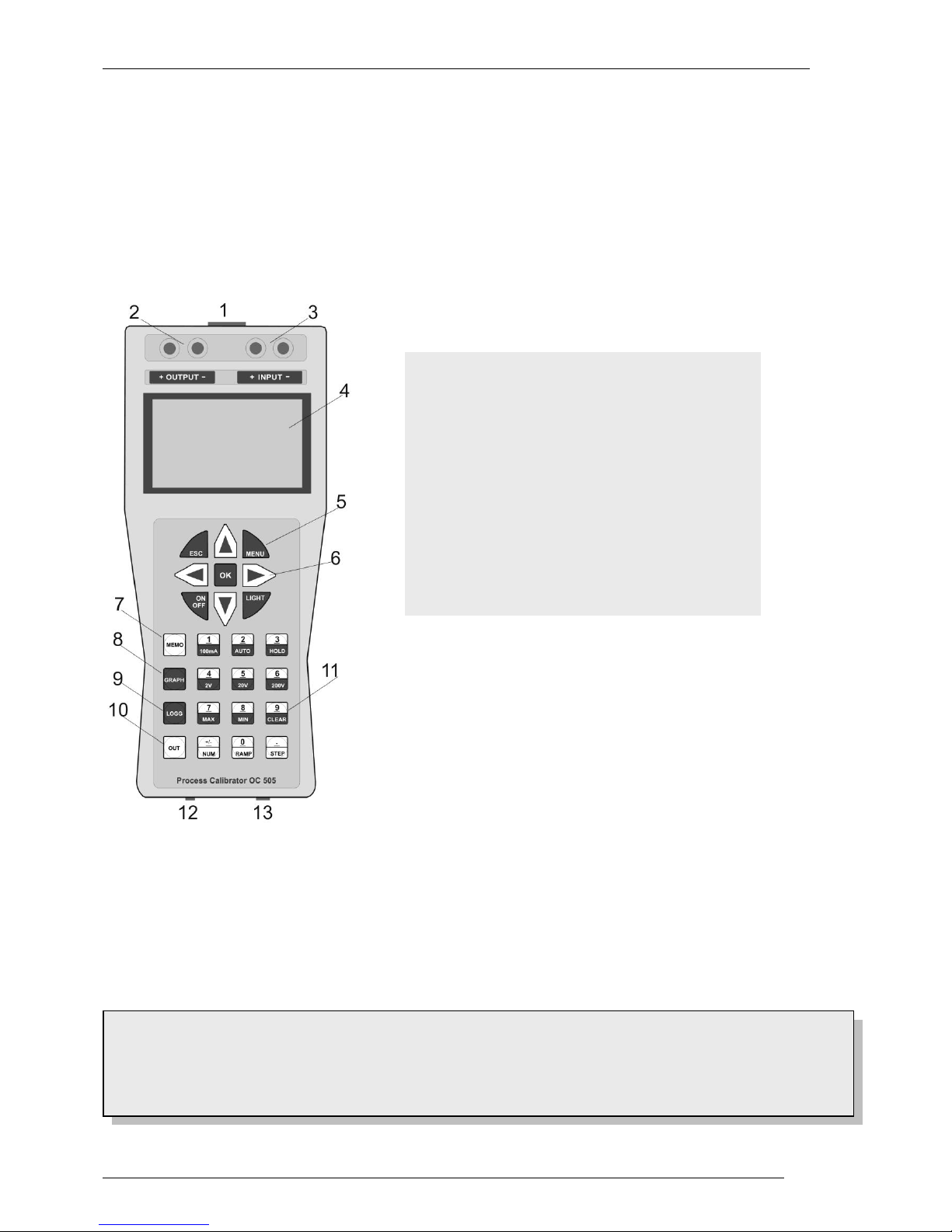

Current Calibrator 0/4 - 22mA, Source/Sink

Voltage Calibrator 0-25V

mV Outputs 0-27mV and 0-540 mV

DIN Thermocouples J, K, N, R, S, T, B, E

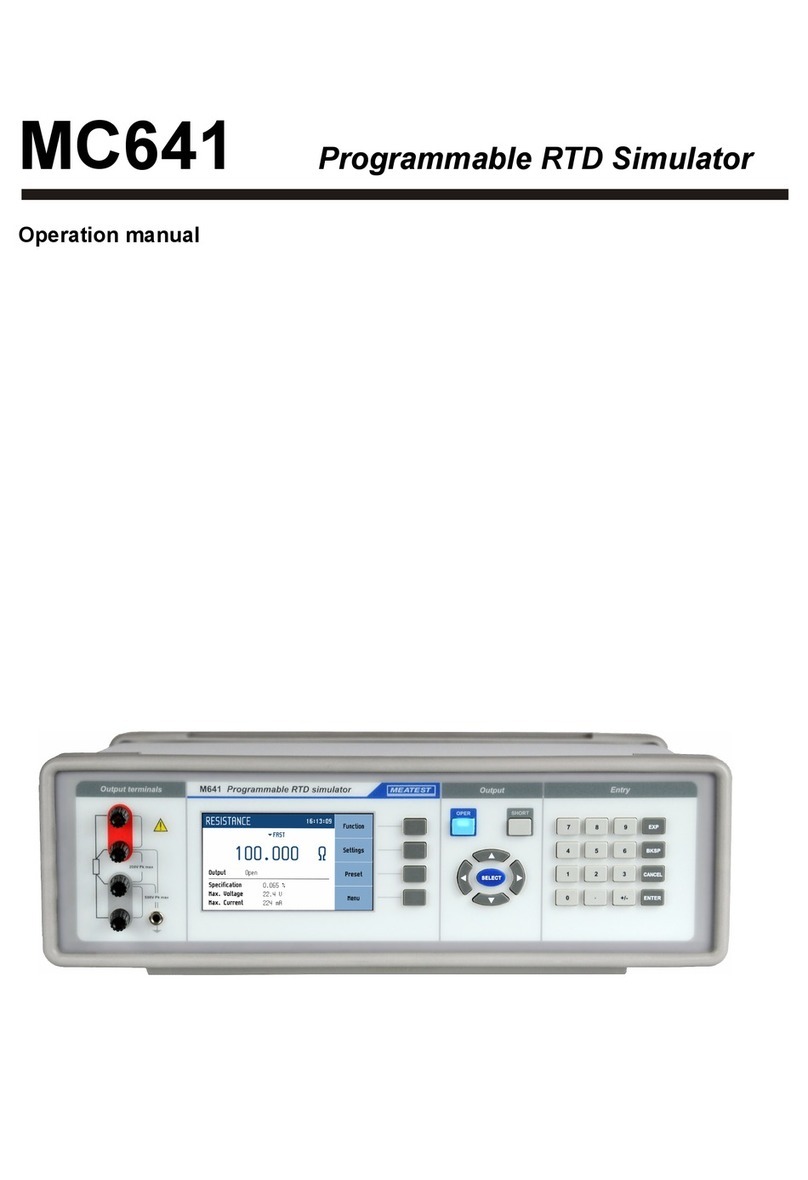

RTD Simulator Pt and Ni

Resistance Simulation to 3kOhm

Multimeter ±2V to ±200V DC and +100mA

Calibrates and Measures Simultaneously

Eight Memory slots for fast Transients

Graphics of Measurements

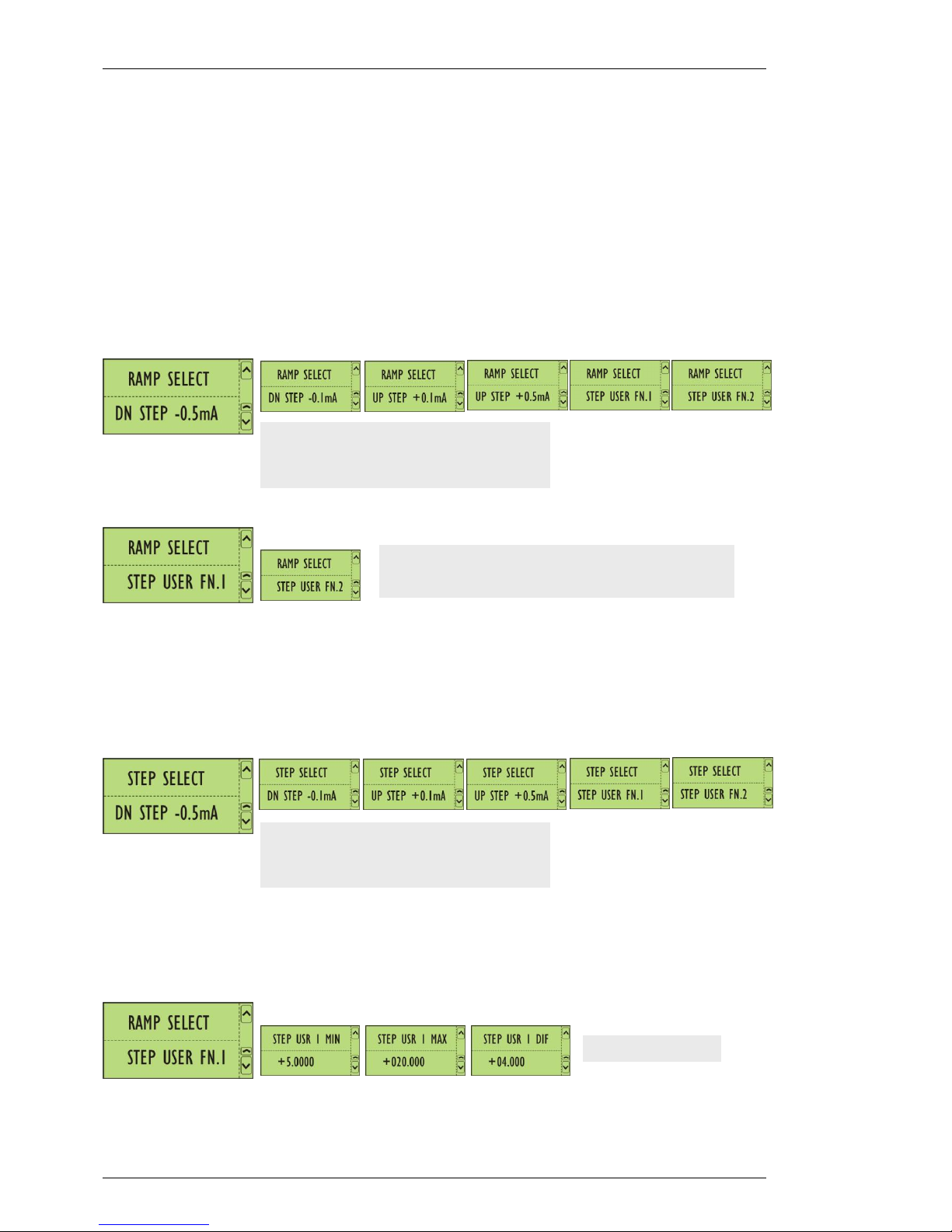

Steps, Ramps, direct value settings

Datalogger Function in M505 D model

M505 is a Calibrator-Multimeter for generation of Currents 0-22mA Sink or

Source und Voltages to 25VDC. External voltages ±2V, ±20V and ±200VDC

(firm ranges or auto ranging) and Currents to ±100mA can be measured

simultaneously and shown at the display.

Further Functions contain generation of calibration mV Signals, Thermo voltages of DIN Thermocouples and RTD

Resistors and simulation of true resistors.

mV voltages of 0-27mV or 0-540mV are mainly used for calibration of Strain Gauges, Transmitters and small

signal inputs with resolution of up to 0.001mV.

Thermocouples J, K, N, R, S, T, B, E are simulated. The temperature is entered with the keyboard and shown at the

display. The cold junction is compensated to the ambient temperature. It can also be switched-off.

RTD Thermometers can be simulated within the DIN temperature range. The temperature is entered with the

keyboard and shown at the display.

Ohm Source Resistance values up to 3kOhm are simulated. The resistance value is entered with the keyboard and

shown at the display.

Graphics and Memorising of measured signals is a standard function. The signals are continuously stored and

shown at the display as graphics. In apart of this eight memory slots for storing of fast signals -Transients- are

available. They can individually be stored and selectively recalled at the display.

Datalogger is an Option. The calibrating signals and the multimeter input are shown at the display and stored as

tables with date and time from internal RTC. They can be downloaded to the PC and edited under Windows and

Excel. A software program is available for Windows.