<10>

5 Product description

5.1 Design and function

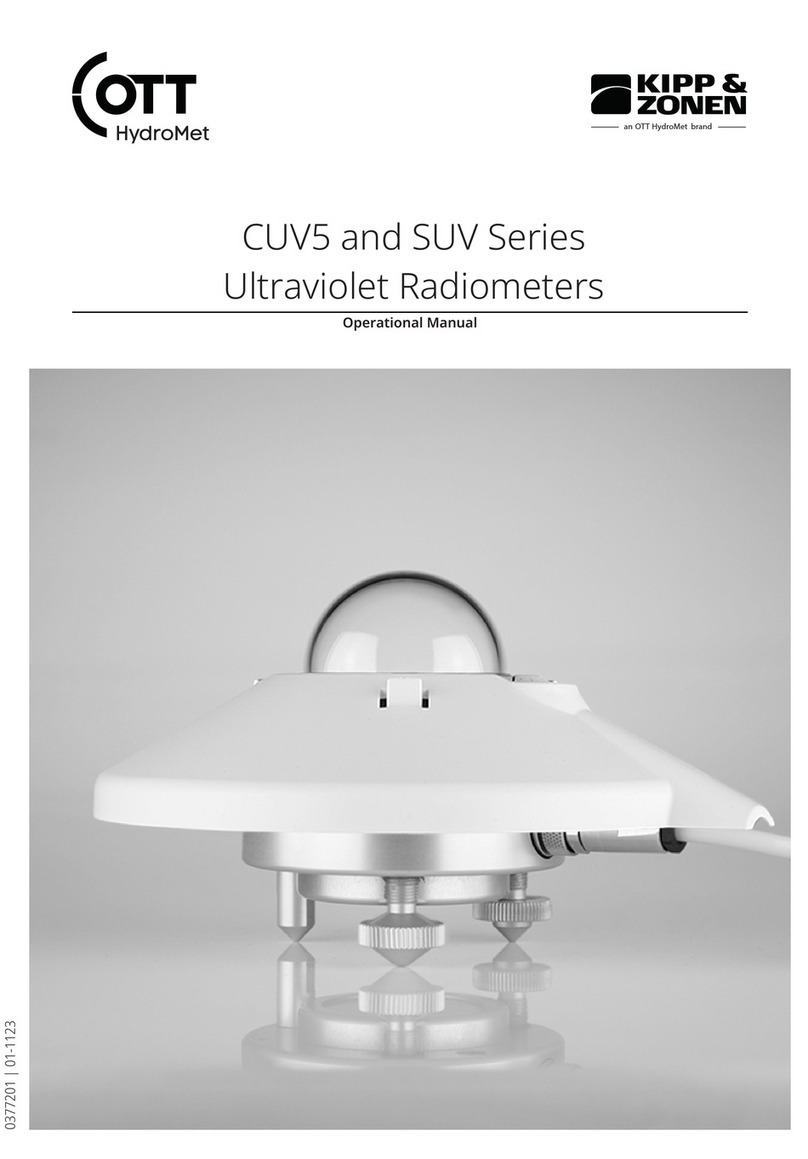

The SMP series instruments are radiometers designed for measuring short-wave irradiance on a plane surface

(radiant flux, W/m2) which results from the sum of the direct solar radiation and the diffuse sky radiation incident

from the hemisphere above the instrument.

Two pyranometers can be used as albedometers. The upper measures incoming global solar radiation and the

lower measures solar radiation reflected from the surface below, when the two signal outputs have been converted

to irradiance in W/m3, the albedo can be simply calculated.

SMP pyranometers feature a 2-wire smart interface with RS-485 Modbus® (RTU) protocol for connection to

programmable logic controllers (PLC’s), inverters, digital control equipment and data loggers. All models are

available in two versions. One has an analog voltage output of 0 to 1V, the other has an analog current output of 4

to 20mA. Digital signal processing provides faster response times and, with an integrated temperature sensor,

corrects for the temperature dependence of the detector sensitivity.

To achieve the required spectral and directional characteristics SMP pyranometers use thermopile detectors and

glass domes. The thermopile responds to the total energy absorbed by black surface coating, which is spectrally

non-selective. The thermopile warms up and the heat generated flows through a thermal resistance to a heat-sink,

the pyranometer housing.

The rise of temperature in the thermopile is easily affected by wind, rain and thermal radiation losses to the

environment and the delicate black coating must be protected. Therefore the detector is shielded by one or two

domes. These domes allow equal transmittance of the direct solar radiation component for every position of the

sun in the hemisphere above the detector. The internal desiccant prevents condensation on the inner sides of the

domes, which can cool down considerably on clear windless nights.

The pyranometers have built-in bubble levels and adjustable leveling feet. Snap-on sun shields reduce solar

heating of the housings. The waterproof connectors have gold-plated contacts.

Albedometers are constructed using two pyranometers, an albedometer mounting rod, and a glare screen to

prevent direct sunlight from below the horizon entering the lower pyranometer.

The pyranometers are delivered with a waterproof plug pre-wired to a signal cable. The cable is 10m long but

other lengths are available. The instruments can also be ordered with a plug only, for the user to fit their own

cable.