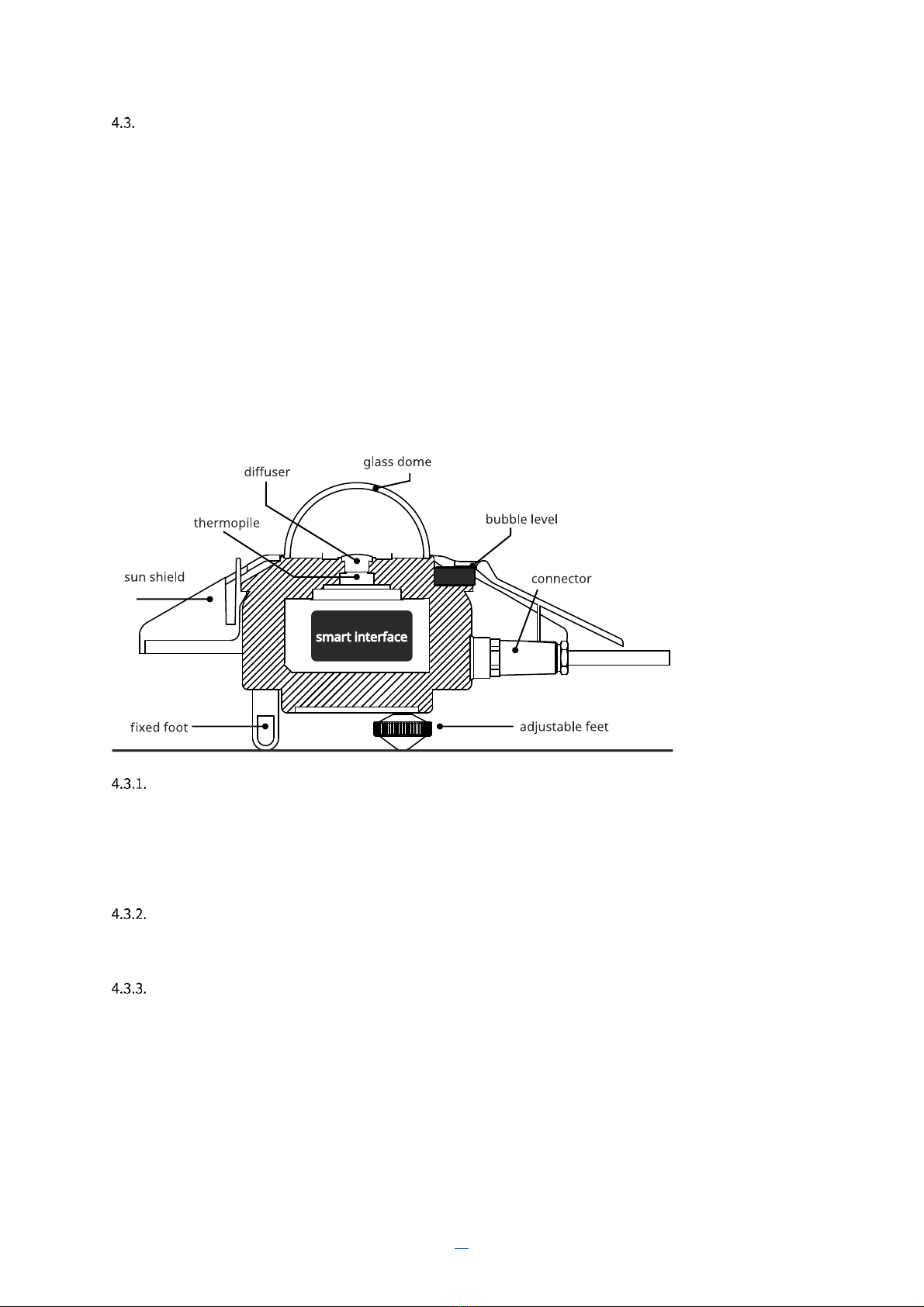

Location ..........................................................................................................................................................24

Mounting.........................................................................................................................................................24

Horizontal orientation ....................................................................................................................................25

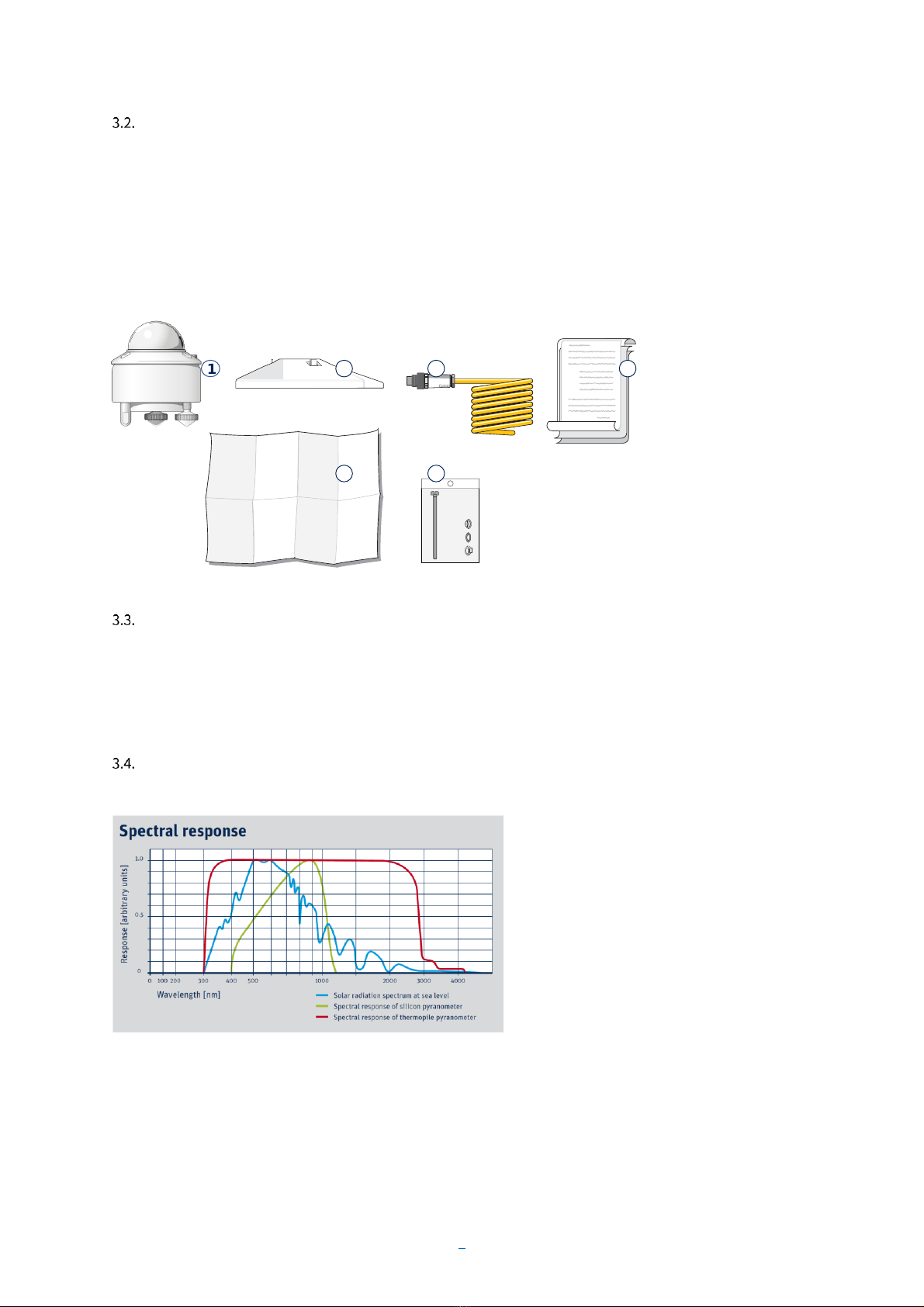

Horizontal levelling of the instrument ...........................................................................................................25

Fitting the connector and cable .....................................................................................................................26

Fitting the sun shield ......................................................................................................................................26

Installation for measurement of tilted (POA) global irradiance.........................................................................27

Tilted installation of the instrument ..............................................................................................................28

Fitting the connector and cable .....................................................................................................................29

Fitting the sun shield ......................................................................................................................................29

Installation for measurement of reflected global irradiance .............................................................................30

Installation for measurement of albedo .............................................................................................................31

Installation for measurement of diffused horizontal irradiance (DHI)...............................................................31

Electrical connections.....................................................................................................................................................32

Power connection................................................................................................................................................33

Power consumption ............................................................................................................................................33

Allowed power supply voltages with cable losses in mind............................................................................34

Connecting to a RS-485 network.........................................................................................................................35

Recommended cable types.................................................................................................................................36

SMP12 EMC and Surge protection details...........................................................................................................36

Maintenance and re-calibration .....................................................................................................................................37

Recommended weekly maintenance..................................................................................................................37

Recommended monthly maintenance ...............................................................................................................37

Recommended yearly maintenance ...................................................................................................................37

Calibration –Recommended every 2 years.........................................................................................................37

Calibration traceability to the WRR................................................................................................................37

Trouble shooting ......................................................................................................................................................38

Output signal not present or incorrect ...............................................................................................................38

Accessories ...............................................................................................................................................................39

Diffuse radiation measurement ..........................................................................................................................39

Mountings ............................................................................................................................................................39

Glare screen kit ....................................................................................................................................................39

Cables...................................................................................................................................................................39

Frequently Asked Questions ....................................................................................................................................40

Customer support.....................................................................................................................................................42

Appendices ...............................................................................................................................................................43

Modbus®...............................................................................................................................................................43

Commonly used Modbus® commands................................................................................................................43

Commonly used input registers ..........................................................................................................................44

Input register details ...........................................................................................................................................45