Page 1

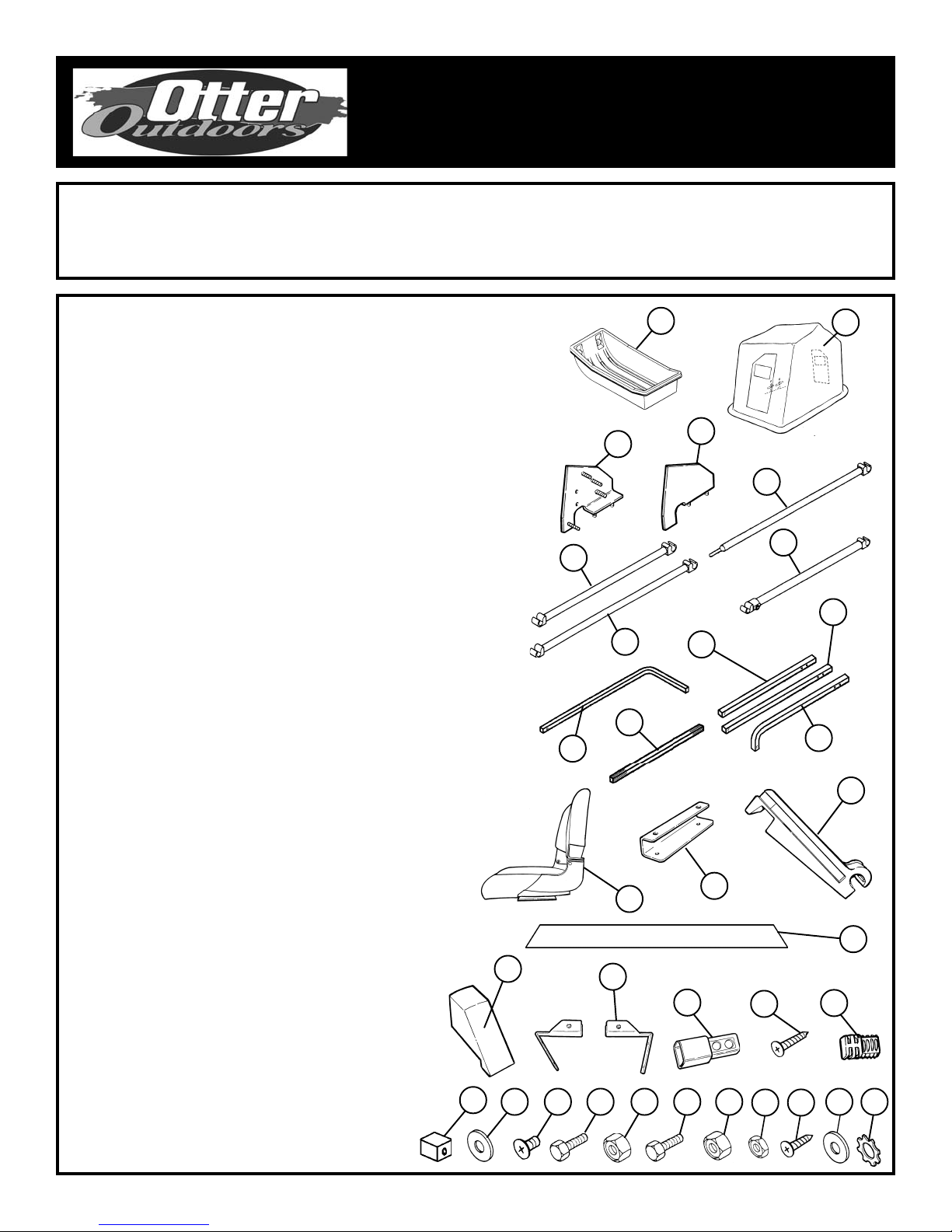

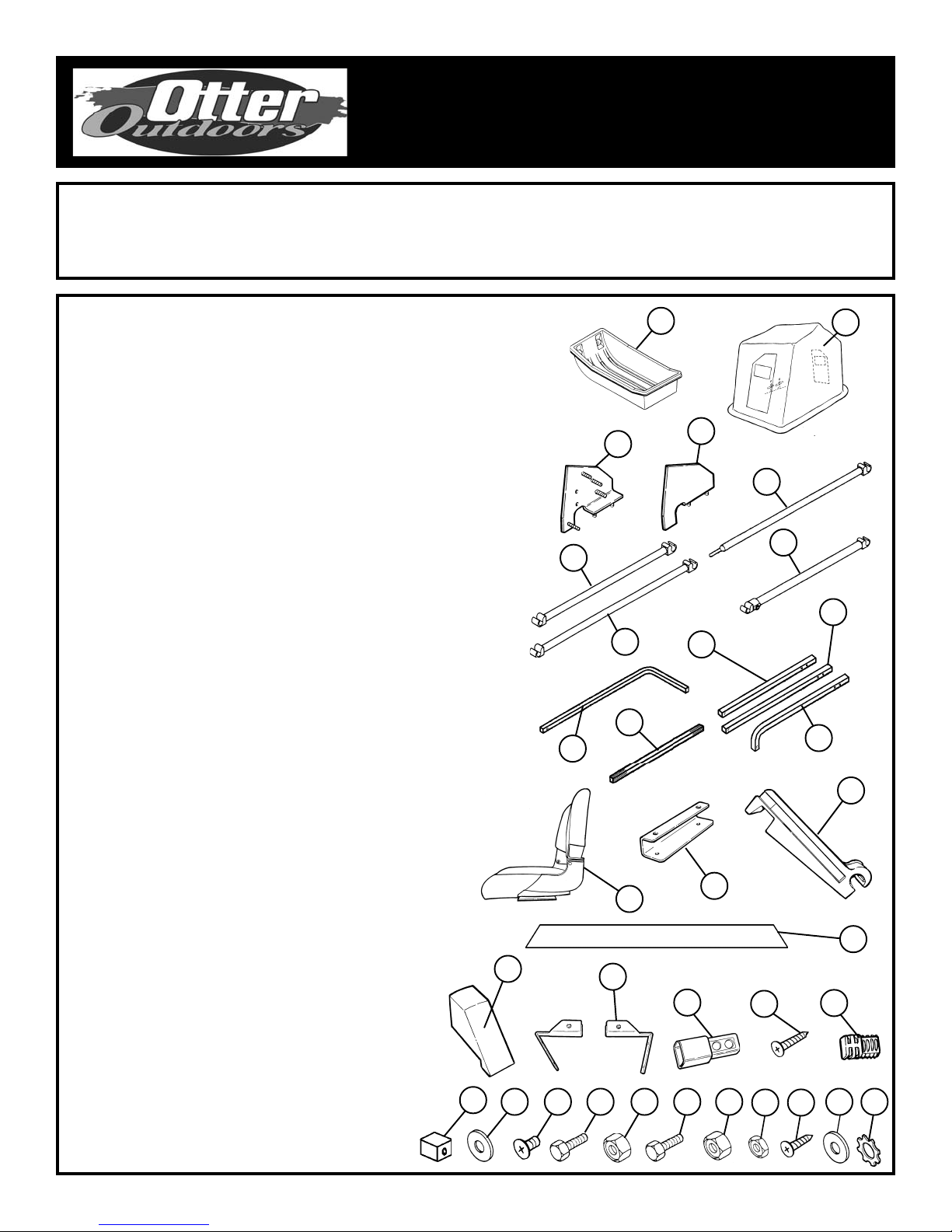

MODELNUMBERS:

Complete Pkg Pro XT 1200 Thermal Cottage 200871

PARTS LIST

Item # Qty Part # Description

1 1 200816 Sled - Black

2 1 200867 Tent-XT 1200 Thermal Cottage

3 1 80172 Frame Bracket “A”

4 1 80171 Frame Bracket “B”

5 1 80537 Back Wind Support Bar - 40 1/2”

6 1 80535 Center Wind Support Bar - 26 5/8”

7 1 80536 Center Wind Support Bar - 33”

8 1 80512 Adjustable Front Wind Support Bar

9 2 80530 Main Frame Extension Bar - 22 7/8”

10 2 80531 Main Frame Extension Bar - 24 1/2”

11 4 80532 Main Frame Extension Bar - 22 1/2”

13 8 80533 Outer Main Frame Bar - 25 1/2”

14 4 80534 Middle Main Frame Bar - 33”

15 1 200861 Seat

16 1 200369 Seat Slide

17 1 200806 Seat Base

18 1 200378 Seat Rail - 48”

19 2 200196 Seat Rail Cap

20 2 200376 Seat Rail Bracket

21 8 200384 Sleeve

22 16 400641 #8 x 3/4” Self Tapping Screw

23 8 200197 Black Plug

24 8 200195 Black End Cap

25 14 200615 5/16 Washer

26 4 200944 1/4 x 1/2 Phillips Head Screw

27 4 401017 1/4 x 3/4 Hex Bolt

28 16 400648 1/4 Nylon Hex Lock Nut

29 2 400367 5/16 x 2 Hex Bolt

30 2 200787 5/16 Nylon Hex Lock Nut

31 4 200235 1/4" Low Profile Nylon Lock Nut

32 12200942 3/8" Self Tapping Screw

33 16 200941 Plastic Protector

Otter Pro XT 1200 Cottage

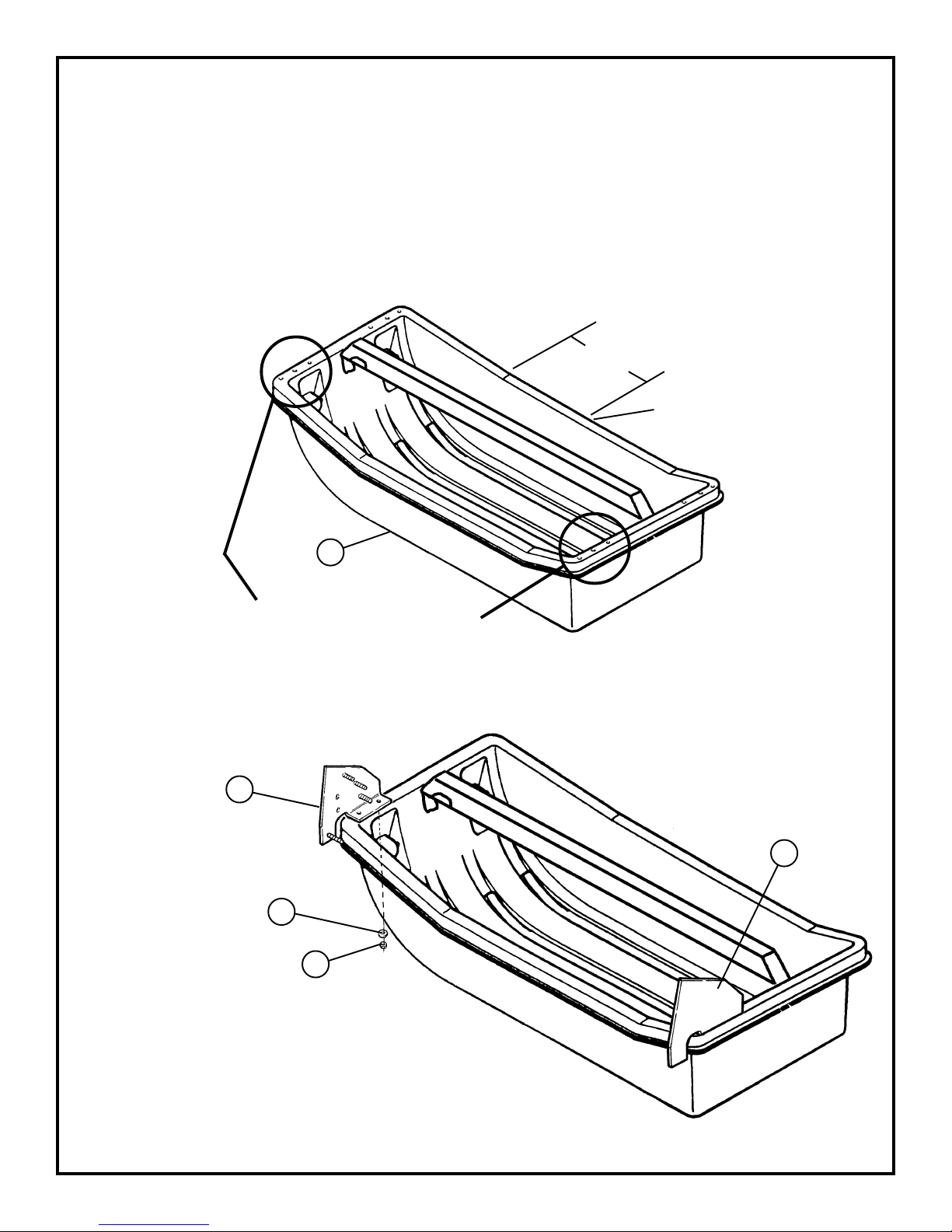

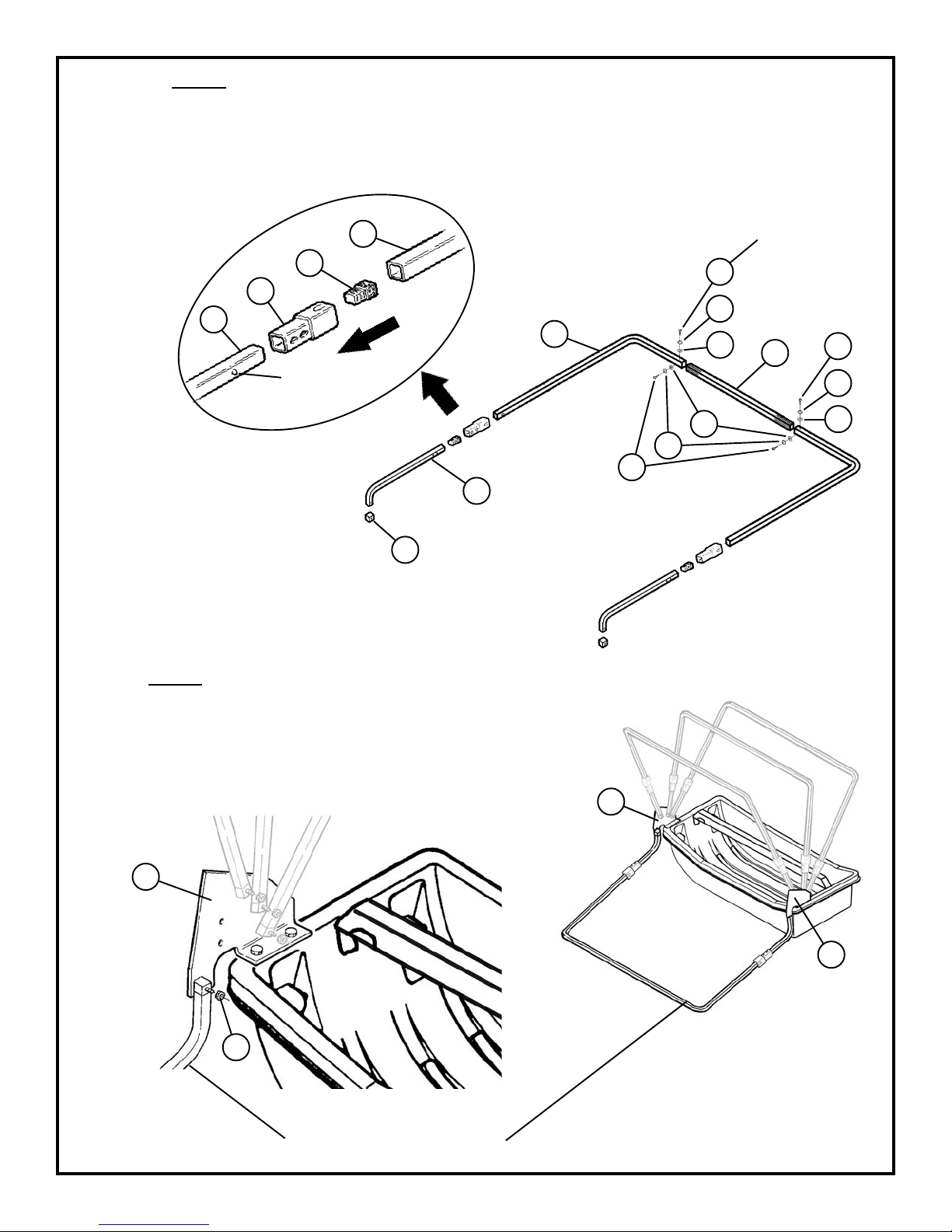

Installation and Set-Up Instructions

Otter Pro XT 1200 Cottage

FitsSmallUltra-WideOtterProandOtterIISledOnly

PartsIdentificationandCheckList

2

1

5

6

7

8

23

22

34

11

10

9

13

14

21

19 20

16

17

18

15

Front

Bottom

Back & Center

All

Instructions - 70764

24 25 282726 3029 32 33 34

31

34 16 200943 Star Washer