Items needed:

Step 2: Raft Floor Installation

1 - PAC 1300 or 1400 raft collar

1 - PAC 1300 or 1400 raft floor

3 - Long cam straps

2 - Lacing ropes

1 - Soapy water

1 - Butane torch / lighter

2 - Scrap pieces of cardboard

1. Flip the softly inflated raft collar upside-down.

2. Run three long cam straps all the way around the raft collar − one at the center, one at the

bow, and one at the stern. This will create a cradle for the floor to rest on and helps keep the

floor in position while you lace it in.

3. The bow of the raft collar has a built-in splash guard. The valve in the floor should be at the

stern of the raft.

4. Place the floor in the cam strap cradle. Be sure the drain holes in the floor are facing up

toward the bottom of the raft.

5. Heat the ends of the lacing ropes with a small torch or lighter to melt about 4”−5”. Roll the

ends of the rope between two pieces of cardboard to create a stiff “needle.” This will make

the rope ends ridged and easy to thread through the lacing loops.

6. Tie a slipknot in the center of each rope.

7. Soak the ropes (except the “needle” ends) in soapy water for about five minutes to help

reduce friction.

8. Align the floor and the collar by the center deep-cut lacing notch found on both sides of the

raft and floor pocket.

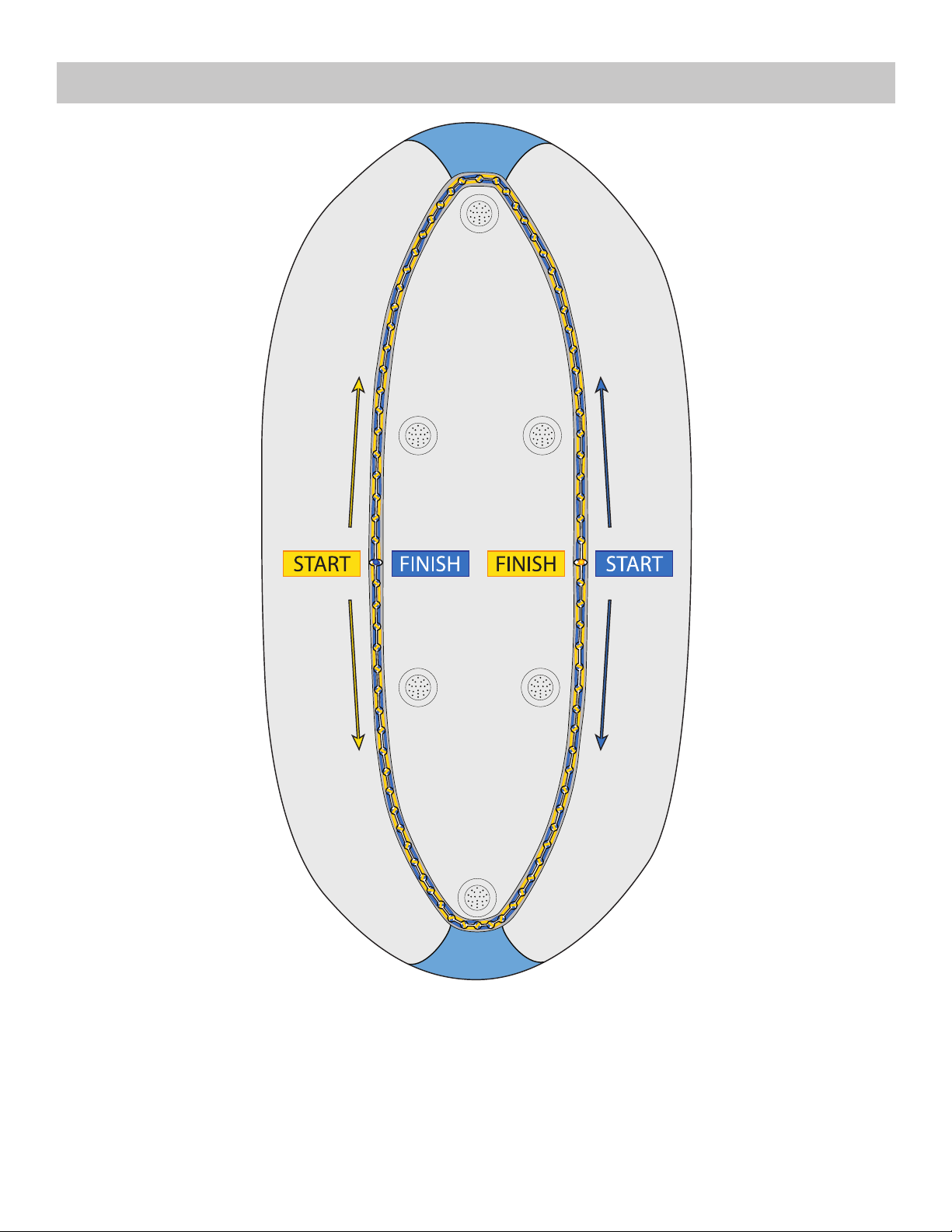

9. Start lacing rope #1 in this deep-cut center notch. The knot will prevent you from pulling all

the rope through.

10. Alternate the rope from the collar to the floor; the pattern is every other lace loop in both the

floor and the collar.

11. Every four or five loops, snug up the rope. When pulling the slack tight, PULL PARALLEL with

the lace loops and never at an angle, because the friction from the rope can damage the

loops.

12. Go half way around the raft to the other deep-cut lacing notch.

13. Go back to the start of rope #1 and untie the slipknot; continue the same pattern around the

other side of the raft. Check that no loops were skipped.

14. With the first rope done, tie a series of square knots, trim the ends, and burn the ends

together (being careful not to burn your raft). Tuck the knots under the lacing so the knots are

on the inside of the floor and not exposed to the bottom of the raft.

15. With lacing rope #2, start on the side you finished lacing rope #1 and repeat steps 9−14,

lacing through the opposite loops.

Raft floor

lacing loops

raft collar

lacing loops

Deep-cut lacing notch