CONTENTS

1. SMART COMMUNICATION UNIT......................................................................................... 4

1.1 General .................................................................................................................................... 4

2. BEFORE YOU BEGIN ............................................................................................................. 5

2.1 Inspection upon Receipt ..........................................................................................................5

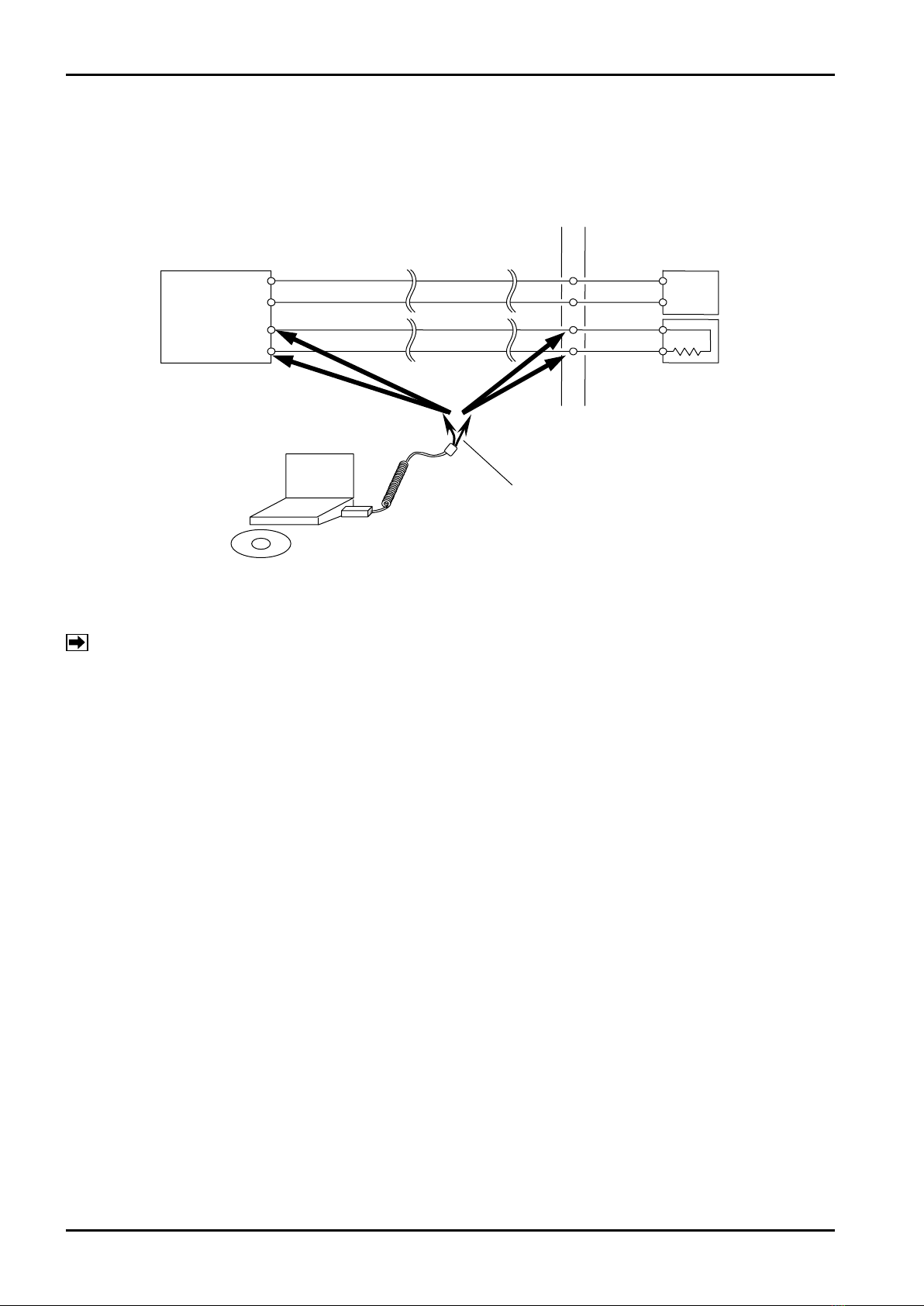

2.2 Hookup with Associated Equipment and Devices ................................................................... 6

2.3 PC Interface Adapter ............................................................................................................... 7

3. EL2310 OPERATION ............................................................................................................... 8

3.1 LinkTop Screen ........................................................................................................................ 8

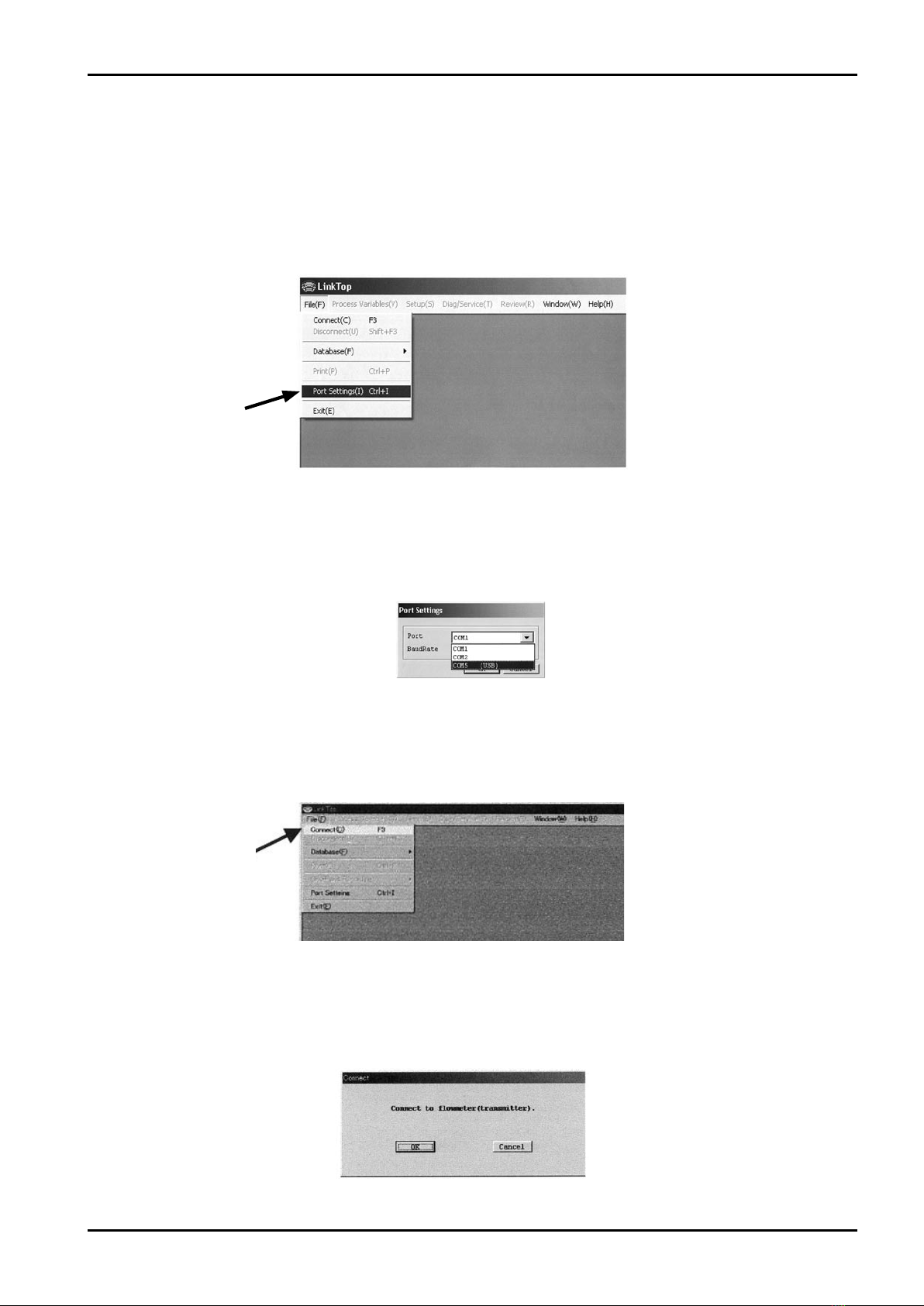

3.2 Starting the LinkTop and Connecions...................................................................................... 9

3.3 Terminating the Connection................................................................................................... 11

3.4 Terminating the LinkTop......................................................................................................... 12

3.5 Menu : Process Variables...................................................................................................... 13

3.5.1 Measure Process Variables (View Fld Dev Vars) ............................................................ 13

3.5.2 H/L Alarm (View H/L alarm)............................................................................................. 14

3.5.3 Measure Total Flow (Totalizer cntl).................................................................................. 14

3.6 Menu : Setup ......................................................................................................................... 15

3.6.1 Assign .............................................................................................................................. 15

3.6.2 Transmitter Parameters (Config fld dev var) .................................................................... 17

3.6.3 Analog output 1 ............................................................................................................... 19

3.6.4 Analog output 2 ............................................................................................................... 20

3.6.5 Pulse output..................................................................................................................... 20

3.6.6 Status input...................................................................................................................... 21

3.6.7 Status output....................................................................................................................22

3.6.8 H/L alarm......................................................................................................................... 24

3.6.9 Error Output Select (Error select) .................................................................................... 26

3.6.10 Output Level in an Error (Error indicator) ....................................................................... 28

3.6.11 Burst Mode Setup (HART output)................................................................................... 29

3.6.12 Bore size ........................................................................................................................ 30

3.6.13 Flow Calibration Factor (Flow Cal) ................................................................................. 31

3.6.14 Density Factor (Density Cal) .......................................................................................... 32

3.6.15 Zero Factor..................................................................................................................... 33

3.6.16 Transmitter Information (Device Information) ................................................................. 34

3.7 Menu : Diag/Service .............................................................................................................. 36

3.7.1 Transmitter Diagnostics (Self test)....................................................................................36

3.7.2 Diagnostics of Transmitter LCD Display (LCD test).......................................................... 38

3.7.3 Loop Test of Analog Output 1 (Fix Analog 1) ................................................................... 39

3.7.4 Loop Test of Analog Output 2 (Fix Analog 2) ................................................................... 40

3.7.5 Loop Test of Pulse Output (Fix Pulse).............................................................................. 41

3.7.6 Loop Test of Status Output (Fix Status output) ................................................................ 42

3.7.7 Loop Test of Status Input (Status input) ...........................................................................43

3.7.8 Key protect....................................................................................................................... 44

3.7.9 Zero Point Adjustment (Auto Zero)................................................................................... 45

3.7.10 Density Calibration (Density cal) .................................................................................... 47