4. INSTALLATION

Installation Location

Select an installation location where

1. Mechanical vibration, shock and corrosive gases

least exist.

2. Air is dry and temperature is near to ambient and

stable.

NOTE : Although the max. allowable temp. is

+50°C, use in place its temp. possibly

near to ambient is recommended.

3. Potential sources of inductive interference, such as

electromagnetic contactors, are located sufficiently

away.

4. A lightening arrestor is provided if incoming signals

aresubjecttopotentialinuenceoflightening.

5. A sufficient working space is secured behind the

instrument to facilitate wiring and maintenance.

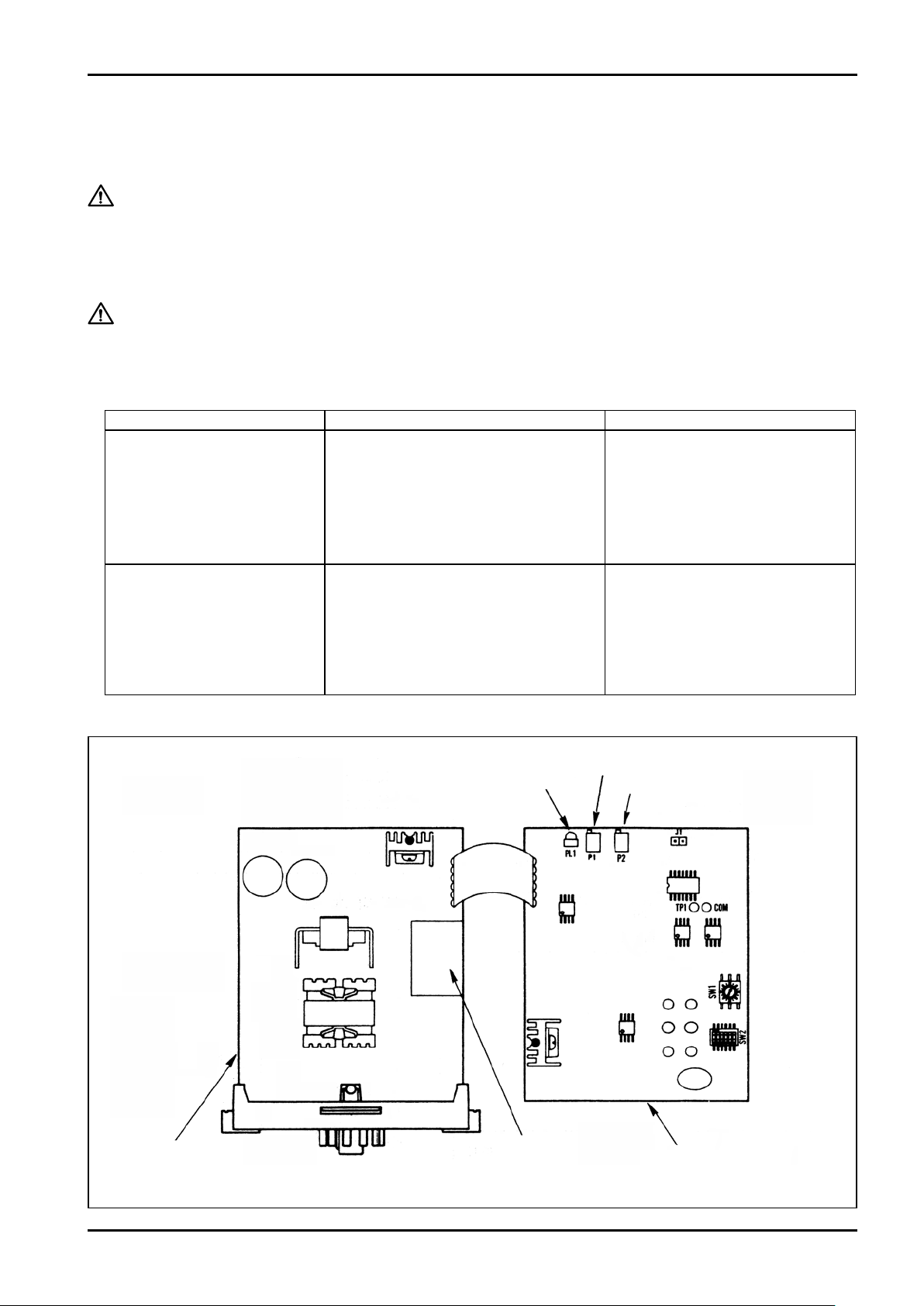

5. WIRING

1. Separate field wiring from other power lines or

powercircuitstominimizethepossibilityofinductive

interference.

2. Terminal arrangement is shown in Fig. 5.

3. M3.5 x 7 screws are used for terminals. Ensure good

electrical connections.

4. Upon completion of wiring connections, install the

converter body into the socket. Then engage the

locking levers on the socket assembly with the

converter body.

5. For signal cables, electrostatically-shielded,

polyethyleneinsulated, vinyl-sheathed control cables

(CEVS1.25to2.00mm2,2-or3-conductor),or

equivalent, must be used. With a conductor area

2mm2, the maximum transmission length is typically

one kilometer.

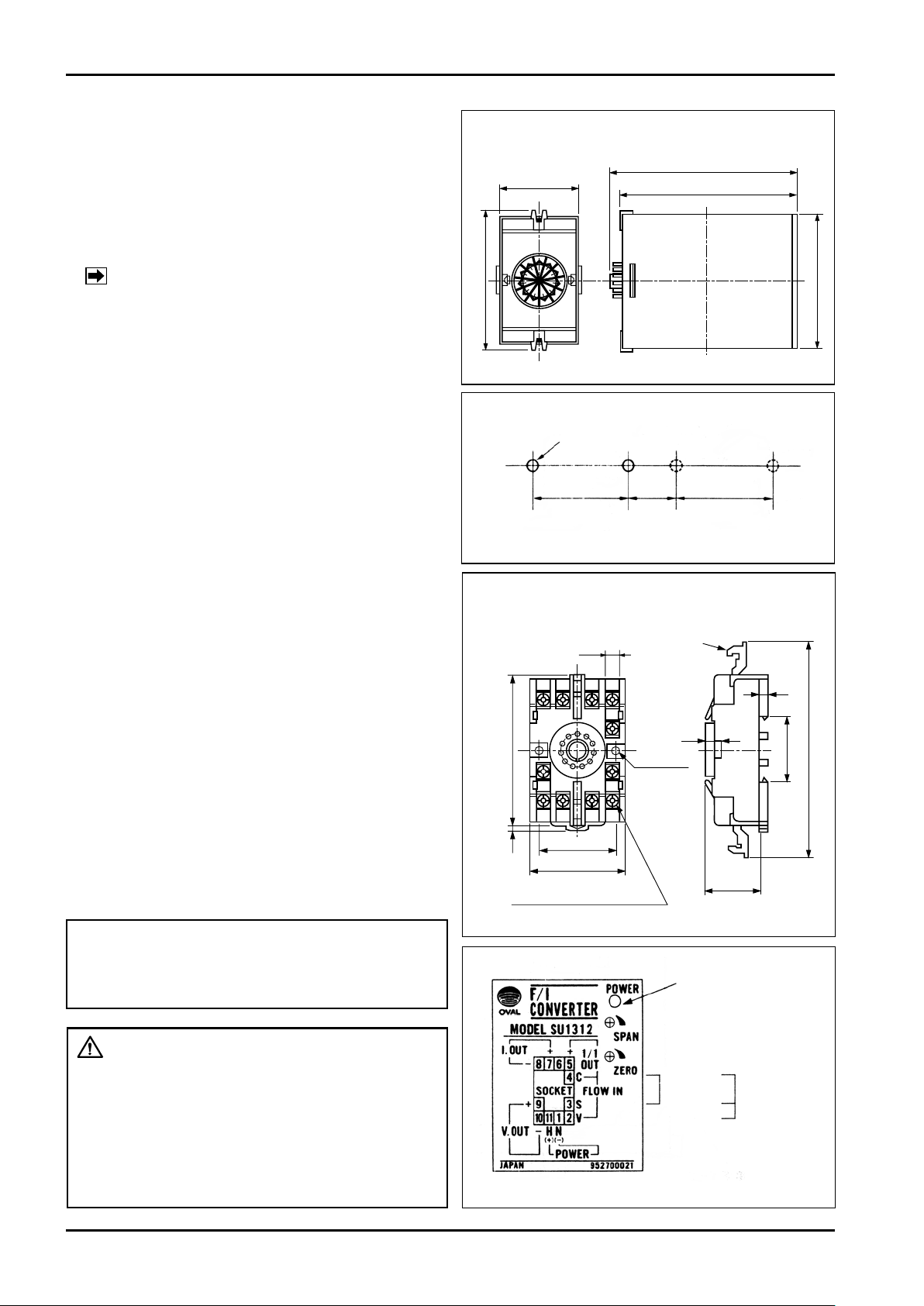

2− φ4.5

7.8

35.4

118max.

4

4

5

33.5max.

81max.

4

40±0.2

51max.

TERMINAL

SCREW : 11−M3.5×7

LOCK LEVER

211110

3

4

5678

9

• OUTLINE DIMENSIONS,

SURFACE CONNECTION SOCKET ASSEMBLY

(11PFA)

Fig. 4

• CONNECTION TERMINALS

Fig. 5

POWER INDICATIOR

2-WIRE

INPUT 3-WIRE

INPUT

COM.

SIG.

SUP.

−

+

• OUTLINE DIMENSIONS, CONVERTER BODY

Fig. 2

• MOUNTING CENTERS

Fig. 3

2−M4FITTINGHOLE

40±0.2 40±0.2min.

20

IMPORTANT :

Make electrical connections upon confirmation of

validity of flowmeter (pulse generator) and receiving

instrument combination by their model No., serial No.,

etc.

CAUTION:

Notes on Wiring

- When I. OUT is not used, make a connection

between terminals (7) and (8). If L OUT is open, V.

OUT is not generated.

- When V. OUT is not used, make a connection

between terminals (9) and (10), then a

connection of load resistance up to 600Ωis

permitted for I. OUT.