2. INTRODUCTION

2.1 General Description

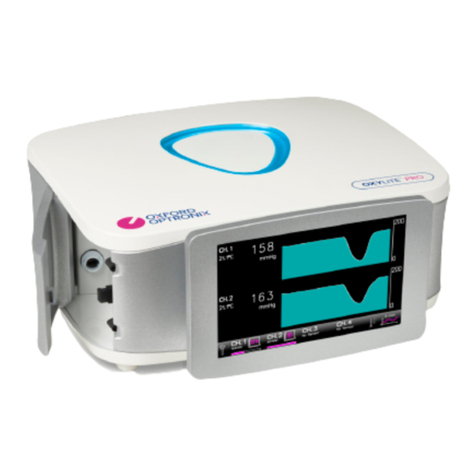

The OxyLite is an instrument capable of continuous, quantitative

measurement of the partial pressure of oxygen (pO2) and temperature in

tissues, physiological fluids, cell cultures and other in vitro applications. pO2

is also variously referred to as an ‘oxygen tension’ or as ‘dissolved oxygen’.

OxyLite is an optical device based upon the principle that the presence of

molecular dissolved oxygen in tissues or fluids can terminate (quench) light

emitted by a fluorescent compound (dye). The quenching of the fluorescent

light is proportional to the pO2in the vicinity of the dye.

The OxyLite system consists of a portable monitor and detachable, re-

usable sensors. The monitor houses a green LED light source, sensitive

photo-detector, a PC module and proprietary signal processing electronics.

All OxyLite sensors comprise a single optical fibre that conducts light from

the monitor to the sensing tip. The sensing tip contains a platinum-based

fluorescent dye held within a polymer matrix.

When the dye is illuminated/excited with light from the monitor, it fluoresces.

The fluorescent light is returned to the monitor using the same optical fibre

and the signal processor determines the fluorescent decay time. From this,

the corresponding pO2is derived. As pO2in the vicinity of the sensing tip

decreases, the extent of quenching decreases and the fluorescence decay

time increases. The quenching process is a purely collisional dynamic where

the energy from the excited fluorescent dye is transferred to the oxygen

molecule during a collision, hence, reducing the emission intensity as well

as the fluorescent lifetime of the dye. Thus, the oxygen content of the tissue

or fluid under investigation is not changed by the measurement process.

Measured pO2is displayed on the monitor’s display in units of either

millimetres of mercury (mmHg) or kilo Pascal (kPa).

Measured pO2is dependent on the local temperature at the sensing tip. In

general it is therefore important that pO2measurements are compensated

for temperature. To this end, the OxyLite monitor incorporates a calibrated

temperature measurement system. The OxyLite monitor performs automatic

temperature compensation and will generate a continuous readout of

temperature when a combined oxygen/temperature sensor is in use.

In order to display an accurate pO2value the OxyLite requires calibration

data. The calibration data is sensor-specific and for maximum ease of use

each sensor is supplied pre-calibrated. The calibration data, as well as setup

information are contained in a miniature ‘EEPROM’ electronic chip integral