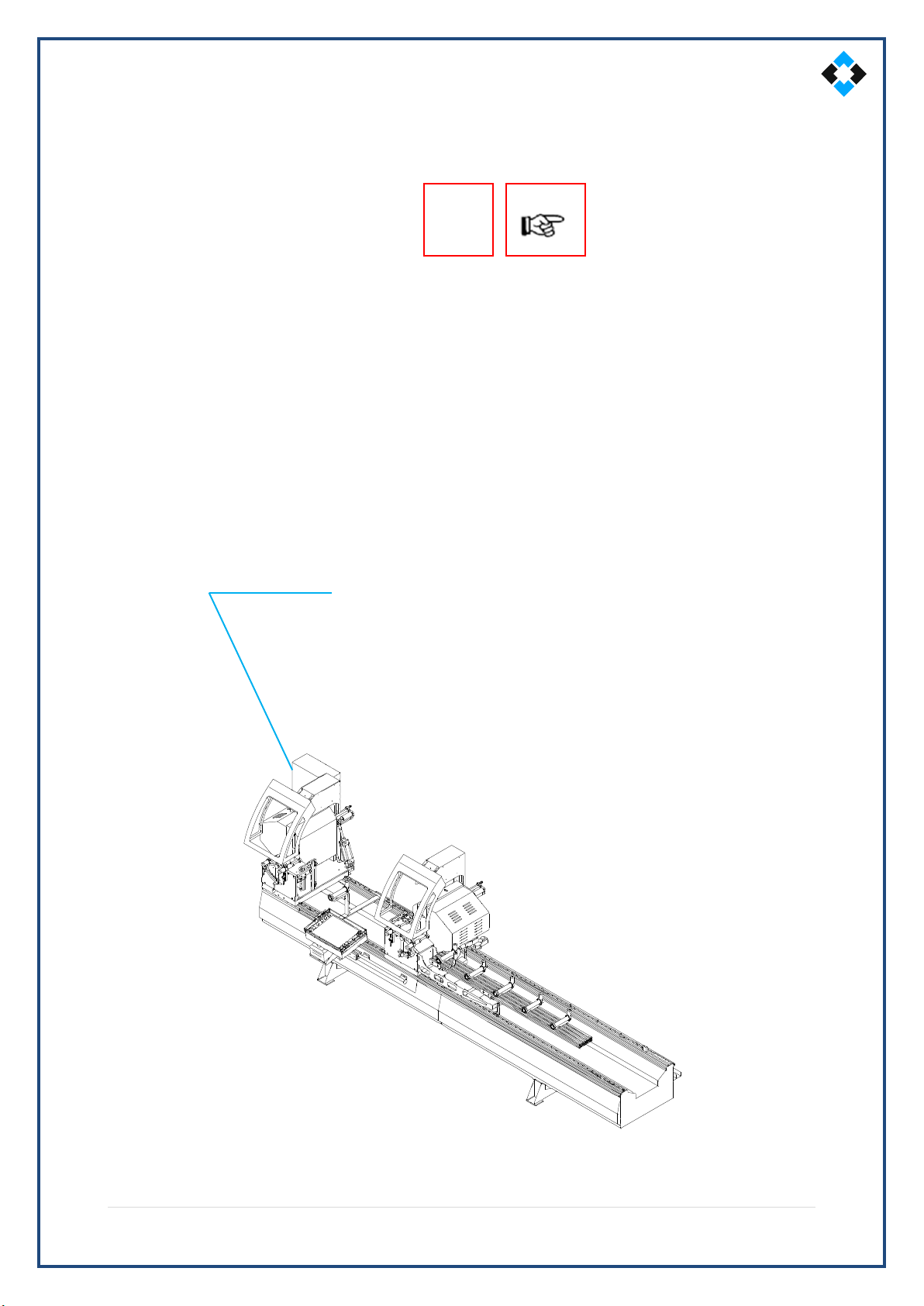

OMRM 113 User Manual

3 | P a g e

9. Machine Installation.......................................................................................................................... 31

9.1. Machine Placement.................................................................................................................... 33

9.2 Fixing on Ground ......................................................................................................................... 33

9.3 Start-up Preparation.................................................................................................................... 33

9.4 Electrical Connections ................................................................................................................. 33

9.5 Electrical Panel Scheme and Equipment Structure..................................................................... 34

9.6 Pneumatic Connections............................................................................................................... 36

10. Machine Use.................................................................................................................................... 39

10.1 Machine Start/Stop ................................................................................................................... 39

10.2 Turning on Machine .................................................................................................................. 39

10.4 Moving Equipment on Machine................................................................................................ 49

10.5 Adjusting Profile Press Pistons According to the Profile ........................................................... 51

10.5 Opening and Closing Top Press Pistons..................................................................................... 53

10.7 Tilting Cutting Units in Intermediary Angles ............................................................................. 54

10.8 Adjusting Saw Cutting Speeds ................................................................................................... 55

10.9 Saw Replacement ...................................................................................................................... 57

10.10 Cooling Water Spray Valve Adjustment .................................................................................. 58

10.11 Lubricating Machine Rails........................................................................................................ 61

10.12 Adding Lubricant to Conditioner............................................................................................. 63

10.13 Features and Use of Control Unit............................................................................................ 65

10.13.1 Manual Cutting Mode ...................................................................................................... 67

10.13.2 Cutting in Manual Cutting Mode...................................................................................... 71

10.13.3 Cutting Short Pieces in Manual Cutting Mode ................................................................. 76

10.13.4 Printing Barcode in Manual Cutting Mode....................................................................... 80

10.13.4 Cutting in Automatic Operation Mode............................................................................. 83

10.13.5 Automatic Operation Mode Screen ................................................................................. 84

10.13.6 Loading New Order in Automatic Operation Mode......................................................... 88

10.13.7 Loading Cutting List Using Load CSV Command in Automatic Operation Mode ............. 89

10.13.7 Profile Cutting in Automatic Operation Mode ................................................................. 93

10.13.8 Profile Cutting in Long Cutting Mode............................................................................... 95

10.13.9 Profile Cutting in Wedge Cutting Mode ........................................................................... 98

11. Calibrating the Machine ........................................................................................................ 101

11.1 Barcode Printer Settings and Operation Manual ............................................................... 106

11.2 Servo Alarm Codes and Meanings...................................................................................... 107