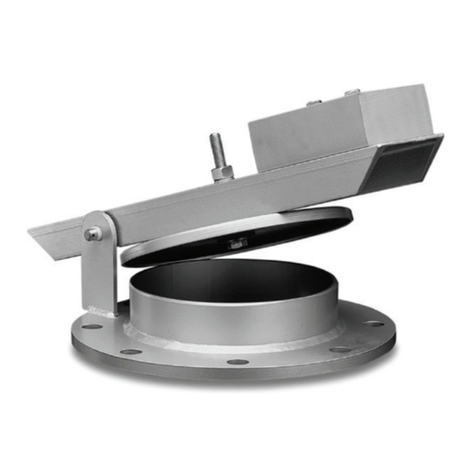

Type 114PL

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Emerson Automation Solutions

Europe, Middle East and Africa Only

Fisher.com

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D104438X012 © 2019, 2022 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 05/22.

The Emerson logo is a trademark and service mark of Emerson Electric

Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a

business of Emerson Automation Solutions.

The contents of this publication are presented for informational

purposes only, and while every eort has been made to ensure their

accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein

or their use or applicability. All sales are governed by our terms and

conditions, which are available upon request. We reserve the right to

modify or improve the designs or specications of such products at any

time without notice.

Emerson Process Management Regulator Technologies, Inc does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

General Installation

1. Install the regulator so that the flange connected

to the spring-loaded pilot’s feeding is in the

inlet side.

2. Use gaskets between pipeline and system flanges.

3. Connect the sensing line to the downstream.

Initial Verification

• PM unscrewed

• RM1 open

• RP1 open 3/4 turn

• R1, R2, R3, V1, V2 closed

Start up

1. Slowly open V1 (upstream valve).

2. Slowly open R1 and check the leakage of the pilot

nozzle PM by the absence of pressure rise on the

downstream pressure gauge.

3. Slowly open R2 and check the leakage of the

nozzle of the BPM1 by the absence of pressure

rise on the downstream pressure gauge.

4. Slowly open R3 and check the leakage of the

BPM2 by the absence of pressure rise on the

downstream pressure gauge.

5. Adjust PM to the required value Pd (read on M1 if

necessary using valve P1).

Maintenance

Disassembly

Check the absence of pressure between inlet and

outlet valves.

Recommended Frequency

Every year:

• Disassemble the manometric boxes and nozzles.

• Control O-rings, diaphragms, grease.

Parts Ordering

When corresponding with your local Sales Office

about this regulator, include the type number and all

other pertinent information stamped on the nameplate.

Specify the 11-character part number when ordering

new parts. See Type BSL85 Instruction Manual,

D103711X012, for the parts list.