page. 1/ 42

INDEX

1. INTRODUCTION ............................................................................................................................... 3

2. SAFETY APPLICATIONS..................................................................................................................... 4

2.1 DESCRIPTION OF THE SYMBOLS USED IN THE INSTRUCTION ................................................. 4

2.2 SAFETY INSTRUCTIONS............................................................................................................ 5

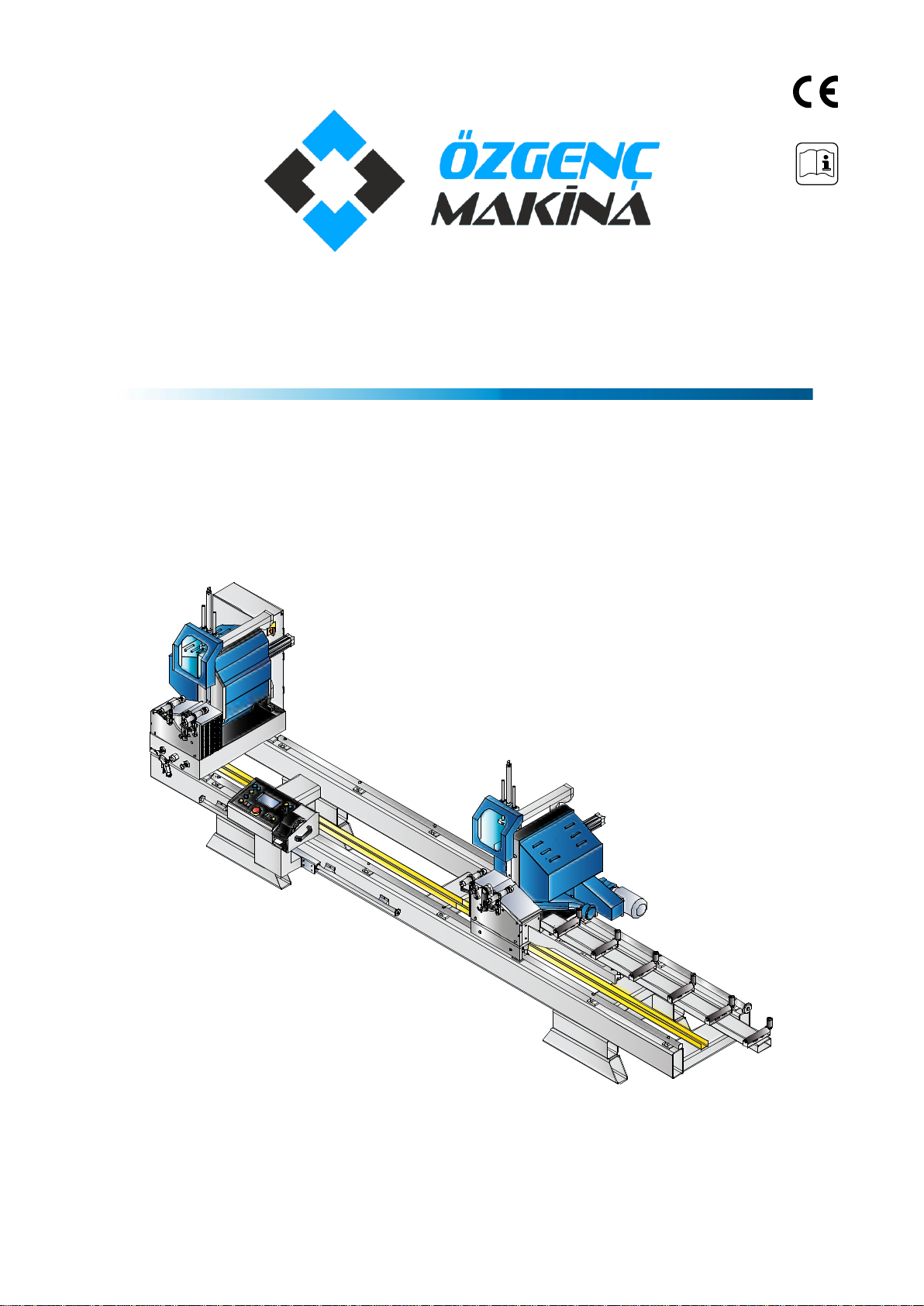

3. PRODUCT DESCRIPTION .................................................................................................................. 7

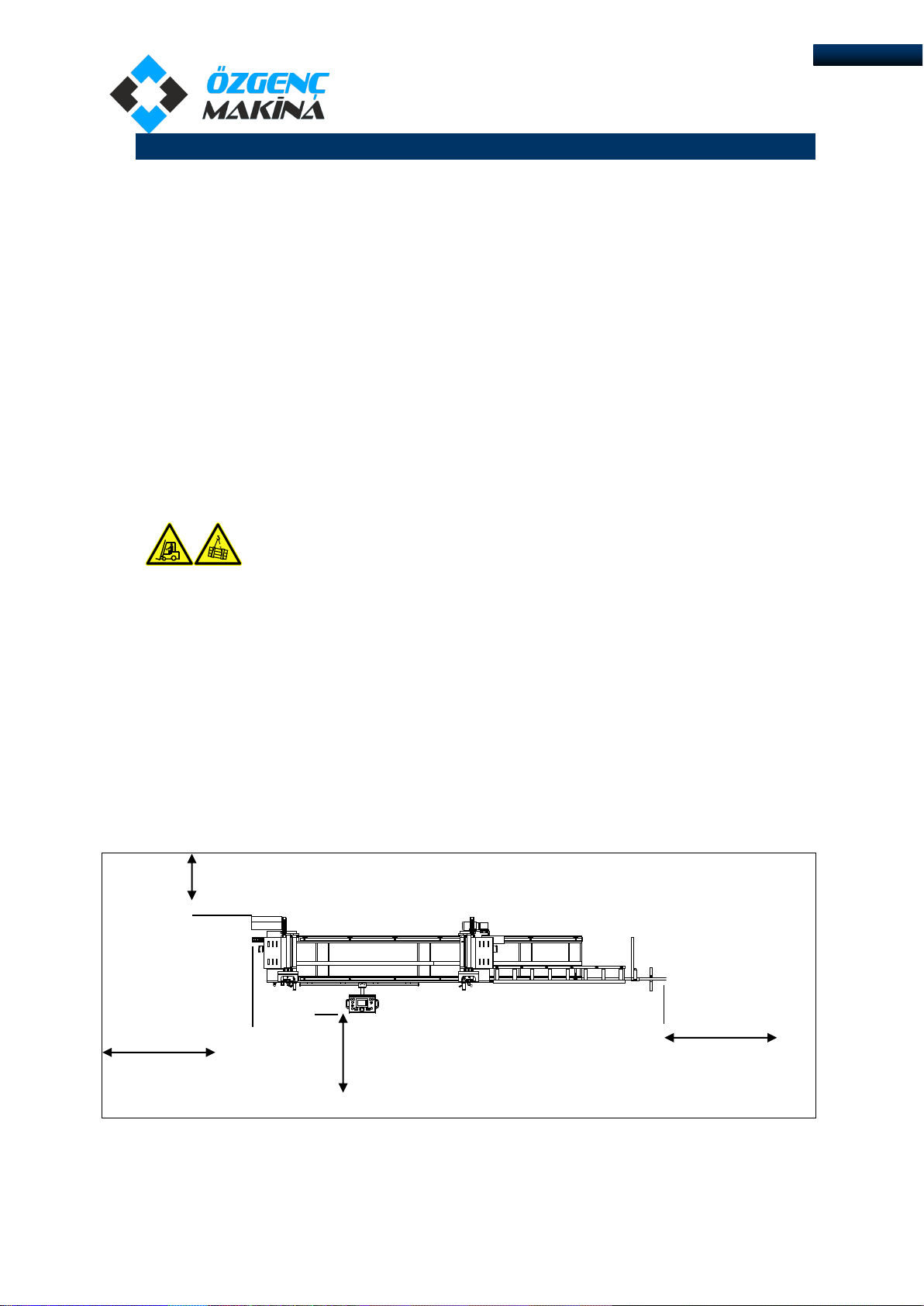

3.1 GENERAL VIEW ........................................................................................................................ 7

3.2 TECHNICAL DESCRIPTION........................................................................................................ 8

3.3 TECHNICAL FEATURES ............................................................................................................. 8

4. INSTALLATION ................................................................................................................................. 9

4.1 TRANSPORTATION INSTRUCTIONS.......................................................................................... 9

4.2 REQUIRED WORKING AREA..................................................................................................... 9

4.3 INSTALLATION SETTINGS....................................................................................................... 10

4.4 FIRST CONNECTION............................................................................................................... 11

5. PRINCIPLES OF WORK.................................................................................................................... 12

5.1 MAIN SETTINGS ..................................................................................................................... 12

5.1.1 DEGREE CALIBRATION 45° - 90° .................................................................................... 12

5.1.2 MEASURE CALIBRATION................................................................................................ 12

5.2 MACHINE CONTROL ELEMENTS ............................................................................................ 13

5.3 PLC......................................................................................................................................... 14

5.4 OPERATION OF THE MACHINE .............................................................................................. 16

5.5 MANUAL MODE..................................................................................................................... 17

5.6 AUTOMATIC MODE ............................................................................................................... 19

5.7 LONG PROFILE CUTTING over 4000 mm ............................................................................... 21

5.8 PIECES CUTTING .................................................................................................................... 22

5.9 ETH. IP (ETHERNET IP) .........................................................Hata! Yer işareti tanımlanmamış.

5.10 INTERMEDIATE DEGREE SETTING.......................................................................................... 23

6. MAINTENANCE AND THE LUBRICATION OF THE MACHINE .......................................................... 24

6.1 MAINTENANCE TABLE ........................................................................................................... 24

6.2 MAGNETIC SENSOR ............................................................................................................... 25

6.3 CHANGING THE BLADE.......................................................................................................... 25

7. PNEUMATIC ELEMENTS................................................................................................................. 26

7.1 VALVE AND CYLINDER CONTROL........................................................................................... 26

7.2 CYLINDER SPEED ADJUSTMENT............................................................................................. 27

7.3 HYDRAULIC SPEED CONTROL CYLINDER................................................................................ 28