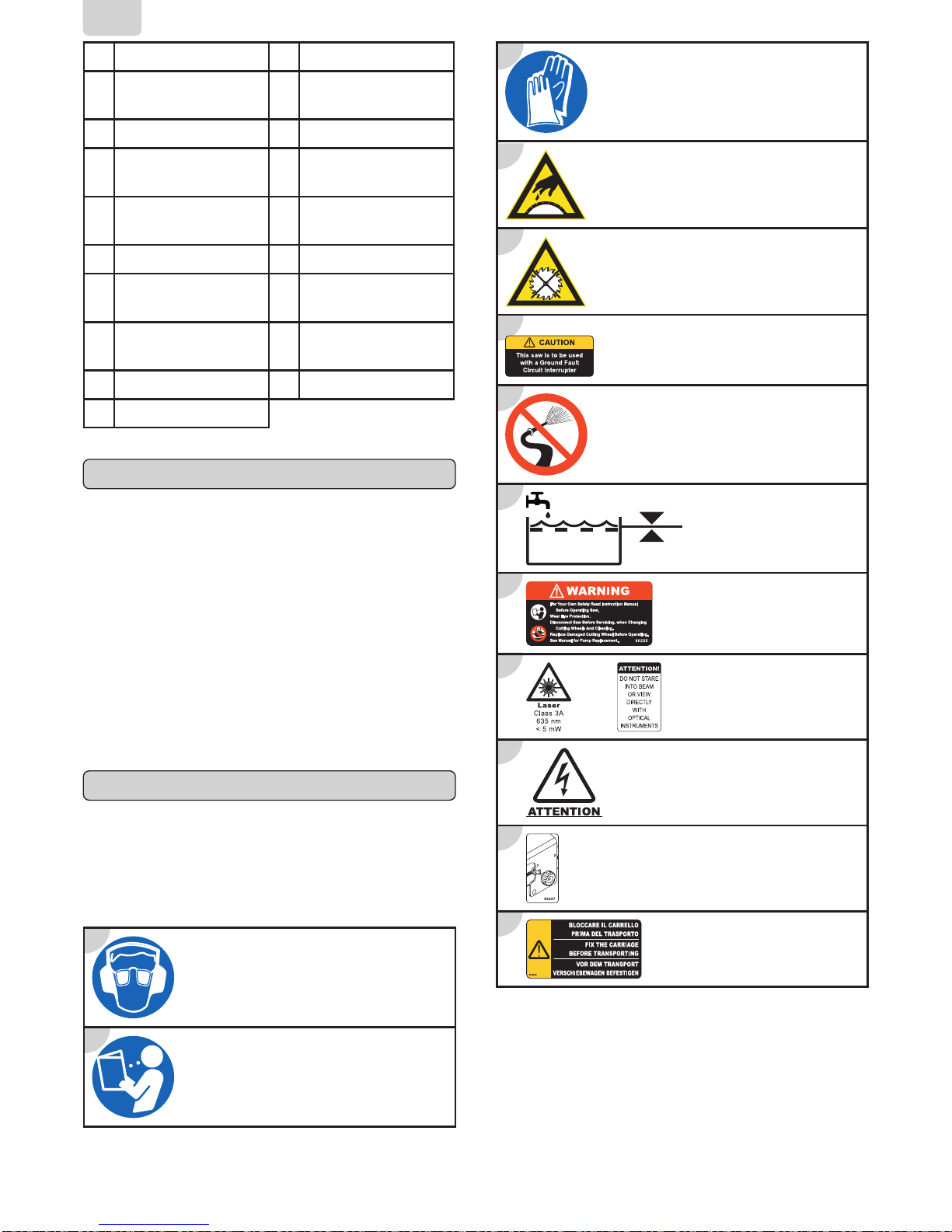

DICHIARAZIONE CE

DI CONFORMITÁ EC DECLARATION

OF CONFORMITY DECLARATION CE

DE CONFORMITE EG-

KONFORMITÄTSERKLÄRUNG

dichiara qui di seguito che la taglierina da

cantiere per ceramica, monocottura,

marmo, granito, laterizi, manufatti in

cemento e simili

herewith declares that the masonry saws

for ceramics, marble, granite, bricks,

concrete items and similar materials

déclare par la présente que la scie sur table de

chantier pour matériaux céramiques, marbre,

granit, briques, ouvrages en béton et

similaires

erklärt hiermit, daß die Schneidemaschine für

die Baustelle, das sich für Schneidarbeiten

auf Keramik, Marmor, Granit, Ziegel,

Zementerzeugnissen, usw. eignet

Data di costruzione N° di Serie: Date of manufacture Series N. Date de fabrication N° de série Produktionsdatum Seriennummer

risulta in conformità a quanto previsto dalle

seguenti direttive comunitarie:

DIRETTIVA 2006/42/CE, DIRETTIVA

2006/95/CE, DIRETTIVA 2004/108/CE,

DIRETTIVA 2002/96/CE.

e che sono state applicate tutte le norme

e/o specifiche tecniche indicate.

is in conformity with the provisions of the

following EC directives:

2006/42/EC, 2006/95/EC, 2004/108/EC,

2002/96/EC

and that the standards and/or technical

specifications referenced have been

applied.

est conforme aux dispositions des

directives CE suivantes:

DIRECTIVE 2006/42/CE, DIRECTIVE

2006/95/CE, DIRECTIVE 2004/108/CE,

DIRECTIVE 2002/96/CE.

et que les normes et/ou spécifications

techniques ont été appliquées.

in Übereinstimmung ist mit den Bestimmungen

der nachstehenden EG-Richtlinien:

EG RICHTLINIE 2006/42, EG RICHTLINIE

2006/95, EG RICHTLINIE 2004/108, EG

RICHTLINIE 2002/96.

und daß die Normen und/oder technischen

Spezifikationen, zurAnwendung gelangt sind.

BP35060000, BP35080000, BP35100000, BP35120000, BP35150000

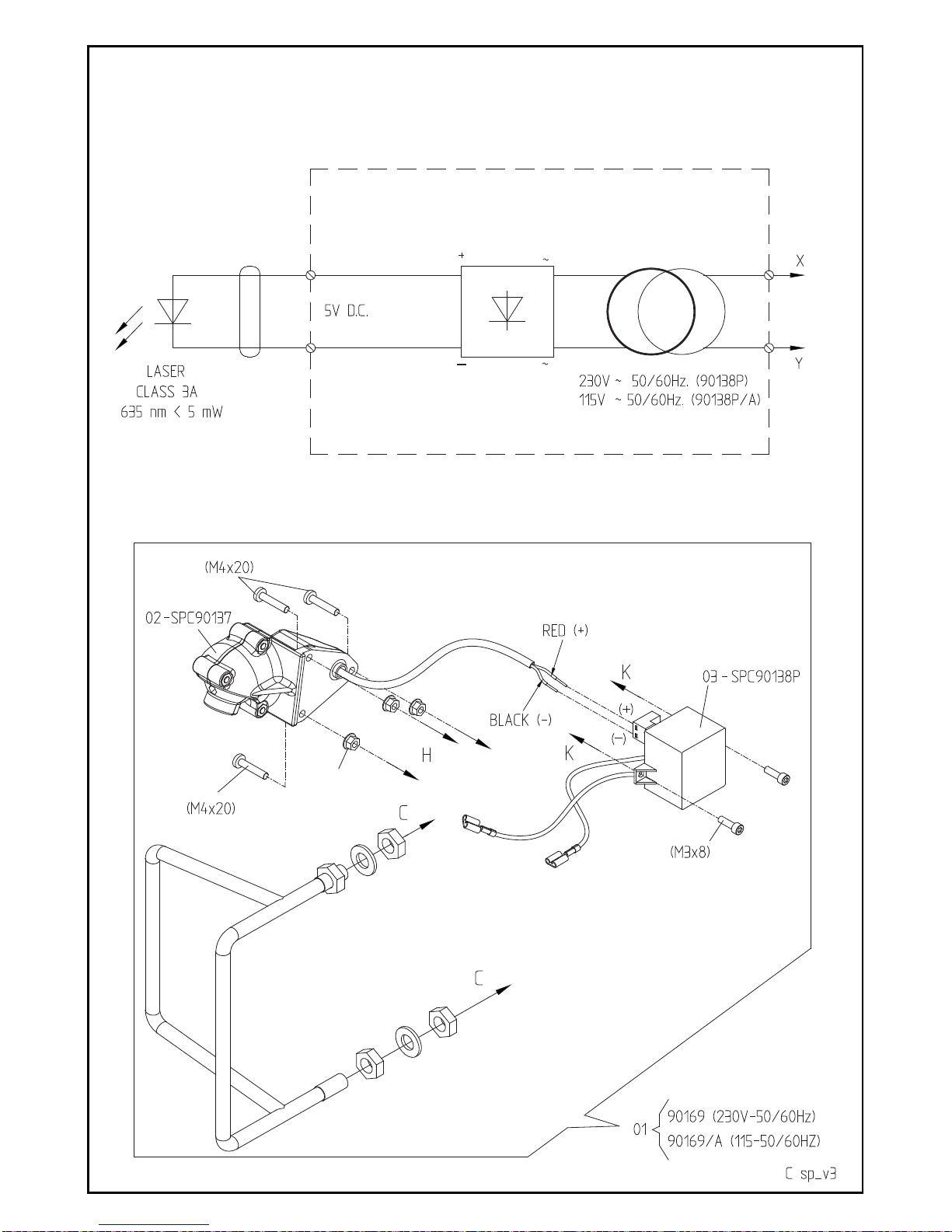

230 V ~ 50 Hz 2200 W

S6 40% 2800 min-1

MOTOR CLASS F

EN ISO 12100-1, EN ISO 12100-2, EN ISO 14121-1, EN 61029-1, EN 60335-1, EN 60335-2-41, EN 12418, IEC 1029-2-7,

EN 55014-1, EN 55014-2, EN 610006-1, EN 610006-3, EN 610006-4-2, EN 610006-4-4, EN 610006-4-5, EN 610006-4-6

IGB FD

The undersigned, representing the

following manufacturer

Il sottoscritto, rappresentante il seguente

costruttore Le soussigné, représentant le constructeur

ci-aprésDer Unterzeichner, der den nachstehenden

Hersteller vertritt

Direttore Generale

Kees van Beek General Manager

Kees van Beek Le Directeur Général

Kees van Beek Der Generaldirektor

Kees van Beek

Carat Nederland BV.

Nikkelstraat 18, - 4823 AB Breda

The Netherlands