Keepthecordclearoftheaccessorybeingused,donotwrapthecordaroundyourarmorwrist.

Hold the tool by the insulated gripping surfaces when performing an operation where the accessory

may contact hidden wiring or its own cord.

Wear ear protectors with impact wrenches. Exposure to noise can cause hearing loss.

Bits, sockets and tools get hot during operation, it’s recommended to wear gloves when handling

them.

Do not overreach while operating the tool. Maintain a balanced working stance at all times.

Do not use this tool for prolonged periods of time. Take regular breaks. Use gloves to provide extra

cushioning in order to avoid any injury from the vibrations of the tool.

Always use safety glasses. Everyday glasses are not Safety Glasses.

Warning! Some dust created by power sanding, sawing, grinding, drilling and other

construction activities contain chemicals known to cause cancer, birth defects or other

reproductive harm.

Some examples of these chemicals are:

•Leadfromlead-basedpaints

•Crystallinesilicafrombricksandcementandothermasonryproducts

•Arsenicandchromiumfromchemicallytreatedtimber

Your risk from exposure to these chemicals varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area and work with approved

safetyequipment,suchasdustmasksthatarespeciallydesignedtolteroutmicroscopicparticles.

IMPACT WRENCH SAFETY WARNINGS

WARNING! Read all safety warnings and all instructions. Failure to follow the

warningsandinstructionsmayresultinelectricshock,reand/orseriousinjury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings

referstoyourmains-operated(corded)powertoolorbattery-operated(cordless)powertool.

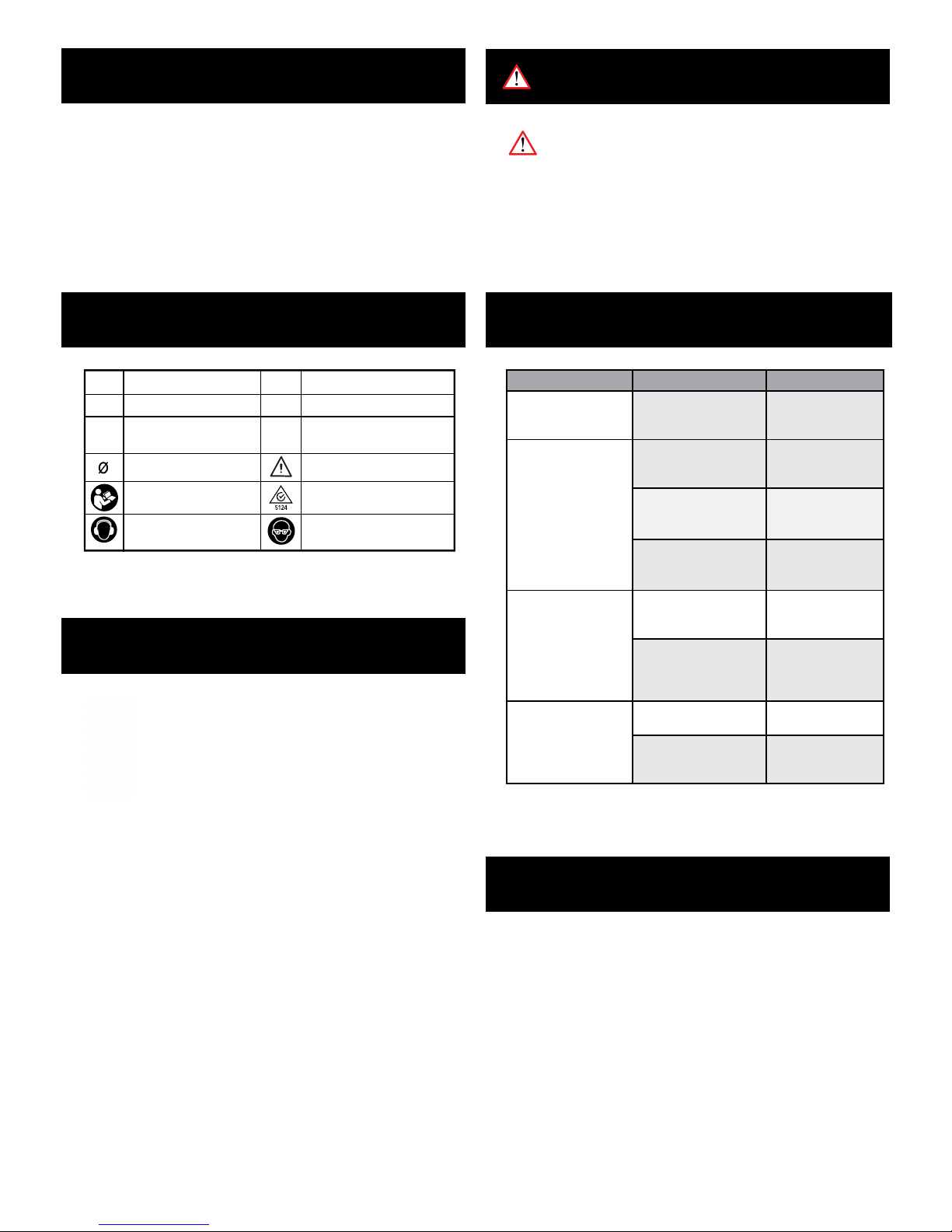

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c. Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools.Unmodiedplugsandmatching

outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs, alcohol

or medication. A moment of inattention while operating power tools may result in serious

personal injury.

b. Use personal protective equipment. Always wear eye protection.Protectiveequipment

suchasdustmask,non-skidsafetyshoes,hardhat,orhearingprotectionusedforappropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position before connecting

to power source and/or battery pack, picking up or carrying the tool. Carrying power

toolswithyourngerontheswitchorenergisingpowertoolsthathavetheswitchoninvites

accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving

parts.

g. If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used.Useofdustcollectioncanreducedust-

related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

b. Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

5. Service

a. Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

GENERAL POWER TOOL SAFETY WARNINGS - PERSONAL SAFETY