explains the following conformity according to EU directives and norms for

the following product

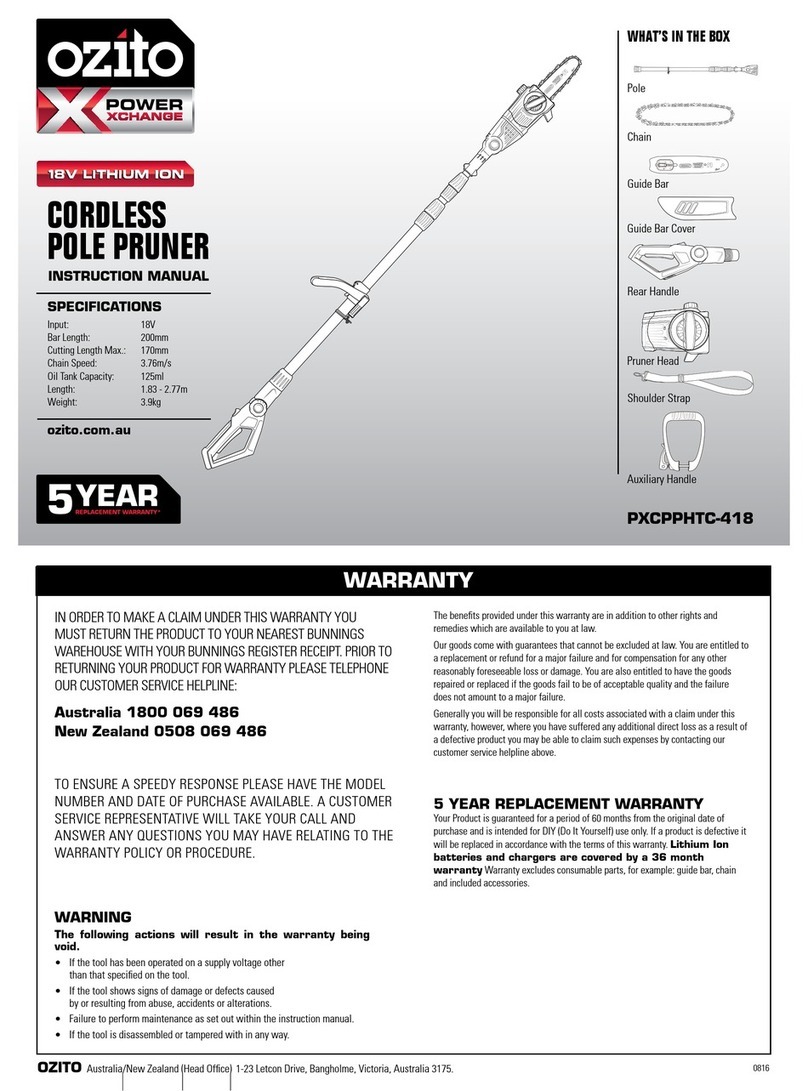

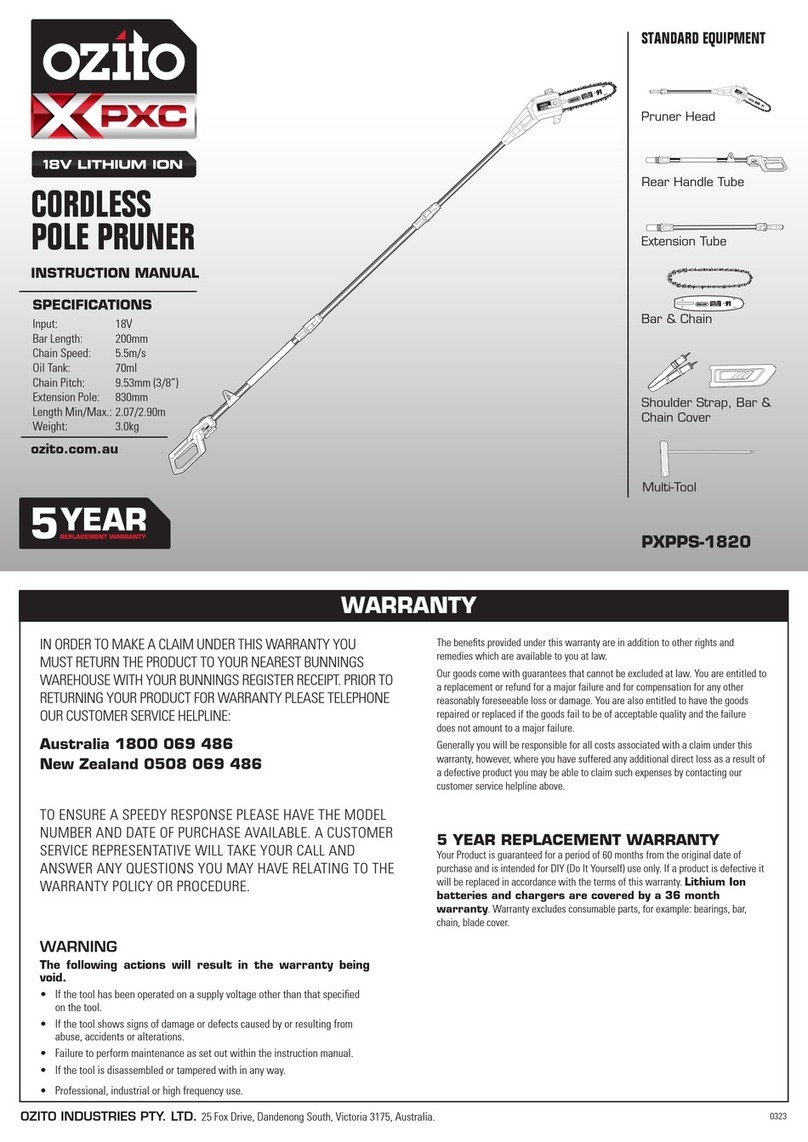

Cordless Pole Pruner PXCPPS-018U (Ozito)

2014/29/EU

2005/32/EC_2009/125/EC

2014/35/EU

2006/28/EC

X2014/30/EU

2014/32/EU

2014/53/EC

2014/68/EU

90/396/EC_2009/142/EC

89/686/EC_96/58/EC

X2011/65/EU

X2006/42/EC

XAnnex IV

Notied Body: TÜV Rheinland LGA Products Gmbh - Tillystraße 2 - 90431 Nürnberg

Germany

Notied Body No.: 0197

Reg. No.: BM 50365795 0001

X2000/14/EC_2005/88/EC (Outdoor)

XAnnex V

Annex VI

Noise: measured LWA = 98,23 dB (A); guaranteed LWA = 102 dB (A)

P = KW; L/Ø = cm

Notied Body: TÜV Rheinland

2012/46/EU (Schadsto - Abgas)

Emission No.:

Standard references: EN 60745-1:2009; EN ISO 12100:2010; EN ISO 11680-1:2011;

EN 55014-1:2006+A1+A2; EN 55014-2:2015

Landau/Isar, den 28.09.2016

First CE: 16 Archive-File/Record: NAPR015300

Art.-No.: 43.108.16 I.-No.: 11016 Documents registrar: R. Gehard

Subject to change without notice Wiesenweg 22, D-94405 Landau/Isar

Danger!

Sound and vibration

Sound and vibration values were measured in accordance with ISO 22868.

LpA sound pressure level ................... 81.05 dB(A)

KpA uncertainty .............................................3 dB

LWA sound power level measured .. 98.23 dB(A)

KWA uncertainty .............................................3 dB

LWA sound power level guaranteed ... 102 dB(A)

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Total vibration values (vector sum of three directions) determined in accordance with ISO 22867.

Handle under load

Vibration emission value ah = 0.947 m/s2

K uncertainty = 1.5 m/s2

The speci ed vibration value was established in accordance with a standardized testing method. It may

change according to how the electric equipment is used and may exceed the speci ed value in exceptional

circumstances.

The speci ed vibration value can be used to compare the equipment with other electric power tools.

The specied vibration value can be used for initial assessment of a harmful effect.

Keep the noise emissions and vibrations to a minimum.

• Only use appliances which are in perfect working order.

• Service and clean the appliance regularly.

• Adapt your working style to suit the appliance.

• Do not overload the appliance.

• Have the appliance serviced whenever necessary.

• Switch the appliance off when it is not in use.

• Wear protective gloves.

We pay a great deal of attention to the design of every battery pack to ensure that

we supply you with batteries which feature maximum power density, durability and

safety. The battery cells have a wide range of safety devices. Each individual cell is

initially formatted and its electrical characteristic curves are recorded. These data

are then used exclusively to be able to assemble the best possible battery packs.

Despite all the safety precautions, caution must always be exercised when

handling batteries. The following points must be obeyed at all times to ensure

safe use.

Safe use can only be guaranteed if undamaged cells are used. Incorrect

handling can cause cell damage.

Important: Analyses con rm that incorrect use and poor care are the main causes

of the damage caused by high performance batteries.

For EU countries only

Never place any electric power tools in your household refuse.

To comply with European Directive 2012/19/EC concerning old electric and electronic

equipment and its implementation in national laws, old electric power tools have to be

separated from other waste and disposed of in an environment-friendly fashion, e.g. by

taking to a recycling depot.

Recycling alternative to the return request:

As an alternative to returning the equipment to the manufacturer, the owner of the electrical

equipment must make sure that the equipment is properly disposed of if he no longer wants

to keep the equipment. The old equipment can be returned to a suitable collection point that

will dispose of the equipment in accordance with the national recycling and waste disposal

regulations. This does not apply to any accessories or aids without electrical components

supplied with the old equipment.

The reprinting or reproduction by any other means, in whole or in part, of documentation and

papers accompanying products is permitted only with the express consent of the iSC GmbH.

Subject to technical changes

This consignment contains lithium-ion batteries.

In accordance with special provision 188 this consignment is not subject to the ADR

regulations. Handle with care. Danger of ignition in case of damage to the consignment

package. If the consignment package is damaged: Check and if necessary repackage. For

further information contact: 0049 1807 10 20 20 66 ( xed network 14 ct/min, mobile phone

max. 42 ct/min) Outside Germany charges will apply instead for a regular call to a landline

number in Germany.