Spare parts can be ordered from the Special Orders Desk

at your local Bunnings Warehouse.

For further information, or any parts not listed here, visit

www.ozito.com.au or contact Ozito Customer Service:

Australia 1800 069 486 New Zealand 0508 069 486

GENERAL POWER TOOL SAFETY WARNINGS

ADDITIONAL SAFETY WARNINGS FOR PUMPS

SYMBOLS

ORDERING REPLACEMENT PARTS

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructionsmayresultinelectricshock,reand/orseriousinjury.

Save these instructions

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Donotoperatepumpsinexplosiveatmospheres,suchasinthepresenceofammableliquids,

gases or dust. Pumps create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while operating a pump. Distractions can cause you to lose control.\

2. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a pump. Do not use

apumpwhileyouaretiredorundertheinuenceofdrugs,alcoholormedication. A moment of

inattention while operating a pump may result in serious personal injury.

b. Avoid accidental starting. Carryingpumpwithyourngerontherecoilstarterinvitesaccidents.

3. Pump use and care

a. Store idle pump out reach of children and other untrained persons. Pumps are dangerous in the hands

of untrained users.

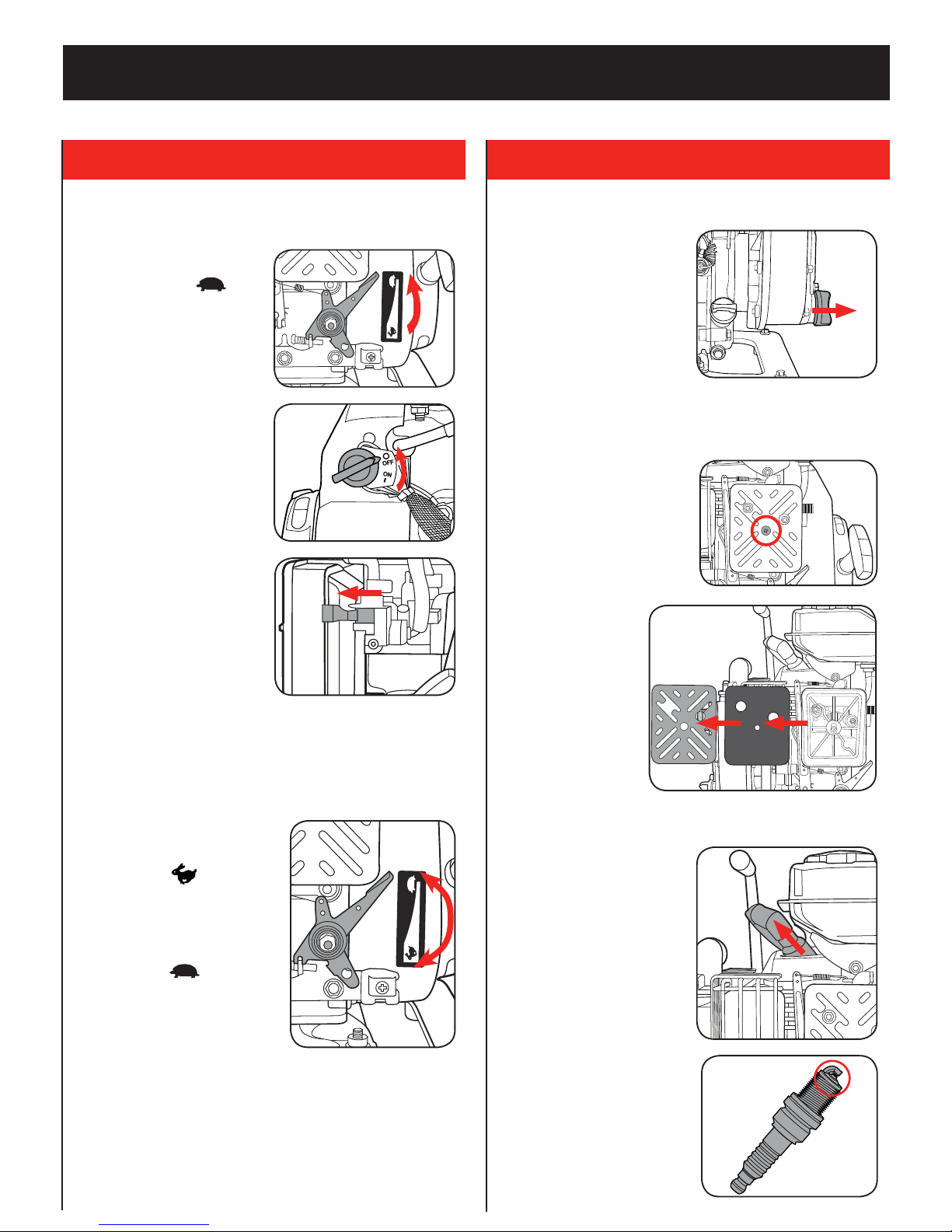

b. Always shut off the engine, allow the engine to cool and remove spark plug before making any

adjustments, changing accessories,or storing pumps. Such preventive safety measures reduce the risk

of starting the pump accidentally.

c. Maintain pumps. Check for misalignment or binding of moving parts, breakage of parts and any other

condition that may affect the pumps operation. If damaged, have the pump repaired before use. Many

accidents are caused by poorly maintained pumps.

d. Use the pump, and accessories etc., in accordance with these instructions and in the manner

intended for the particular type of pump, taking into account the working conditions and the work to

be performed.Useofthepumpforoperationsdifferentfromintendedcouldresultinahazardoussituation.

4. Service

a. Haveyourpumpservicedbyaqualiedrepairpersonusingonlyidenticalreplacementparts.This will

ensure that the safety of the pump is maintained.

WARNING! This product is intended for pumping water in a Home Domestic application. Do

not use it for corrosive, abrasive, explosive or dangerous liquids. Fluids other than water will

damagethewaterpumpand/orcreatearehazard.Failuretofollowallinstructionslisted

belowmayresultinelectricshock,reand/orseriousinjury.

WARNING! This product is not suitable for use with drinking (potable) water.

This appliance is not intended for use by person (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

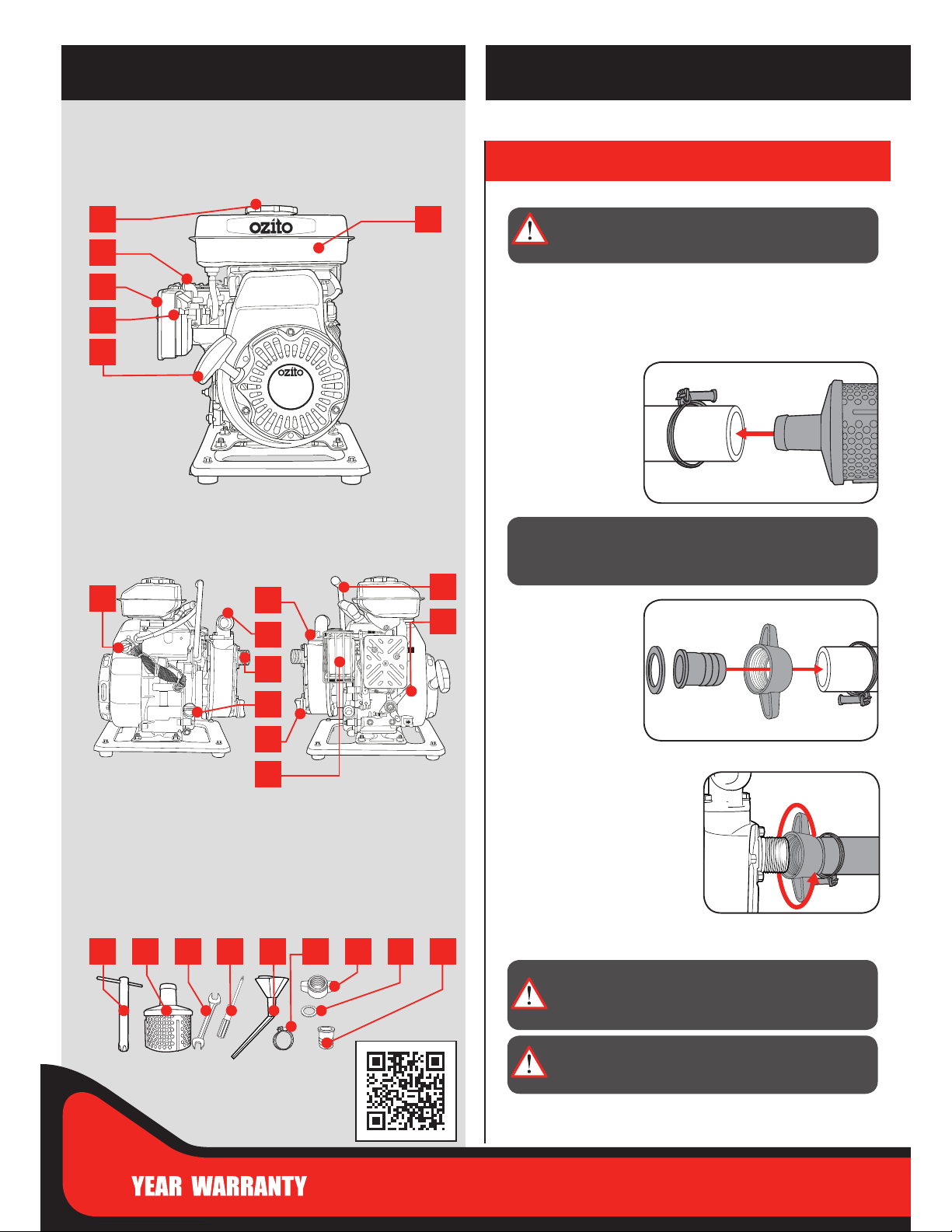

• Ensure the water pump is switched off when installing.

• Donotinstalloroperatethewaterpumpinanexplosiveenvironmentornearammablematerial.

• Do not operate the water pump without liquid.

• Do not run the water pump dry.

• Never refuel while engine is running or hot.Fuelspilledonahotenginecouldresultinareorexplosion.

• Usecautionwhenhandlingpetrol.Refuelinwell-ventilatedarea.Donotoverllfueltankanddonot

spill fuel. Make sure tank cap is closed properly.Petrolisextremelyammableandisexplosiveunder

certain conditions.

• Neverruntheengineinanenclosedorconnedarea. Exhaust contains poisonous carbon monoxide gas;

exposure may cause loss of consciousness and may lead to death.

• Donotusetopumpammableorexplosiveliquidssuchasgasoline,fueloil,kerosene,solventsor

thinners. Pump should only be used with liquids compatible with pump component materials. Failure

to follow to this warning can result in serious personal injury, death and/or property damage.

• Pump must be located on a solid level surface. Pump could tip or fall causing serious injury.

• Do not hold or suspend pump by means of a discharge pipe. Pipe could break or come loose.

• Becarefulnottotouchthemuferwhileitishot.Toavoidsevereburnsorrehazards,letthe

engine cool before transporting or storing it indoors. Themuferbecomesveryhotduringoperationand

remains hot for a while after stopping the engine. Exhaust may contain chemicals that may cause cancer or

reproductive harm.

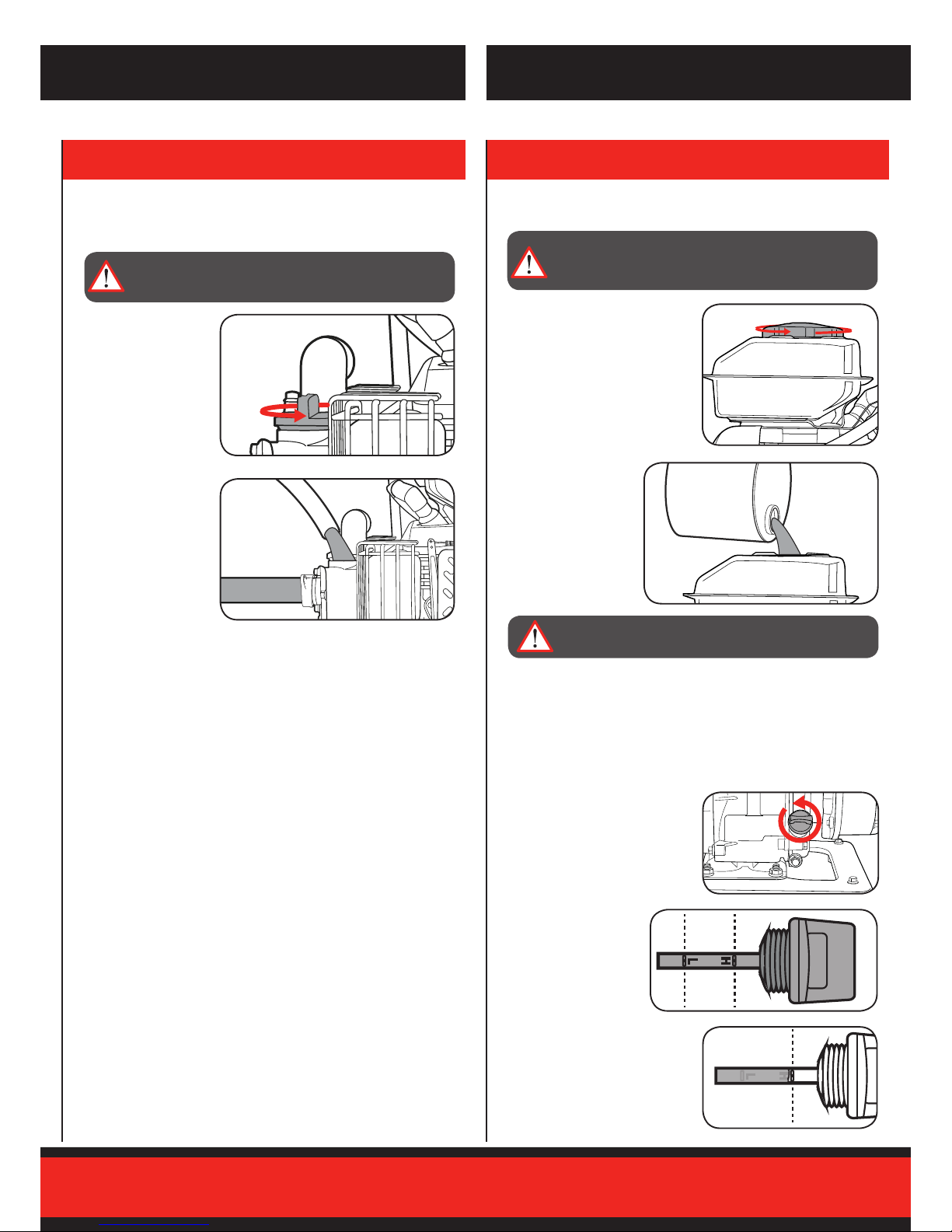

WARNING! The water pump together with associated pipework operate under pressure. Do not

disconnect water pump or pipework until internal pressure has been released. Failure to do this

could result in personal injury and damage to property.

• Avoid inserting hands into the inlets/outlets of the water pump while it is operating.

• Before using the water pump, always inspect it visually. Do not use the pump if it is cracked and/or damaged.

Ifthewaterpumpisdamaged,contactOzitocustomerservice.

• The pump must not be used when people are in the water.

• Pollutionoftheliquidcouldoccurduetoleakageoflubricants

Ifnowaterisproducedwithin10minutes,stoppump,releaseallpressure,removeprimingplug,rellandtry

again.

WARNING! Hazardous pressure and risk of explosion and scalding. If pump is run continuously

atnoow(thatis,withdischargeshutofforwithoutpriming),watermayboilinpumpand

pipingsystem.Understeampressure,pipesmayrupture,blowoffttingorblowoutpump

ports and scald anyone near.

To prevent explosion, do the following:

A.Ensuredischarge(valve,hosenozzle,etc)isopenwheneverpumpisrunning.

B.Ifpumpfailstoproducewaterwhenattemptingtoprime,releaseallpressure,drainpumpandrellwithcold

water after every two attempts.

C. When priming, monitor pump and piping temperature. If pump or piping begin to feel warm to the touch, shut

offpumpandallowsystemtocool.Releaseallpressureinthesystemandrellpumpandpipingwithcold

water.

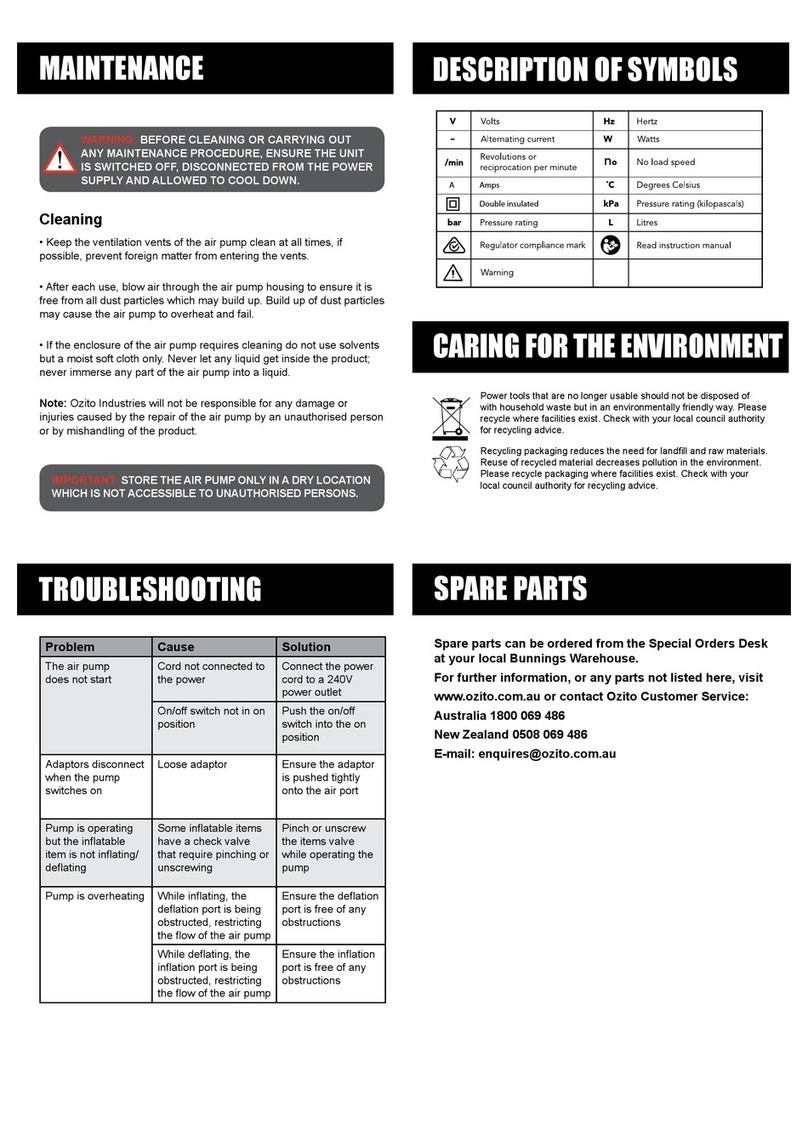

VVolts Hz Hertz

~Alternating current WWatts

/min Revolutions or

reciprocation per minute

Hp Horse power ˚C Degrees Celsius

p/hr Per hour kPa Pressure rating (kilopascals)

bar Pressure rating LLitres

FInsulation class PVC Polyvinyl chloride

n

o No load speed

Regulatorcompliance mark

Warning Read instruction manual

IPX8 Ingress protection from water

cc Cubic centimeters

Fire Toxic fumes

Hot surface