P.B.M. SE User manual

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.it e-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

TECHNICALMANUALFOR

“SE”

BATTERYCHARGER

(withPBM753 electroniccardSWV1.1)

HANDBOOKFORAUTHORIZEDTECHNICIANSAND SERVICEPERSONNELONLY

TECHNICAL MANUAL "STAR"(PBM750 rev2 SW2.2) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.it e-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 1

CONTENTS

CHAPTER1: INTRODUCTION.........................................................................................................................2

CHAPTER2: DESCRIPTIONOF THEPBM753 CONTROLCARD ..................................................................2

2.1: MAINFEATURES OF THE PBM753 CARD ......................................................................................................3

CHAPTER3: COMMISSIONING AND STARTUP.............................................................................................4

CHAPTER4: SETTING OF THEBATTERYVOLTAGE, ADJUSTMENT OF THETHRESHOLD (GASSING)

VOLTAGE, AND CHARGING STAGES............................................................................................................4

4.1: CARD SETTINGONBATTERYCHARGERWITHOUTBATTERY .............................................................................5

CHAPTER5: BATTERYCHARGERFUNCTIONS..........................................................................................5

CHAPTER6: DESCRIPTIONOF THECHARGE.............................................................................................6

FLOATING CHARGE....................................................................................................................................7

7.1. BATTERYDISCONNECTION UNDERCHARGE.............................................................................................8

7.2CURRENTDELIVERY DURINGANOFF STAGE .................................................................................................8

7.3FAILURETODELIVERCURRENT DURINGANONSTAGE ...................................................................................8

7.4SAFETYTIMER............................................................................................................................................8

CHAPTER8: LEDINDICATIONS.....................................................................................................................8

CHAPTER9: INSTALLATION, SAFETY, FAILUREDETECTION, AND MAINTENANCE.................................9

9.1: INSTALLATION......................................................................................................................................9

9.2: SAFETYNOTES ....................................................................................................................................9

CHAPTER10: FAILUREDETECTION............................................................................................................ 10

10.1: NECESSARYINSTRUMENTS.......................................................................................................... 10

10.2: FIRST CHECKS TO BE PERFORMED............................................................................................. 10

10.3: FAILUREDETECTIONAND MEASURES ........................................................................................ 10

CHAPTER11 : MAINTENANCEAND CLEANING.......................................................................................... 16

CHAPTER12: WIRING DIAGRAMS AND PARTSLIST................................................................................. 17

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 2

CHAPTER1:INTRODUCTION

AsofSeptember2016,the “SE” series battery chargerhasbeen renewed bothexternally,withacabinet

supplied withnewcoloursand anewgraphicalpanel,and technicallybyadding anewcircuitboard.The main

technicalfeaturesare:

•New PBM-753 cardat microprocessor, adaptableforthree-phaseand singlephasebattery charger.

•SMDtechnologycomponents.

•Battery chargeroperating range withrated voltage from24Vto96V.

•Card powered bymainsonly (24Vac).

•ON/OFF relay24VAC/10Awithcontactson connector.

•Battery chargerfunctionsconfiguration jumpersset bythe useraccording torequirements.

•Newfunctioning configuration options: 3h Autostart, Safetytimersettableat 11h.

•NewEqualisation and Floating charge mode.

•2calibration modesavailable: preset mode and adjustablemode.

•ON/OFF button integrated on the card.

•Jumperformanualrelaydrive.

•Powersupplyfusetoprotect the card(fromincorrect setting ofbattery selection jumpers)

CHAPTER2:DESCRIPTIONOF THEPBM753 CONTROL CARD

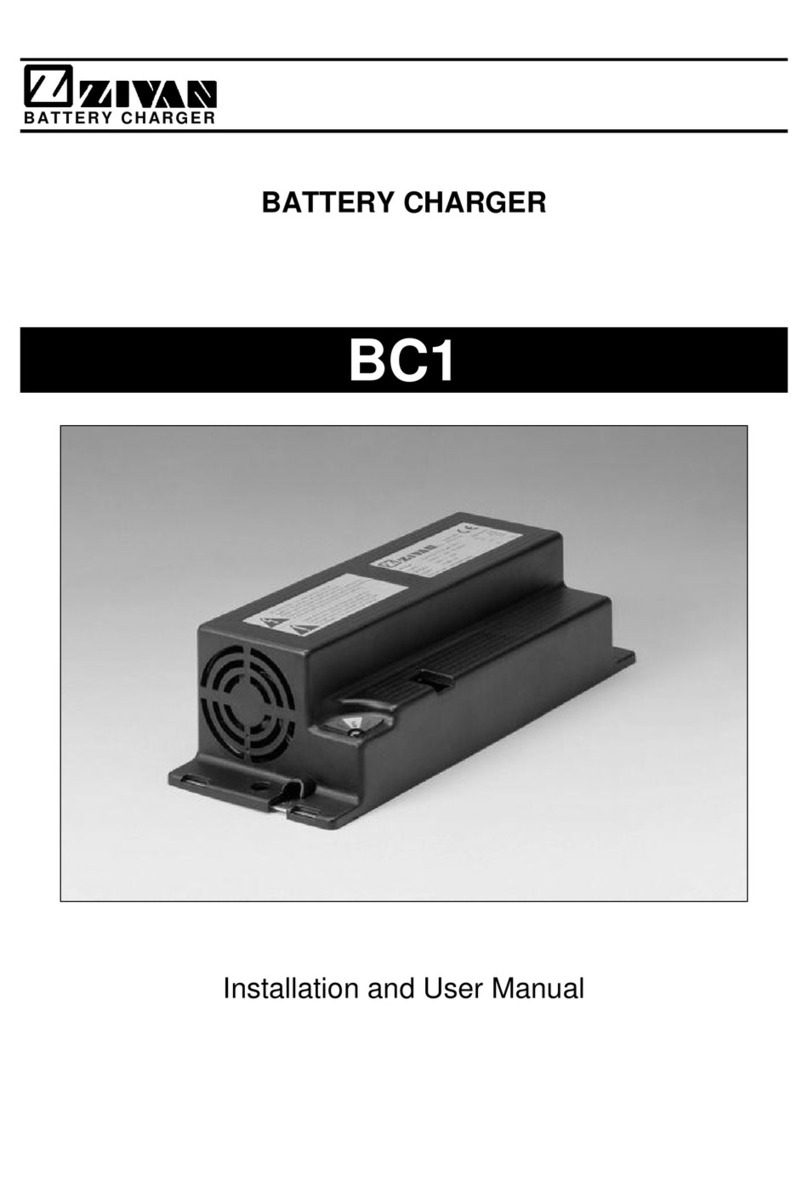

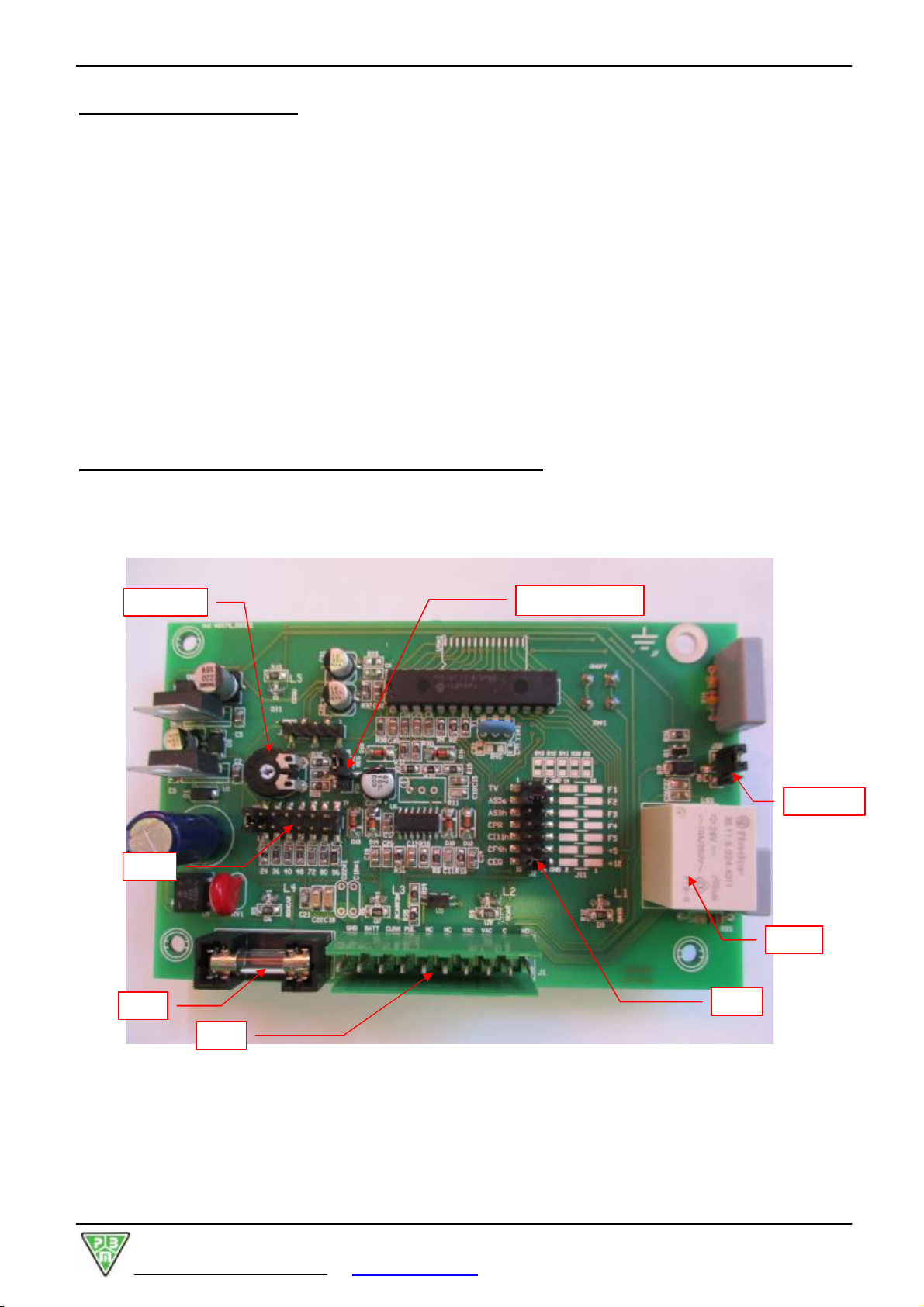

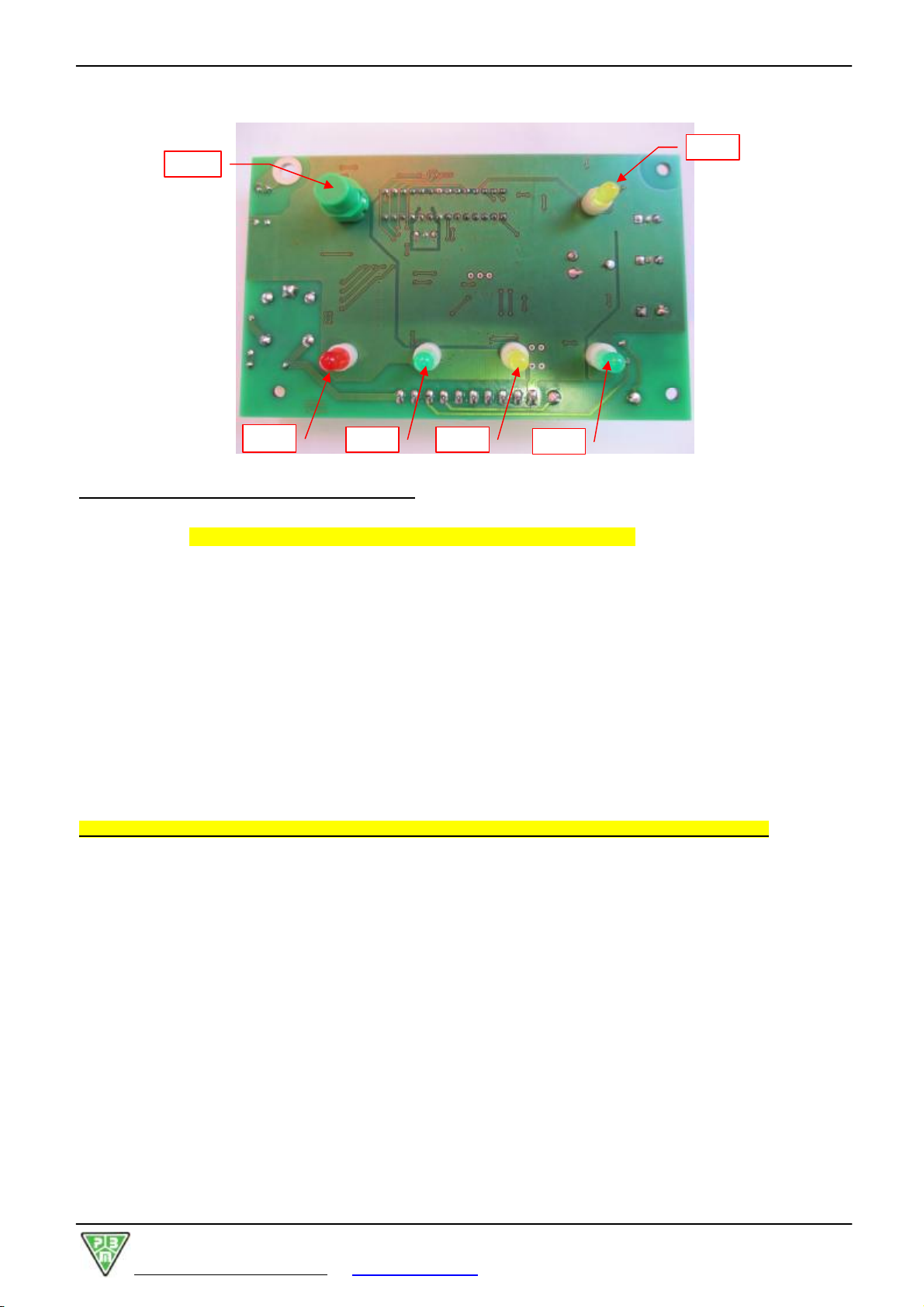

The twopicturesbelowshowthe maincomponentsbothon the side ofcomponentsand weldingsofthe card.

Figure2a : PBM753 –side ofcomponents

RL1

RL1

ON

J1

F1

V_GAS

J

10

J2

J9: FIX-REG

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 3

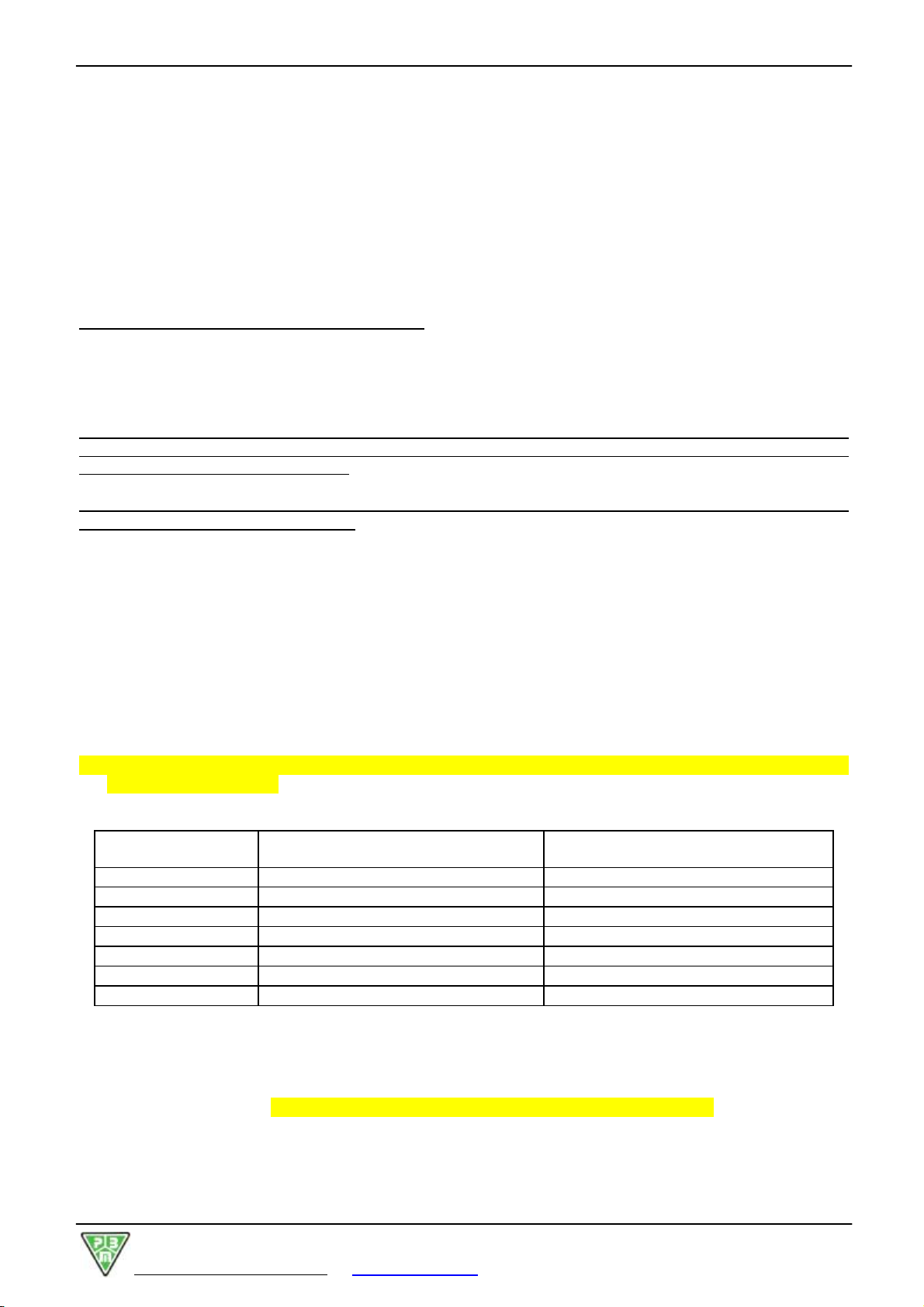

Figure2b : PBM753 –side ofweldings

2.1:MAINFEATURES OF THEPBM753 CARD

RL1ON:Manualcharge: connecting the jumperRL1 on, the relayisclosed manually

Warning:thebattery charger can bestopped manuallyonly.

J2 Function selection

TV Quick test(itallowstoshortlycheck the operation ofthe battery charger:the internalclock is

accelerated and the charging process issimulated)

AS5s Autostart withadelayof5seconds

AS3h Autostartwithadelayof3hours(the automaticstartofthe chargerisenabled 3hoursafter

connection topower)

CPR Proportionalcharge

CI11h Safetytimerset at 11 hours(instead of9, whichisthe default setting)

CF4h 4h-long finalcharge (instead of3, whichisthe default setting)

CEQ Equalizing charge

J9 2-position jumpertoselect the gassing voltage setting mode (FIX, fixed, or REG., adjustable)

J10 Selection ofbattery rated voltage (24V-36V-40V-48V-72V-80V-96V)

NOTE:ALL THETIMES YOUCHANGES THEJUMPERSSETTING, RESETALSO MAINSAND BATTERY!

VGAS One-turntrimmertoset the gassing point (2,4V/cell)

RL1 ON-OFF relay

L5 LEDindicating the EQUALIZING CHARGE(yellow)

L4 LEDindicating aFAULT (red)

L3 LEDindicating END OF CHARGE(green)

L2 LEDindicating FINALCHARGE(yellow)

L1 LEDindicating BATTERYCONNECTED/ CHARGING PROCESS (green)

F1 500 mAfuse, 5x20 fuse, asaprotection on cardpowersupply

P1

L1

L

2

L

3

L

4

L

5

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 4

J1 Connection connector, inwhich:

1=-shunt (negativepole)

2=+battery (positivepole)

3=+shunt

4=ON-OFF button

5=

6=

7=24VAC

8=24VAC

9=relaycontact

10 =relaycontact

CHAPTER3:COMMISSIONING AND STARTUP

The PBM753 cardispowered frommainsbymeansofa24VACauxiliary transformerwithan inputof100mA

max. Thereforeno message isdisplayed onlybattery connection.

Onconnecting alsomains, the PBM753 cardperformsatest lighting up all LED’s.

Oncethe self-test hasbeen completed, onlythe green “BATTERYCONNECTED”LED(L1)remainslit.

NOTE: a24Valternated current, generated bythe auxiliary transformer,powersthe card.Ifthe chargeris

powered frommainsand the carddoesnotswitchon,check the corresponding circuit(frommainsinputtothe

cardthrough the auxiliary transformer).

CHAPTER4:SETTINGOF THEBATTERYVOLTAGE,ADJUSTMENTOF THETHRESHOLD(GASSING)

VOLTAGE, AND CHARGING STAGES

•Selectbattery voltage byinserting the J1 jumpersaccording tothe rated voltage ofthe installed battery.It

ispossibletoset 24V, 36V, 40V, 48V, 72V, 80V, and 96V.

•Afterthe J10 jumperhasbeen properlyset, the cardautomaticallysetsthe voltage value corresponding to

the gassing voltage, whichmayrange between 2,3and 2,5V/cell.

•By turning the one-turn VGAS trimmer,itispossibletosetthe gassing voltage withavery high accuracy,

asdescribed inChapter4.1.

•The PBM753 cardfeaturestwomodesofgassing voltage setting bymeansofthe J9 jumper:

•By setting the J9 jumper toFIX,thegassing threshold issetto2.4V/cell withanerrorof±0,05V,due

tothe componentstolerance.

•Setting the J9 jumper toREG., the gassing voltage can be setwiththe highestaccuracy (±0,01V/cell)by

meansofthe one-turnVGAS trimmer.

•NOTE:Thecalibration at2,4V/cell)once itisdone, itremainsvalid (with an accuracy of±0,02V/el.)

forall battery voltages.

At roomtemperature(25°C), the standardSETTING VALUES arethe following:

Nominal

Voltage battery Calibration valueswithEXACT setting –

J9>REG (2,4V/el.) Calibration valueswithQUICKsetting –

J9>FIX(2,4V/el.±0,05)

24 V 28,8V 28,3V÷29,2V

36 V 43,2V 42,6V÷43,8V

40 V 48,0V 47,3V÷48,7V

48 V 57,6V 56,7V÷58,4V

72 V 86,4V 85,1V÷87,7V

80 V 96,0V 94,5V÷97,4V

96 V 115,2V 113,5V÷116,9V

•Pleasenotethatthe above-mentioned voltage istobe measured on battery side.Ifthe cardisnotseton

site, the VGAS trimmerhastobe calibrated foravoltage, measured on the card, exceeding the rated value

by0,3-0,4V. Thisallowstotakeintoaccount the voltage drop whichusuallyoccurson the charging cables.

•Onreaching the thresholdvalue, the yellowLD4 LEDlightsup.

•Ifthe thresholdvoltage isexceeded formorethan 10 seconds, the LD4 LEDremainslit.

•Thereforethe thresholdsetting hastobe completed withinthat time.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 5

4.1:CARD SETTING ONBATTERYCHARGERWITHOUTBATTERY

Material required:

•DC voltage generatorfrom0Vto150V(e.g. PBM SLV150)

•digitalvoltmetertomeasureDC voltagesranging from0Vto400V

•thinscrewdrivertomakeadjustments

Procedure:

•Disablethe AUTOSTART function removing the AS5sand/orAS3h jumpers

•Warning:disabling the AUTOSTARTfunction isnecessary topreventthe battery chargerfromfeeding

powertothe stabilized powersupplythusdamaging it.

•Connect the battery chargertomains.

•Powerthe chargerfromthe voltage generatorbymeansof the charging cables,afteradjusting the voltage

generatortothe desired voltage threshold.

•Foralead battery witharated voltage of48V(24 cellsx2,00V/cell)the voltage thresholdgenerally

correspondsto2,4V/cell +0,3V,equalling the average drop value on the charging cablesduring the

charging process. Therefore, the battery input voltage must be 2,40 x24 +0.3=57.9Volts.

•Useathinscrewdrivertoturnthe VGAS trimmeron the PBM753 cardcounter-clockwiseuntil the yellow

LD4 LEDlightsup.Ifthe LEDisalreadylit, turnthe VGAS trimmerclockwiseuntil the LEDlightgoesoff,

then turnit counter-clockwiseuntil it lightsup again.

Warning :to avoid damaging thepower supply, becareful notto push theON-OFF button.

NOTE :Ifthe yellow L2 LEDremainslitlongerthan 10 seconds,itmeansthatthe chargerhaspermanently

switched tothe finalcharge stage (the LEDlightwill notgo off anymore, even ifthe battery voltage fallsbelow

2.40V/cell).

In thiscase resetthemainsand make theprocedure again.

CHAPTER5:BATTERYCHARGERFUNCTIONS

•QUICK TEST: byconnecting ajumperto J2 at TV the controlSWacceleratesall the timerssuchasthe

safetytimer,finalcharge timerand equalisation times.Thisfunction isusefulforquick overall check of the

battery chargerworking cycle.

•FINALCHARGEof4h: connecting ajumperon J2 at CF4h lengthensthe finalcharge timefrom3h to4h.

•AS5: connecting ajumperon J2 at AS5s enablesthe automaticcharging startfunction (AUTOSTART)5

sec. afterthe battery hasbeen connected.

•AS3h: connecting ajumperon J2 at AS3h enablesthe automaticcharging startfunction (AUTOSTART)3

hoursafterthe battery hasbeen connected.

•PROPORTIONALCHARGE: connecting ajumperon J2 at CPR enablesthe proportionalcharge bywhich, if

the battery reachesthe gassing thresholdwithinthe first 20 minutesofcharging, the finalcharge iscarried

out for10 minutes. Thisfunction istoprotect the battery alreadycharged and recharged anothertimeby

mistake.

•Ifthe electroniccardPBM753 detectsthe reaching ofthe final charge thresold(yellowled lighting )

within thefirst20 minutes, the charge goeson forother10 minutes(total20+10 =30 minutesmax)

and then it finallystopsshowing “charge completed “through the green led.

•Ifit isnot sothe charge continuesuntil it reachesthe finalcharge thresoldand goeson for3hours(orthe

timeset )and, tofollowthe equalization charge (ifprogrammed).

•CI11h: connecting ajumperon J2 at CI11h setsthe safetytimerat the first stage at 11h

•CEQ: connecting ajumperon J2 at CEQ activatesthe equalisation and floating function.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 6

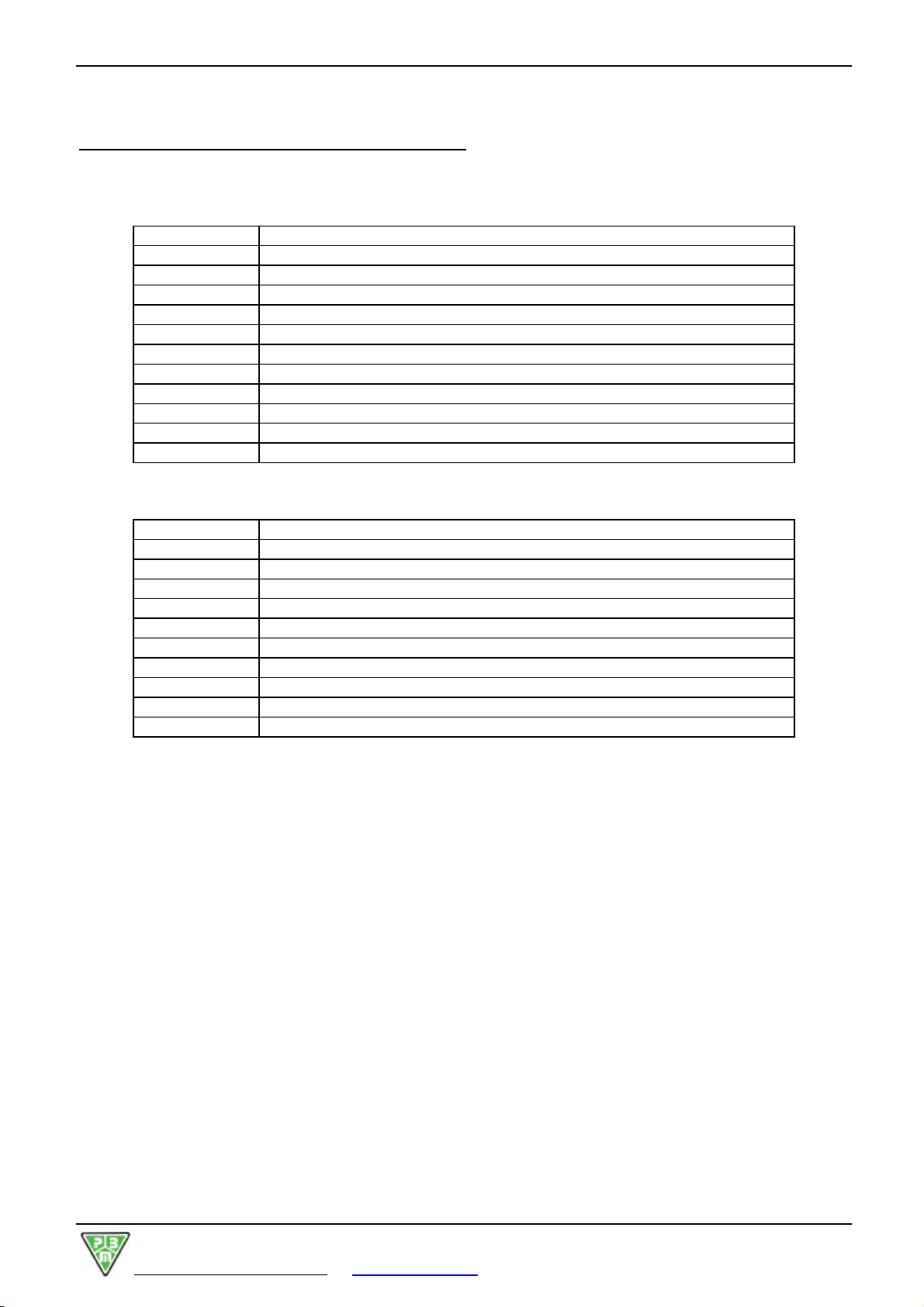

FUNCTIONSUMMARYTABLE

Jumper

symbol Function Description offunction

withoutjumper with jumper

TV Quick test Standardtimes(*) Accelerated times

CF4 Finalcharge time Finalcharge at 3hours(*) Finalcharge at 4hours

AS5s Standardautostart Manualstart Autostart after5seconds(*)

AS3h Delayed autostart Autostart after3hours

CPR Proportionalcharge No proportionalcharge (*) Proportionalcharge on

CI11h Safetytime Safetytimerat 9hours(*) Safetytimerat 11 hours

CEQ Equalisation charge Not programmed Programmed*

*Default setting

CAUTION! : Thecardchecks thesetting ofthejumpers whenitturnson, namelywhenthecharger is

poweredbymains.Tomake modifiedsettingseffective withtheboardpowered, thecharger mustbe

disconnected and then reconnected.

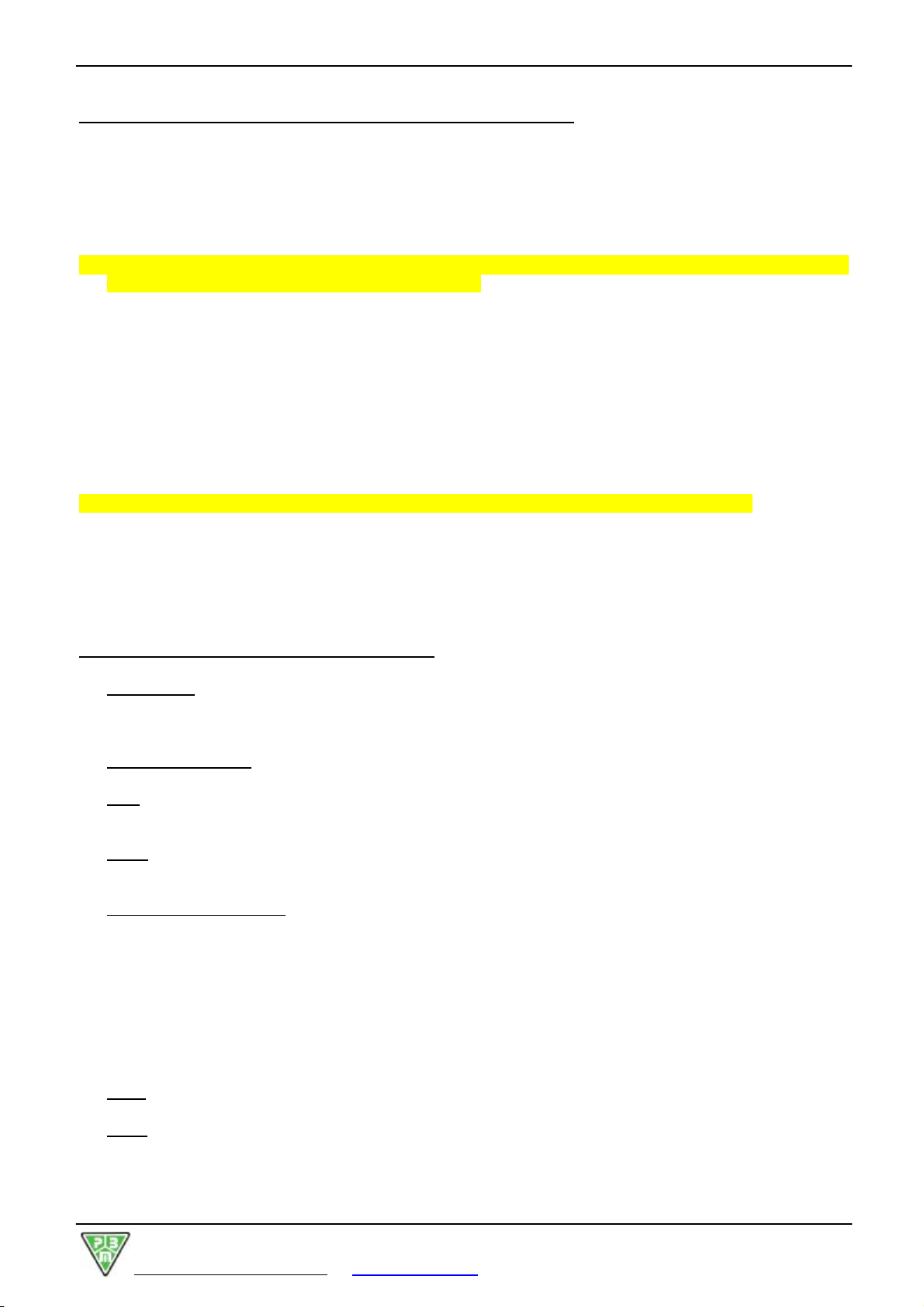

CHAPTER6:DESCRIPTIONOF THECHARGE

Onceall connections(mainsand battery) havebeen performed, the electroniccardPBM 753 makesa lighting

testofall theleds. Afterthistest just the L1 green led ison “BATTERYCONNECTED”and eventuallythe

LED L5 ifalsothe equalizing charge isset.

Charging curve

The charging characteristicshownaboveismade up ofthe following stages:

Initialcharge: performed withdecreasing currentuntil athresholdisreached,corresponding tothe gassing

voltage set bymeansofthe VGAS trimmer(standardvalue is2.4V/cell).

The initialcharge maylast 9or11 hours max (depending on the setting ofthe CI11H jumper).

Ifthe initialcharge isnotcompleted withinthattime,the safetytimeroperatesand the redL4LED lightsup to

signalaFAULT.

Final charge: beginswhen the yellow L2LED (corresponding toathresholdequalto2,4V/cell)lightsup.

It isperformed withdecreasing currentand goeson time-controlled (3hoursasdefaultsetting;4hourswhen

the CF4h jumperisinserted).

TIME

100

I(%)

V/el.

2,40 V

2,00 V.

INITIALCHARGE

MAX 9-11 h

Safety timer

FINALCHARGE PAUSE

50

25

EQUALIZATION

2,70 V.

5impuls

ooo

5impuls

ooo

5impuls

ooo

15h 15h

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 7

End ofnormalcharge: when the above-mentioned timehaselapsed,the greenL3LED,indicating

“BATTERYOK”, lightsup.

Then an equalizing charge, ifenabled (CEQ jumper), takesplace.

Pause:60min-long charge interruption whichseparatesthe end ofnormalcharge and the beginning ofthe

equalizing charge.

Equalizing charge:

Afterthe normalcharge apausewill takeplace(T.Pause =60 min)afterwhichEqualizing will be performed

(fora Teq time =45h).

Equalizing ismade up ofacertainamount(Np=3)ofpulse(Neq=5)packages,eachofwhichconsistsof

charges (T.ON=12min)and pauses (T. OFF=48min).

The abovementioned pulsepackagesalternatewithpauses(Ts=15h).

Thesepulsesareperformed during the Active cycle(=45h), followed bya Stop cycle(=120h).

Thisequalizing systemhasno timelimitsand stopson battery disconnection.

The systemisvery usefulduring holidaysand week-ends,sinceitmakesitpossibletokeep battery charged

whilepreventing overcharging, overheating, and/orwaterconsumption.

FLOATING CHARGE

Atthe end ofacompleteequalized charge cycle(45 hours)if the battery remainsconnected (during holidays

forinstance)the equalization cyclesarerepeated every 120 hours(5day)

Thiscycleofcharge,thatcompensatesthe battery self–discharge , isrepeateduntil theuser remove the

battery.

Warning :

•Before disconnecting thebattery,check whether thecharging process has beencompleted. Ifthe

charging process isstill being performed and needsbeing interrupted, press theON-OFF button.

•Never disconnectthebattery connectorbefore interrupting thecharging process !

The charging process can be interrupted withoutdisconnecting battery bypressing the ON-OFF button;inthis

waycharging timesarestored and bypressing the ONbutton again,the charging process isresumed fromthe

point ofinterruption.

Ifbattery isdisconnected during apauseofthe equalizing charge orafterentering the OFF statusbypressing

the relevantpush-button,the battery chargerwill resetand itwill beginanewcharge on connecting the new

battery.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 8

CHAPTER7:FAULTS

The PBM753 cardisabletorecognize4typesoffaults:

7.1. BATTERYDISCONNECTIONUNDERCHARGE

Disconnection ofbattery during acharging process mightbedangerous.

Ifnevertheless battery isdisconnected fromchargerduring acharging process,the charging process will be

temporarilystopped and afaultwill besignalled bymeansoftheyellow L2LEDblinking.

Onconnecting againabattery tothe charger, the cardwill reset and start anewcharging process.

All information concerning the previouscharging timesgo lost.

7.2CURRENTDELIVERYDURING ANOFF STAGE

During an inactive(notcharging)stage the battery chargerdetectscurrentpresencetowardsbattery,and

signalsit bymeansofthe red L4LEDblinking slowly. Thissignalsadefect eitherofthe relayorcontactor.

7.3FAILURETO DELIVERCURRENTDURING ANONSTAGE

During an active(charge)stage the battery chargerdetectscurrent failuretowardsbattery and signalsit by

meansofthe red L4LEDblinking quickly.

7.4SAFETYTIMER

Ifthe safetytimeroperatesduring the initialcharge, the battery chargerstopsthe charging process and signals

it bymeansof thered L4LEDwhich lightsup constant.

To exitfromall faultconditions, thebattery charger needsresetting:disconnectthecharger fromthe

power supplyand connectitagain to it.

CHAPTER8:LEDINDICATIONS

Indication L1

green L2

yellow L3

green L4

red L5

yellow

Onlymainspowersupply OFF OFF OFF OFF ON

Onlymainspowersupply(self-test) ON* ON* ON* ON* ON*

Onlybattery powersupply OFF OFF OFF OFF OFF

Mainsand battery powersupply ON OFF OFF OFF -

Autostart inprogress OFF OFF BL BL BL

Initialcharge BL OFF OFF OFF -

Finalcharge BL ON OFF OFF -

End ofcharging ON ON/OFF ON OFF -

Equalizing charge disabled - - - - OFF

Equalizing charge enabled - - - - ON

Pauseduring the equalizing charge ON ON/OFF ON OFF BL

Equalizing charge BL ON ON OFF BL

ANOMALY/ ALARMS

Mainsfailure NO INDICATION

Battery disconnection during the charging process OFF BL OFF OFF OFF

Current delivered even ifbattery chargerisOFF ON OFF OFF BL OFF

Current 0delivered even ifbattery chargerisON OFF OFF OFF BV OFF

Operation ofthe safetytimer(set at 9or11h) ON OFF OFF ON OFF

ON* on forinitialself-test

OFF off

ONLight constant

BLblinking slowly

BV blinking quickly

-LEDcan be inanycondition

Note:the yellowLD1 LED(equalizing charge)isalwayslit, if the equalizing charge isenabled,oralwaysOFF,

ifthe equalizing charge isdisabled. During the quick test, LED’sblinkmorequickly.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 9

CHAPTER9:INSTALLATION, SAFETY, FAILUREDETECTION, AND MAINTENANCE

Inthischapterthe maininfoareprovided,necessary tothe Service Personnel tocarry outacorrect

installation of the battery charger,aquick detection of the mostcommon failures,and apropermaintenanceof

the unit.

9.1:INSTALLATION

The generalnoteson installation arealreadyprovided inthe usermanualenclosed toeachbattery charger.

Onlythe majoritemsaresummarized below.

•It isessentialtoconnectthe chargertoamainssupplyofstandardscorresponding tothe powerofthe

battery chargerinstalled tobe surethat the chargerfunctionsproperly.

•The chargerisequipped withtapstoadjustthe chargertomains,compensating forpossibledifferences

between the voltage availableat the user’ssiteand the rated voltage.

•The single-phasechargersarepreset forarated voltage of230VAC.

•The three-phasechargersarepresetforarated voltage of400VAC(orother values depending on the

destination country).

•Checking themainsvoltageisessential:amainsvoltage whichistoo high ortoo lowcompared withthe

rated value,mayresultinbigdifferencesinthe currentdelivered bythe battery chargerwithfollowing

malfunction ofthe chargerand lowerperformancesofthe battery.

9.2:SAFETYNOTES

•Ensurethatthe battery chargerispositioned ontoasolid,flat, and even floor,and isprotected against

possibleimpactsfromforklift trucksand othervehicles.

•The battery chargerhastobe installed inasitefree frommaterialswhichmaypreventitsnatural

ventilation, necessary todissipatethe produced heat.

•Do not position the chargernearexplosive, inflammable, and/ordangerousmaterials.

•Makesurethat the battery chargerisneitherexposed torain, moistureorfog, norsplashed withwater.

•Do notinstall itoutdoor*,underunstableshedsorshelters,withthe exception ofspecialversionswith

protection class IPX3orhigher.

•Check the condition ofsockets,fusesand/orswitches,existing atuser’ssite,and ofconnection cables.Do

not usepatchcordstoprolong the existing powercord!!

•Makesurethatthe battery chargerisequipped withan electricalconnectorsuitableforitspowerand current

and it isconnected toan adequatemainssocket!! (check inputsand powerson the rating plate).

•Check connectionsbetween battery and charger:iftheyaredamaged and/orworn-outtheymayproduce

dangerousoverheatings.

•All checks and/orsettingshave tobeperformedbyqualified, skilled, and authorisedpersonnel

only.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 10

CHAPTER10:FAILUREDETECTION

Belowyou will find onlygeneralinformation.Sincedifferentkindsoffailuresand/ormalfunctionsmayoccur,

pleaserefertoexperienced ServiceTechniciansforanyproblem.

Note:chargers withdecreasing currentmay alsohave seeming malfunctions duetoexternalcauses,

suchas electricalsystems and/orbatteries in badconditions.Take thisintoaccountwhenchecking

them.

10.1:NECESSARYINSTRUMENTS

-Multifunctionaldigitaltester

-DC clampmeter

10.2:FIRSTCHECKSTO BEPERFORMED

•Preliminary check on the generalconditionsofbattery chargerand battery (see previousparagraph).

•Makesurethatthe powercordofthe chargerhasbeen properlyconnected tomainsand thatthe mains

switchisOFF.

•Check the mains.

•Makesurethat chargerhasbeen properlyconnected tobattery and check the condition ofconnectors.

10.3:FAILUREDETECTIONAND MEASURES

FAILURE POSSIBLECAUSES REMEDIES AND/ORCHECKSTO BEPERFORMED

BATTERYISCONNECTED,

CHARGERISPOWERED,

BUTTHECARD DOES NOT

SIGNALITAND CHARGER

DOES NOTSTART

CHARGING

-Blownfuses

-Defectiveconnections

and/orcontacts

-Defectivecard

1)Check the DC output fuseF2(battery side).

2)Check the fuseF1on the PBM753 card.

3)Check the pathof the charging cablesmaking surethat

thereareneitherbad contacts

on plugsnor

overheatingson partsofcablesorcableterminals.

5)Check the voltage paththrough contactor,auxiliary

transformer,and cardinputconnector,making sure

thata24VACvoltage ispresenton the

outputaux

trasfoand PBM753 cardinput. See following photo

6)Check all, ifneeded, replacethe PBM753 controlcard.

BATTERYAND MAINSARE

CONNECTED, THE

CONTACTORORRELAY

CLOSES BUTTHE

CHARGERDOES NOT

DELIVERANYCURRENT

-Powerfailure

-Blownfuses

-Defectiveconnections

and/orcontacts

-Defectiverectifier

bridge

1)Check the phasevoltage outputfromthe contactor

contactsand phasevoltage inputtomainTransformer

(TR).

2)Check thatcablesareingood conditionsand thereare

no defectivecablesand/orterminals.

3)Check the output fuseon battery side (F2)

4)Check the efficiency ofthe rectifierbridge* (RD).

THEBATTERYCHARGER

DELIVERSLITTLE

CURRENT

-Powerfailure

-Blownfuses

-Defectiveconnections

and/orcontacts

-Defectiverectifier

bridge

-Lowmainsvoltage

-Wrong wiring ofthe

MainTransformer

1)Battery alreadycharged ornot completelydischarged.

2)Failureofone ormoremainsphases;check the mains

fusesand the contactsofthe contactor(TL).

3)Check thatthe pinforadjustmenttomains(CM) isin

the correct position astothe mainsvoltage present.

4)Check the integrityofcablesmaking surethat thereare

neitherburntwiresnoroxidized terminalsinthe power

circuit up tothe charging cables.

5)Check the condition ofthe rectifierbridge (RD)

see

belowinstructions.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 11

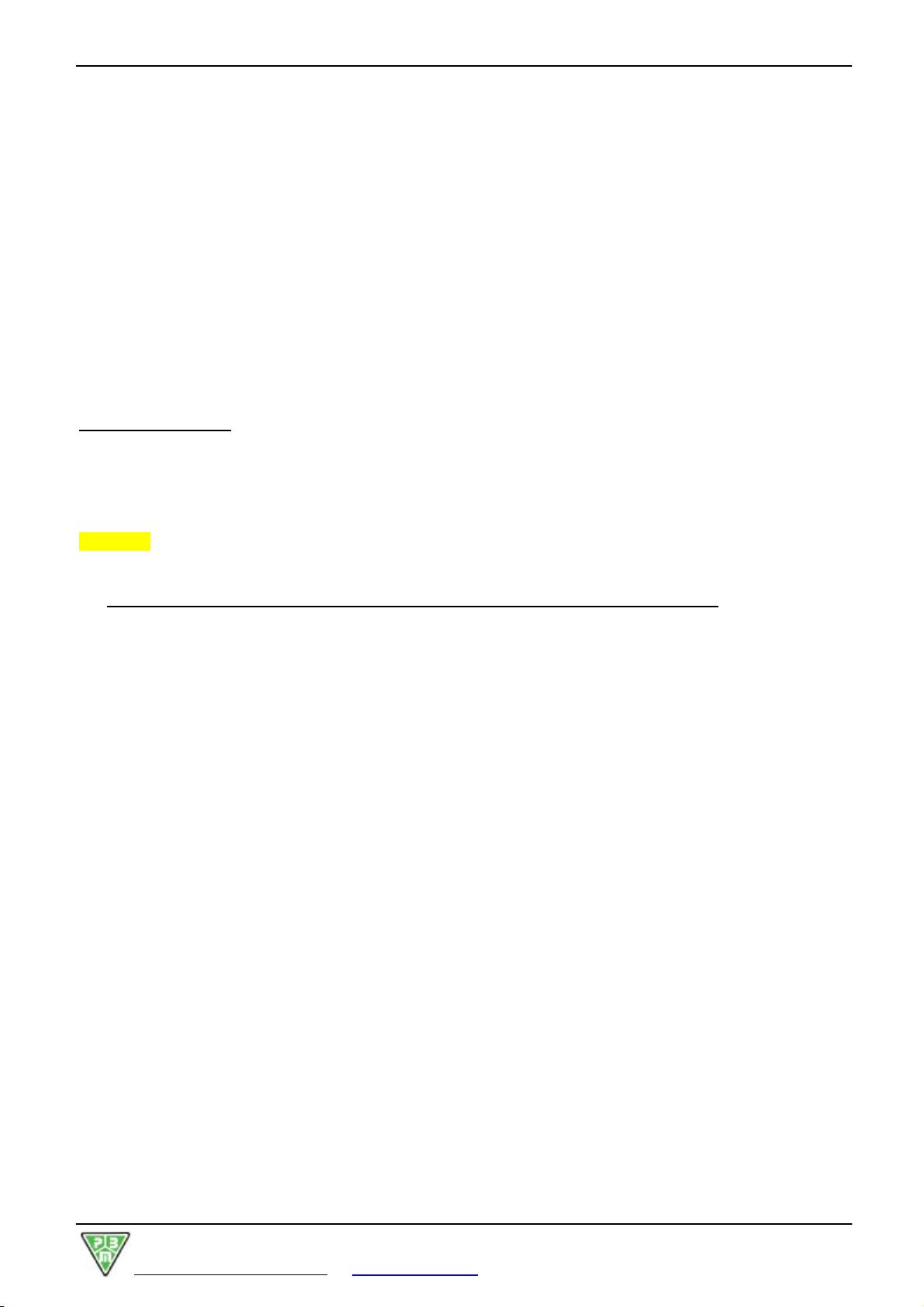

CHECK Auxtransformer:

-Open the front door;

-Connect the chargertothe mainssupply: 3x400VAC(orotherVoltage on plant)

-Incaseit doesnot 24VACoutput, meansthat the auxiliary transformerisfaulty.

-The cardshouldlight up with24VAC

FAILURE POSSIBLECAUSES REMEDIES AND/ORCHECKSTO BEPERFORMED

THECHARGERDELIVERS

TOO MUCH CURRENT

-Mainsvery high

-Adjustmentsnot correct

-Battery too low

-Wrong wiring ofthe

MainTransformer

1)Makesurethatthe chargerhasapower

suitableforthe

battery tobe recharged.

2)Check thatthe pinforadjustmenttomainsisinthe

correct position astovoltage available.

3)Check thatbattery doesnothavetoo long and/ortoo

strong dischargesincomparison withitsowncapacity.

4)C

heck thatmainsvoltage doesnotexceed the one

foreseen bythe transformer

5)Check the properconnection ofthe InputVoltage on

the input connectorofTransformer.

Check mains

input presence Check 24 VAC

output presence

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 12

FAILURE POSSIBLECAUSES REMEDIES AND/ORCHECKSTO BEPERFORMED

THECUT-OUTSWITCH ON

THEPANELOPERATES

-Littlepoweravailable

-Short-circuited

components

1)Makesurethatthe power(kW)availableatcustomer

siteissuitableforthat needed bythe charger.

2)Check the efficiency ofthe auxiliary transformer(TA).

3)Check thatthe c

oil ofthe TLcontactorisnotburntor

short-circuited.

4)Check the MainTransformer(TR),making surethat

thereareneithershort-circuited norburnt windings.

5)Makesurethatthe rectifierbridge*(RD)isnotshort-

circuited.

6)Check thatchargerd

oesnotdelivertoo muchcurrent

(see the above-mentioned information).

7)Ifafterafewminutesthe cut-

outswitchon the panel

operates,check the switchinstalled sincethe charger

isaparticularlyheavyload froman electricalpointof

view.

It issuggested touseautomaticand/ordifferentialcut-

outsasprotectionsofbattery chargerswithoperation

characteristicssuitableforthe specificload (

Kand D

curves).

BURNTFUSE ONCARD -Defectivecardorwrong

powersupplyofthe

card.

1)Makesurethatthe voltage battery iscorrect;

see

JumperJ10 position.

2)Replacethe PBM753 card.

BURNTOUTPUTFUSE ON

BATTERYSIDE

-Polarityreversal

-Defectiveand/orshort-

circuited components

1)Check thatpolarityofthe outputcablesand on battery

conne

ctoriscorrect(polarityreversalmayoccurwhen

maintenanceisperformed and/orcablesand/orbattery

connectorsarereplaced).

2)Check thatbattery chargerdoesnotdelivertoo much

current (see the above-mentioned information).

3)Makesurethatthe rectifierbridge* (RD)isnotshort-

circuited.

THECHARGERDOES NOT

“STOP”ATTHEEND OF

CHARGING

-Cardsetting not correct

-Battery not ingood

condition

-Defectivecard

1)Check the condition ofeachsinglebattery cell,making

surethattherearenotshort-

circuited cellsorcellswith

avery lowvoltage.

2)Makesurethatthe cardthresholdvoltage corresponds

tothe referencevoltage (2,4V/cell).

3)Check efficiency of timerson the cardperforming proof

testsasexplained inthe relevant instructions.

4)Replacethe PBM753 card.

THECHARGERDETECTS

AND SIGNALSAN

"ALARM"CONDITION(refer

tochp. 7/8) -Overall check

1)Check the differentcomponentsdepending on the

alarmsignalled and followthe above-

mentioned

information.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 13

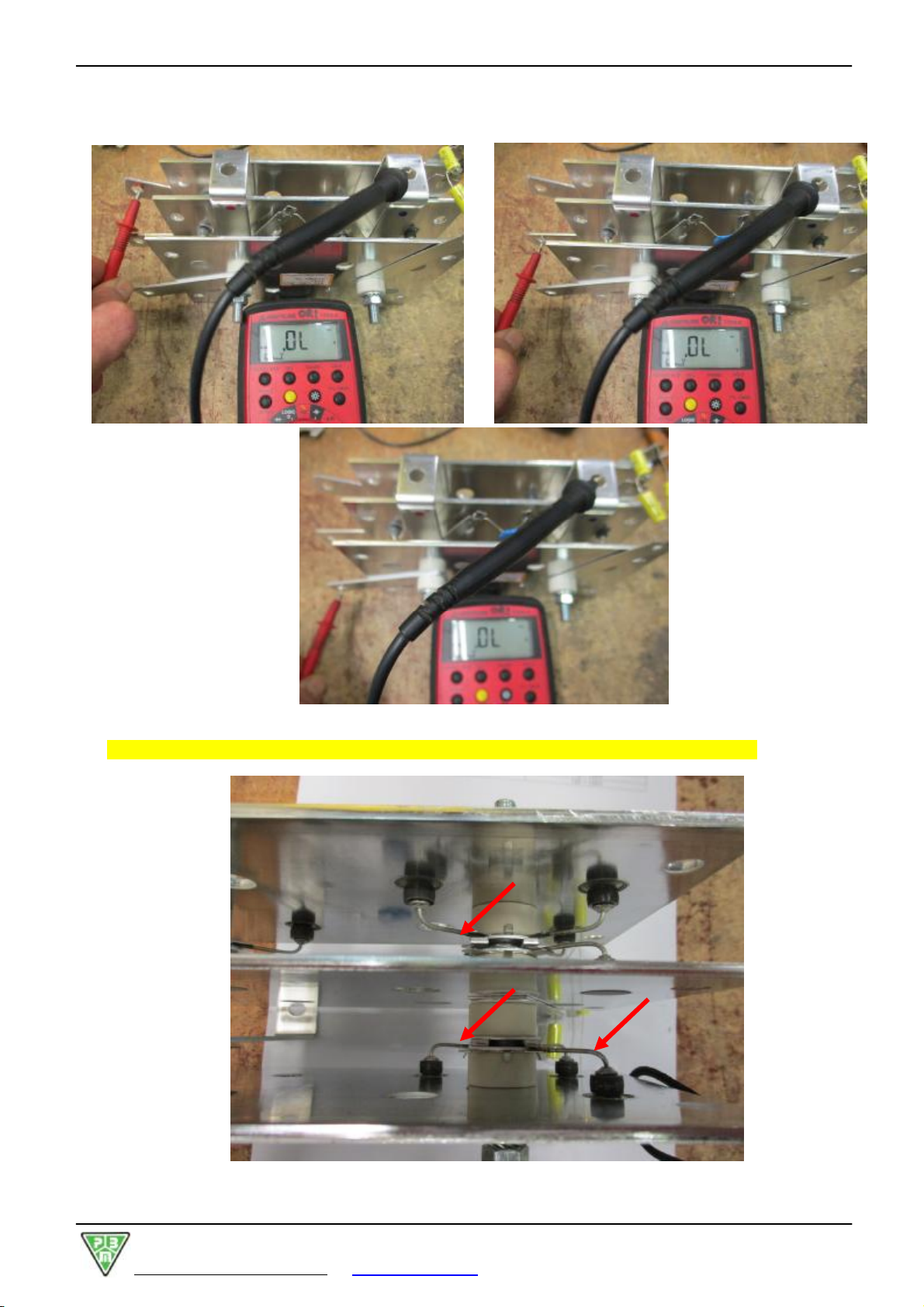

Checking therectifier bridge

The rectifierbridge ismade up ofbutton diodeson aluminiumsheetswhichact asdissipaters.

Toachievedifferentcurrentcapacities,the bridge ismade up ofavariablenumberofdiodes,positioned in

parallelon the sameplate.

Totest operation ofthe RectifierBridge, removeit fromthe charger.

Tocheck the condition ofthesediodes,

usea Digital tester in “Check-Diode” mode :

1)Makesurethata diodevoltage (0,4V÷0,8V) ispresentbypointing the positive testprod on thephases

input fromtransformerand the negative testprod on thepositive outputpole.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 14

2)Makesurethatthereis aninfinitediode bypointing the positivetest prod on positivepoleofbridge output

and negativetest prod on eachphasesinput.

3)Makesurethata diodevoltage (0,4V÷0,8V) ispresentbypointing the positive testprod on the

negative outputpoleofthebridgeand thenegative testprod on thephases input fromtransformer.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 15

4)Makesurethatthereis aninfinitediodevoltage bypointing the positivetestprod on the phasesand

negativetest prod on the negativeoutput ofbridge.

Inaddition totheseinstrumentalchecks, the following empiricalcheckscan be performed:

•Visualchecks toexcludethatthere are blown diodes oranunsolderedrheophore (see photos

following).

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 16

•If strong vibrations areheardduring the charging process and the charging process isnotperformed

regularlybecausethe cut-out-switchorthe fusesoperate, itmeansthatthebridgeisin short-circuitand

itneedsreplacing.

•Onthe otherhand itiseasytodiagnosethe openbridge failureon a three-phase charger byoperating

the chargerwithoutconnecting the battery and forcing the powersupplyofthe transformer.Ifan

anomaloustransformervoltage,instead ofano-load voltage,isdetected undertheseconditions,itmeans

that the rectifierbridge isatleastpartiallyopen and needsreplacing.

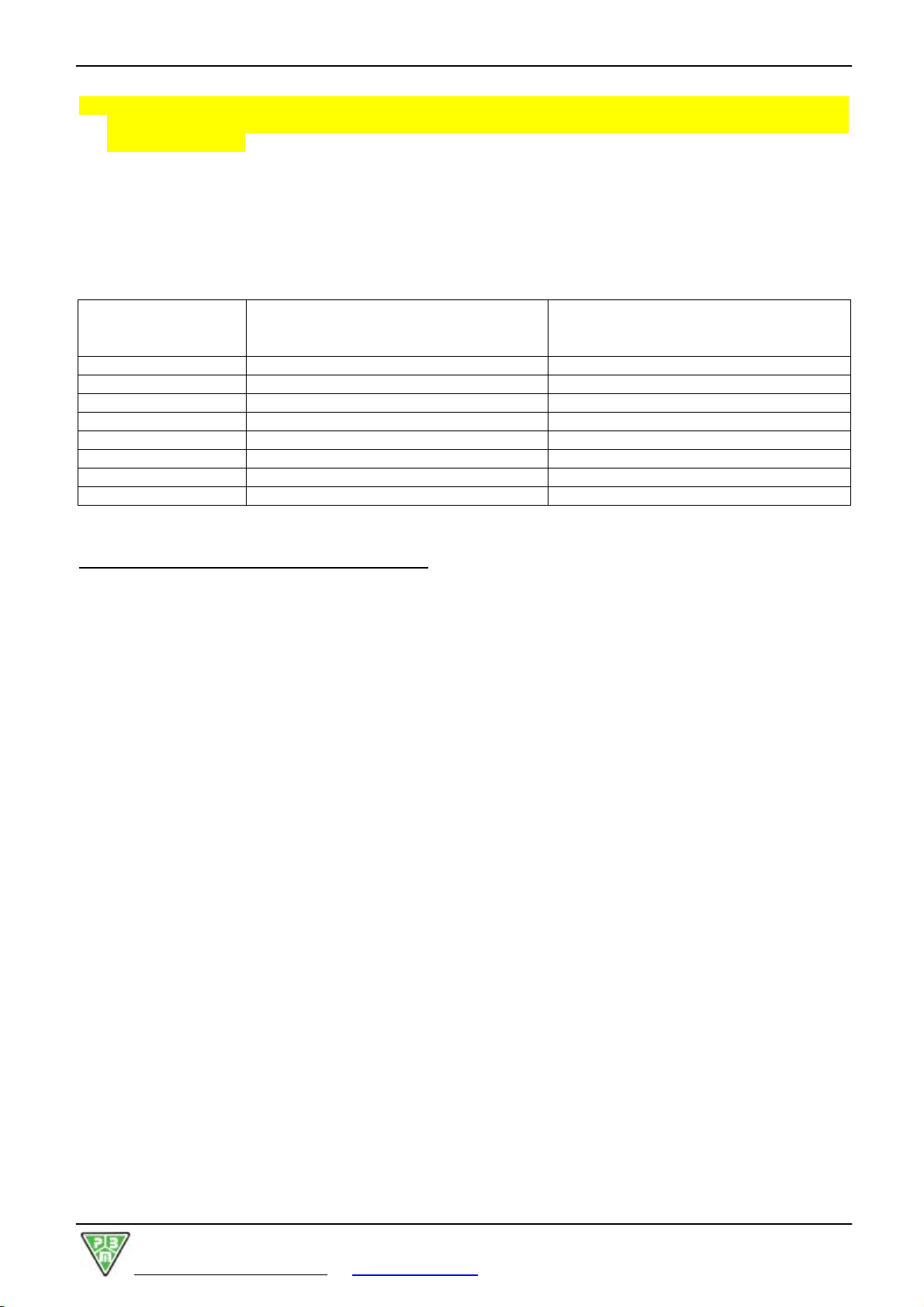

•Asfor single-phase and three-phase battery chargers,the no-loadoutputvoltage correspondstothe

valuescontained inthe following table(provided that transformeriscorrectlypowered).

RATEDBATTERY

VOLTAGE

NO-LOADOUTPUTVOLTAGE(DC)

FORASINGLE-PHASE BATTERY

CHARGER

NO-LOADOUTPUTVOLTAGE(DC)

FORATHREE-PHASE BATTERY

CHARGER

12V 14 ÷15V 18 ÷24V

24V 28 ÷30V 33 ÷38V

36V 42 ÷44V 50 ÷58V

40V 46 ÷48V 60 ÷70V

48V 56 ÷58V 72 ÷80V

72V 85 ÷87V 100 ÷108V

80V 95 ÷98V 110 ÷120V

96V 112 ÷115V 130 ÷150V

CHAPTER11 :MAINTENANCEAND CLEANING

All maintenance and cleaning processes have tobeperformedbyqualified, skilled, and authorised

personnel.

•Sincethe battery chargerisan electricalequipmentwithoutanymoving mechanicalpart, itdoesnotneed

anyspecialmaintenance.

•It ishoweversuggested tocheck,inspect, and clean the charger atleastonce ayear ifitoperatesina

fairly“clean”environment.

•In“hard”conditions, that isindustyand wet environments, checkshavetobe performed more frequently.

The maincheckstobe performed arethe following:

−Placethe charger/soutdoorand removethe closing panel.

−Wearafaceplateand protection devices.Using compressed air,removedustaccumulated inside the

charger.

−Usenon-corrosivedetergentstoremovesludge depositsorotherdirt.

Oncethe chargerhasbeen cleaned, performthe following actions:

−Check the generalcondition ofcomponentsand theirintegrity.

−Replaceoxidized cablesand/orterminals, ifany.

−Useproperspraystoclean electricalcontactson contactors, switches, and commutators.

−Check the tightening ofscrewsand bolts, replacethe rusted items, ifany.

−Performa“dry cleaning”oruseproperspraystoclean electroniccards.

−Check the statusofbothcontroland powerconnectors.Check the “wear” ofpowerconnectorsand

replacethem, ifnecessary.

−Check the condition ofelectricalplugs.

−Onceall the above-mentioned operationshavebeen performed,closepanels,doorsand coversagain,

and placethe charger/sinits/theirposition/sagain.

TECHNICAL MANUAL "SE"(PBM753) Revisionno. 1dd. 01/02/2017

P.B.M. S.r.l. viaBarella, Z.I. -VIGNOLA(MO )ITALIATel. +39 (059)7705311 Fax+39 (059)7705300

http://www.gruppopbm.ite-mail : pbm@gruppopbm.it file: ManualeSE PBM753 GBrev.1.doc

page 17

CHAPTER12:WIRING DIAGRAMS AND PARTSLIST

PARTSLIST“SE” THREE-PHASE see wiring diagramsn° HC01/3

F2 Battery side output fuseNH00 ........ A-T

TL 3-polemainscontactor+NC / 24VAC

PT Thermalcut-out on transformer

CT Terminalboardforvoltage change 230/400 V

CM Terminalboardformainsregulation

TA Auxiliary transformer30VA 0-230-400-420-440V/ 0-24V

TR Three-phasetransformerTAseries

RD Diode rectifierbridge PTSxxx/E

SH1 Shunt 100A/100mVor200A/100mV

P1 ON/OFF green button

PBM753 ElectroniccontrolcardwithmicroprocessorV1.1

F1Fuseforcardpowersupply(5x20 glass 500mAquick)

PARTSLIST“SE” SINGLE-PHASE see wiring diagramsn° HD01/2

F2 Battery side output fuseNH00 ........ A-T

TL 4-poleNO mainscontactorNO / 24VAC

PT Thermalcut-out on transformer

CM Terminalboardformainsregulation

TA Auxiliary transformer30VA 0-220-230-240-250V/ 0-24V

TR Mono phasetransformerC2Aseries

RD Diode rectifierbridge PMSxxx

SH1 Shunt 100A/100mVo200A/100mV

P1 ON/OFF green button

PBM753 ElectroniccontrolcardwithmicroprocessorV1.1

F1 Fuseforcardpowersupply(5x20 glass 500mAquick)

Table of contents

Other P.B.M. Batteries Charger manuals