P-Tronic 40P User manual

Instruction Manual GB

P-Tronic 40P - P-Tronic 70 - P-Tronic 100

This manual is completed by the “CE Operating and service maual” Edition Rev.20130304

P-Tronic 40P - 70 - 100

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

INDEX

Chap. Description Page

Introduction

1. Conformity declaration 1

1.1 RAEE Norm 2

1.2 safety precautions 2

1.3 thermal limits (en 60974-1) 2

2. Safety device 3

2.1 Safety device signal 3

3 Explanation of technical specication 3

3.1 Technical specication table 4

4 Start-up and use 4

4.1 Main supply connection 4

5. P-TRONIC 40P general description 5

5.1 P-TRONIC 40P front pannel description 5

6 P-TRONIC 40P optional kit air reducer 5

6.1 P-TRONIC 40P assembling of the optional

pressure reducer 5

6.2 P-TRONIC 40P use of the equipement 6

7. P-TRONIC 70 general description 7

7.1 P-TRONIC 70 installation 7

7.2 P-TRONIC 70 front pannel description 7

8. P-TRONIC 70 standard stand o- grating

- gouging 7

8.1 P-TRONIC 70 standard stand o 8

8.2 P-TRONIC 70 grating 8

8.3 P-TRONIC 70 gouging 8

Chap. Description Page

9. P-TRONIC 70 use of the equipement 9

10. P-TRONIC 100 general description 9

10.1 P-TRONIC 100 Installation 9

10.2 P-TRONIC 100 front panel description 9

11. P-TRONIC 100 standard stand o –

grating – gouging 10

11.1 P-TRONIC 100 standard Stand O

in Solid Cutting 11

11.2 P-TRONIC 100 standard Solid Cutting 12

11.3 P-TRONIC 100 grating 12

11.4 P-TRONIC 100 gouging 13

12. P-TRONIC 100 use of the equipement 13

13. Complete torch TER - 80 direct 14

14. Complete torch TER - 80 15

15. Complete torch TER - 100 16

16. Machanized applications

complete torch TER - 100M 17

17. P-TRONIC 40P spare Parts 18

18. P-TRONIC 40P electric wiring diagram 19

19. P-TRONIC 70 spare Parts 20

20. P-TRONIC 70 electric wiring diagram 21

21. P-TRONIC 100 spare Parts 22

22. P-TRONIC 100 electric wiring diagram 23

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

WARNING

IMPORTANT: BEFORE STARTING THE EQUIPMENT, READ THE CONTENTS OF THIS MANUAL, WHICH MUST BE STORED IN A PLACE FAMILIAR TO ALL

USERS FOR THE ENTIRE OPERATIVE LIFE-SPAN OF THE MACHINE.THIS EQUIPMENT MUST BE USED SOLELY FOR CUTTING OPERATIONS.

INTRODUCTION

To obtain the best performance from the machine and ensure the longest possible life of all its components you must careully follow the instructions for use and

maintenance detailed in this manual. In the interest of our customers we suggest any maintenance or repair of the equipment is made by qualied personnel.

All our products are subject to a constant development. We are therefore constrained to reserve the right to make any necessary or useful changes in design and

equipment.

ROUTINE MAINTENANCE

Prevent metal powder from accumulating inside the equipment. Disconnect the power supply before every operation ! Carry out the following periodic controls on

the power source:

• Clean the power source inside by means of low-pressure

compressed air and soft bristel brushes.

• Check the electric connections and all the connection cables.

For the use and maintenance of the pressure reducers, consult the specic manuals.

1. Conformity declaration

The machines descripted in this manual, P-TRONIC 40P, P-TRONIC 70, P-TRONIC 100, must be used solely for professional purposes in an industrial environment

and they are manufactured in compliance with the instructions contained in the harmonized standard EN50199 (electromagnetic compatibility) and EN60974-1.

IN CASE OF BAD OPERATION YOU DEMAND THE ATTENDANCE OF QUALIFIED STAFF.

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

1. Conformity declaration

TER SRL – 36030 Caldogno (VI) – Italy

declares that the machines descripted in this manual must be use solely for professional purposes

in an industrial environment and they are manufactured in compliance with the instructions con-

tained in the harmonized standard:

2006/95/CE (LDV) – 2004/108/CE (EMC) – 2002/95 (RoHs)

and with the instructions contained in the harmonized standard,

if applicable:

EN 60974-1 EN 60974-2 EN 60974-3 EN 60974-5 EN 60974-7

EN 60974-10 EN 60974-12

Date 30/01/2012 Maurizio Terzo

General Manager

IN CASE OF BAD OPERATION YOU DEMAND THE ATTENDANCE OF QUALIFIED STAFF

- 1 -

The equipment don’t compiles with EN/ IEC 61000-3-12.

The installer or the user must be sure that it can be connected to the public low voltage power line,

if necessary, in consultation with the network distributor.

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

1.1 RAEE Norm

The symbol on the product or on its packaging indicates that this product may not

be treated as household waste. Instead it shall be handed over to the ap-

plicable

collection point for the recycling of electrical and electronic equipment. By

ensuring

this product is disposed of correctly, you will help prevent potential negative

consequencesf or the environment and human health, which could otherwise be

caused by inappropiate waste handling of this product. For more detailed infor-

mation about recycling of this product, please contact your local city oce, your

household waste disposal service or the shop where you purchased the product.

1.2 SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE HARMFUL TO YOURSELF AND

OTHERS. The user must therefore be educated against the hazards, summarized

below, deriving from welding operations.

1.3 THERMAL LIMITS (EN 60974-1)

a) The use of a cutting equipment is normally not continuous, since there are actual

work periods (cutting time) and pause periods (positioning work pieces etc.).

This cutting unit has been manufactured to supply the maximum nominal current

I2 in complete safety for a working time of ED% of the total time. The standards in

force, state a work period of 10 minutes. The maximum duty cycle is the ED of the

data check. If you exceed the recommended work/pause periods, you will cause

overheating of the machine components that could put it out of order.

A thermal protection device is then activated, shown by the turning on of LED lo-

cated on the front Panel.

After a few minutes this device automatically turns on the machine, the LED goes

o and the machine is ready for use again.

b) These machine is built according to IP 21 CS protection standards.

ELECTRIC SHOCK – May be fatal.

Install and earth the welding machine according to the applicable regu-

lations. Do not touch live electrical parts or eletrodes with bare skin,

gloves or wet clothing. Isolate yourselves from both the earth and the

workpiece. Make sure your working position is safe.

FUME AND GASES – May be hazardous to your health.

Keep your head away from fumes.

Work in the presence of adequate ventilation, and use ventilators

around the arc to prevent gases from forming in the work area.

ARC RAYS – May injure the eyes and burn the skin.

Protect yuor eyes with welding masks tted with ltered lenses, and

protect your body with appropiate safety garments.

Protect others by installing adequate shields or curtains.

RISK OF FIRE AND BURNS

Sparks (sprays) may cause res and burn the skin; you should

therefore make sure there are no ammable materials in the area, and

wear appropriate protective garments.

NOISE

This machine does not directly produce noise exceeding 80dB. The

plasma cutting/welding procedure may produce noise levels beyond

said limit; users must therefore implement all precautions required by law.

PACEMAKERS

The magnetic fields created by high currents may affect the operation of pace-

makers. Wearers of vital electronic equipment (pacemakers) should consult

their physician before beginning any arc welding, cutting, gouging or

spotwelding operations.

EXPLOSIONS

Do not cut in the vicinity of containers under pressure, or in the

presence of explosive dust, gases or fumes. All cylinders and pressu-

re regulators used in cutting operation should be handled with care.

PLASMA ARC can injure.

Keep your body away from nozzle and pla-

sma arc. Operate the pilot arc with caution.

The pilot arc is capable of burning the ope-

rator, others even piecing safety clothing.

- 2 -

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

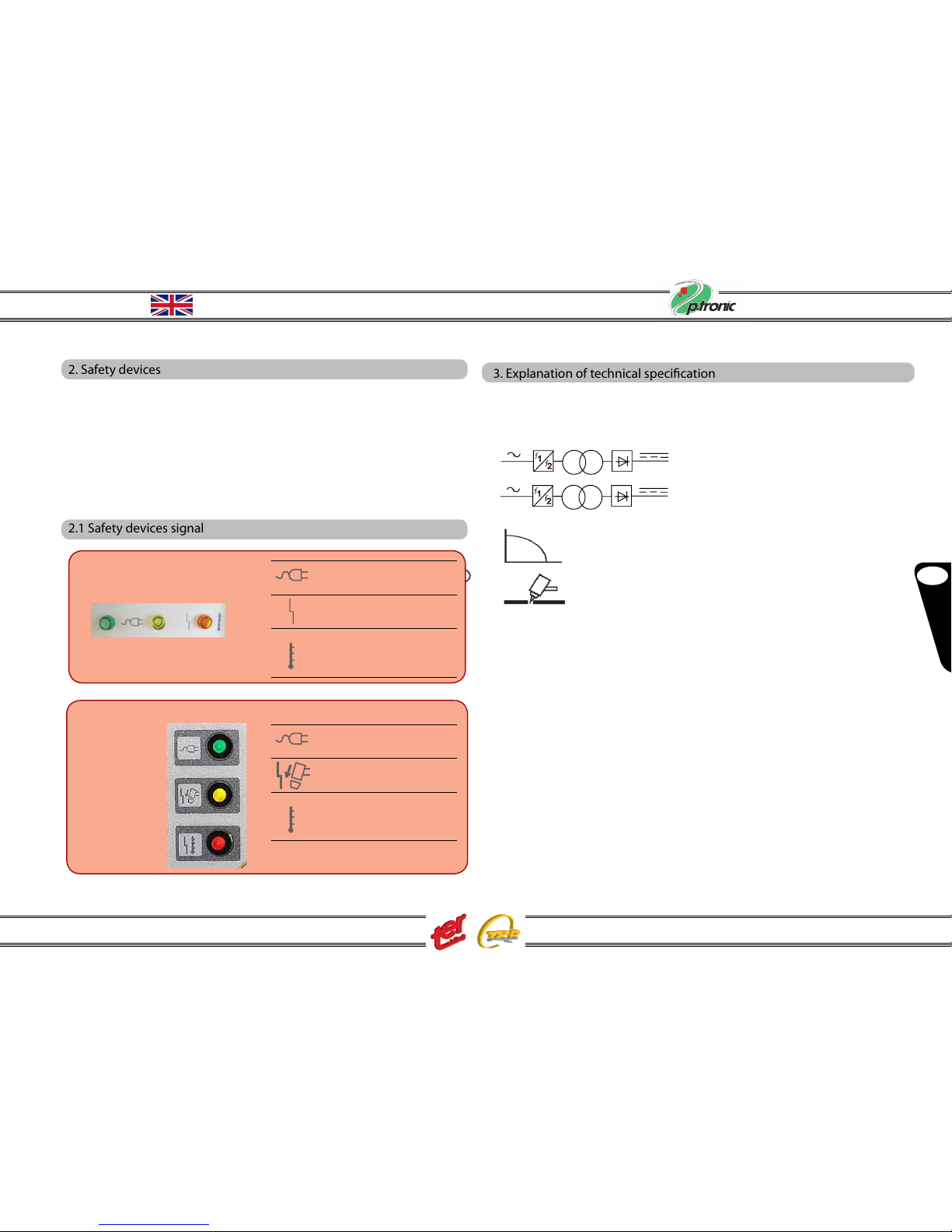

Led P-Tronic 70 - 100

2. Safety devices

This system comes equipped with the following safety devices: (see table 1 )

Overload cut out: to avoid overload while cutting.

Pneumatic: located on the torch inlet to prevent low air

pressure.

Electrical:

* In the event of the main voltage is too low or too high.

* In the event of torch maintenance with main power on. In this event all cutting

function are prevent

2.1 Safety devices signal

Led P-Tronic 40P

Green Led ON/OFF

Allarm when torch

nozzle is loose

Alarm when over load,

over current supply

voltage outside limits

Green Led ON/OFF

Alarm when torch

nozzle is loose

Allarm when over load,

over current, supply

voltage outside limits

3. Explanation of technical specication

EN 60974.1 The machine has been built according to this European standards

EN 60974.10

N............ Serial number. Always indicate this for any request

Single phase static transformer rectier

frequency converter, inverter.

Three phase static transformer rectier

frequency converter, inverter.

Drooping characteristic.

Suitable for plasma cutting.

TORCH TYPE.. Type of torch that may be used with this machine.

U0 ................... Secondary open-circuit voltage Peak value.

X%................... Percentage duty cycle.

The duty cycle expresses the percentage of 10 minutes for

which the machine may work at a certain current I2 and

voltage U2 without overheating.

I2...................... Cutting current.

U2.................... Secondary voltage at cutting current I2.

This voltage in measured when cutting with the gas nozzle

in contact with the work piece.If this distance increases,

the cutting voltage also increases and the duty cycle X%

may drop.

U1.................... Main supply voltage

1/3~50/60 Hz... Single phase 50/60 Hz power supply, treephase 50/60Hz

I1...................... Primary supply current at the corrispondind cutting current

I2 and cutting voltage U2 .

IP21S............... Housing protection rating.

3

3

1

- 3 -

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

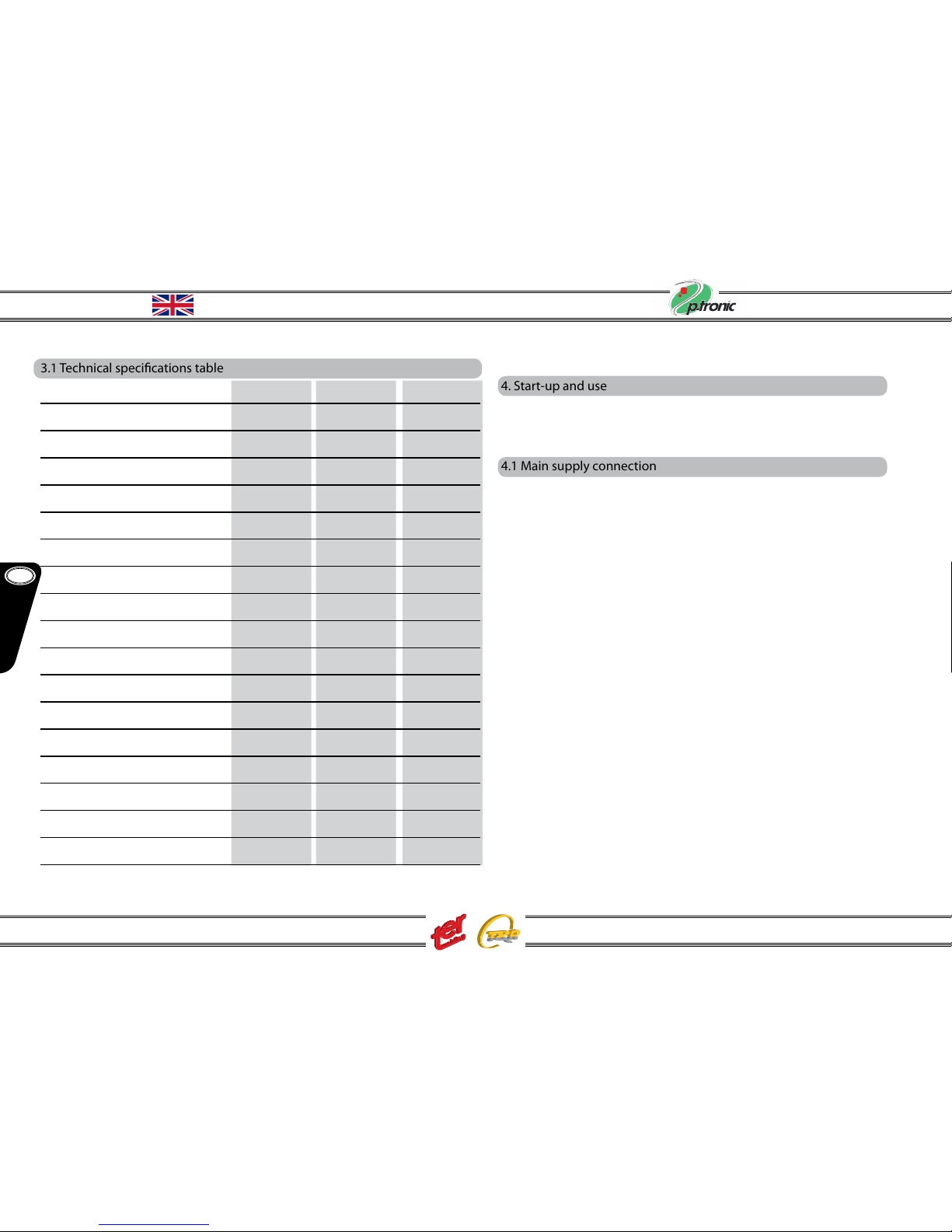

3.1 Technical specications table

Technical data P-Tronic 40P P-Tronic 70 PTronic 100

Code V0042AA VOO82AA V0059AA

Main supply (-10%/+15%) VAC 1Ph x 230V 3Ph x 400V 3Ph x 400V

Frequency Hz 50/60 50/60 50/60

Main power (60%) KVA 6 / ED50% 11 16

Open current voltage V0 V 260 280 310

Current range I2 A 20 ÷ 40 20 ÷ 70 20 ÷ 100

Cutting current I2 (X%) A 40A + ED50% -------- ----------

Cutting current I2 (60%) A 36 70 100

Cutting current I2 (100%) A 25 55 75

Recommended cutting capc. mm 12 18 22

Maximum cutting capacity mm 20 25 30

Severence cutting capacity mm 30 35 40

Gas pressure (torch 6 m.). bar 4,5 ÷ 5 5,5 ÷ 6,0 5,5 ÷ 6,0

Insulation class F F F

Protection degree IP 21S 21S 23

Dimensions mm 310x180x480 360x350x630 610x340x680

Weight Kg 9 25 39

4. Start-up and use

The machine must be installed by qualied personnel. All connections must be

made in compliance with current safety standards and full observance of

safety regulations.

4.1 Main supply connection

Connect the power cord A: the yellow-green cable wire must be connected to an

ecient grounding socket on the system. The remaining wires must be

connected to the power supply line by means of a switch placed as close as pos-

sible to the cutting area, to allow it to be shut o quickly in case of emergency.

The capacity of the cut-out switch or fuses installed in series with the switch must

be equal to the current I1 absorbed by the machine. The absorbed current I1 may

be determined by reading the technical specications shown on the machine

under the available supply voltage U1 . Any extension cords must be sized

appropriately for the absorbed current I1.

- 4 -

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

5. General description

This apparatus is a constant direct current (DC) generator, designed to cut

electro conductive materials (metals and alloys) by a plasma arc process. The

plasma gas is generated by using compressed air.

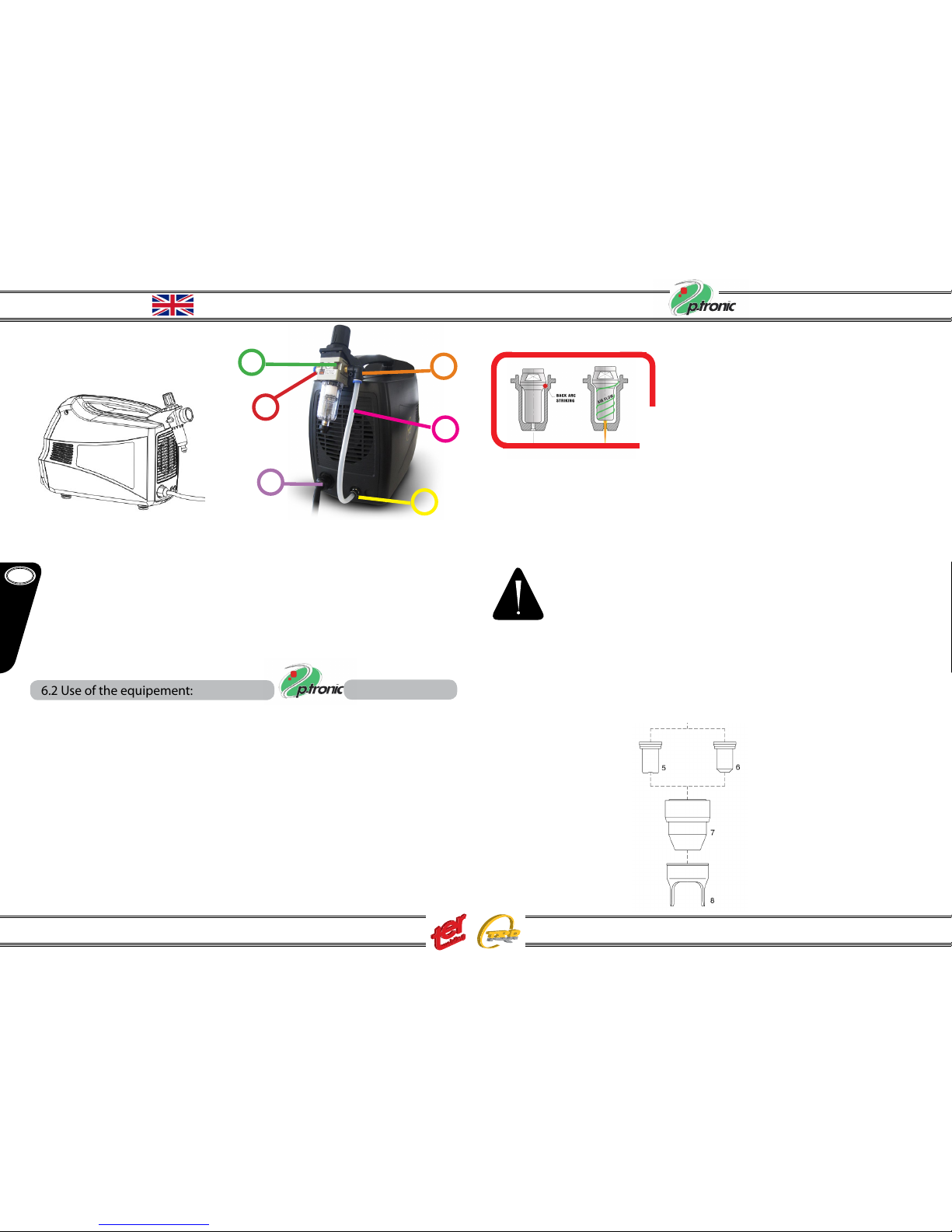

5.1 Front panel description P-Tronic 40 model

56

4

7

3

2

1

1 Output current knob: it sets the output cutting current

2 ON/OFF switch: it turns the apparatus on and o.

3 Manometer: it shows the air pressure (bar) during the cut – using the gas pressure

reducer knob, it must be positioned at 4,5 – 5,0 bars

4 Earth clamp socket

5 ON/OFF led: it lights up when machine is ON

6 Safety led : it lights up when the torch safety circuit is activated

7 Thermal and over-voltage led: it lights up in case of thermal problems or wrong volta

ge supply

8 Torch output

WARNING: the generator is equipped with a TER PT-80 plasma torch,

cod. ZO132AA 6 mt long. This torch has to be considered as integral

part of the generator and its functioning and safety are guaranteed

only with the original torch. For any spare parts refer to the appendix

list. The torch is equipped with a safety circuit which prevents any

accidental contacts with conductive elements: the generator does

not work if the safety circuit is activated.

Switch always the machine OFF when working on the torch.

6. Optional kit - Air reducer P-Tronic 40

The P-Tronic 40 generator is equipped with a manometer but the air pressure reg-

ulation must be set with a pressure reducer that has to be connected externally.

The optional kit “Pressure reducer P-Tronic 40” cod. Z0157AA consists in a pres-

sure reducer and relevant xing hanger.

6.1 Assembling of the optional Pressure reducer P-Tronic 40 kit

Proceed as shown in the pictures:

Step 1:

Insert the hanger on the handle

Step 2:

Rotate the hanger of about 90°

until the closing “click”

- 5 -

P-Tronic 40P

P-Tronic 40P

P-TRONIC 40P

8

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

Step 4:

The reducer has an “IN” nipple that has

to be connected to the compressed air

net and an “OUT” nipple: provide an 8x6

teon tube of about 30 cm to link the out-

put nipple “OUT” with the machine air in-

put nipple positioned on the back of the

machine.

Step 3:

Put the hanger on the handle back

side and x the reducer using the

proper ring nut

23

5

1

4

6

IN nipple

Supply Cable

Air Input

Filter/Reducer OUT nipple

Teon

tube

E) Press the torch trigger: the pilot arc stricks, becoming cutting arc as

soon as you will place the torch on the work

piece. The P-TRONIC 40 generator does

not work with high-frequency arc ignition:

it uses the no HF technology with BACK

STRIKING system. The torch can work only

if the generator is connected to the com-

pressed air plant

F) The pilot arc stops automatically after about 5 seconds if you do not place

the torch on the work piece

G) Check the manometer value and adjust eventually the air pressure

H) Once the cutting process is terminated release the torch trigger: the air

ow will continue to allow the cooling down of the torch

Warning: never aim the plasma jet towards people or

foreign objects !

6.2 Use of the equipement:

A) Connect the earth clamp cable to the work piece

B) Connect the machine to the power supply net and turn ON the power

switch (position 2. page. 5); the ON/OFF led (position 5 page. 5) light on

C) Check the air pressure on the manometer as indicated in the previous

paragraph

D) Set the current value with the knob (1st position fig. pag. 5) according to

the work piece tickness

According to the cutting type and mode, the torch must be equipped with suitable

spare parts. The P-Tronic 40 generator enables either the contact or stand-o

cutting.If you have to make a precision cut on sheet metal and when the spacer (8)

cannot be used, we recommand the Tip 0,9 (5) code Z0050AA. In case of spacer/

stand o cutting, use the Tip 1,0 (6) code Z0051AA.

- 6 -

P-Tronic 40P

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

P-TRONIC 70

7. PLASMA P-TRONIC 70 General description

This apparatus is a constant direct current (DC) generator, designed to cut

electro conductive materials (metals and alloys) by a plasma arc process.

The plasma gas is generated by using compressed air.

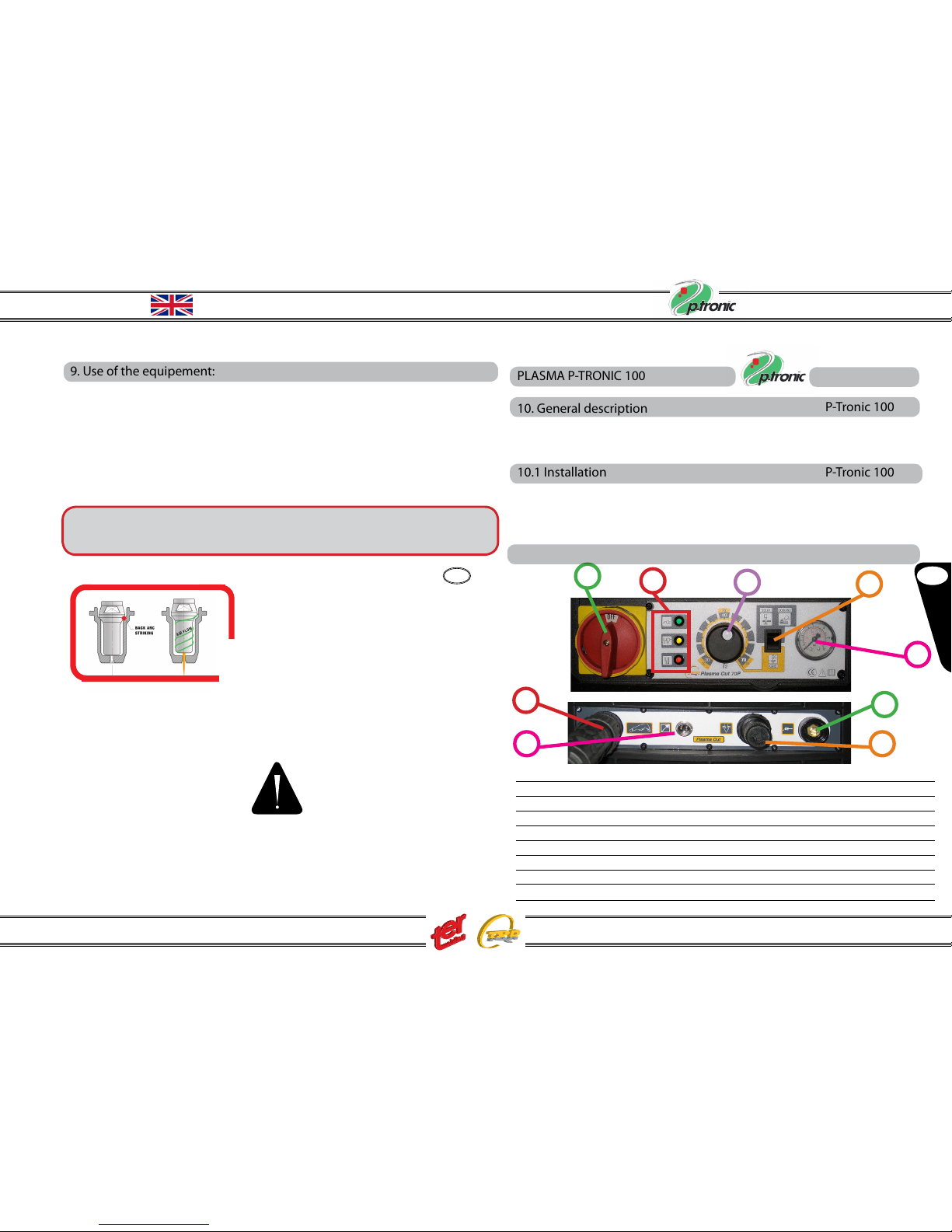

7.1 Installation

The machine needs to be supplied with clean and dry air. Set the air pressure

at 5,5-6,0 bars and make sure it does not change during the cut; a bad and/or

uncorrect air supply generates problems on the cutting quality and the torch

might be damaged too.

1 Output current knob: it sets the output cutting current

2 Manometer: it shows the air pressure (bar) during the cut

3 Cutting mode selector: grating, standard stand o, gouging

4 Earth clamp socket

5 pressure regulator knob

6 remote control socket

7 torch connector

8 ON/OFF switch

9 Monitor Led (see page 2)

8

3

4

9

2

1

5

7

6

- 7 -

7.2 Front panel description P-Tronic 70 model

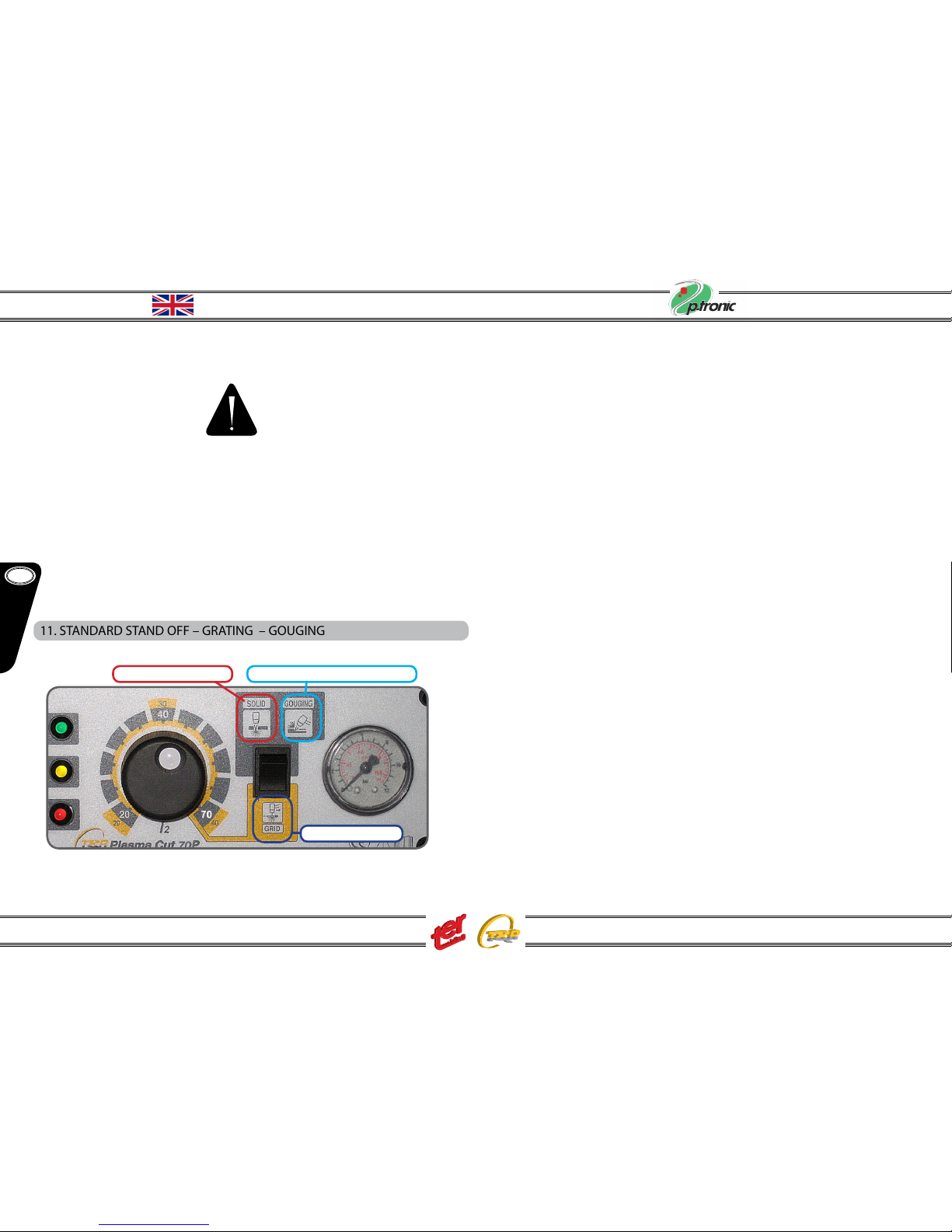

The generator can work in three dierent modes:

8. STANDARD STAND OFF – GRATING – GOUGING

SOLID CUT GOUGING APPLICATION

GRATING CUT

WARNING: the generator is equipped with a TER PT-80 plasma torch, cod

Z0133AA 6 mt long. This torch has to be considered as integral part of the

generator and its functioning and safety are guaranteed only with the origi-

nal torch. For any spare parts refer to the appendix list.

The torch is equipped with a safety circuit which prevents any accidental

contacts with conductive elements: the generator does not work if the safety

circuit is activated.

Switch always the machine OFF when working on the torch.

P-Tronic 70

P-Tronic 70

P-Tronic 70

P-Tronic 70

P-Tronic 70

P-TRONIC 70

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

In certain applications the contact cutting may be required even with currents over the 40A (ex. high

cutting speed on thin metal sheet or on high ticks where a high cutting precision is required).

Inthoseapplications,use the spare parts described in the picture:

pos (9) Currents until 50A Tip diam 1,0 cod Z0145AA

pos (9) Currents until 70A Tip diam 1,1 cod Z0146AA

pos (9) Currents over 70A Tip diam 1,2 cod Z0147AA

pos 11 Use Shield cup body cod Z0089AA

pos 12 Use Shield cup hand cod Z0140AA

NOTE: the spare parts are the same even if a straight automatic torch is used

- 8 -

8.1 Standard Stand O

This is the typical and most commun cutting type; you can adjust the current from a minimum

of 20A to a maximum of 70A. Once the cutting is terminated the arc strikes off and it can be

reactivated pressing the torch trigger once again. Use always the spacer (8) unless you have

particular precision needs as described in “GRATING” paragraph.

Electrode (3) and gas diffuser (4) remain always the same for all applications and currents:

pos (3) Electrode cod. Z0048AA

pos (4) Gas diuser cod. Z0049AA

pos (7) Outer nozzle cod. Z0055AA

Chose tip size (5) for contact cutting without the spager (8) the current set must be

lower than 40A. Pos (5) contact tip 0,9 cod: Z0050AA

Choose the tip size (6) according to the used current. Consider that the cutting width

is about twice as much the tip diameter:

currents until 50A Tip diam 1,0 mm cod. Z0051AA

currents from 50 up to 70A Tip diam 1,2mm cod. Z0053AA

8.2 Grating

In GRATING cut position, the minimum current stays at 20A and the maximum at 40A.

When the arc moves from the solid to the grating open area, the generator re-

turns automatically in pilot arc condition and the cutting arc starts again touch-

ing a new solid area. We recommand the stand o spacer to improuve the

spare parts life and the use of the tip (6)

Currents until 30A cod: Z0087AA (diam 0,8)

Currents until 40A cod: Z0051AA (diam 1,0)

Consider that the cutting width is about twice as much the tip diameter. This

position (grating) is suggested even for precision cuttings, on thin metal sheets

(thickness less than 6 mm): use a tip for contact cuttig and spare parts as

shown in position 5 of the picture.

Take off the spacer (8) and use the Tip position (5) cod. Z0050AA (diam 0,9)

8.3 Gouging

In GOUGING position you can remove material with a high eciency; the cur-

rent regulation from 20A up to 70A enables the increasing of the groove’s deep.

The torch spare parts remains the same for each current regulation:

pos 10 Tip gouging cod: Z0088AA

pos 11Shield cup body cod: Z0089AA

pos 13 Shield cup hand cod: Z0090AA

P-Tronic 70 P-Tronic 70

P-Tronic 70

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

- 9 -

9. Use of the equipement:

A) Connect the earth clamp cable to the work piece

B) Connect the machine to the power supply net and turn ON the power

switch (8). The green led ON/OFF light on

The yellow led lights up if the torch safety circuit is open

The red led lights up in case of low pressure, wrong voltage supply, or

thermic alarm

C) With the selector (3), choose the cutting mode

D) Check the air pressure on the manometer and adjust eventually by using

the pressure reducer knob ( 5) at 5,5-6 bars. Make sure the pressure stays

at the same level during cutting

E) Set the current value with the knob ( 1 ) according to the basic material tickness

F) Press the torch trigger: the pilot arc stricks, becoming cutting arc as

soon as you will place the torch on the work

piece.

P-TRONIC 70 generator does not work with high-

frequency arc ignition: it uses the no HF technol-

ogy with BACK STRIKING system. The torch can

work only if the generator is connected to the

compressed air plant.

G) The pilot arc stops automatically after about 5 seconds if you do not place

the torch on the work piece

H) Once the cutting process is terminated release the torch trigger: the air

ow will continue to allow the cooling down of the torch

Warning: never aim the plasma jet towards people or foreign objects !

PLASMA P-TRONIC 100

10. General description

This apparatus is a constant direct current (DC) generator, designed to cut elec-

tro conductive materials (metals and alloys) by a plasma arc process. The plas-

ma gas is generated by using compressed air.

10.1 Installation

The machine needs to be supplied with clean and dry air. Set the air pressure

at 5,5-6,0 bars and make sure it does not change during the cut; a bad and/or

uncorrect air supply generates problems on the cutting quality and the torch

might be damaged too.

4

5

7

6

83

9

2

1

1 Output current knob: it sets the output cutting current

2 Manometer: it shows the air pressure (bar) during the cut

3 Cutting mode selector: grating, standard stand o, gouging

4 Earth clamp socket

5 pressure regulator knob

6 remote control socket

7 torch connector

8 ON/OFF switch

9 Monitor Leds

10.2 Front panel description P-Tronic 100 model

P-Tronic 70

P-Tronic 100

P-Tronic 100

P-Tronic 100

P-Tronic 100

P-TRONIC 100

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

WARNING: the generator is equipped with a TER PT-100 plasma torch, cod

Z0042AA 6 mt long. This torch has to be considered as integral part of the

generator and its functioning and safety are guaranteed only with the origi-

nal torch. For any spare parts refer to the appendix list.

The torch is equipped with a safety circuit which prevents any accidental

contacts with conductive elements: the generator does not work if the safety

circuit is activated.

Switch always the machine OFF when working on the torch.

The generator can work in three dierent modes:

11. STANDARD STAND OFF – GRATING – GOUGING

SOLID CUT GOUGING APPLICATION

GRATING CUT

- 10 -

P-Tronic 100

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

11.1 Standard Stand O in Solid Cutting

This is the typical and most commun cutting type; you can adjust the current from a minimum of 20A to a maximum of 100A. Once the cutting is terminated the arc strikes off and it can

be reactivated pressing the torch trigger once again. Use always the spacer (11) unless you have particular precision needs as described in “GRATING” paragraph.

The solid cutting can be performed in three modes:

A) Contact, precison cutting without using the spacer

B) Standard stand o for a current up to 70A

C) Standard stand o for a current higher than 70A

A) Contact precision cutting

Use Code

3 electrode Z0060AA

4 gas diuser Z0061AA

6 cutting tip 0,9 Z0063AA

9 outer nozzle Z0070AA

P-Tronic 100

B) Standard stand o for current up to 70A

Use Code

3 electrode Z0060AA

4 gas diuser Z0061AA

9 outer nozzle Z0070AA

11 double pointed spacer Z0072AA for current 40÷50 A

7 tip cutting 1,0 Z0064AA for current 40÷50A

7 tip cutting 1,1 Z0065AA for current 50÷60A

7 tip cutting 1,2 Z0066AA for current 60÷70A

C) Standard stand o for current 70A - 100A

Use Code

3 electrode Z0060AA

5 gas diuser Z0062AA

10 outer nozzle Z0071AA

11 double pointed spacer Z0072AA

8 tip cutting 1,4 Z0067AA for current 80÷90A

8 tip cutting 1,5 Z0068AA for current 100÷110A

8 tip cutting 1,6 Z0069AA for current 110÷120A

Note: the current must be set less than 40A, it is suggested the grating set.

Note: the spare parts are the same if the straight automatic

torch is used.

P-Tronic 100

P-Tronic 100

P-Tronic 100

- 11 -

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

11.3 Grating

In GRATING cut position, the minimum current stays at 20A and the maximum at 40A.

When the arc moves from the solid to the grating open area, the generator returns automatically in pilot arc condition and the cutting arc starts again touching a new

solid area. We recommand the stand o spacer to improuve the spare parts life and the use of the tip (6)

11.2 Standard Solid Cutting

Contact Cutting:

in certain applications the contact cutting may be required even with current over 40A (ex.:high cutting speed on thin metal sheet or on high ticks where an high cutting precision is required).

In those application use spare parts described in the picture.

Use for current 40÷70A code

4 gas diuser Z0061AA

15 outer nozzle Z0096AA

16 shield cup Z0140AA

12 Contact tip Ø 1,0 | for current 40÷55A Z0093AA

12 Contact tip Ø 1,2 | for current 55÷70A Z0094AA

Use for current 70÷100A code

5 gas diuser Z0062AA

15 outer nozzle Z0096AA

17 shield cup Z0097AA

13 contact tip Ø 1,5 | for current 100A Z0095AA

Use code

4 gas diuser Z0061AA

6 contact tip Ø 0,9 Z0063AA

9 outer nozzle Z0070AA

11 doubler pointer spacer Z0072AA

Consider that the cutting width is about twice as much the tip diameter.

This position (grating) is suggested even for precision cuttings, on thin metal sheets

(thickness less than 6 mm): take o the spacer 11 and use contact cutting.

P-Tronic 100

P-Tronic 100

- 12 -

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

12. Use of the equipement:

A) Connect the earth clamp cable to the work piece

B) Connect the machine to the power supply net and turn ON the power

switch (8). The green led ON/OFF light on

The yellow led lights up if the torch safety circuit is open

The red led lights up in case of low pressure, wrong voltage supply, or

thermic alarm

C) With the selector (3), choose the cutting mode

D) Check the air pressure on the manometer and adjust eventually by using

the pressure reducer knob ( 5) at 5,5-6 bars. Make sure the pressure stays

at the same level during cutting

E) Set the current value with the knob ( 1 ) according to the basic material tickness

F) Press the torch trigger: the pilot arc stricks, becoming cutting arc as

soon as you will place the torch on the work

piece. P-TRONIC 100 generator does not work

with high-frequency arc ignition: it uses the no

HF technology with BACK STRIKING system. The

torch can work only if the generator is connected

to the compressed air plant.

G) The pilot arc stops automatically after about 5 seconds if you do not place

the torch on the work piece

H) Once the cutting process is terminated release the torch trigger: the air

ow will continue to allow the cooling down of the torch

Warning: never aim the plasma jet towards people or foreign objects !

11.4 Gouging

In GOUGING position you can remove material with a high eciency; the

current regulation from 20A up to 100A enables the increasing of the groove’s

deep.

Use the following spares on the torch:

Use code

4 gas diuser Z0061AA

14 tip gouging Z0092AA

15 outer nozzle Z0096AA

18 gouging shield cup Z0090AA

P-Tronic 100 P-Tronic 100

- 13 -

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

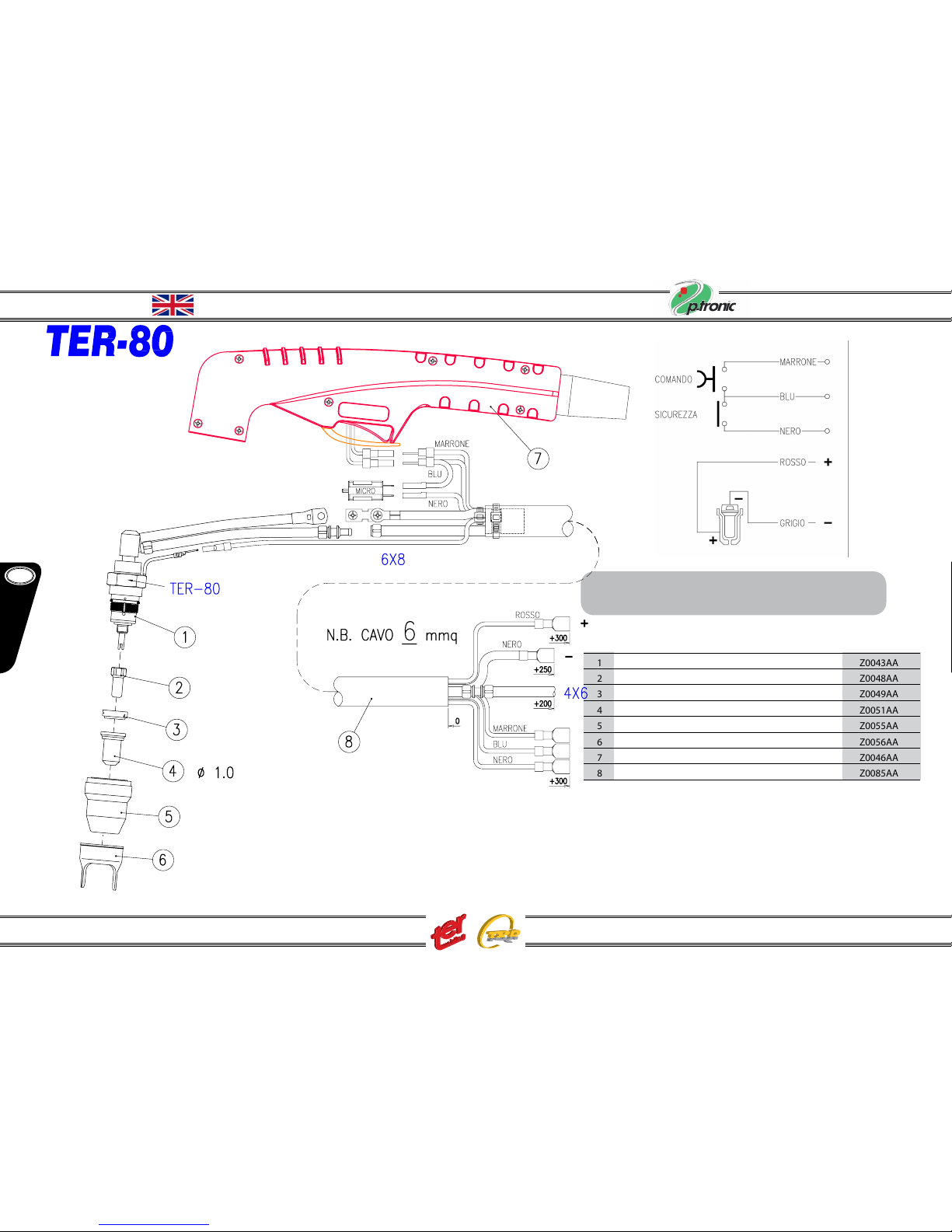

- 14 -

POS. DESCRIPTION CODE

1 TER - 80 torch body Z0043AA

2 TER - 80 electrode Z0048AA

3 TER - 80 diusor Z0049AA

4 TER - 80 tip cutting 1,0 Z0051AA

5 TER - 80 retaining cup Z0055AA

6 TER - 80 spacer 2 points Z0056AA

7 TER - 80 handle kit Z0046AA

8 TER - 80 direct 6 m. cable Z0085AA

13. TER - 80 direct (for p-tronic 40P)

Complete torch cod. Z0132AA

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

- 15 -

14. TER - 80 (for p-tronic 70)

Complete torch cod. Z0133AA

POS. DESCRIPTION CODE

1 TER - 80 torch body Z0043AA

2 TER - 80 electrode Z0048AA

3 TER - 80 diusor Z0049AA

4 TER - 80 tip cutting 1,2 Z0053AA

5 TER - 80 retaining cup Z0055AA

6 TER - 80 spacer 2 points Z0056AA

8 TER - 80 6 m. cable Z0151AA

9 TER - 80 handle kit Z0046AA

10 TER - 80 central adaptor kit Z0152AA

GB

English

Instruction Manual P-Tronic 40P - 70 - 100

POS. DESCRIPTION CODE

1 TER - 100 torch body Z0057AA

2 TER - 100 electrode Z0060AA

3 TER - 100 diusor Z0062AA

4 TER - 100 tip cutting 1,5 Z0068AA

5 TER - 100 outer nozzle Z0071AA

6 TER - 100 double pointed spacer Z0072AA

8 TER - 100 handle kit Z0046AA

9 TER - 100 6 m. cable Z0151AA

10 TER - 100 central adaptor kit Z0152AA

15. TER - 100 (for p-tronic 100)

Complete torch cod. Z0042AA

9

- 16 -

This manual suits for next models

2

Table of contents

Popular Welding System manuals by other brands

Riland

Riland TIG 200 AC/DC operating manual

MasterCraft

MasterCraft MIG 180 instruction manual

Lincoln Electric

Lincoln Electric PANTHER K2874-2 Operator's manual

Cebora

Cebora SoundMIG 2035/M Pulse instruction manual

REHM

REHM INVERTIG.PRO digital 240 DC, 240 AC/DC operating instructions

WELDKAR

WELDKAR WK PLASMA 5035 COM PFC instruction manual

INE

INE SkyLine KME 3000 TY4 operating manual

Migatronic

Migatronic AUTOMIG2 183i instruction manual

Habasit

Habasit PQ-18 Use and maintenance manual

Lincoln Electric

Lincoln Electric SAF-FRO PRESTOTIG 200 AC/DC Operator's manual

Lincoln Electric

Lincoln Electric SYNERGIC 7 AND 7H IM557 Operator's manual

Lincoln Electric

Lincoln Electric PRO-CUT SVM146-A Service manual