PA SDI-Drives Midi™ / Maxi™ Edition 07.44 Power Automation

2.3 Safe Restart Lock (only SDI/RL – Interface)

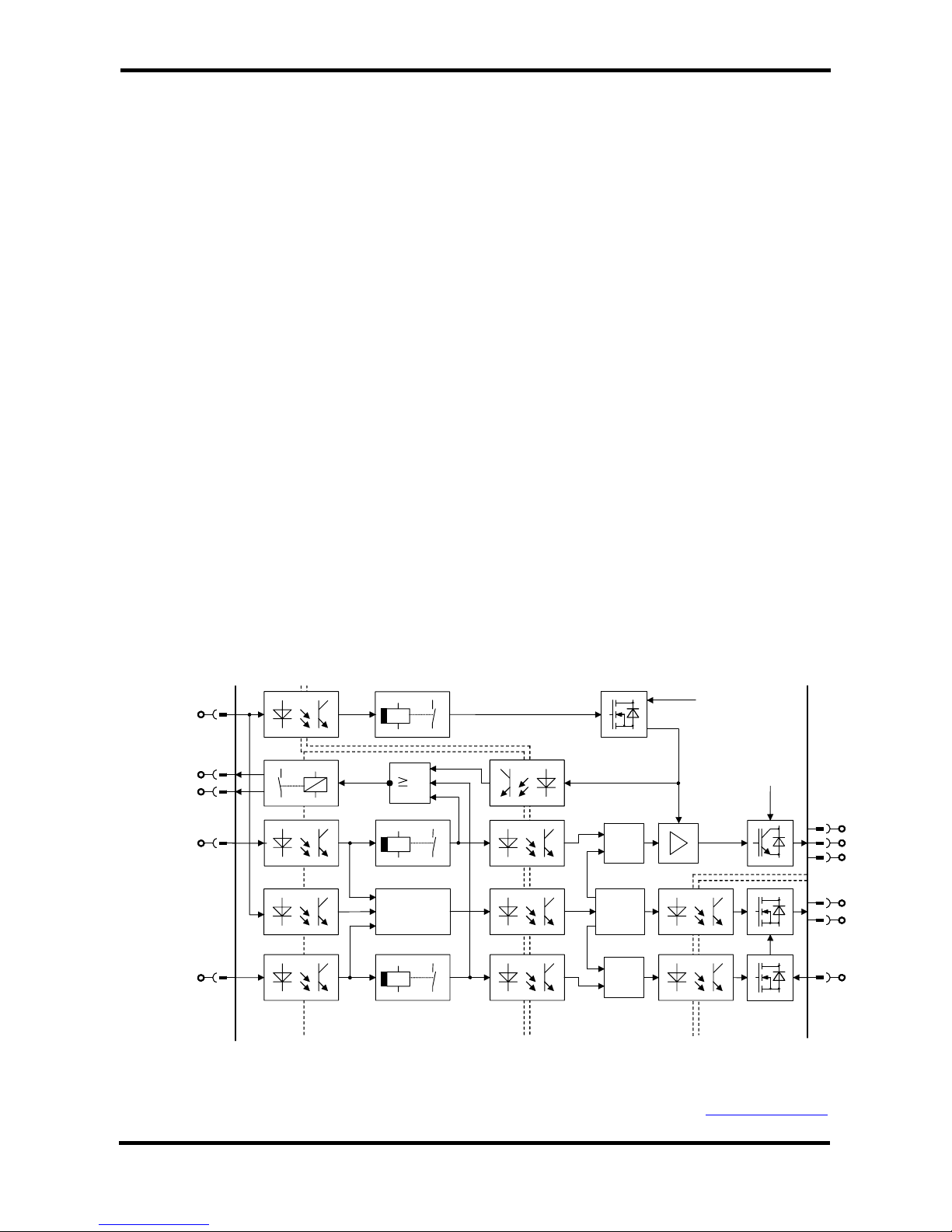

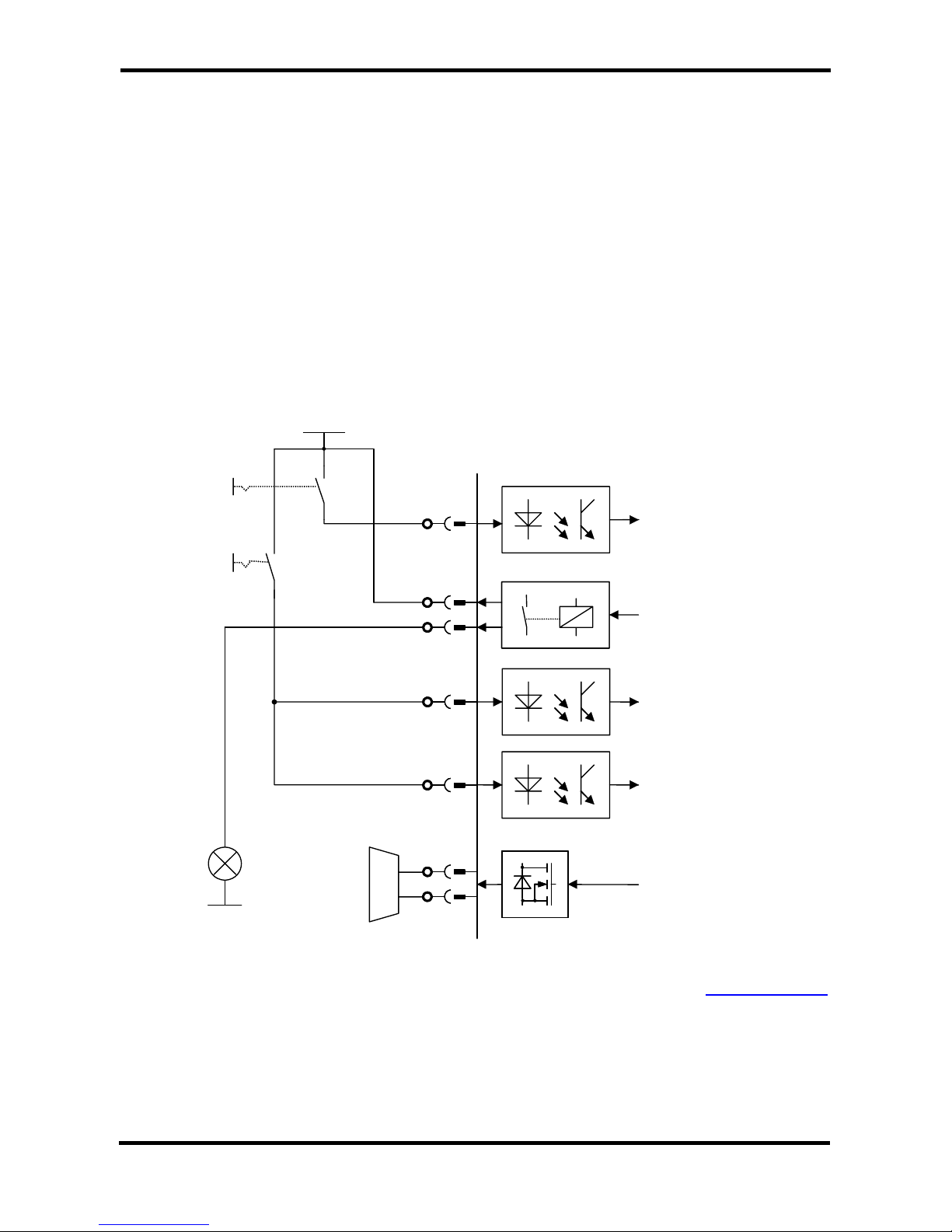

PA SDI-Drives Midi™ / Maxi™ in combination with the SDI/RL – Interface, supports the

safety function “safe restart lock” according to the requirements of the control category of

EN 954 Part 1 and Part 2 category 3 and ISO 13849 performance level “d”.

For this purpose, the drive has two independent safety paths in parallel connection.

The safety category is reached, when the signal ”SAFE LOCK” is additionally verified.

In addition to that, also the holding brake is part of the circuitry. The control category of

EN 954 Part 1 and Part 2 category 1 and ISO 13849 performance level “c” is reached for

the electrical circuitry of the holding brake processing. If the holding brake supply input

+24V-BR has an additional circuitry; the safety category can be increased.

2.3.1 Implementation

The following block diagram gives an overview over the internal circuitry.

The signals LOCK and ENABLE are directly connected to the microcontroller and also to

two independent switch-off delayed circuitries, which delay the signals in hardware for

about 0.5sec.

The delayed LOCK – signal switches off the power supply of the driver for the IGBT-power-

stage. The delayed ENABLE – signal switches off the control signals to the power stage, so

two independent signals switch off the power stage in different ways.

The signal EN-BRAKE is also galvanic isolated from the internal electronic potential by opto

coupler and is connected to a switch-off delayed circuitry, which delays the signal in

hardware for about 0.5sec. The undelayed signal is connected to the microcontroller and

the delayed signal switches off the 24V power supply of the holding brakes.

The effect of the three signals is supervised and only if all signals are in the safe state, the

relay “SAFE LOCK” closes the contact between S1 and S2.

If one or all of the signals ENABLE, LOCK or EN-BRAKE are switched off in emergency

stop condition, the drive decelerates the motors (stop category 1 according to EN 60204-1).

If all three signals are switched off, the drive is brought into the safe restart lock condition

after the delay time of 0.5sec.

Motor

Low power

supply for power

stage driver

Mains power

supply

0.5s

0.5s

µP

1

X10

S1

S2

LOCK

ENABLE

X3, X4, X5

Power stage potentialElectronic potential

Digital I/O

potential

UU

VV

WW

11

22

55

66 &

µP

B+B+

B-B-

&

24V Aux. potential

0.5s

EN-BRAKE

77 11

X1A

SAFE

Block diagram of the safe restart lock circuitry

Back to Contents

SDI Interface Manual 6