Model MMC200 Multi-Material Cutter

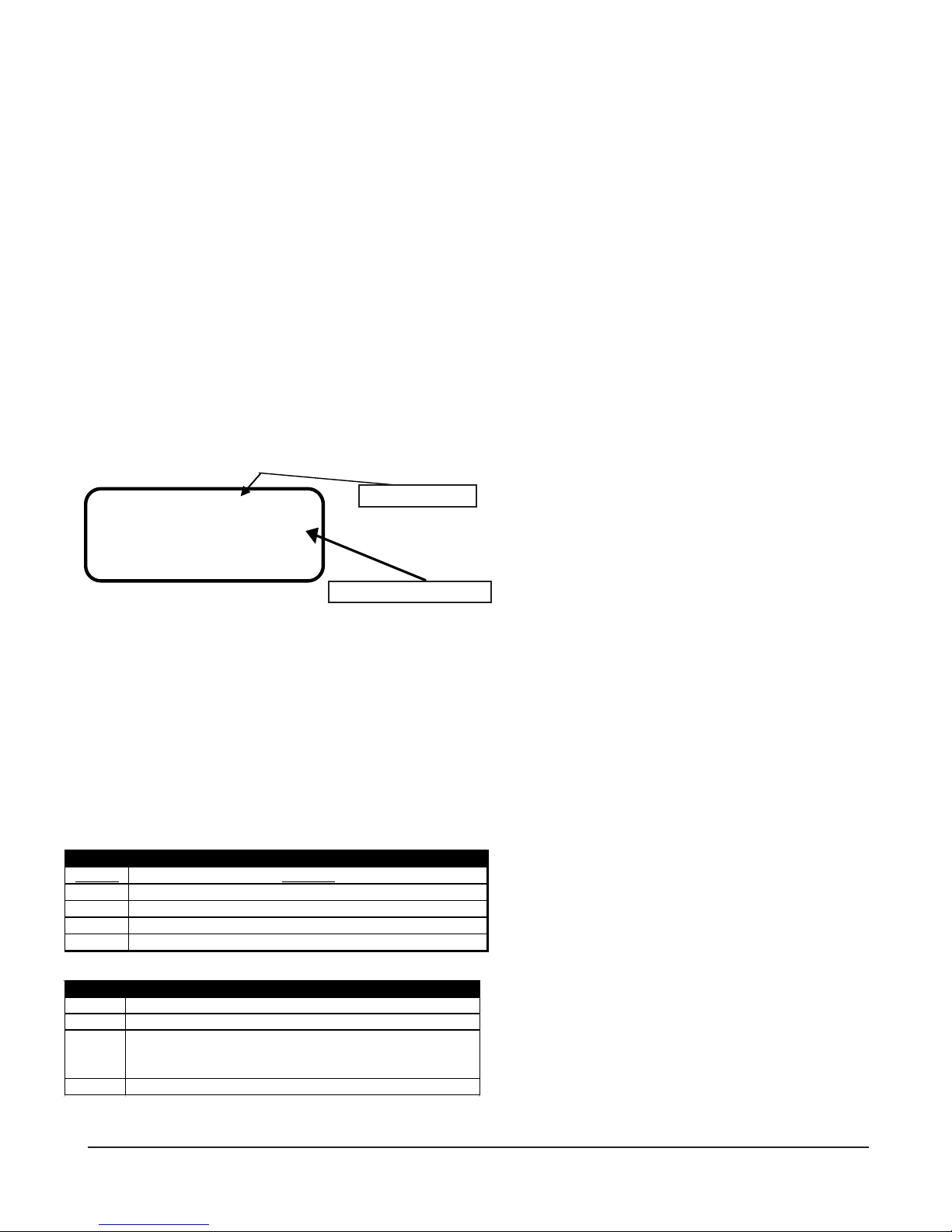

The current batch number is shown beside the #

at the top right. The cursor will be flashing just be-

fore the in (inch), indicating that the field is cur-

rently editable. In general, the line being edited will

display a blinking cursor. Press the <ENTER> key

to accept the default of inches, or press the <+>

or <-> key to toggle to cm, for centimeters, then

press the <ENTER> key to store cm. Each time

the <ENTER> key is pressed, the cursor advances

to the next parameter.

Enter a value for the length parameter. If the

<ENTER> key is pressed accidentally before a

value is entered, press the <ESC> key to go back

to the main batch select menu. If a mistake is made

during data entry, press the <BACKSPACE> key

to back space over the entry. If the <ENTER> key

has been pressed, press the <ESC> key and start

over. All values entered so far will have been stored,

so you would only have to press the <ENTER>

key until you returned to the parameter where that

is incorrect-the values would not have to be en-

tered again. The cut length parameter requires a

value between .01 and 99,999 to be entered. The

limitation here is that the value can be a maximum

of 6 characters, including the decimal place. For

example, 123456, 123.45 and 1234.5 are permis-

sible but the value 1234.56 isn’t allowed. The

MMC200 is capable of 1% cut length accuracy only,

so, it doesn’t make sense to enter a decimal place

value in lengths over 100 (inches or centimeters).

Due to variations in materials, pre-feed systems

and feed wheel pressure, actual cut length may

vary from the inputted length by a proportional

amount. If the cut lengths are consistent with each

other, the machine requires no further adjustment

to pre-feed system or feed wheel pressure. The

MMC200 incorporates a length compensation fea-

ture to provide an easy adjustment in these cases.

The length can be compensated +/-1% to +/- 10%

of the inputted length. The length compensation

display will show (-) for a negative value. Example:

If 10" (25.4cm) is entered as the desired length,

but the actual average cut piece measures 9.8"

(24.9cm), a length compensation of +2% will

increase the cut length by .200 (0.5 cm) to the

desired 10" (25.4 cm). The <+> or <-> keys may

be used to add or decrease length compensation

value. NOTE: Often it will not be known if length

compensation is needed until after a trial run is

completed. When programming a batch, leave the

field at 0 and edit the batch later if necessary to

add length compensation. Once a value has been

entered, or if the default of 0 is to be used, press

the ENTER key. The length compensation will re-

main with the batch program. An alternate, more

accurate, method would be simply to enter the

desired cut length, run several pieces, measure/

calculate the average error and add/subtract the

error to/from the targeted length as necessary (e.g.

a desired 10.00" is entered into the length param-

eter; a measured 9.82" is cut. The operator com-

pensates for this by adding 0.18" to the targeted

cut length value. The new cut length value be-

comes 10.18").

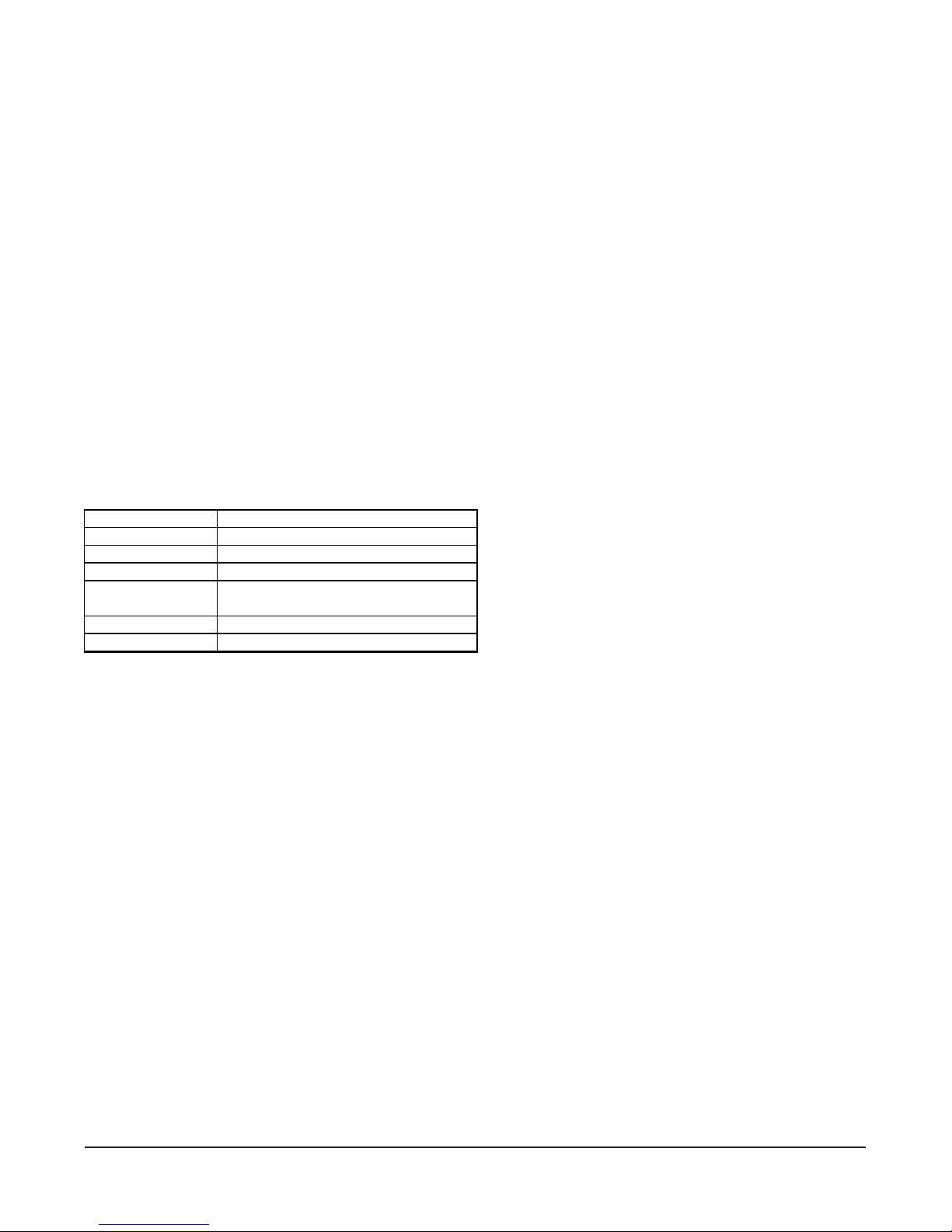

After the quantity is entered, cut rate edit screen

appears:

FEED RATE 3 #1

-MAX SPEED 8.0

-MAX ACCEL 20.0

-MAX DECEL 40.0

The default feed rate is feed rate #3, as depicted

above. The feed rate can be changed at this point

by entering a number (0 through 9) or by pressing

the <+> or <-> keys. Feed rate #3 is a good start-

ing point. Adjust this value upward if the produc-

tion rate isn’t high enough and adjust this value

down if there is a lot of slippage at the feed belts.

The units for acceleration are in revolutions per

second2 and the units displayed for speed is revo-

lution per second. Press <+> or <-> to increment

or decrement the feed rate value. As the value is

changed, the rate values are updated to show what

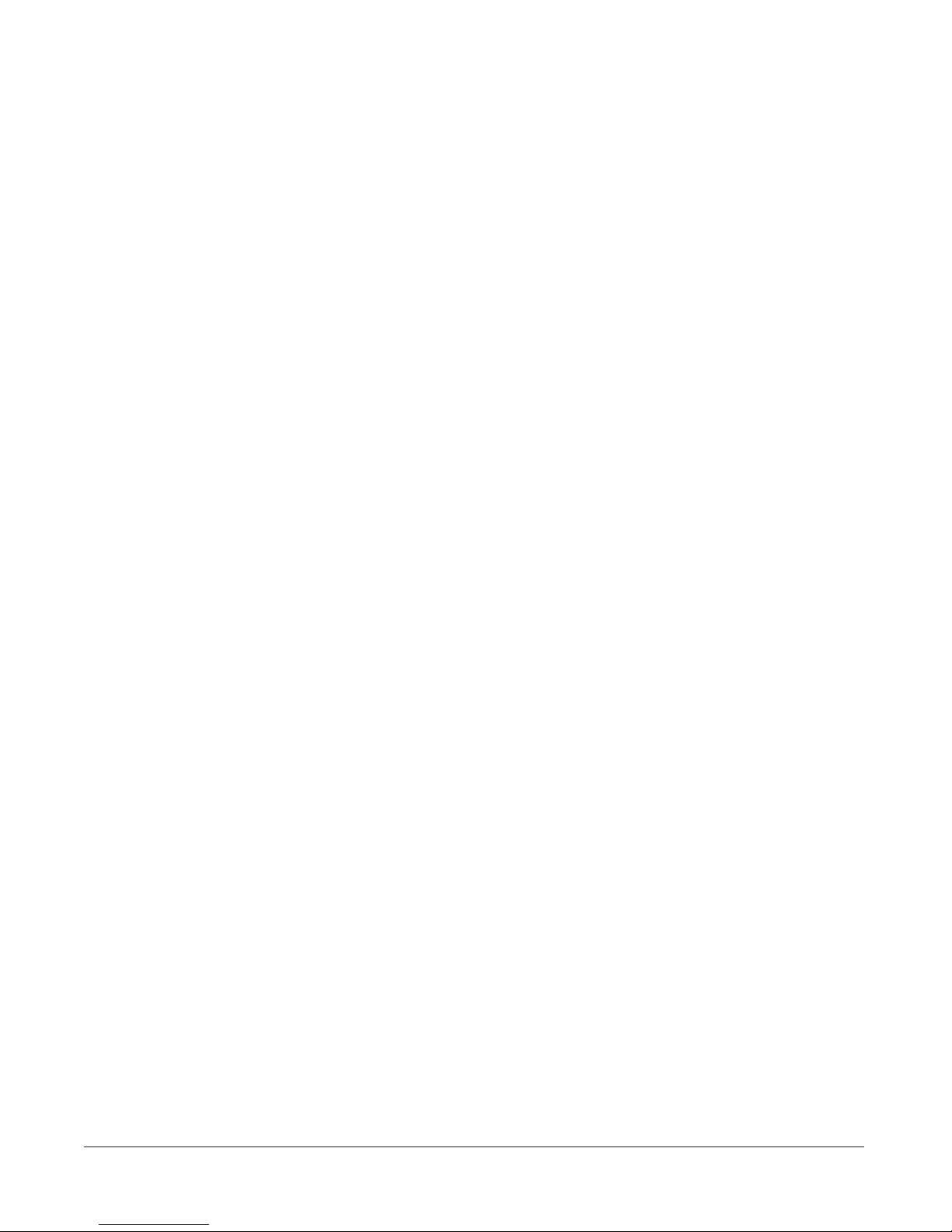

values are active for that feed rate. The following

table represents the maximum speed at any feed

rate of the feed belts:

NOTE: The slower the feed rate, the more accu-

rate in length the cut pieces will be. It is advised to

start with the lowest feed rate and check results,

then adjust the feed rate if desired.

If an incorrect key is pressed for a given param-

eter input (e.g. a number key is pressed at the

Production Automation • Eden Prairie, MN USA• Ph: 888-903-0333 • info@gotopac.com • www.gotopac.com • Fax 952-903-0315