Mount the BNC in the plate and secure using its nut. The BNC

connectors ay be supplied with a red rubber gasket that should

be re oved before installation

Install the stainless wing nut screw onto the end of the 1/4-20

bolt in the center. It is used to secure the ring ter inals for

connection of the radials.

Once the BNC is securely installed, use the sections of green

and red wire to connect fro the BNC to the cri p ter inals.

The red wire goes the center ter inal of the BNC. The red wire

will indicate the antenna end of the feed point.

Measure the necessary wire and cri p and or solder the

ter inals to the wire. Next, re ove each screw and place it

through the ring ter inal and reattach to the end cap.

This co pletes the asse bly of the feed point insulator. Check for continuity using an

oh eter between the center and shell of the BNC and the end caps of the antenna. Resistance

readings should be no ore than one or two oh s including the eter lead resistance. Also

verify that there is no short by checking resistance between the end caps or across the BNC.

Resistance should read very large or infinite here.

Note that the feed point insulator is sy etric. This feature allows the antenna to be used as a

dipole as well as a vertical. When used as a dipole, the bolt in the center serves as the antenna

support point for attaching to a ast. When using the antenna as a vertical, ake sure to install

the feed point insulator with the center conductor of the BNC connected to the antenna and the

shell to the radials.

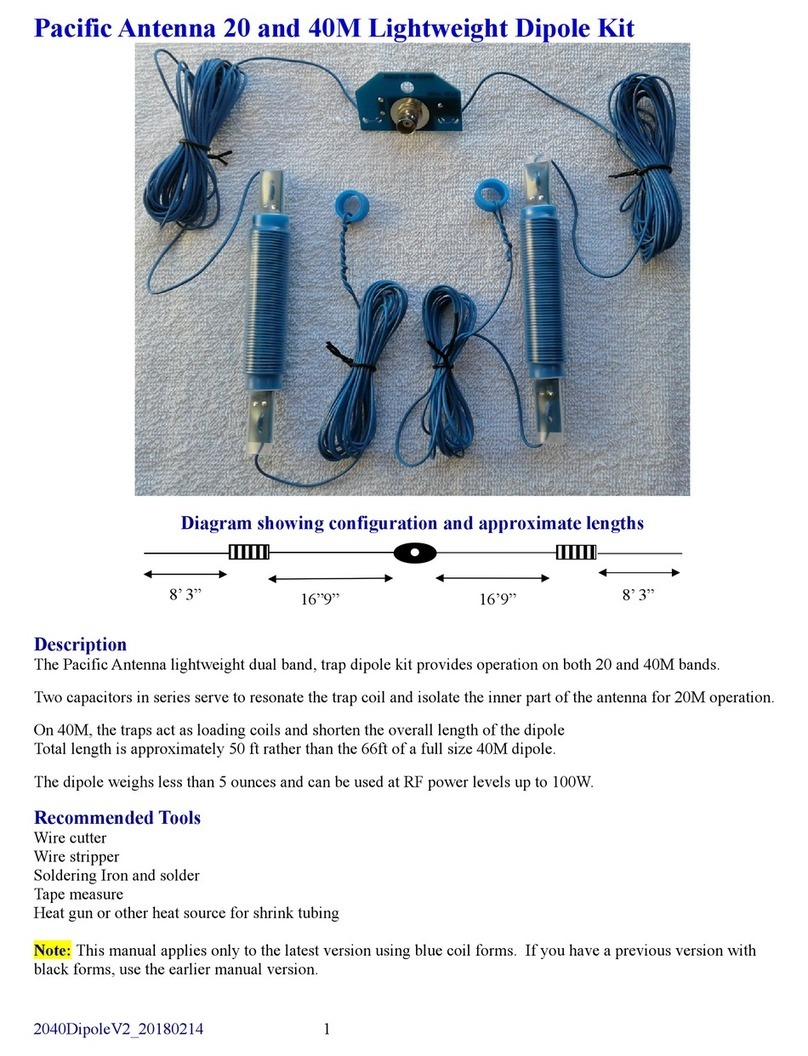

PAC-12 standard oil kit assembly

Full size oil kit assembly

Note: If asse bling the ulti-band coil version, skip ahead to that section.

Parts:

PVC oil form, light gray (1)

Aluminum end aps (2)

8-32 x 3/8” Phillips s rews (4)

#8 internal tooth lo k washers (4)

#8 rimp ring terminals (2)

#18 enameled opper wire

PAC12_Manual

V3.0_20160712