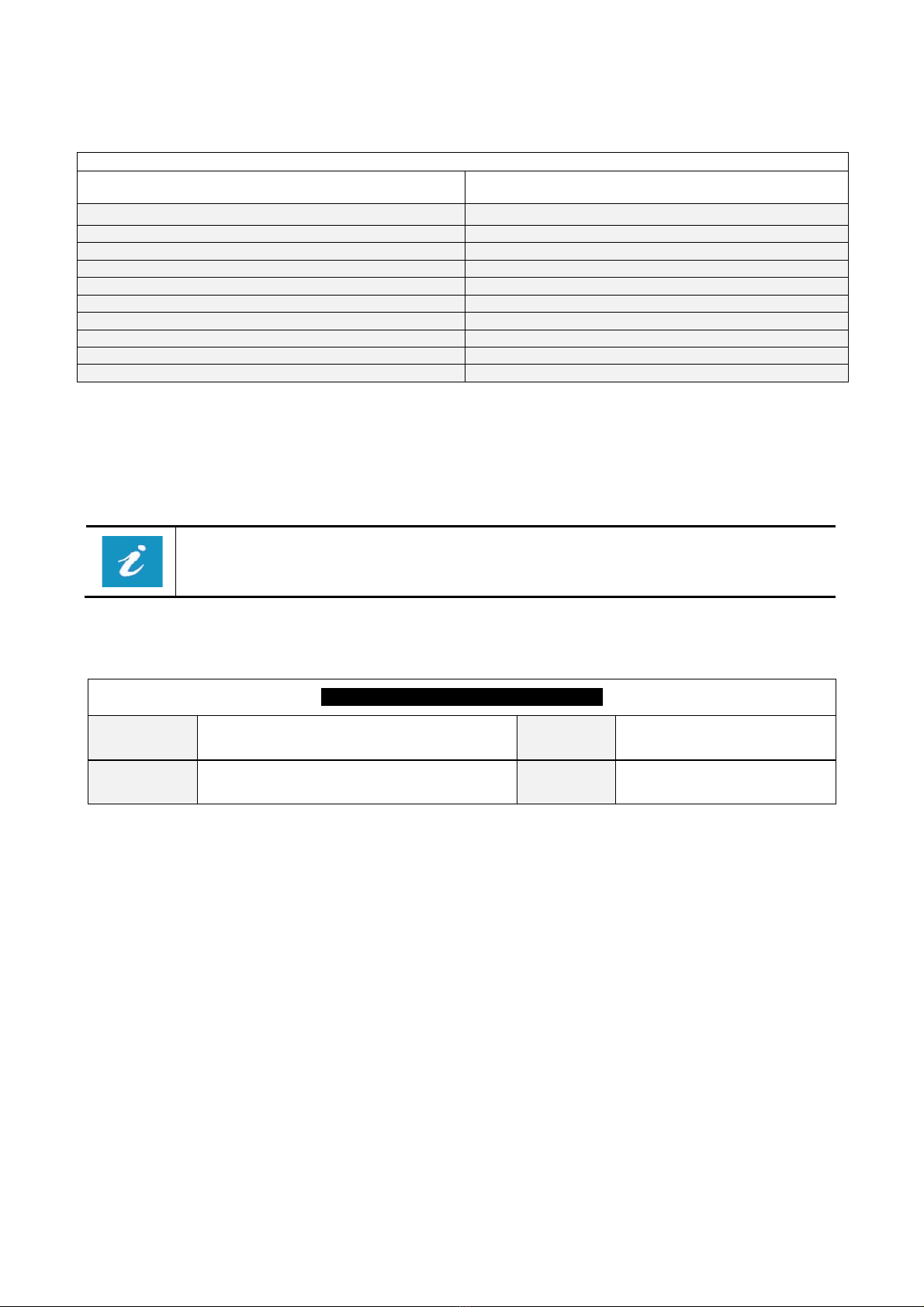

Warranty does not cover the following:

•

Failure to following the procedures and operation instructions included in this manual.

•

Equipment modifications without the approved written consent of Pacific Floorcare.

•

Non-use of genuine wear parts.

•

Repairs made by unauthorized personnel.

•

Improper or missing maintenance.

•

Natural calamities or Acts of God.

WARRANTY TERMS

Labor: Only a Pacific Floorcare Authorized Service Provider with a written factory service agreement may

evaluate and/or repair Pacific Floorcare equipment. Labor for any warranty repair is authorized for one (1) year

following the date of sale to the end-user. Once an Authorized Service Provider has been identified, it is the end

user’s responsibility to contract repairs. The authorized service provider will file any verified warranty claims with

Pacific Floorcare in accordance with the written factory agreement.

Parts: Parts determined to be defective are covered for three (3) years following the date of sale to the end-user.

Pacific Floorcare reserves the right to inspect defective parts prior to crediting any warranty claims.

AGM Maintenance Free Batteries: In addition to the terms above, any original equipment Pacific Floorcare

Battery which becomes unserviceable under normal use within two (2) years (730 days) from date of sale to the

original user will be repaired or replaced with one of equal specification with no charge to the user.

Disclaimer: This warranty limits Pacific Floorcare’s liability to the repair of the equipment and/or replacement of

the defective parts and does not include incidental or consequential damages arising from the use of a Pacific

Floorcare machine whether defective or not. This warranty is in lieu of all other expressed or implied warranties

and is extended to the original purchaser/user only.

Return Material Authorization (RMA): Warranty credit or replacement of returned parts is subject to an

incoming inspection of those items.

EXCLUSIONS

Warranty does not cover normal wear parts and materials (brushes, squeegee blades, etc…).

APPLICATION

In order to establish potential failure cause(s) and so the warranty may be applied, it may be necessary for

the defective components need to be sent to Pacific Floorcare. Repairs, replacement or substitutions under

the provisions of the warranty will be made at Pacific Floorcare’s discretion.

AUTHORIZATION

Authorization must be granted by Pacific Floorcare’s technical service department either in writing or by

phone. To properly start a warranty claim the following information must be provided:

•

Machine model as shown on the equipment label (reference section 2.1)

•

Machine serial number as shown on equipment label (reference section 2.1)

•

Detailed description of issue and relevant information on how the issue happened or was discovered

•

Part number and position of possible defective component as referenced from spare parts list

GOODS TO BE RETURNED – RETURN MATERIAL AUTHORIZATION (RMA)

In the case of goods to be returned for warranty replacement, it is necessary to have written acceptance

from the Pacific Floorcare technical service department. A Return Material Authorization (RMA) number

will be issued.

All defective parts must be carefully packed in order to avoid further damages during transport.