5

Unplug the connector from the back of the meter before jump-starting,

battery-charging, or welding on the truck

ON-BOARD WEIGHING SYSTEMS

The PNT 9700 AccuWeigh digital on-board weighing system consists of

a digital meter, load cells, transmitters, and cables designed for logging

trucks. The meter is optimized to be used with PNTechnologies trans-

mitters and cables but will also function with other equipment.

Benefits of using the PNT 9700 include:

Flexibility to read individual axle weights

A reliable two-wire hookup between the transmitters and the meter

An extremely bright weight display, visible even in bright sunlight

Ability to calibrate the meter without having to have the truck load-

ed

A unique load-hold feature, useful when loading at several different

sites

Measurements in increments of 10, 20, 50, or 100 pounds or kilo-

grams

Internal software that can be updated to include the latest en-

hancements.

A modern on-board weighing systems consists of load cells to sense the

load’s weight, transmitters and cables to send the load-cell output to

the meter, and a meter to change the signals into information usable

by the operator.

Load cells are precision-machined high-strength steel beams with

strain gages bonded inside. The load cell is installed on the truck be-

tween the log load and the truck frame. When the logs are loaded on

the truck, the strain gages sense the weight of the logs and send a

small electrical signal to the meter by way of the transmitter.

The transmitter provides the voltage to the load cell to power the

strain gages. A signal voltage from the load cell is returned to the

transmitter where it is converted to a digital signal before being sent to

the PN9700 meter through the two-wire cable.

6

Do not use pencils or other sharp-pointed objects to press the meter’s keys.

The PNT 9700 meter receives the digital signal from the transmitter

and interprets and displays it as a weight in pounds or kilograms.

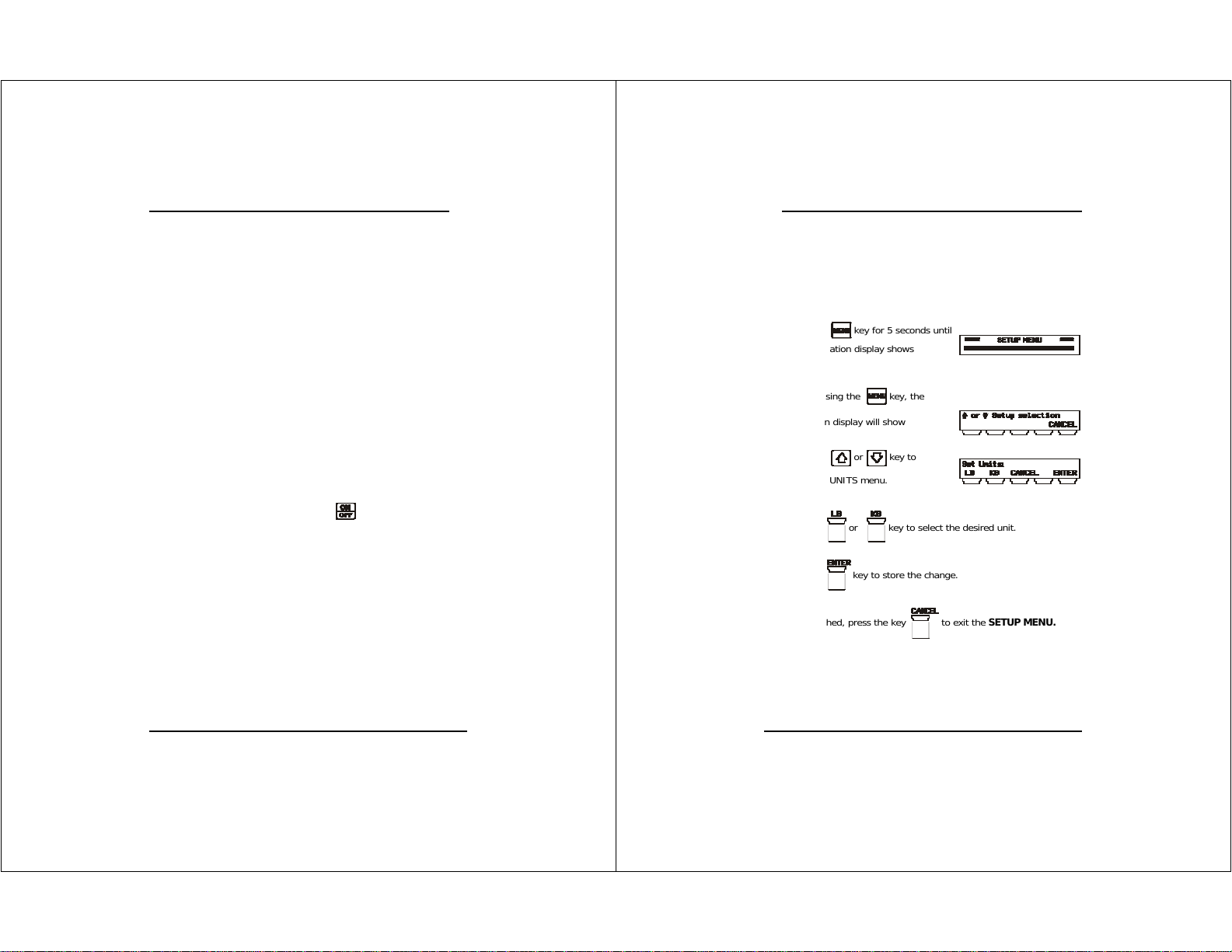

Two displays are used on the front of the meter. The top LED display

shows the weight of the load and can easily be switched between

truck, trailer, or total weight. The lower dot-matrix information dis-

play complements the top display by showing the two non-displayed

weights. For example, if the top LED display is set to show the truck

weight, the upper line of the information display will show the trailer

weight and the total weight.

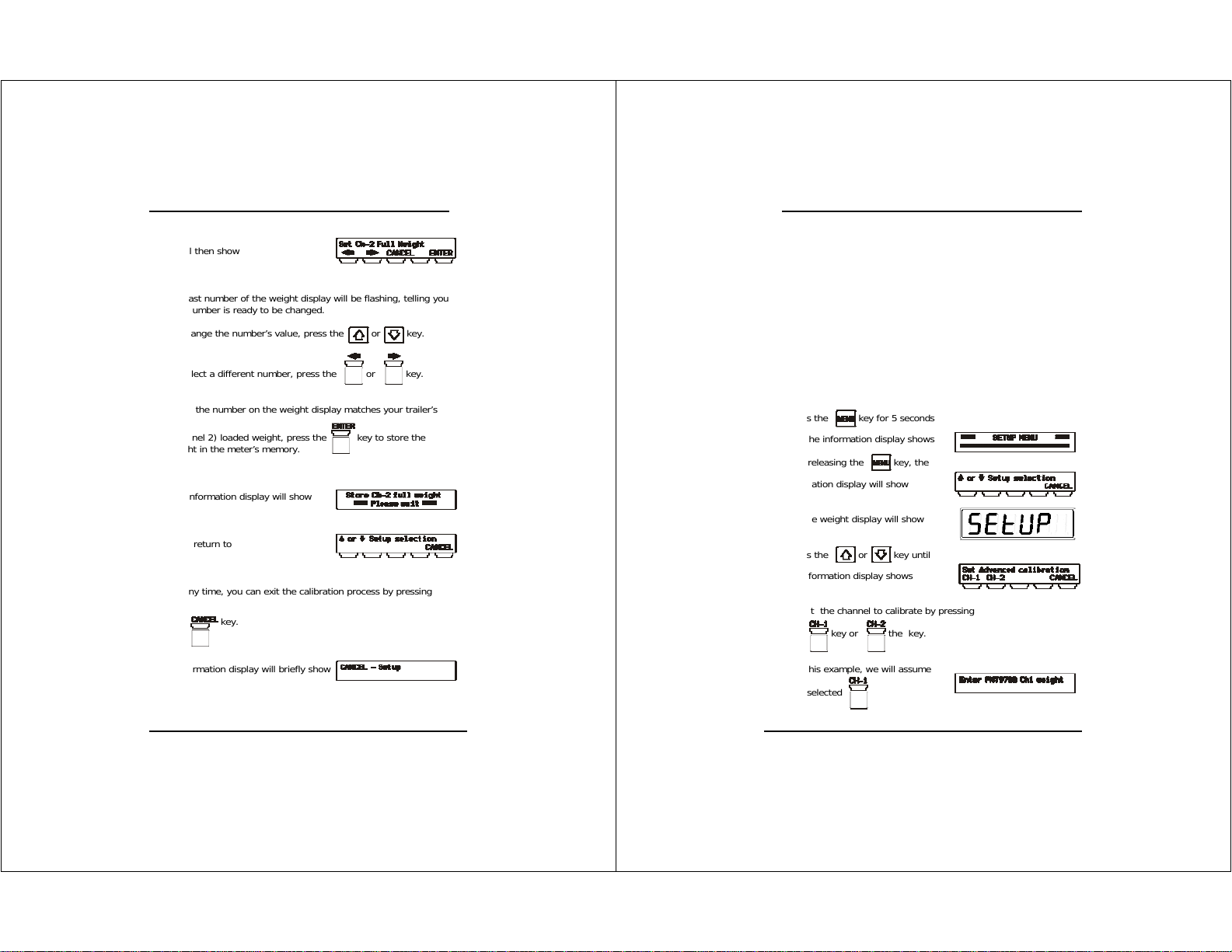

When the meter is in either the calibration or setup modes, the upper

line of the information display will show a calibration or setup mes-

sage. The lower line will show the appropriate legend for the blue

“soft” keys, F1 through F5. The function of each of these keys

changes depending on the mode that the PNT 9700 is in. The labels

will change as various menus are selected during calibration or setup.

During normal operation, the keys will select:

CH-1 [F1] Channel 1 or truck weight

CH-2 [F2] Channel 2 or trailer weight

TOT [F3] Total weight

AUTO [F4] Autocycle between Ch 1, Ch 2, and Total