LNW-6

Manual Version 5 - effective 15 January 2013 • 1 •pacificscale.com & forkliftscales.us

Introduction

Your new LIFT-N-WEIGH Model LNW-6 was designed to provide you with a reliable,

versatile and compact weighing system. While there are a number of variables affecting the

hydraulic system pressure - fluid viscosity, temperature, mechanical friction, leaking seals,

etc., this manual is intended to show you how to get the best performance out of your LIFT-

N-WEIGH.

Description

Principle of Operation

The lift truck scale works on the principle that the lift truck hoisting pressure is directly

proportional to the applied weight on the forks. The hydraulic pressure is converted into an

electrical signal by a pressure transducer. After the completion of calibration procedures,

the reading on the display is the weight on the forks.

Pressure Transducer

The transducer uses a strain gauge bridge to convert the hydraulic pressure in the lifting

cylinder into a proportional electrical output. This unit is capable of sensing pressure from 0

psi. to 5,000 psi at full scale. The transducer is built into the indicator enclosure for maximum

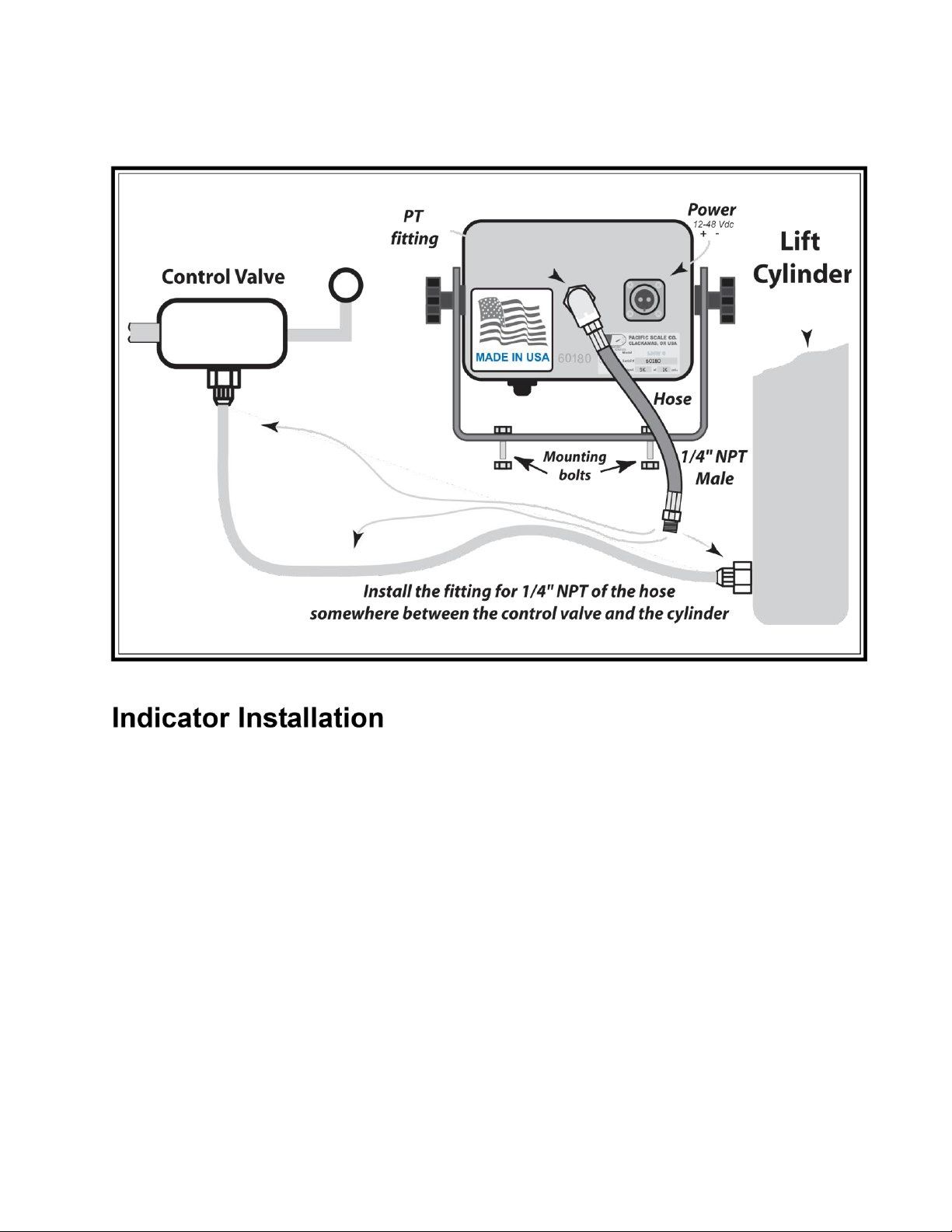

protection and easier installation. A high pressure hose from the lift truck (see installation

page) connects to a 1/4” NPT female swivel fitting on the back of the indicator housing.

Digital Indication

The LNW indicator uses solid state technology to achieve a high degree of accuracy on the

test bench. This however, is downgraded by the friction and slight differences in psi. during

the lifting cycle in the lift truck. The load on the forks is displayed on a backlighted liquid

crystal display for easy viewing in both bright and poorly lighted situations.

Housing

A heavy cast aluminum housing helps protect the indicator against mechanical damage. All

openings are gasketed and sealed to minimize contamination from dust and moisture.

Power Requirements

The LNW-6 indicator has approx. 100 mA current draw. The LNW Units have the Wide

Input Voltage Regulator (WIVR) installed, as part of the standard unit, and can operate

from 12 to 48 Vdc input and provide regulated power for the Printer and Setpoint options, if

purchased, provided reasonably clean power is supplied.

Due to problems of dirty power, including voltage spikes from gear pump

motors, if the LNW Unit is to be used on DC systems of greater than 24 volts, or used

with options on systems greater than 12 vdc, the installation of a Heavy Duty Line

Filter (HD-LF) and a Heavy Duty Voltage Regulator (HD-VR) may be required.

On 36V or greater systems, use without the HD LF & VR cannot be guaranteed.

Note: If supplied Power falls below 11.5 volts on a regular basis, WIVR may need to be

bypassed. Contact Pacific Scale for information.