3

4

T

HE MACHINE PREPARATION FOR THE PERFORMANCE

The machine mounting and its initial adjustment is carried out by the

manufacturer’s representative or by a trained specialist.

Initial adjustment and starting without the assistance of appropriate

specialist is forbidden !!!

The following operations have to be performed prior to the machine starting:

4.1 Unpack the machine.

4.2 Take the machine frame legs out of the box. Screw the legs into the

special holding holes placed at the frame corners. Adjust the machine level by

means of the legs rotating (pic.1). When the machine will reach the horizontal

position, screw the contra-bolts. Therefore the machine legs will be fastened

relatively to the frame.

4.3 Release the machine from the packing materials and cut off all the plastic

straps, holding the movable parts of the machine during the transportation.

4.4 Inspect the machine and make sure that all the mobile parts are released

and there are no strange subjects at the machine.

4.5 Connect the hopper, outlet conveyer and outlet table to the machine in

accordance with the appropriate’ marking.

4.6 Inspect the machine and make sure that all the wires are connected and

that they have not been damaged during the transportation. Make sure that

there is the suitable electric voltage in the electric socket, prior to switch on

the machine (see technical data). Make sure that there is the earth in the

electric socket. Insert the machine’s plug into the socket. Switch on the

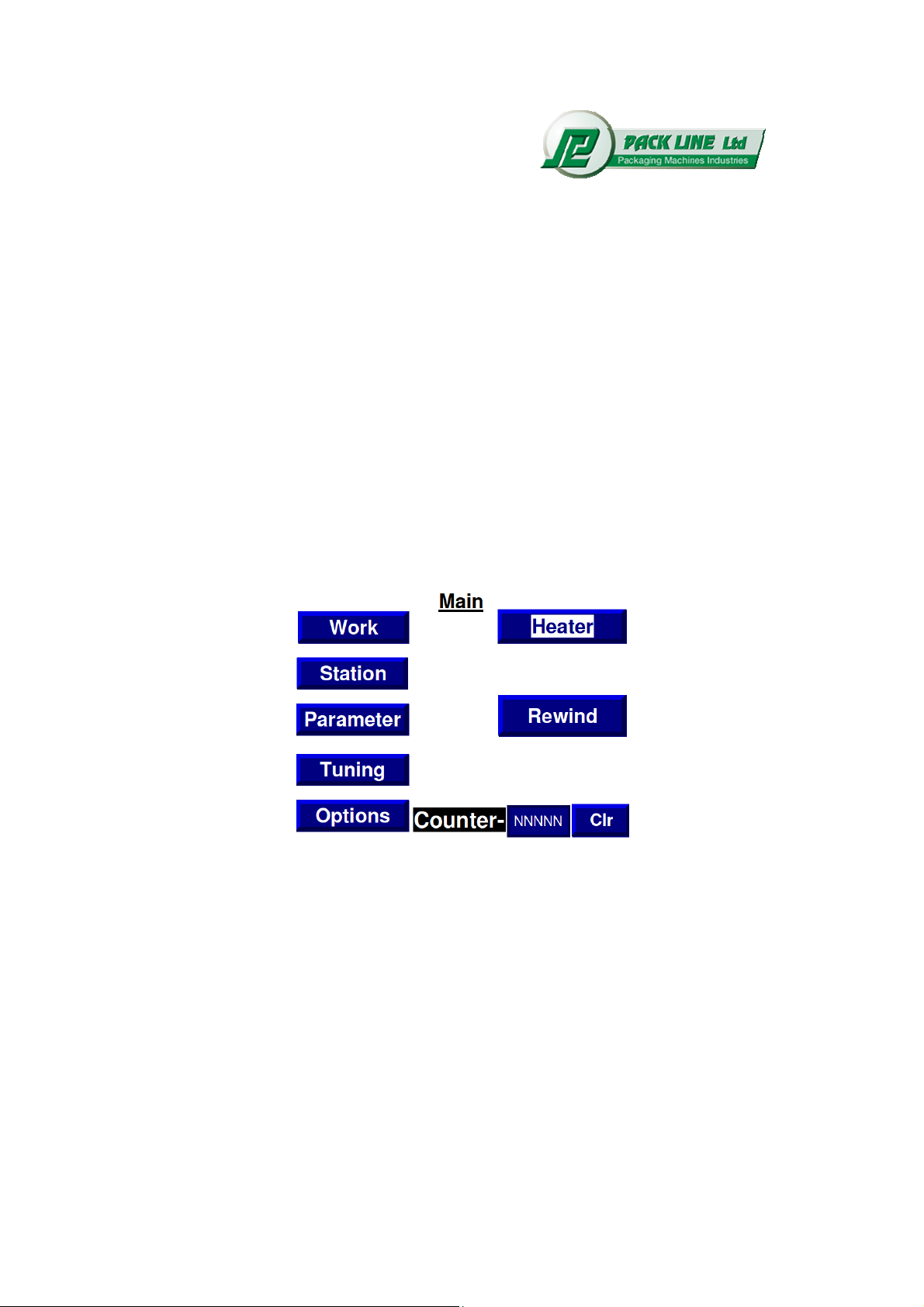

general switcher. At that the indicating lamp will light up at the power supply

unit (inside the cabinet), and the computerized controller screen will be

switched on as well. If the above mentioned has not been performed, it's

necessary to switch off the machine and to invite a technician.

4.7 Check the pneumatic system tubes integrity. Inspect the machine and

make sure, that all pneumatic tubes are connected and that they have not

been damaged during transportation and adjustment. It is necessary to feed

the pressed air to the machine and to switch on electric supply (see p. 4.6) at

that all the machine’s assemblies will get in their initial position. Inspect the

machine once more and check the tubes and connections make sure that

there is no air leakage. If you find the air loss, disconnect the pressed air

from the machine and eliminate the fault reason.

4.8 Perform the machine connection to the plant earth system by means of

the earth bolt placed under the electric cabinet on the frame.