mitec Table of Contents

Rev 2

i

Table of Contents

1INTRODUCTION ........................................................................... 1

1.1 Receiving and Inspection .........................................................................................2

1.1.1 Equipment Damage or Loss .............................................................................2

1.1.2 Return of Equipment ........................................................................................2

1.2 Preparing for Installation ........................................................................................3

1.2.1 Safety Precautions ............................................................................................3

2INSTALLATION & OVERVIEW .................................................. 5

2.1 General Description .................................................................................................5

2.2 Specifications ............................................................................................................5

2.2.1 Controls, Indicators and Connectors ................................................................7

2.2.2 General Considerations ....................................................................................7

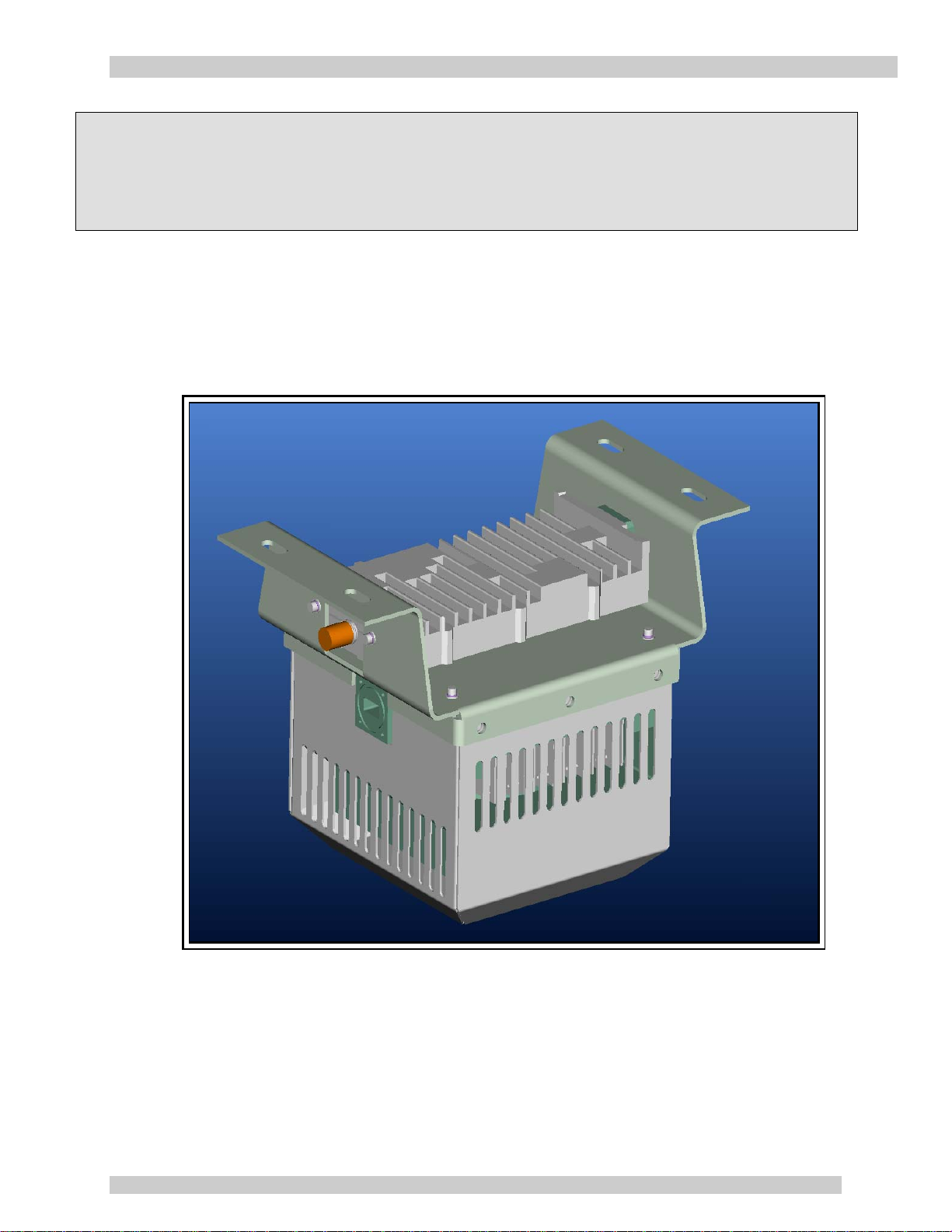

2.3 Basic Mechanical Characteristics ...........................................................................7

2.3.1 External View of the Transmitter Module........................................................7

2.3.2 Connections and Mounting Hardware..............................................................8

2.4 Assembly and Installation........................................................................................8

2.4.1 Lifting the Transmitter Module into Position and Temporary Attachment .....8

2.4.2 Securing the Transmitter Module.....................................................................9

2.5 Functional Overview ................................................................................................9

2.5.1 General .............................................................................................................9

2.5.2 IF/RF Conversion and Amplification.............................................................10

2.5.3 Protection and Control....................................................................................10

2.5.4 Internal Power Distribution Reference...........................................................11

3OPERATION ............................................................................... 13

3.1 Procedure ................................................................................................................13

3.1.1.1 Interface ............................................................................................................ 14

4MAINTENANCE .......................................................................... 15

4.1 Preventive Maintenance.........................................................................................15