EU-20-OI-v-1.2 gb. 28.07.14.docx 3

Table of Contents:

1.0 Declaration for Incorporation (Original Document) ........................5

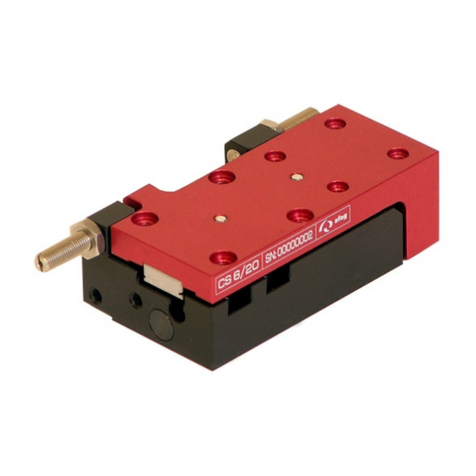

2.0 Modul Information...........................................................................7

2.1 Safety instructions ...............................................................................................7

2.2Transport, handling, storage.................................................................................7

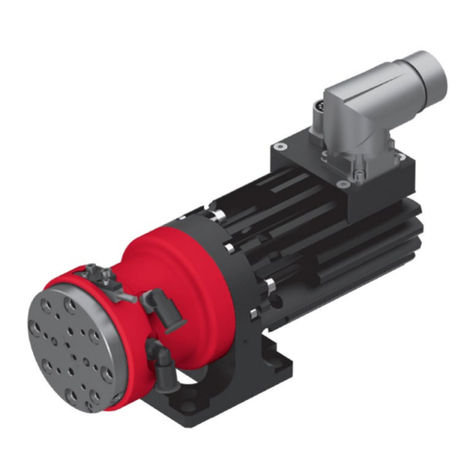

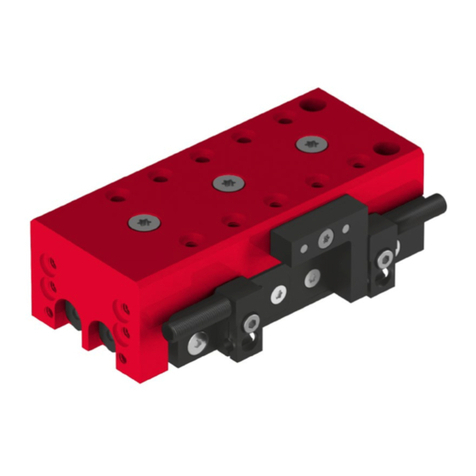

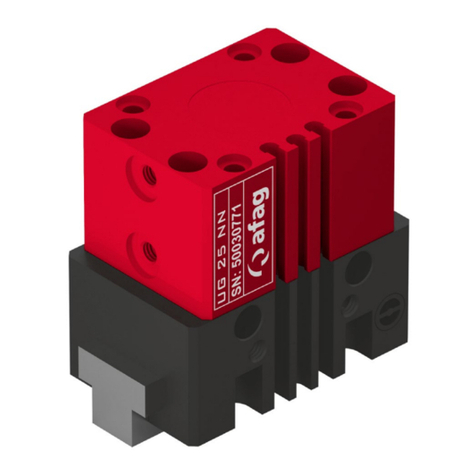

2.3 Module description...............................................................................................8

2.4 Gripper finger .......................................................................................................9

2.5 Mounting Connection ..........................................................................................9

2.6Installation and fastening possibilities ................................................................10

2.7Option with connecting plate...............................................................................11

2.8 Tightening torques for bolts................................................................................11

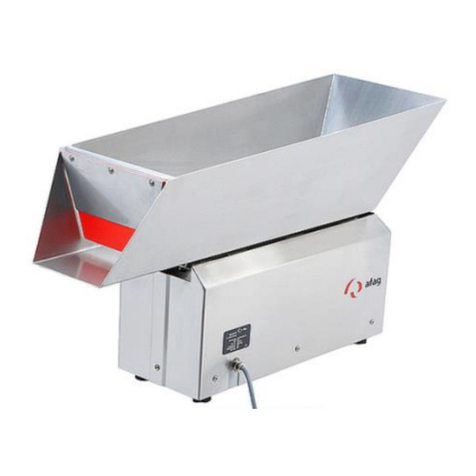

2.9 Incorporation into a line .....................................................................................12

2.10 Preferred combinations of the EU-20...............................................................14

3.0 Montage Instruction......................................................................15

3.1 Scope of delivery................................................................................................16

3.2 Intended use .....................................................................................................16

3.3Warranty............................................................................................................17

3.4Safety instructions .............................................................................................17

3.5Dimension drawing............................................................................................18

3.6Technical data....................................................................................................19

3.7Gripper load........................................................................................................20

3.8Electrical interface..............................................................................................20

3.9 Standard operation............................................................................................21

3.10 Checking the gripping process with external sensors.......................................23

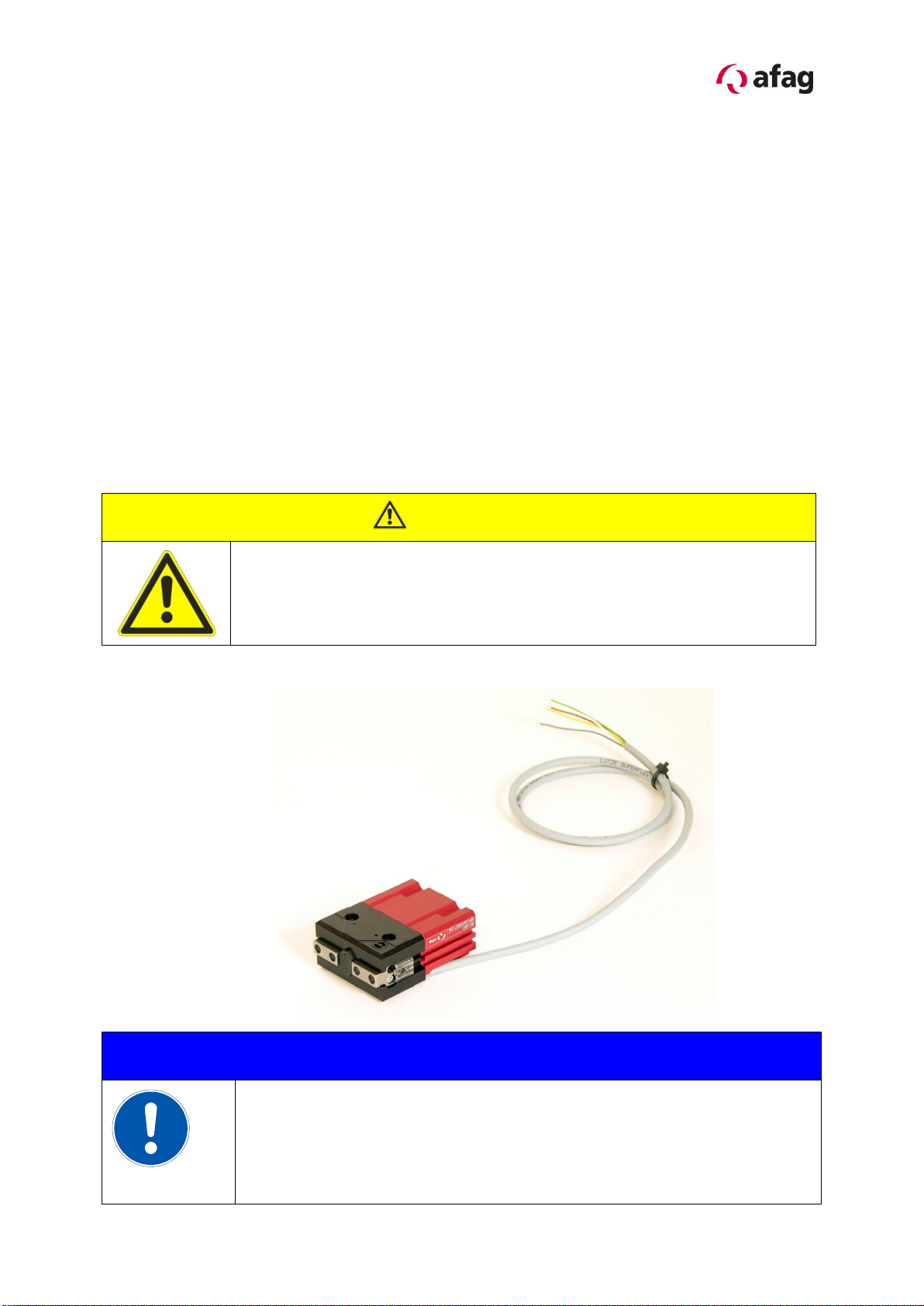

3.11 Fitting the EU-20 gripper with initiators……………………………………………23

3.12 LED-Display.....................................................................................................24

3.13 Commissioning, operation, training .................................................................25

3.14 Preparation for start-up.....................................................................................25

3.15 Start-up........................................................................................................... 26

3.16 Adjustement rerofitting.....................................................................................26

3.17 Normal operation.............................................................................................27