2 | C4 A s s e m b l y & I n s t a l l a t i o n G u i d e

Contents

ASSEMBLY INSTRUCTIONS ............................................................................................................................3

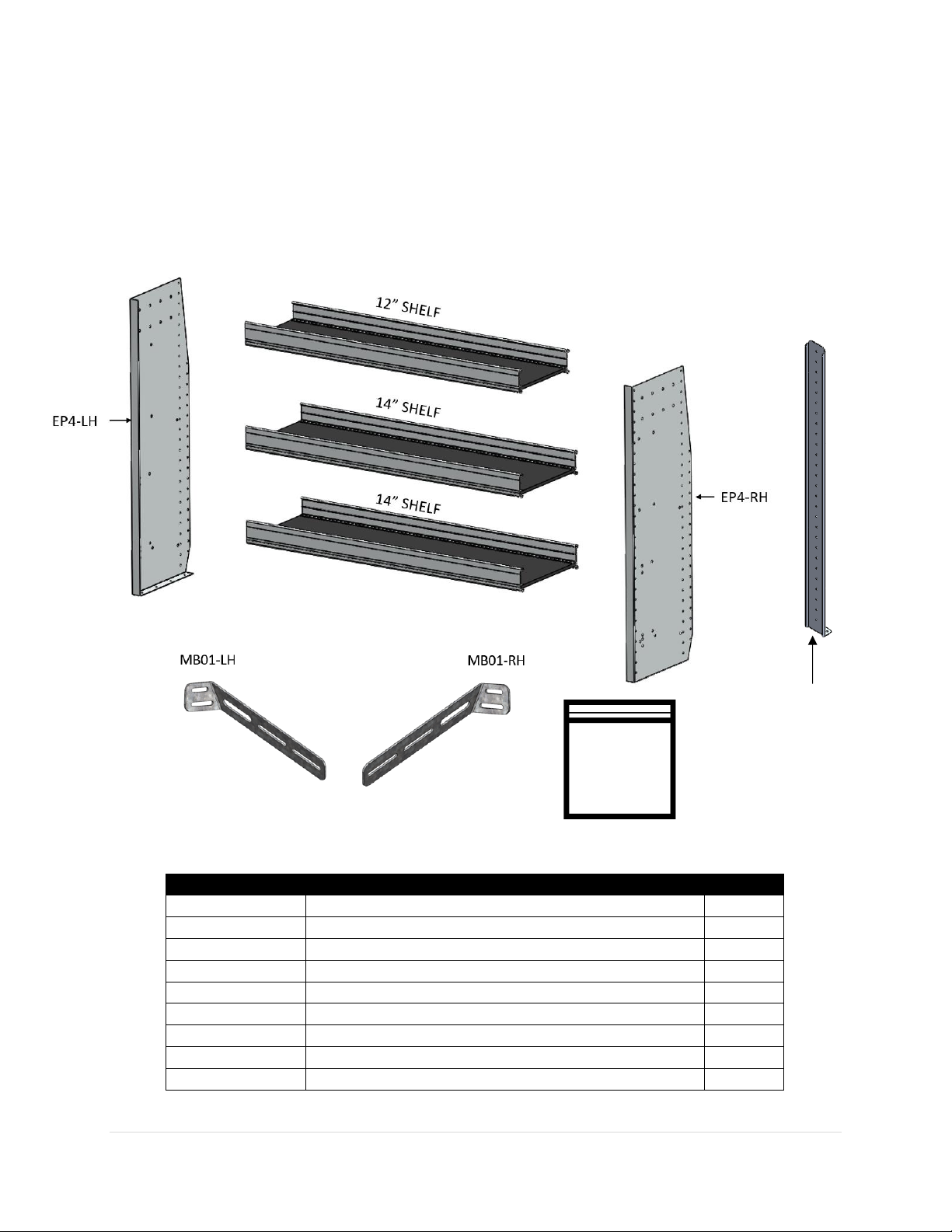

1PREPARATION ...................................................................................................................................3

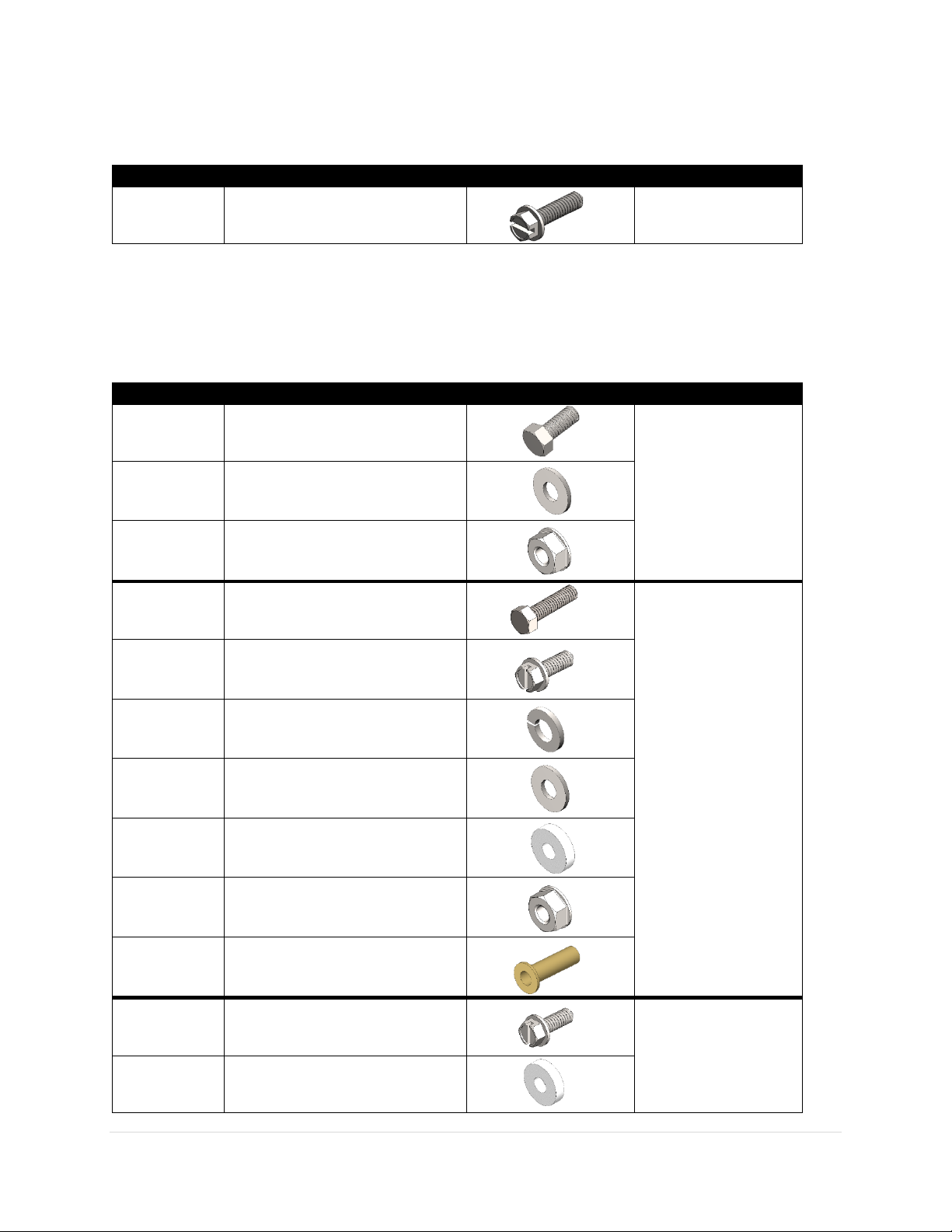

2ASSEMBLY FASTENER KIT..................................................................................................................4

3INSTALL FASTENER KIT ......................................................................................................................4

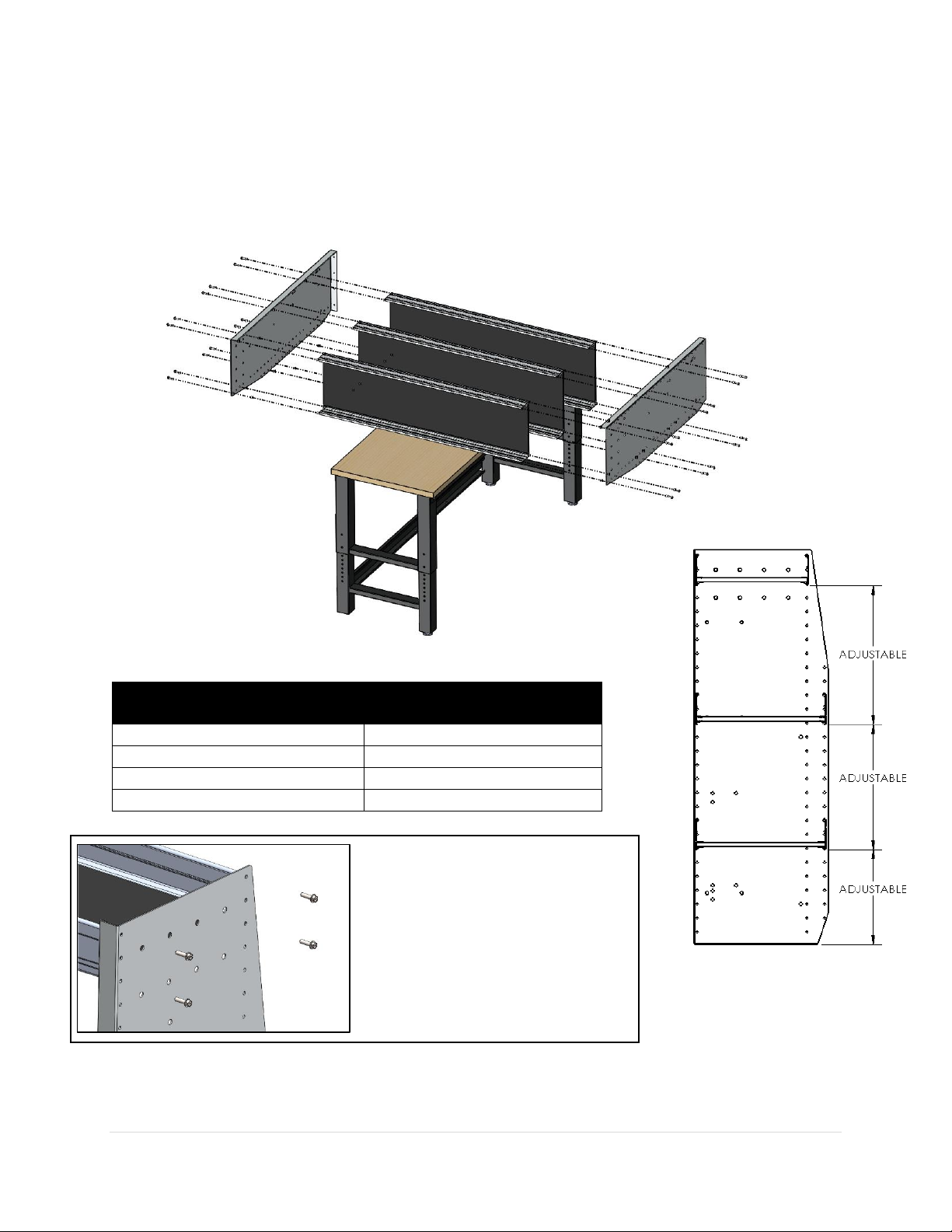

4SHELF ASSEMBLY...............................................................................................................................5

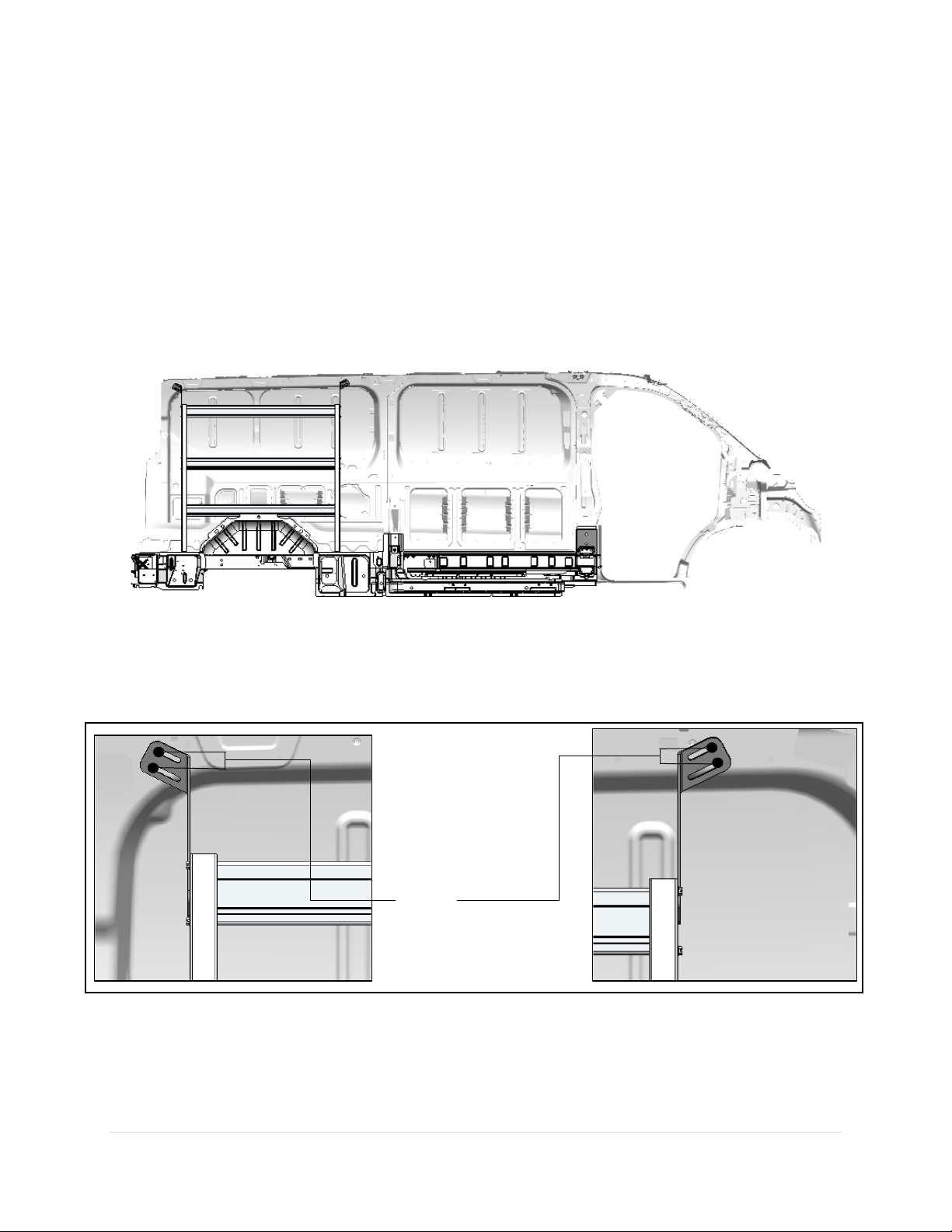

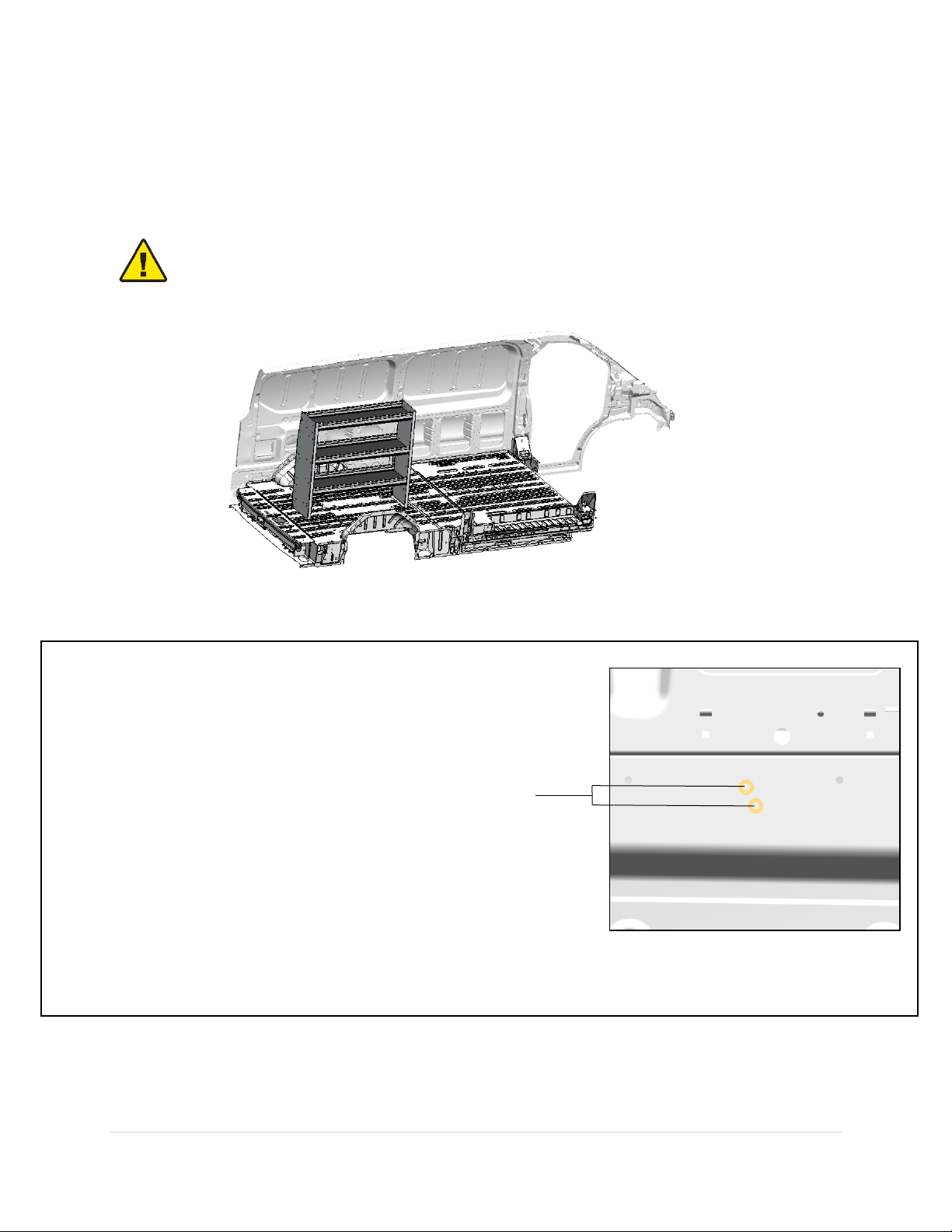

INSTALLATION INSTRUCTONS.......................................................................................................................6

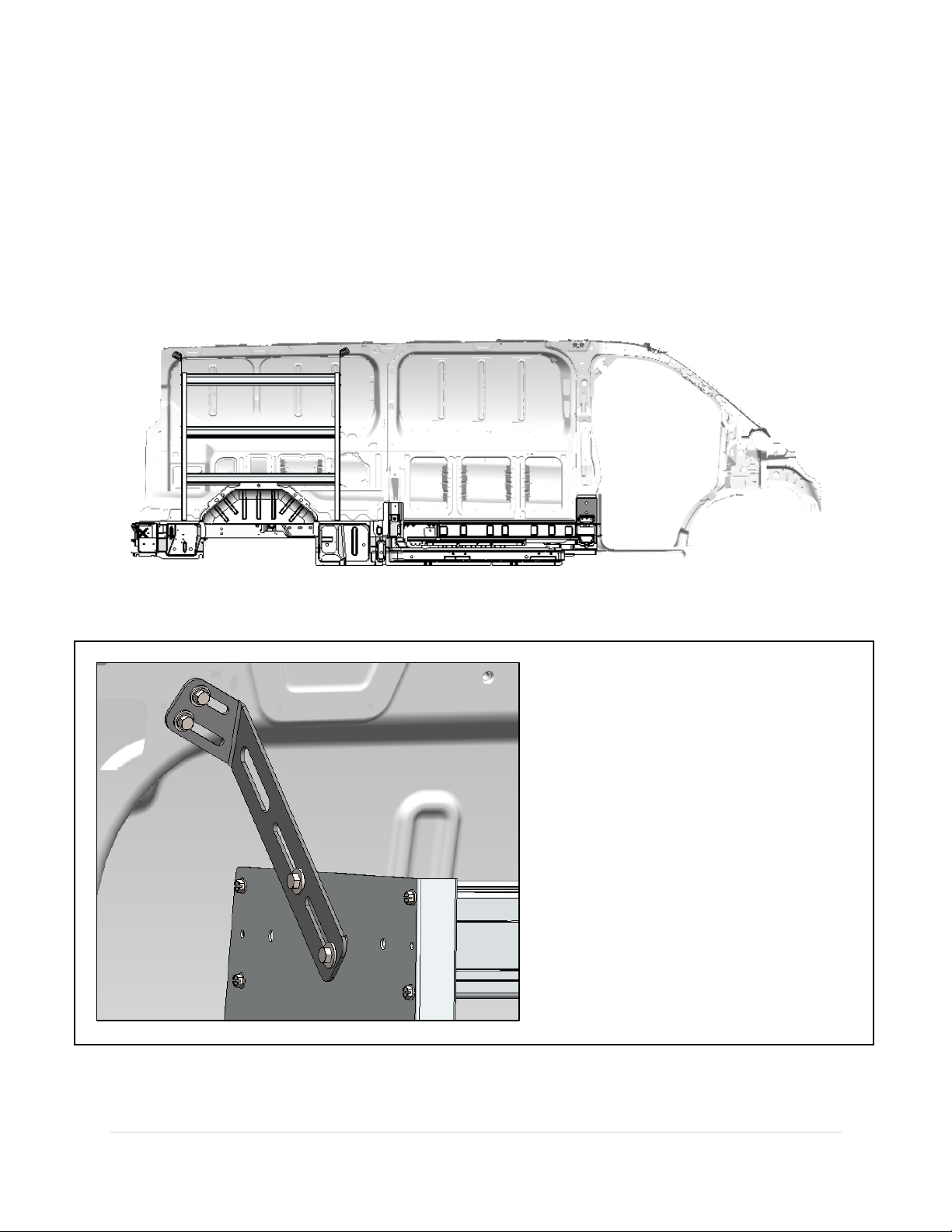

1FASTENING BRACKETS TO END PANELS............................................................................................6

2MARKING HOLES FOR PLUS NUTS.....................................................................................................7

3INSTALLING PLUS NUTS.....................................................................................................................8

4FASTENING SHELF UNIT TO THE WALL ...........................................................................................10

5FASTENING SHELF UNIT TO THE FLOOR..........................................................................................12

6INSTALLING CENTER SUPPORT........................................................................................................14

Required Items

2 People (To Lift Shelf Unit)

3/8” Drill Bit

3/8” Nut Driver Bit

1/2” Drill Bit w/ Drill Collar (Set at 1/2")

1/2" Nut Driver Bit

9/16” Wrench

1” Hole Saw

Plus Nut Tool or Plus Nut Gun (5/16”)

Marker

Cordless Drill

Cordless Impact Driver

Tape Measure

Large Square