4

B1d.1

4/06

Supercedes 8/05

PACOPACO

PACOPACO

PACO

PUMPS

groovedbefore the concrete sets to providea suit-

ablebonding surface for grout. Anchor bolts should

be set in pipe sleeves for positioning allowance, as

showninFig. 2a. Allow enough bolt length for grout,

lower base plate flange, nuts and washers. Allow

thefoundationtocureseveral days before proceed-

ing with pump installation.

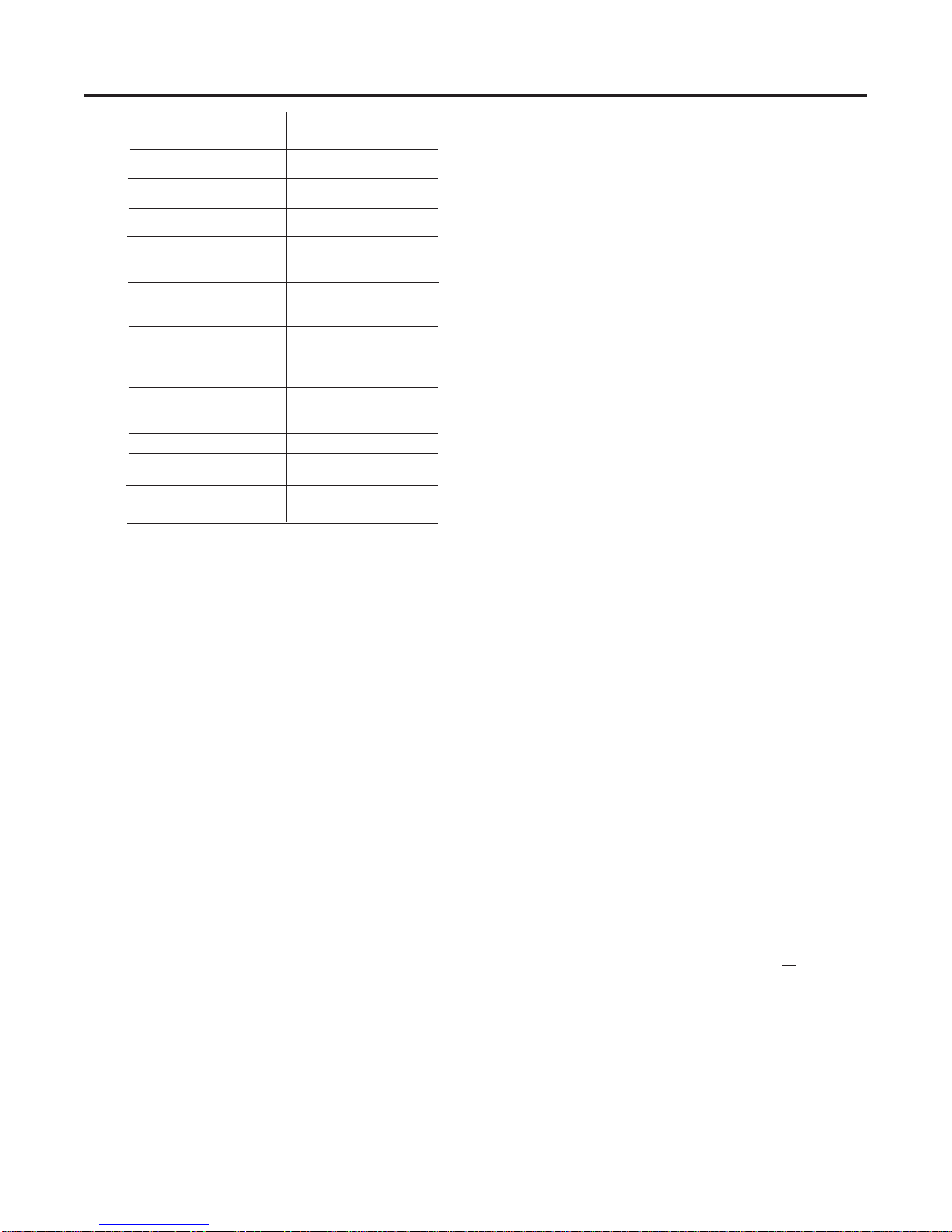

F. SECURING THEBASE PLATE

•After the concrete pad has been poured and set,

lowerthepumpbase plate over the anchor bolts and

rest it on loose adjustment wedges or shims placed

G. PIPING-GENERAL

• Do not use pump as a support for piping! Use

pipehangers or other supports atproper intervals to

providecompletepiping support near the pump.

• Bothsuction and dischargepiping should be inde-

pendentlysupportedand properly aligned to insure

no strain is transmitted to the pump when the bolts

aretightened. Use of expansion jointsor vibration

padsdoes not preclude the need to properly support

thepiping.

• Do not spring or force piping when making

connections!

• Make sure all piping is as direct as possible.

• Avoid unnecessary bends and fittings.

H. SUCTION (INLET) PIPING

The sizing and installation of suction piping is particu-

larly important. It must be selected and installed in a

manner that minimizes pressure loss and permits suffi-

cientliquid flow into the pumpduring starting and opera-

tion. Many NPSH problems can be traced directly to

improperdesignof suction piping systems. Observe the

followingprecautionswhen installing piping:

•Suction piping should be as direct as possible, and

ideally the length should be at least ten times the

pipediameter. Short suction piping canbethesame

diameter as the suction opening. Longer piping

shouldbe one or two sizes larger (depending on

length),reducingtothediameter of the suction open-

ingnear the pump.

•Use an eccentric reducer, with the eccentric side

down, as shown in (Fig. 3a on page 5) when

reducingpipe diameter to the diameter of the pump

suctionopening.

• At no time should suction piping be smaller in

diameter than the pump suction opening.

•Horizontalsuction lines should follow aneven

gradient, if possible. A gradual upward slope to the

pump is recommended for suction lift conditions,

andagradualdownward slope for positive suction

head.

•Avoidany high points, such aspipe loops, as shown

in (Fig. 4a on page 5), that may create air pockets

and throttle the system or produce erratic

pumping.

24" along each side.

•Shimsorwedgesmust be placed to raise the bottom

of the base 3/4" to 1-1/4" above the pad, allowing

clearancefor grout. Level the pumpshaft, flanges,

and base plate using a spirit level, adjusting the

wedges or shims, as required.

•Checkto make sure the piping can be aligned to the

pump flanges without placing any strain on either

flange.

•Afterpump alignment hasbeen established, put

nutsonfoundation boltsandtightenthemjust enough

tokeeptheunit base plate from moving. Construct a

formor dam around the concrete padand pour grout

in and around the pump base. (See Fig. 2a). Grout

compensatesforunevenfoundation,distributes the

weight of the unit, and prevents shifting. Use an ap-

proved,non-shrinkinggrout(suchasEmbeco 636 by

MasterBuilders,Cleveland,Ohioorequivalent).

Allow at least 24 hours for this grout to set before

proceedingwithpiping connections.

•After the grout has thoroughly hardened, check the

foundation bolts and tighten if necessary. Recheck

thepumpalignmentafterthefoundationboltsarese-

cured.

BASEPLATE

.75 TO 1.25

ALLOWANCEFOR

GROUT

DAM

PIPESLEEVE

WASHER

WEDGESORSHIMS

LEFTINPLACE

LUG

FINISHED

GROUTING .25

TOPOFFOUNDATIONLEAVE

ROUGHCLEAN&WETDOWN

GROUT

FIGURE 2a: Anchor Bolt Installation.