®

ProSeries-M M-2 Peristaltic Metering Pump

QUICK START GUIDE

All diagrams are strictly for guideline purposes only. Always consult an expert before installing metering pump on

specialized systems. Metering pump should be serviced by qualified persons only.

Always wear protective clothing, face shield, safety glasses and gloves when working on or near your metering

pump. Additional precautions should be taken depending on solution being pumped. Refer to MSDS precautions

from your solution supplier.

Risk of chemical overdose. Be certain pump does not overdose chemical during backwash and periods of no flow in circulation

system.

!

CAUTION

Mounting Hole Spacings

(for standard and extended type brackets)

M-2 Series

7.75” (19.7 cm)

2.5” (6.35 cm)

Maximum bolt hole size

0.200” diameter (4 places)

Risk of electric shock – cord connected models are supplied with a grounding conductor and grounding-type attachment plug. To

reduce risk of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle.

!

CAUTION

!

CAUTION

WARNING

Electrical connections and grounding (earthing) must conform to local wiring codes. Be certain that a grounding conductor is

connected to terminal T11-1 located in the wiring compartment.

WARNING

Risk of electric shock - Disconnect electricity before removing the wiring compartment cover.

WARNING

Maximum working pressure (excluding pump tubes):

125 psig (8.6 bar)

Note: see individual pump tube assembly maximum pressure ratings.

Maximum Fluid temperature (excluding pump tubes):

o o

3/8” OD x 1/4” ID tubing connections: 130 F (54 C)

o o

M/NPT connections: 185 F (85 C)

Note: see individual pump tube assembly maximum temperature ratings.

Ambient Operating Temperature

O O O O

14 F to 115 F (-10 C to 46 C)

Ambient Storage Temperature

O O O O

-40 F to 158 F (-40 C to 70 C)

Operating Voltage:

115VAC/60Hz, 1ph (1.5 Amp Maximum)

230VAC/60Hz, 1ph (0.7 Amp Maximum)

220VAC/50Hz, 1ph (1.0 Amp Maximum)

240VAC/50Hz, 1ph (1.0 Amp Maximum)

Mounting Location

[Choose an area located near the chemical supply tank, chemical injection point, and electrical supply. Install the

pump where it can be easily serviced.

[Mounting brackets are included. Mount the pump to a secure surface using the enclosed mounting hardware.

[Mount the pump close to the injection point. Keep the inlet (suction) and outlet (discharge) pipe or tubing as short as

possible. Longer discharge tubing increases back pressure at pump head.

[Keep the suction lift height as low as possible. Increased suction lift heights can decrease the pump’s efficiency.

[A back flow prevention check valve is recommended at the injection point to prevent system fluid from flowing back

through the pump during tube replacement or if the tube should rupture. The check valve internals must be kept

clean. Any build up in the valve will increase the pressure at the pump reducing the life of the pump tube. Back

flow check valves are available from the factory.

[The Flex-Pro does not require back pressure. Pressure regulator valves should NOT be used as back-flow preven-

tion valves unless adjusted to the minimum possible opening pressure. Any additional pressure at the pump will

reduce the life of the pump tube.

[A pressure relief valve is recommended at the discharge of the pump to prevent excessive pressure resulting in

premature wear and damage to the pump tube in the event the discharge line becomes blocked.

FLEX-PRO

Peristaltic Metering Pump

®

Flex-Pro QUICK START GUIDE

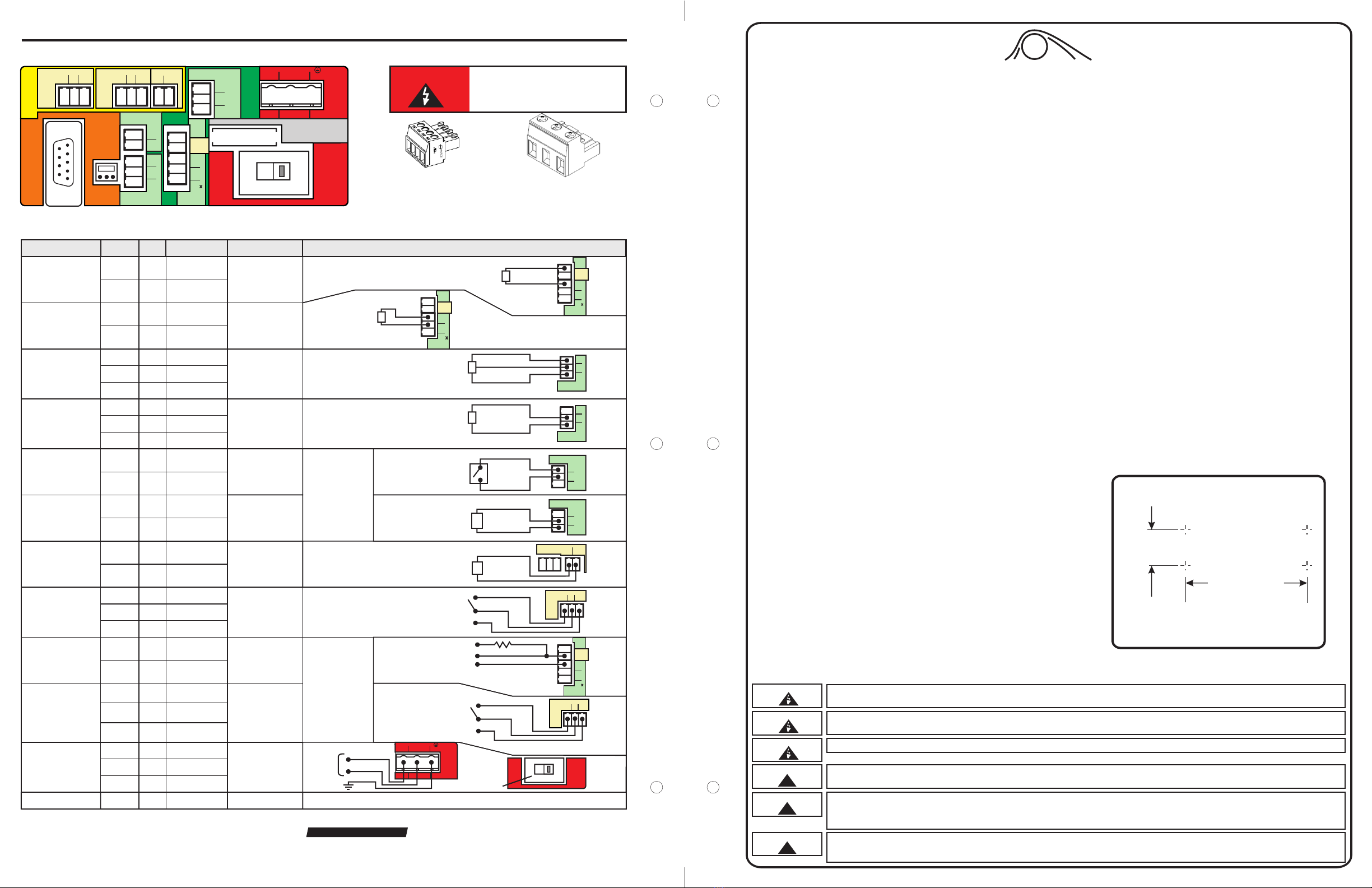

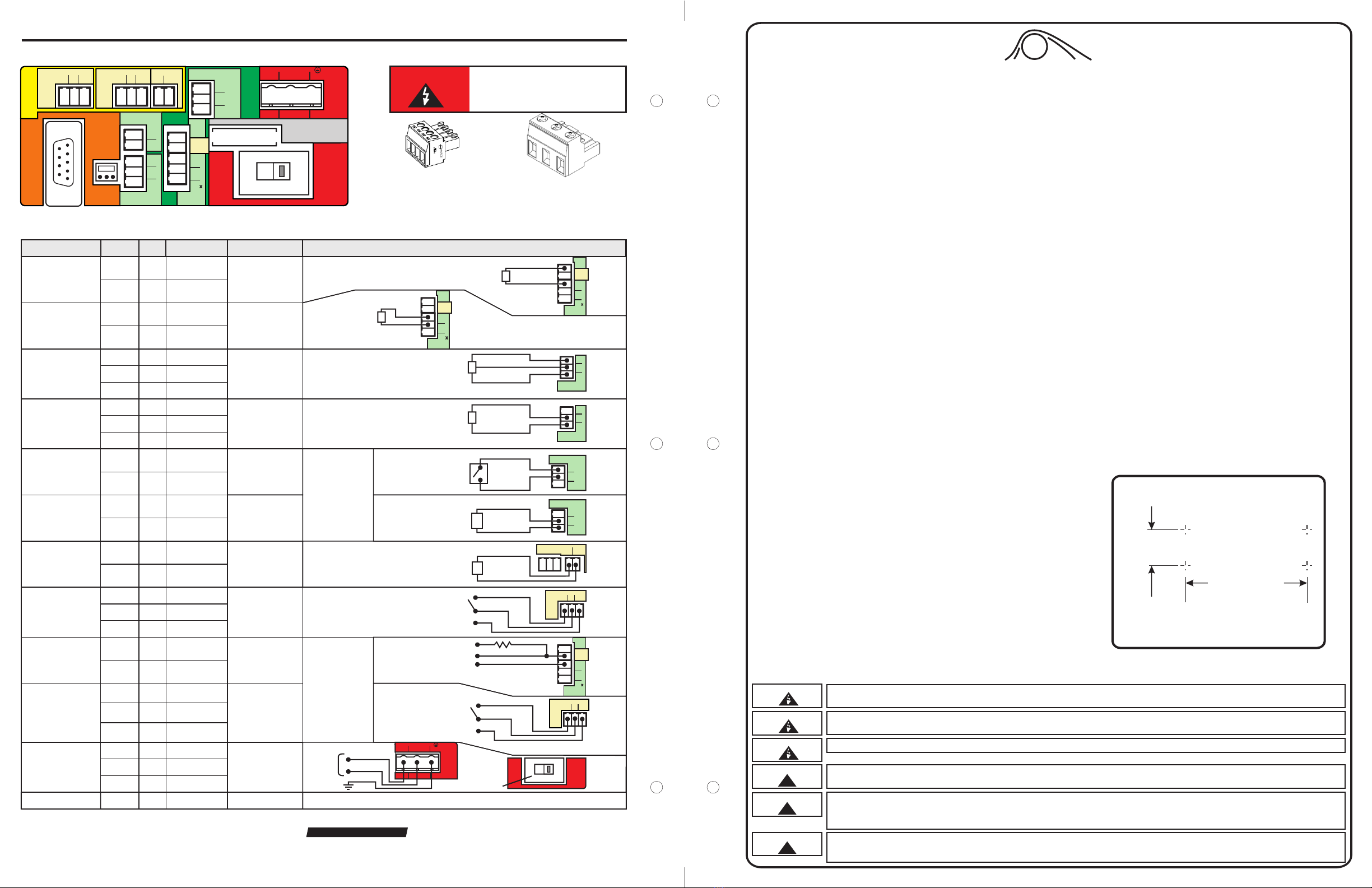

Wiring Terminals and I/O Schematics

5300 Business Drive, Huntington Beach, CA 92649 USA

Phone: 714-893-8529 FAX: 714-894-9492

ProSeries-M

by Blue-White Ind.

®

WARNING

T1

1

3

PLS

4

4-20 (+)

2

Motor

Active

(-)

5

+

-

ACTIVE 4-20mA

TRANSMITTER

SOURCE GND (-)

4-20(+)

INPUT:

4-20 mA

INPUT:

FREQUENCY, AC

SINE WAVE, TTL,

CMOS

FUNCTION TERM PIN # RATING ELECTRICAL SP. BLOCK DIAGRAM

T1

T1

T1

T1

T4

T4

T4

1

3

3

4

3

4

5

(+) POSITIVE

SIGNAL

(-) NEGATIVE

OUTPUT:

4-20 mA

OUTPUT:

RELAY, 3 AMP

OUTPUT:

OPEN COLLECTOR

MOTOR ACTIVE

T6

T6

2

1

(+) POSITIVE

(-) NEGATIVE

T7 1

T7

T7

2

3

120 OHM

IMPEDANCE, NON

POWERED LOOP

6 TO 30 VOLT DC

1 AMP MAX.

120 OHM

RESISTANCE

ACTIVE LOOP

Form C

3 AMP MAX AT

250 VAC,

3 AMP MAX AT

30 VOLT DC

0-1000 HZ MAX.

NO VOLTAGE

(+)

(-)

NO

C

NC

SWITCH LOAD

3 AMP MAX @ 250V AC

3 AMP MAX @ 30V DC

EXTERNAL DEVICE

6 TO 30V DC

OPEN CIRCUIT

IMPEDANCE MUST

BE GREATER THAN

50K OHM

4-20mA RECEIVER

600 OHM LOAD MAX.

(+)

(-)

Risk of electric shock - All

wiring must be insulated

and rated 300V minimum.

Terminals T1 Thru T8

Plug type

16 - 24 AWG

Power Input Terminal T11

Plug type

14 - 30 AWG

Single or dual pump (series) input.

Loop voltage must not exceed 24 Volts.

T1

1

3

PLS

4

4-20 (+)

2

Motor

Active

(-)

5

+

-

FREQUENCY

TRANSMITTER

SOURCE

GND (-)

PULSE

T4 FVS

3

4

5

(+)

(-) SIG

BLUE-WHITE

FVS SENSOR

GND (-)

SIGNAL

PWR (+)

RED (+)

BLACK (-)

BARE

T3 REMOTE

IN

3

1

2

DRY

RMT

COM

T3

T3

1

2

(+) POSITIVE

(-) NEGATIVE

T3

T3

2

3

(+) POSITIVE

(-) NEGATIVE

T3 REMOTE

IN

3

1

2

DRY

RMT

COM

T4

T4

4

5

SIGNAL

(-) NEGATIVE

T4 FVS

3

4

5

(+)

(-) SIG

BLUE-WHITE

MICRO-FLO

FLOWMETER

PULSE OUTPUT

GND (-)

SIGNAL

PWR (+)

NEGATIVE (-)

SIGNAL

12

(-) (+)

T6

T7

RELAY

OUT

123

N.C. COM N.O.

(-)

(+)

T1

1

3

PLS

4

4-20 (+)

2

Motor

Active

(-)

5

GND (-)

T1

T1

2

3

CLOSED WHILE

MOTOR IS

ENERGIZED

NEGATIVE (-)

SIGNAL OUT

4.7K OHM MOTOR

ACTIVE

5 TO 24 VDC

INPUT:

POWER T11 1

T11

T11

2

3

T11

GROUND

N EUTRAL

(COMMON)

LINE

(HOT)

1

23

POWER

AC

VOLTAGE

115V OR 230V AC

MANUAL SWITCH

50 / 60 HZ

100W

GROUND

NEUTRAL

LINE (HOT)

115V

POWER

S1

POWER

VOLTAGE

SWITCH

SWITCH

FROM

115V TO 230V

FUSE F1 N/A 5 AMP 5A SLOW BLOW

(20 X 5MM)

(+) POSITIVE

(-) NEGATIVE

(-) NEGATIVE

(+) POSITIVE

INPUT:

FVS SYSTEM

(FLOW VERIFICATION

SENSOR)

FS or FP MICRO-FLO

FLOW METER ONLY

INPUT:

FVS SYSTEM

(FLOW VERIFICATION

SENSOR)

FV SENSOR ONLY

INPUT:

REMOTE

START / STOP

(DRY CONTACT C.)

INPUT:

REMOTE

START / STOP

(WET CONTACT C.)

NORM. CLOSED

NORM. OPEN

COMMON

4-20

COMMON

SIGNAL

NOTE: USE

ONLY DRY

CONTACT FOR

REMOTE S/S

WHEN USING

4-20mA INPUT

Shielded cables should be used on all input signal wires.

OUTPUT:

MOTOR ACTIVE

(CONTACT CLOSURE)

Form C

1 AMP MAX AT

125 VAC,

0.8 AMP MAX AT

30 VOLT DC

T8 1

T8

T8

2

3

NORM. CLOSED

NORM. OPEN

COMMON

T8

MOTOR

ACTIVE

123

N.C. COM N.O.

T8

MOTOR

ACTIVE

123

N.C. COM N.O.

NO

C

NC

SWITCH LOAD

1 AMP MAX @ 125V AC

0.8 AMP MAX @ 30V DC

P1

RS-232

TO COM

BOARD

T12

OUTPUT

T7

RELAY

OUT

123

N.C. COM N.O. 4-20mA

12

(-) (+)

T6

T8

MOTOR

ACTIVE

123

N.C. COM N.O.

T2

T4 FVS

1

2

(-) (+)

3

4

5

(+)

(-) SIG

DIR

115V

FUSE 5A SLOW

BLOW (20 X 5MM)

POWER

T11

GROUND

N EUTRAL

(COMMON)

LINE

(HOT)

1

23

S1

INPUT

T3 REMOTE

IN

T1

3

1

2

DRY

RMT

COM

1

3

PLS

4

4-20 (+)

POWER

F1

(-)

5

2

Motor

Active