INSTRUCTIONS FOR:

DOUBLE DIAPHRAGM FUEL

TRANSFER PUMP

MODEL: TP6918

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT

IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE

WARRANTY.

PLEASE RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will give you years of trouble free performance if these

instructions are carefully followed and the product is correctly maintained.

WARNING! Ensure all Health and Safety, local authority and general workshop practice regulations are strictly adhered to when using this

equipment.

Petrol is a highly flammable liquidand any spillage will evaporate to form a flammable, heavier than air vapour, which is easily ignited.

Common sources of ignition include, but are not limited to, smoking and lighting matches, welding and cutting equipment, heaters, all types

of electrical equipment unless specifically designed as suitable for use in a flammable atmosphere. Even low voltage inspection lamps, if

damaged can ignite petrol vapour.

Please take time to read the following safety information before commencing work with the TP6918.

Familiarise yourself with the applications, limitations and potential hazards of this product.

Maintain the pump in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Unauthorised parts will invalidate the warranty.

Use only with oils, petrol, diesel, paraffin, anti-freeze, degreasants and other non-corrosive fluids.

Ensure safety eye protection and protective clothing are worn when using this product.

Keep a foam or dry powder fire extinguisher nearby.

Ensure that containers cannot easily be knocked over during filling.

Keep the work area clean and uncluttered and ensure that there is adequate lighting.

Remove all combustible materials from the work area.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the work area.

HSE guidance recommends use of metal containers with secure caps for holding drained fuel.

Mark fuel containers with hazard labels to identify the contents.

Keep any fuel containers in a well ventilated, lockable store, preferably away from the working area.

Soak up any spill immediately using absorbent granules or similar material.

Dispose of waste liquids in accordance with local authority regulations.

DO NOT use an open flame or smoke anywhere near the tool or around stored fuel.

DO NOT use the pump to transfer hazardous or harmful chemicals, corrosive liquids, solvents, alkalis or acids.

DO NOT use the pump with water.

DO NOT use the pump near sources of heat or sparks.

DO NOT allow work which can produce a source of ignition, such as welding, electrical or other hot work, to be carried out whilst

dispensing fuel.

DO NOT use cordless, mobile phones or pagers, ensure these items are turned off before dispensing fuel.

DO NOT use the pump for any purpose other than for which it is designed.

DO NOT attempt to move the fluid drum by pulling on the pump.

DO NOT use whilst under the infuence of drugs, alcohol or other intoxicating medication, or if you are fatigued,

Keep the pump clean and well oiled and store in a safe, dry, childproof location when not in use.

Users/Businesses should perform their own hazard risk assessment based on their specific environment

and following the guidelines laid out above.

TP6918 Issue No: 1 - 19/08/08

2. INTRODUCTION

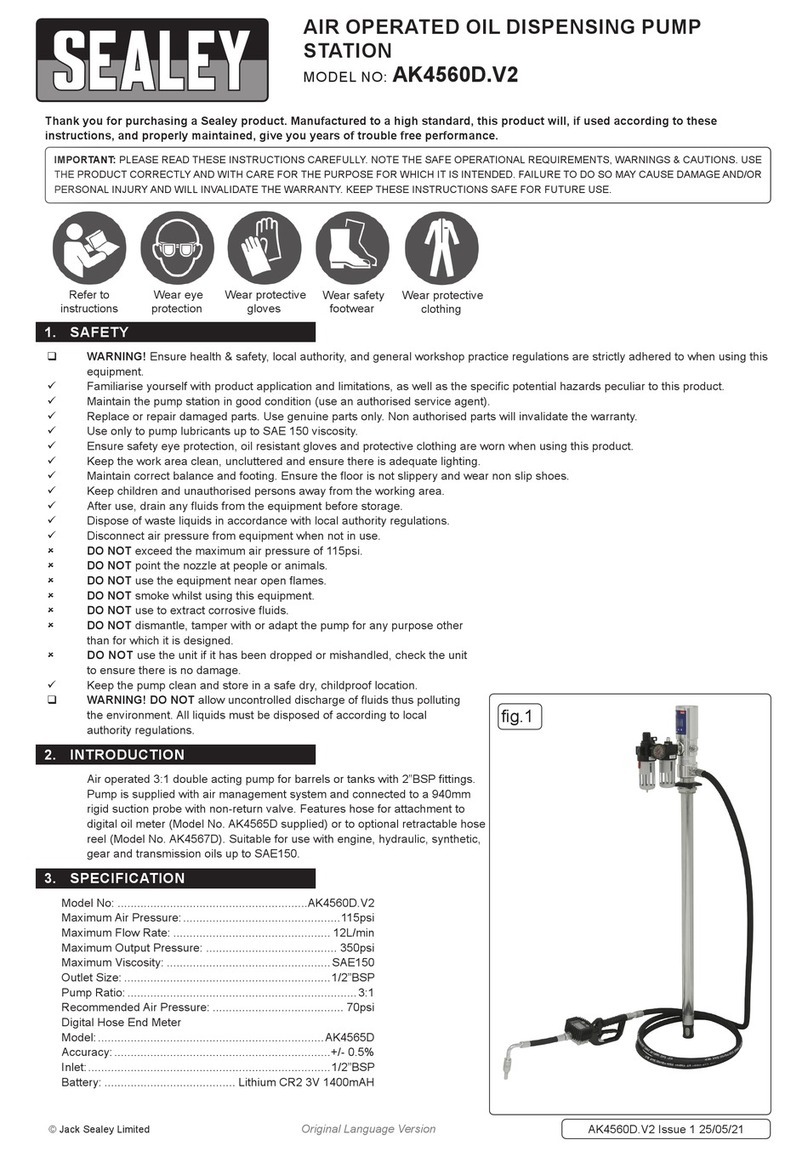

Self-priming high performance double diaphragm lever pump. Heavy-duty die cast aluminium pump head with stainless steel pistons and fuel

resistant nitrile rubber diaphragm. 2”BSP Connector and telescopic dip tube to suit 50 to 205ltr drums. Approximately 800ml per full stroke

discharge. Supplied with 8ft anti-static discharge hose, delivery nozzle with holder. Suitable for various oils, petrol, diesel, antifreeze, paraffin

and other non-corrosive fluids.

3. ASSEMBLY

3.1 Slide the bung nut onto the octagonal base at the pump inlet. Tighten the bung on the base using the two bolts on the bung.

3.2 Prepare the threads of the telescopic suction tube with some PTFE tape and screw into the pump inlet and tighten.

3.3 Fully extend the telescopic tube and insert the suction tube through the 2" threaded hole into the drum, until the suction tube hits the

bottom of the drum. Screw the bung nut into the drum.

3.4 Connect the dispensing nozzle onto one end of the rubber hose and the other into the outlet of the pump. Use PTFE tape on both

threads before assembly.