Revision 1.0

1

Table of Content

Table of Figures...................................................................................................................2

1. Important Notes......................................................................................................3

1.1 Attention.....................................................................................................3

1.2 Important Notes..........................................................................................3

1.3 General Information....................................................................................4

2. Safety Information..................................................................................................6

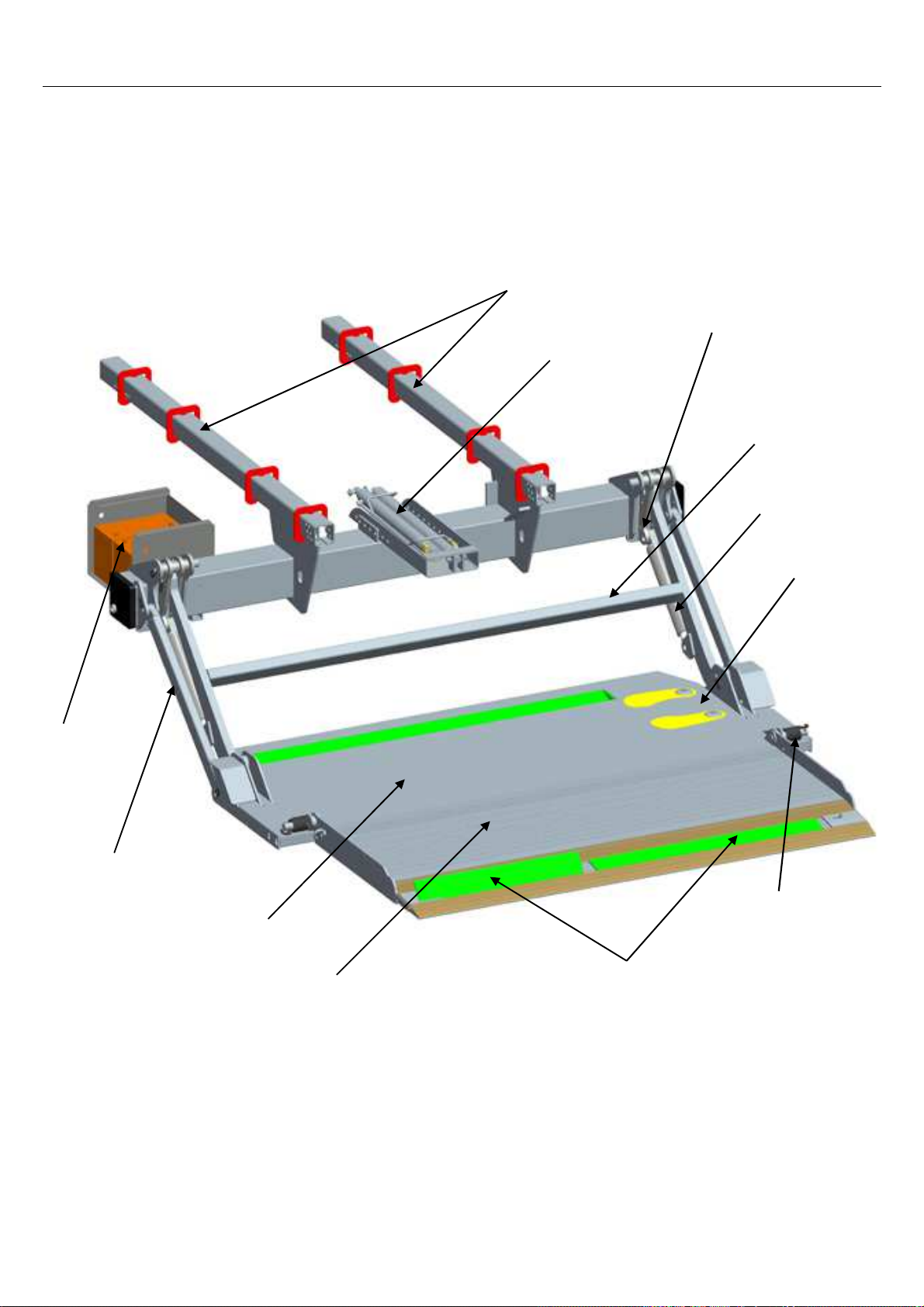

3. Basic Parts in Detail...............................................................................................8

3.1 General View of Liftgate .............................................................................8

3.2 Circuit Board Connector Cables .................................................................9

3.3 Control Box...............................................................................................10

3.4 Flush mounted control (optional) ..............................................................10

4. Maximum Load and Placing of Load on Platform.............................................. 11

5. Operation of Liftgate............................................................................................12

NOTE: Never slide platform in or out with load on the platform.................12

5.1 Operating the ILSL with Control Box.........................................................12

5.2 Operating the ILSL with the 3-Button flush mounted control .....................13

5.3 Operation by Hand Held Remote Control..................................................14

5.4 Operation by Foot Control ........................................................................14

6. Preventive Maintenance and Quick Check......................................................... 15

6.1 Maintenance and Care.............................................................................15

6.2 Trailer to Tractor Connection Test............................................................16

6.3 Lubrication................................................................................................17

6.3.1 Lubrication Plan..........................................................................17

6.3.2 Checking and Changing the Oil...................................................19

6.3.3 Recommended Hydraulic Fluids .................................................19

6.4 Decal Placement and Inspection ..............................................................20

6.5 Quick Check List.......................................................................................22

7. Troubleshooting...................................................................................................23

7.1 Basic Function Check...............................................................................24

7.1.1 LIFTGATE is competely DEAD (No Clicking or Movement at all) 24

7.1.2 ON-OFF switch on, but all functions are dead.............................25

7.2 Electrical and Hydraulic Schematic...........................................................26

7.2.1 Main Wiring Diagram ..................................................................26

7.2.2 Electrical Schematics..................................................................27

7.2.2.1 Control board wiring and connector setup..................... 27