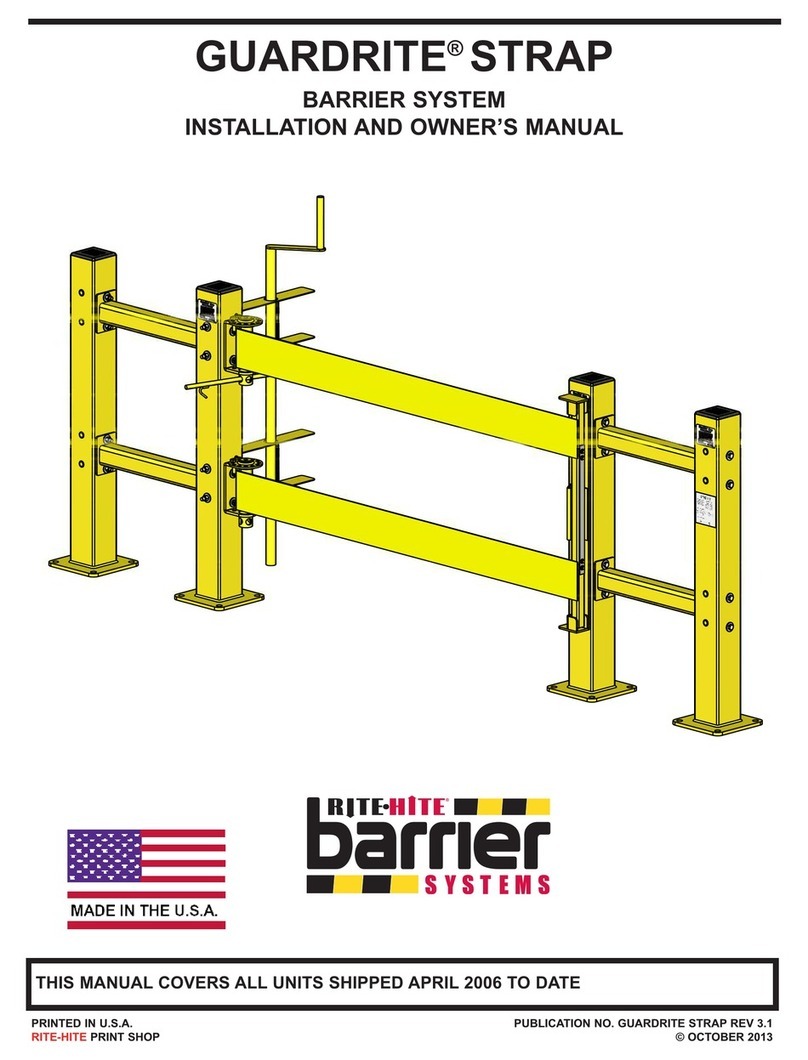

INSTALLATION

Posts Continued

Anchoring to Concrete*

The Dok-Guardian Light Duty Safety Barrier requires a

minimum concrete thickness of 6.75in [170mm] to provide

proper unit support.

Tools Required:

• Hammer drill with 1/2in x 7in concrete drill bit

• Impact wrench (65ft-lbs [88Nm]) with 3/4in impact socket

1. Tighten all rails and brackets securely before

anchoring the system to concrete.

2.

Titan HD Concrete Anchor Installation Instructions

Tools Required:

Hammer Drill with ¾” x 8” Concrete Drill Bit

Impact Wrench with 1-1/8” Impact Socket

Installation:

Drill a ¾” Diameter hole in the concrete. The hole should be drilled a minimum of 8” deep

or completely through the concrete.

Using a drill bit that is too small or excessively worn will make it very hard to install the

anchor. Using a drill bit that is too large will reduce the anchors load capacity.

Use compressed air to blow the concrete dust out of the hole. If this is not done, you may

not be able to tighten the anchor completely.

Using the Impact wrench and 1-1/8” socket, install the anchor through the base plate and

into the hole you drilled into the concrete.

Securely tighten all anchors with the impact wrench. Make sure the hex washer head is in

contact with the base plate.

Position the safety barrier in its

intended position. Use the base

plates of the post as a template

and drill (6) 1/2in diameter holes a

minimum of 7in [178mm] deep (or

completely through the concrete).

– Drill the appropriate size hole in

the concrete per anchor being

used. The hole should be drilled

a minimum of 1in [25mm] deeper

than the length of the anchor or

completely through the concrete.

– Using a drill bit that is too small or

excessively worn will make it very

hard to install the anchor. Using a

drill bit that is too large will reduce

the anchor's load capacity.

3.

Titan HD Concrete Anchor Installation Instructions

Tools Required:

Hammer Drill with ¾” x 8” Concrete Drill Bit

Impact Wrench with 1-1/8” Impact Socket

Installation:

Drill a ¾” Diameter hole in the concrete. The hole should be drilled a minimum of 8” deep

or completely through the concrete.

Using a drill bit that is too small or excessively worn will make it very hard to install the

anchor. Using a drill bit that is too large will reduce the anchors load capacity.

Use compressed air to blow the concrete dust out of the hole. If this is not done, you may

not be able to tighten the anchor completely.

Using the Impact wrench and 1-1/8” socket, install the anchor through the base plate and

into the hole you drilled into the concrete.

Securely tighten all anchors with the impact wrench. Make sure the hex washer head is in

contact with the base plate.

Use compressed air to clean the

drilled hole so you can tighten the

anchor completely.

4.

Titan HD Concrete Anchor Installation Instructions

Tools Required:

Hammer Drill with ¾” x 8” Concrete Drill Bit

Impact Wrench with 1-1/8” Impact Socket

Installation:

Drill a ¾” Diameter hole in the concrete. The hole should be drilled a minimum of 8” deep

or completely through the concrete.

Using a drill bit that is too small or excessively worn will make it very hard to install the

anchor. Using a drill bit that is too large will reduce the anchors load capacity.

Use compressed air to blow the concrete dust out of the hole. If this is not done, you may

not be able to tighten the anchor completely.

Using the Impact wrench and 1-1/8” socket, install the anchor through the base plate and

into the hole you drilled into the concrete.

Securely tighten all anchors with the impact wrench. Make sure the hex washer head is in

contact with the base plate.

Use an impact wrench and 3/4in

socket to install the (provided)

1/2in x 6in Titen HD concrete

anchors through base plate and into

the holes drilled into the concrete.

5.

Titan HD Concrete Anchor Installation Instructions

Tools Required:

Hammer Drill with ¾” x 8” Concrete Drill Bit

Impact Wrench with 1-1/8” Impact Socket

Installation:

Drill a ¾” Diameter hole in the concrete. The hole should be drilled a minimum of 8” deep

or completely through the concrete.

Using a drill bit that is too small or excessively worn will make it very hard to install the

anchor. Using a drill bit that is too large will reduce the anchors load capacity.

Use compressed air to blow the concrete dust out of the hole. If this is not done, you may

not be able to tighten the anchor completely.

Using the Impact wrench and 1-1/8” socket, install the anchor through the base plate and

into the hole you drilled into the concrete.

Securely tighten all anchors with the impact wrench. Make sure the hex washer head is in

contact with the base plate.

Securely tighten all anchors to

65ft-lbs [88Nm] with the impact

wrench. Make sure the hex washer

head is in contact with the base plate.

6. Repeat this process for all of the concrete anchors on

the post.

*Image credits: Titen HD Concrete Anchor instructions (strongtie.com)

Dok‑Guardian™ LD Safety Barrier Installation/Service/Owner's Manual Rite‑Hite®

8 Publication: AMEN00150 2019-11-13