CONTENT

General ..................................................................... 1

Symbols ...................................................... 2

Safety for individuals.................................. 3

General....................................................... 4

Installing company ..................................... 4

Crane installer ............................................ 4

Control of delivery .................................................... 5

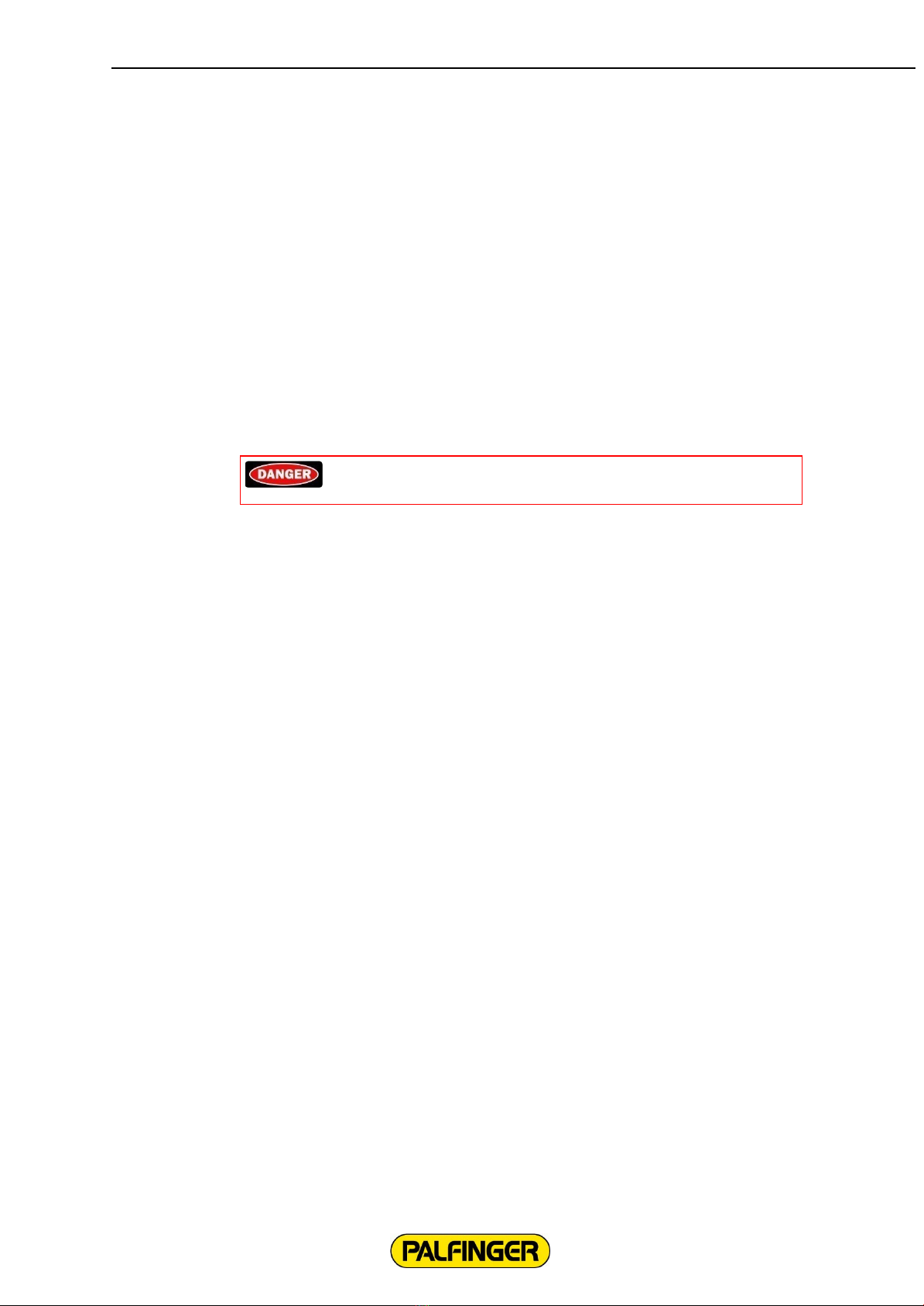

Overview component transport................. 6

Visual check for transport damages........... 6

Control of delivery...................................... 6

Overview of tools..................................................... 7

General....................................................... 8

Check of threaded fasteners ...................... 9

Crane handling........................................................ 12

Crane handling ......................................... 13

Storage ..................................................... 16

Set-Up..................................................................... 17

Main components .................................... 18

Crane Mounting ....................................... 20

Preparation for base assembly................. 22

Process of tightening................................23

Preserving the screw joints ...................... 24

Hydraulic system................................................... 28

Cleanness during assembly ...................... 29

Hydraulic circuit diagram ......................... 30

Electric system ....................................................... 30

Connecting the electric motor ..................31

Venting and cooling the electric motor.... 31

Electric circuit diagram............................. 32

Power Pack............................................................. 34

Filling the power pack tank ...................... 35

Start-Up ..................................................................36

Checklist before start-up.......................... 37

Start-up .................................................... 37

Bringing the crane into parking position.. 39

Checklist after start-up............................. 40

Post-assembly check..............................................41

Post-assembly check ................................ 42

Commissioning....................................................... 43

Commissioning ......................................... 44

Term Definitions....................................... 44