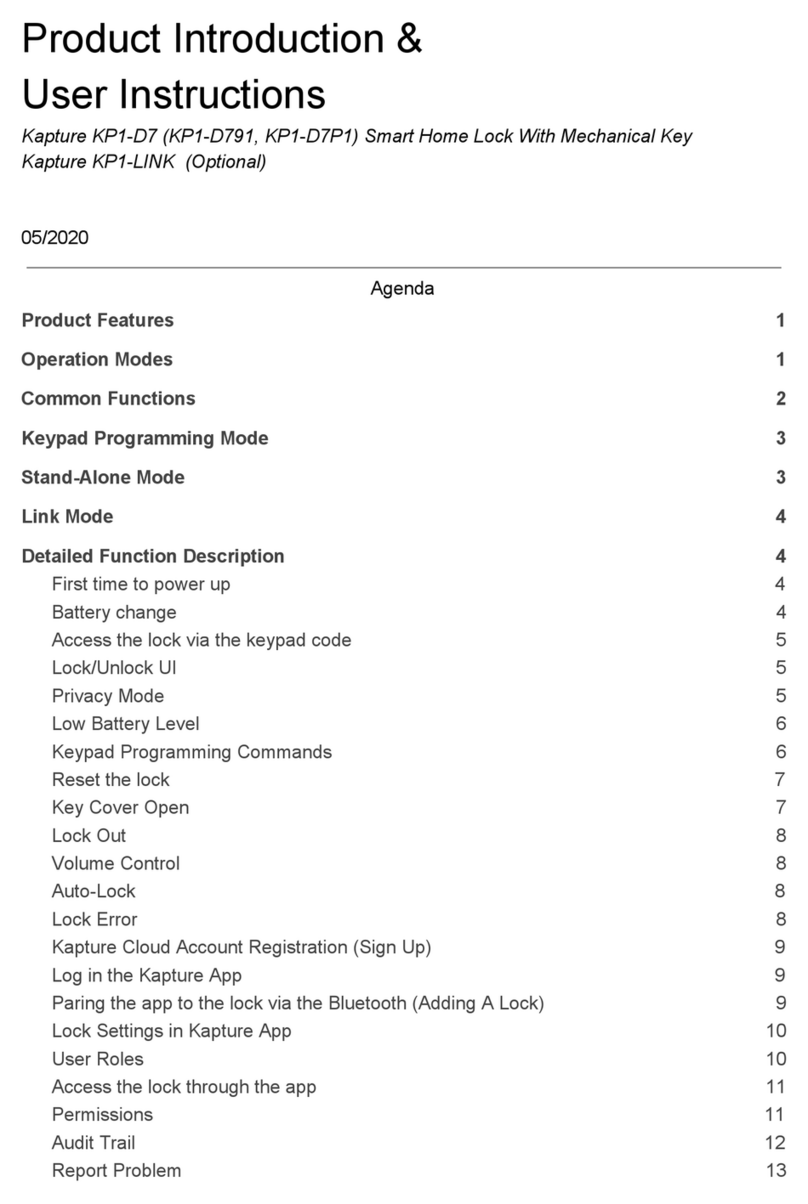

Top Jamb Installation-Push Side

14.3

22

31.7

A

1-14

78

916

C

OF HINGE PIVOT

11 18 (282.5mm)

136.5

5 38

14.3

916

44

1-34

Left hand door illustrated .Same dimensions apply to Right hand door

Measured from hinge Dimensions are in

Do not scale drawing

Cinches

(mm)

Door /wall/hardware/jamb conditions permitting

Opening Dim.A

TO 120°

120°-180° 3-15 16(100mm)

7-332(180mm)

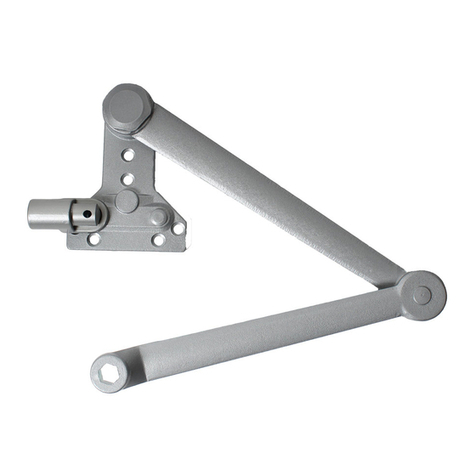

Screw and washer

Frame

Door

Leaf

Pinion cap

Power

Nut

Foot

1. Select degree of door.Use dimensions shown in chart to mark

location of attaching screws on door leaf and frame.

2. Assemble main arm to closer spindle

3. Attach closer body to frame with speed regulating valves toward

hinge.

4. Attach the foot of the forearm to door leaf.

Note:The nut is on the top for LH door and bottom for RH

Door.

5. Adjust length of forearm to position forearm at right angle to door

leaf. Then tighten the screw of forearm.

6. Snap pinion cap over spindle on top of closer.

7. Adjust door closer speed,Backcheck /Delayed action.

8. Loosen the Hex nut at the elbow of the forearm by wrench.

Open the door to the angle you need, and then tighen the hex Nut

to hold the door open.

Installation sequence:

Parallel Arm Installation-Push Side

Frame

Door

leaf

1. Select degree of door.Use dimensions shown in chart to

mark location of attaching screws on door leaf and frame.

2. Attach closer body to door with speed regualting

valves BACK of hinge.

3. Attach main arm as follows:

(a) Place open end wrench on bottom shaft and turn toward

hinge about 30°.

(b) Place main arm on top shaft, and insert arm screw into

top of shaft and tighten.

4. Attach P.A.B to top frame as shown.

5. Attach foot of forearm to P.A.B.

Note:The nut is on the top for RH door and bottom for LH

Door.

6. Adjust length of forearm to position main arm at parallel to

frame when connected to main arm.Use washer and screw

provided to secure pivot connection.

7. Snap pinion cap over spinle at bottom of the closer.

8. Adjust door closer speed,Backcheck /Delayed action.

9. Loosen the Hex nut at the elbow of the forearm by wrench.

Open the door to the angle you need, and then tighen the

hex Nut to hold the door open.

Installation sequence:

B

76

A

3

2-34

2

70

50.5

C

OF HINGE PIVOT

s

L

30°

516 8

1116 18

P.A.B

R

11 18 (282.5mm)

14.3

916

14.3

916

Opening Dim.A

TO 120°

120°-180°

9-1/2

(241mm)

5-7/8

(149.2mm)

5-3/16

(131mm)

1-9/16

(40mm)

Dim.B

Right hand door illustrated .Same dimensions apply to left hand door

Measured from hinge Dimensions are in

Do not scale drawing

Cinches

(mm)