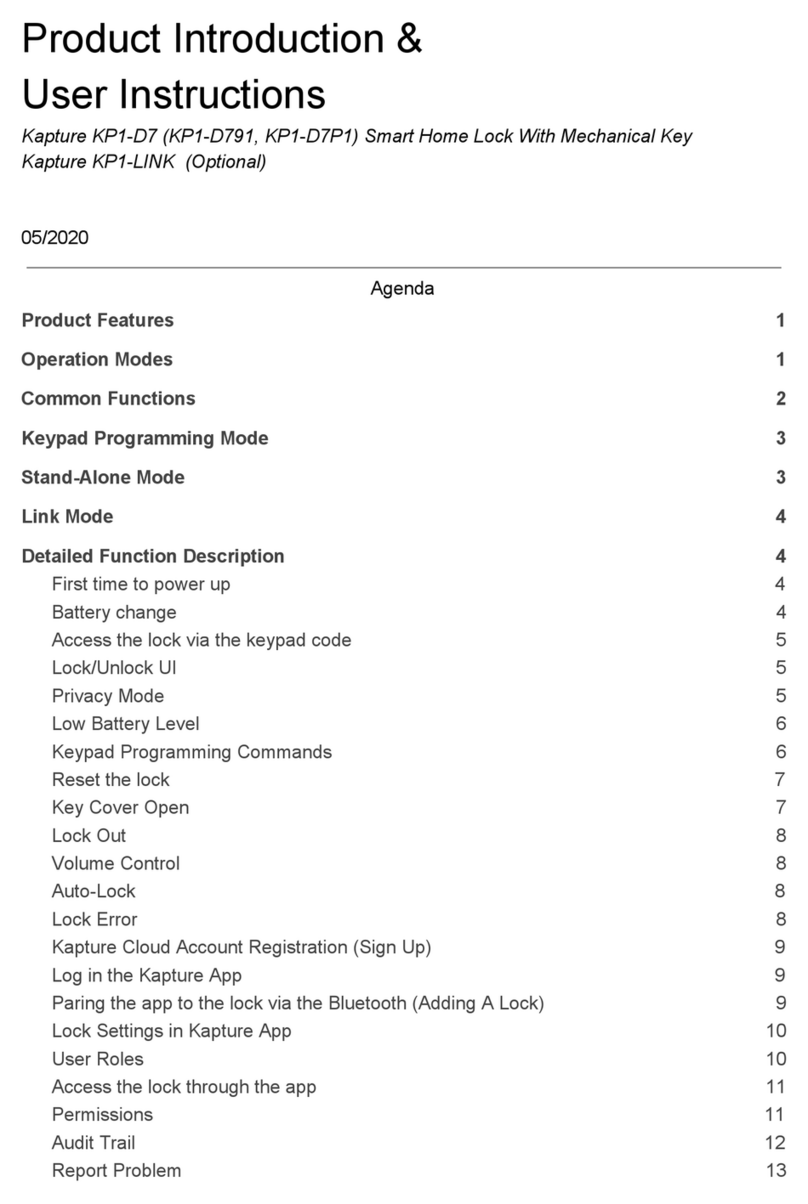

RIGHT HAND ASSEMBLY SHOWN

Fig.1 5/16" or 8 mm

HEX WRENCH

FILTER PLUG ARM STOP

CAUTION

IMPROPER INSTALLATION MAY RESULT IN

PERSONAL INJURY OR PROPERTY DAMAGE.

FOLLOW ALL INSTRUCTIONS CAREFULLY

PLEASE.

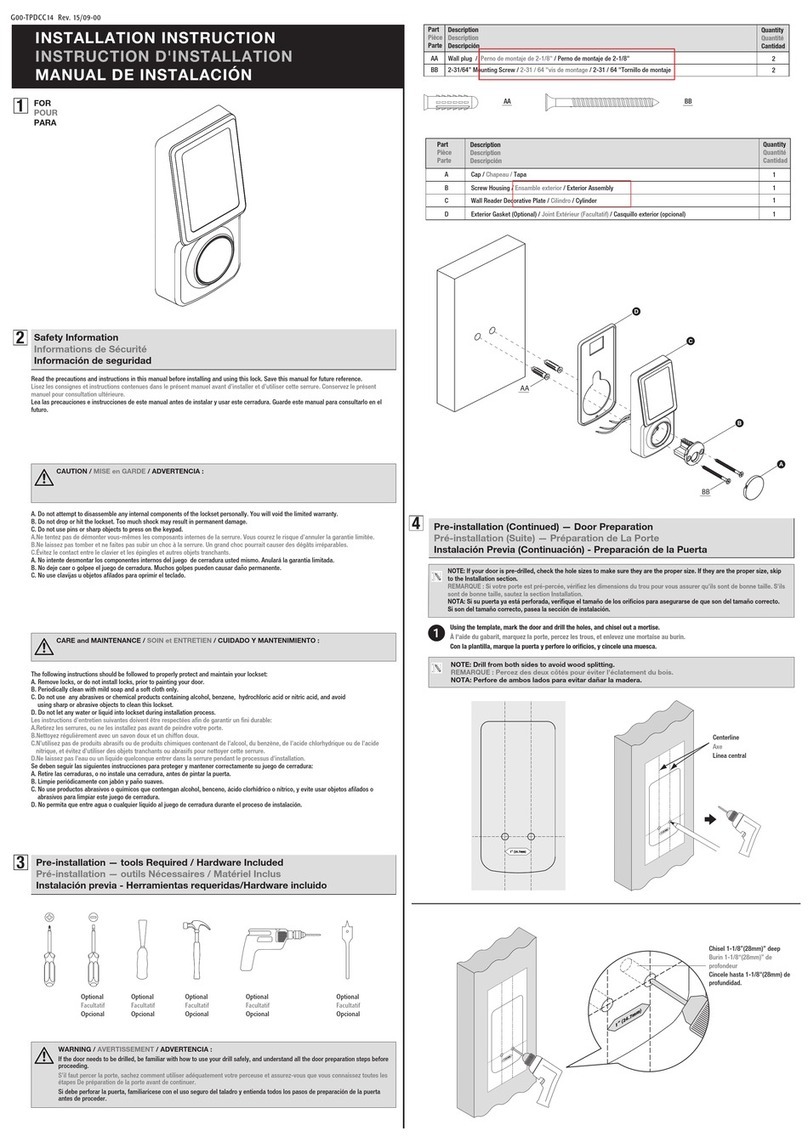

Fig.2 30 APPROX.

MAIN ARM

MAIN SPEED SCREW

COVER SCREW

SIZE NUT

BACKCHECK

SCREW

SELECTOR

VALVE SCREW

REMOVABLE INSERTS

TO CONVERT TO OPPOSITE

HAND COVER OPTIONAL DROP PLATE

Both the DS and DSHO shoes must be "Handed" to match

door. Before mounting, see Fig.1.

For left hand doors: All shoes are shipped assembled

for left hand doors. Insert 5/16" (8mm) Hex Wrench into arm

stop and turn counter-clockwise to seat stop as tightly as

possible.

For Right hand doors: (See illustration) Push filter

plug out of shoe. Using 5/16"(8 mm) Hex wrench, turn arm

stop clockwise to remove from shoe. Thread arm stop in

hole. Turn wrench counter-clockwise, seating stop as lightly

as possible. Insert filter plug into other hole.

INSTALLATION & ADJUSTMENT

INSTRUCTIONS

(LEFT HAND SHOWN-RIGHT HNAD OPPOSITE)

BEFORE INSTALLING THE ARM-TURN

BACKCHECK SELECTOR (on back of closer)

ALL THE WAY IN.

1. Adjust spring power to match door width as indictaed

by chart on page 1.

2. Select proper templating based on degree of

opening /dead stop. The closer and arm holes must be

located for same degree of opening/dead stop. Drill and

or top mounting holes in door and head jamb.

3. Attach complete arm to closer as shown at left . Arm will

be at about 30 angle to closer body.

Fasten with arm shaft screw. The arm will appear to be in

an incorrect position. This is to accomodate the pre-load

required for parallel arm mounted door closers

See Fig.2

4.Mount closer on door, using fasteners provieded.

NOTE:Arm will provied resistance.

5. Swing door open about 45 . Mount shoe to frame stop

per proper templating. Be sure to install the "Fifth" screw.

If Stop is not wide enough, use spacer block provided.

REGULATION

GC4400 Series closer has been regulated prior to shipment.

If adjustments are necessary. Carefully follow instructions:

ClOSING SPEED: See closer control diagram on page

1. To adjust main speed, turn reg. screw clockwise to

decrease or counter -clockwise to increase. To adjust latch

speed, turn reg. screw clockwise to decrease or

counter-clockwise to increase. Reg.screw locations are

shown at left on label.

BACKCHECK: is essential for proper operation of

cush-stop. Use enough backcheck to prevent arm from

striking arm stop with impact .To increase resistance, turn

reg. Screw clockwise.

-DO NOT USE ABRUPT BACKCHECK!.

6. Attach cover: Place cover insert into proper slots for either

R.H or L.H door. Place cover over closer and hold against

door while tightening cover screw firmly.

Page 3

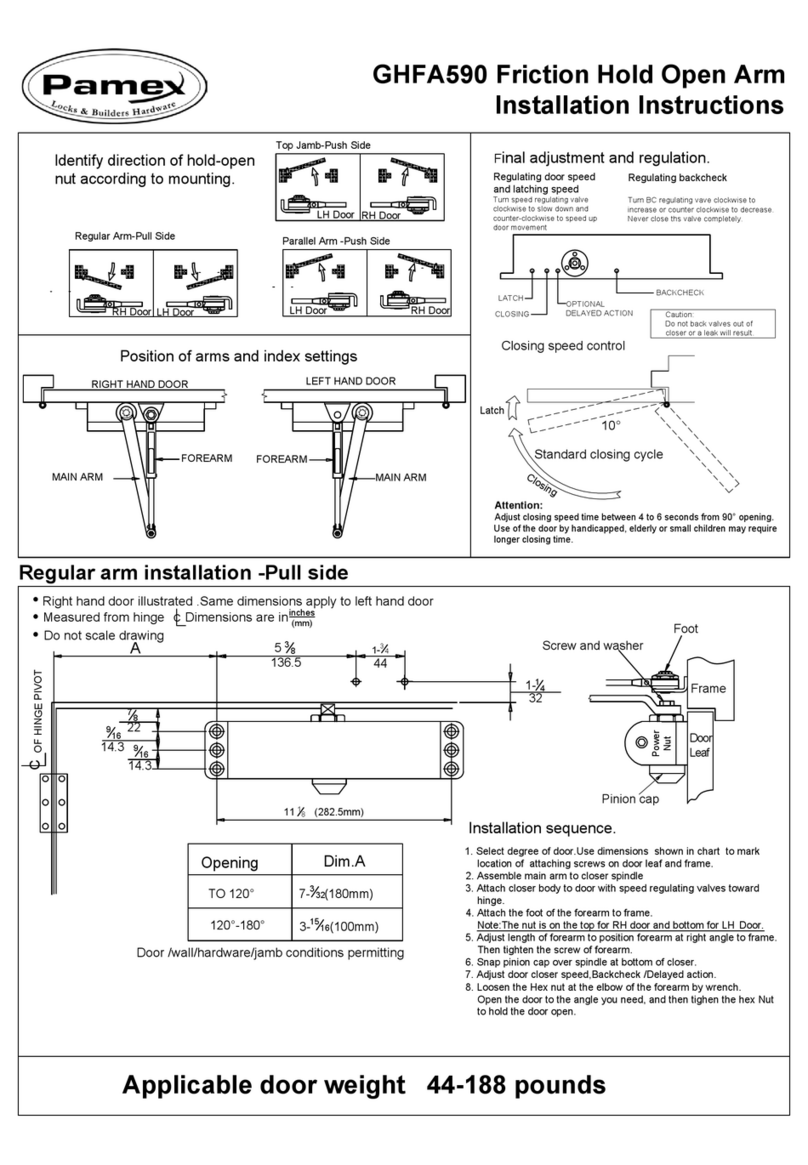

LATCH SPEED SCREW

SHAFT

SCREW

MAIN ARM

STUD

FOREARM

HOLD OPEN CONTROL

HANDLE(HOLD OPEN ARM)

HOW TO HOLD -OPEN

A quarter turn on the HOLD-OPEN CONTROL HANDLE engages or

disengages hold -open.