3 types of AHU Kit: Deluxe, Medium and Light.

Model Code IP 65 0-10V demand

control*

Outdoor temperature shift

compensation. Cold draft prevention

PAW-280PAH2 Yes Yes Yes

PAW-280PAH2M Yes Yes No

PAW-280PAH2L Yes No No

* With CZ-CAPBC2.

3

1

45

6

7

8

System & regulations. System overview

1. AHU Kit equipment (Field supplied)

2. AHU Kit system controller (Field supplied)

3. AHU Kit controller box (with control PCB)

4. Thermistor for Gas pipe (E2)

5. Thermistor for Liquid pipe (E1)

6. Thermistor for Suction air

7. Inter-unit wiring

8. Outdoor unit

Optional parts: Following functions are available by using different control accessories:

CZ-RTC4 Timer remote controller.

· Operation-ON/OFF

· Mode select

· Temperature setting

* Fan operation signal can be taken from the PCB.

PAW-OCT, DC12 V outlet. OPTION terminal.

· Output signal= Cooling/Heating/Fan status

· Defrost

· Thermostat-ON

CZ-CAPBC2 Mini seri-para I/O unit (advanced version only).

· Easy integration in external AHU control systems and BMS

· Demand control: 40 to 115 % (5 % steps) of nominal current by 0–10 V

input signal*

· Target temperature setting by 0–10 V or 0–140 Ωinput signal*

· Mode select or/and ON/OFF control

· Fan operation control

· Operation status output/ Alarm output

· Thermostat ON/OFF control

* Demand control by external BMS cannot be combined with the demand control or target temperature

setting accomplished by the thermostat. However, if simultaneous demand control and target temperature

setting is needed, this can only be achieved by using a second (optional) CZ-CAPBC2 interface.

CZ-T10 terminal / PAW-T10 PCB to connect to T10 connector.

· A Dry contact PCB has been developed to easily control the unit

· Input signal operation ON/OFF

· Remote control prohibition

· Output signal Operation ON status maximum 230 V 5 A (NO/NC)

· Output signal alarm status max. 230 V 5 A (NO/NC)

· Alarm output (by DC12V)

· Additional available contacts:

- External humidifier control (ON/OFF) 230 VAC 3 A

- External fan control (ON/OFF) 12V DC

- External filter status signal potential free

- External float switch signal potential free

- External leakage detection sensor or TH. OFF contact potential free

(possible usage for external blow out temperature control)

PCB, Power trans,

Terminal block

AHU Connection Kit

Standard wired remote controller.Thermistor x2

(Refrigerant: E1, E2)

Thermistor

(Air: TA; 1 sensor)

1. Remote control CZ-RTC4

2. New plastic IP 65 Box

3. PAW-T10 PCB for Dry Contact

4. 0-10V demand control PCB

5. Intelligent thermostat for:

· Cold draft prevention

· Outdoor temperature shift compensation

6. Terminal base for sensors and power supply

SET

AL1

OUT

ATU

PV

SV

ºC

ºC

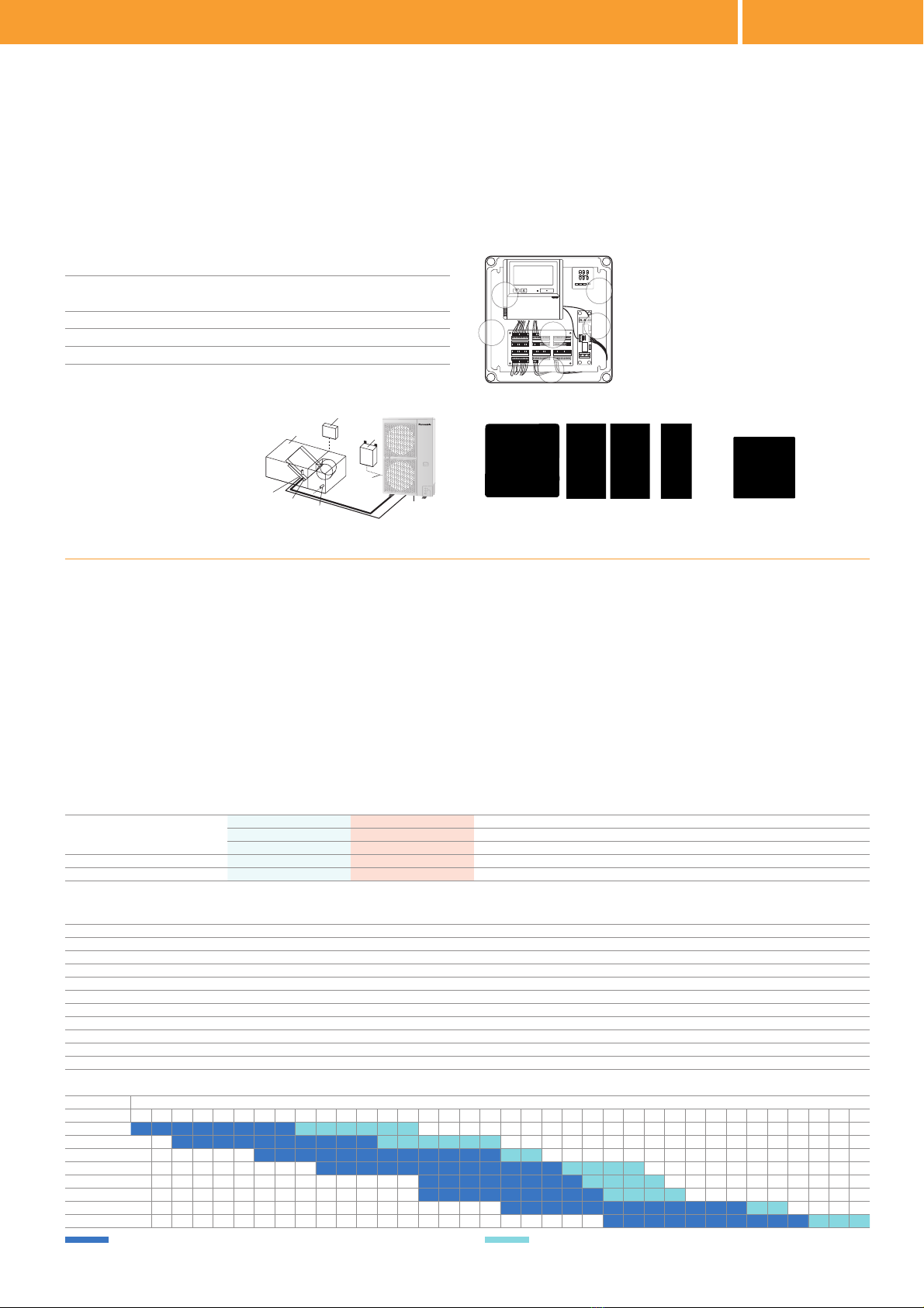

Air volume Dimensions Piping length Elevation difference (in/out) Piping connections

AHU connection kit / System combination Min / Max H x W x D Min / Max Max Liquid pipe Gas pipe

Outdoor unit capacity AHU m³/min mm m m Inch (mm) Inch (mm)

5,00kW PAW-280PAH2 8,00 / 13,00 404 x 425 x 78 5 / 30 10 1/4 (6,35) 1/2 (12,70)

6,00kW PAW-280PAH2 9,00 / 16,00 404 x 425 x 78 5 / 30 10 3/8 (9,62) 5/8 (15,88)

7,50kW PAW-280PAH2 12,00 / 25,00 404 x 425 x 78 5 / 30 10 3/8 (9,62) 5/8 (15,88)

10,00kW PAW-280PAH2 14,00 / 33,00 404 x 425 x 78 5 / 30 10 3/8 (9,62) 5/8 (15,88)

12,50kW PAW-280PAH2 19,00 / 35,00 404 x 425 x 78 5 / 30 10 3/8 (9,62) 5/8 (15,88)

14,00kW PAW-280PAH2 19,00 / 35,00 404 x 425 x 78 5 / 30 10 3/8 (9,62) 5/8 (15,88)

20,00kW PAW-280PAH2 28,00 / 66,00 404 x 425 x 78 5 / 70 10 3/8 (9,62) 1 (25,40)

25,00kW PAW-280PAH2 38,00 / 74,00 404 x 425 x 78 5 / 70 10 1/2 (12,70) 1 (25,40)

AHU PACi Elite

Cooling capacity Heating capacity Dimensions Piping length Elevation difference (in/out)

Nominal Nominal H x W x D Min / Max Max

kW kW mm m m

PAW-280PAH2 6,00 / 25,00 7,00 / 28,00 404 x 425 x 78 5 / 30* 10

PAW-280PAH2+PAW-280PAH2 50,00 56,00 404 x 425 x 78 5 / 30* 10

* For U-200PE2E8A and U-250PE2E8A.

Air flow rate m³/min

Outdoor unit 8,00 8,33 9,00 10,00 10,83 11,67 12,00 13,00 13,33 14,00 15,00 16,00 16,67 18,00 19,00 20,00 25,00 26,67 28,00 30,00 33,00 35,00 36,00 38,00 40,00 43,33 45,00 50,00 58,33 66,00 66,67 71,67 74,00 75,00 83,33 90,00

5,00kW

6,00kW

7,50kW

10,00kW

12,50kW

14,00kW

20,00kW

25,00kW

Standard range of air flow rate under standard conditions (air intake temperature in cooling mode from 18 to 32°C DB). Extended range of air flow rate under special conditions (air intake temperature in cooling mode from 18 to 30°C DB).

1

4

2

5

3

6

AHU Kit connects PACi outdoor units to Air Handling Units system.

The Panasonic AHU Kits offer a wealth of connectivity possibilities so can

be easily integrated into many systems.

Application: Hotels, offices, server rooms or all large buildings where air

quality control such as humidity control and fresh air and is needed.

259

NEW —COMMERCIAL

03 EU BIGRAC GEN 19.indd 259 5/4/19 9:28