3

SAFETY PRECAUTIONS

xEntrust all installation and electrical work to the dealer where the system was purchased or a professional

installer. Faulty installation performed by the purchaser can result in water leakage, electrical shock, fire or other

mishaps.

xPerform all installation and electrical work in accordance with the instructions in "Attention Installation Work

Coordinators" and "Attention Electrical Work Coordinators." Faulty installation can result in refrigerant or water

leakage, electrical shock, fire or other mishaps.

xHave all electrical work conducted by persons qualified to perform such electrical work, in accordance with

"Technical Standards for Electrical Equipment," "Internal Wiring Regulations," "Attention Installation Work Co-

ordinators," "Attention Electrical Work Coordinators" and the gas heat pump air-conditioner power supply speci-

fications, always using a dedicated circuit. Inadequate power supply circuit capacity, defective construction or

other problems can result in electrical shock or fire.

xAlways use a dedicated branch circuit for electric wiring, not sharing the use of that circuit with other electric

machinery. Such shared use can trip the circuit breaker and cause secondary damage.

xFor wiring, use and correctly connect the stipulated cable, carefully securing the cable to prevent transmission

of external force to the terminal connecting section. Faulty connections or securing can generate heat, fires or

other damage.

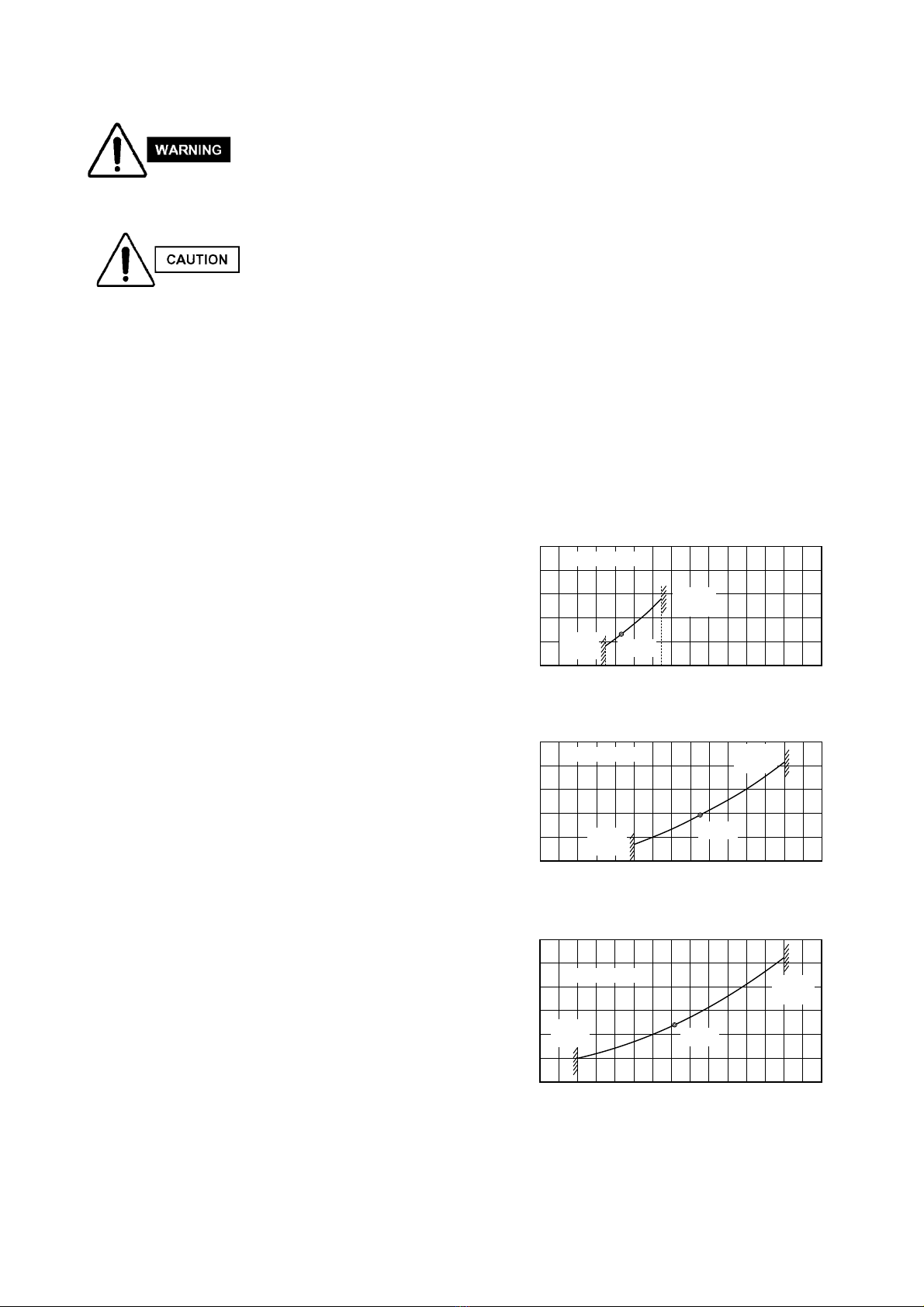

xBased on the refrigeration air-conditioner equipment facility standards (S0010) of the High Pressure Gas Safety

Institute of Japan, indoor leakage of refrigerant gas must not be allowed to surpass the critical concentration

level of 0.3kg/m3(the limit for safe human activity). When exceeding this level, openings should be created

between neighboring rooms or installation should be made of mechanical ventilation equipment operated in

linkage with gas leakage alarm devices. Refrigerant gas leaks in cramped indoor spaces that exceed the critical

concentration can cause oxygen depletion accidents.

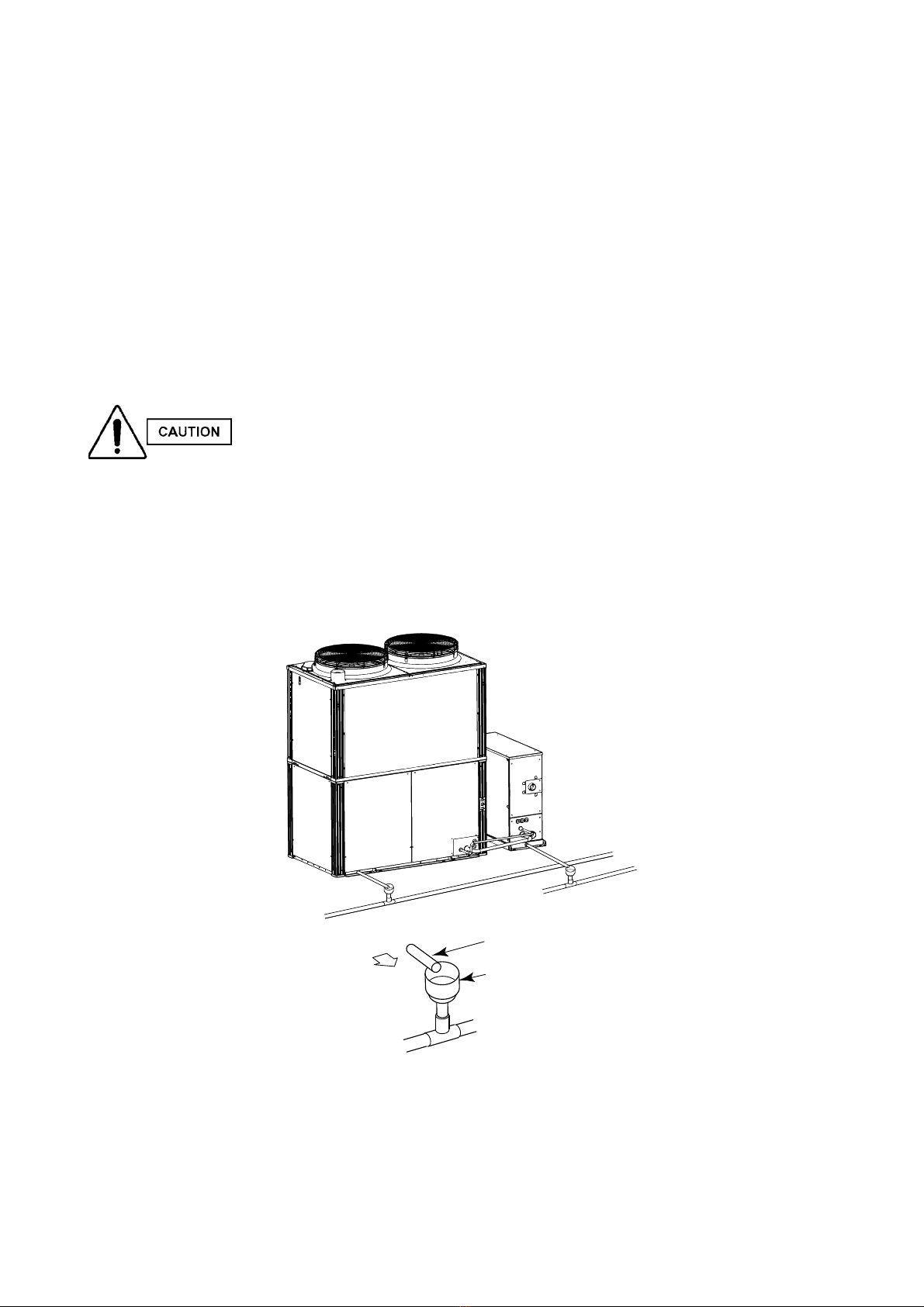

xAlways install the water heat exchanger unit at locations capable of supporting its weight (fixing the anchor bolts

in place). Inadequate strength can cause the unit to tip over or result in other injury-threatening accidents.

xPerform the stipulated installation work with full consideration and preparations for the threat of typhoons and

other strong winds, earthquakes and other emergency situations. Faulty installation work can result in the units

tipping over or other injury-threatening accidents in such circumstances.

xIn the event of refrigerant gas leaks during the work process, the area should be ventilated immediately. Refrig-

erant gas coming into contact with welding burner fires can result in the generation of toxic gas.

xUpon completion of the refrigerant pipe work, perform air tightness tests using nitrogen gas to confirm the

absence of leaks. Leakage of refrigerant gas into indoor areas, followed by contact with fire from fan heaters,

stoves, ranges or other appliances, can result in the generation of toxic gas.

xAvoid shared use of outdoor unit exhaust drainpipes and water heat exchanger unit drainpipes. Flows of exhaust

gas into the room can result in gas poisoning and other accidents.

xDo not directly connect the water heat exchanger unit drain pipes to drainage generating sulfuric gases or other

harmful gases. Flows of harmful gases into the room can result in gas poisoning and other accidents.

xNever directly touch refrigerant gas when handling it. Such contact can cause frostbite.

xNever install a water heat exchanger unit in locations where there is a threat of the generation, inflow, buildup or

leakage of combustible gas, or in locations where volatile flammable items are handled. Ignition of combustible

materials or ignitable gas can cause fires.

xInstall drain pipes in accordance with the stipulations in "Attention Installation Work Coordinators" to ensure

reliable drainage, while applying insulation to avoid dew condensation. Defective piping work can result in water

leakage, water damage to household effects and other problems.

xPerform the refrigerant pipe insulation work in accordance with the stipulations in "Attention Installation Work

Coordinators." Failure to properly insulate can cause water leakage, burns and other accidents and injuries. (For

thick pipes, use insulation materials with heat resistance of 120°C or above.)

xInstall ground connections, but do not connect the grounding cable to gas pipes, water pipes,

lightning conductors or telephone ground cables. Defective ground connections can cause

electrical shock.

xAlways install a ground leakage breaker.

Failure to attach such a breaker can cause electrical shock and fire.