9

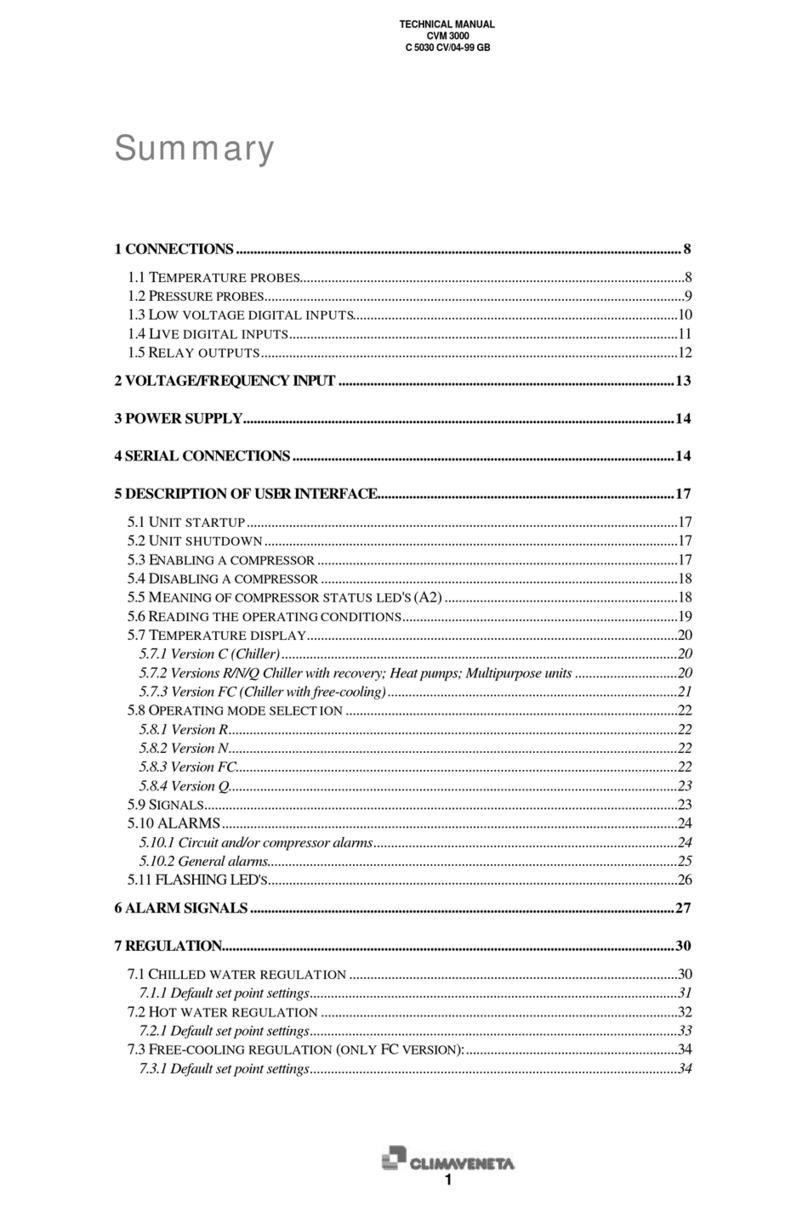

WORKING TEMPERATURE SETTING7.

HEATING SET POINT SETTING

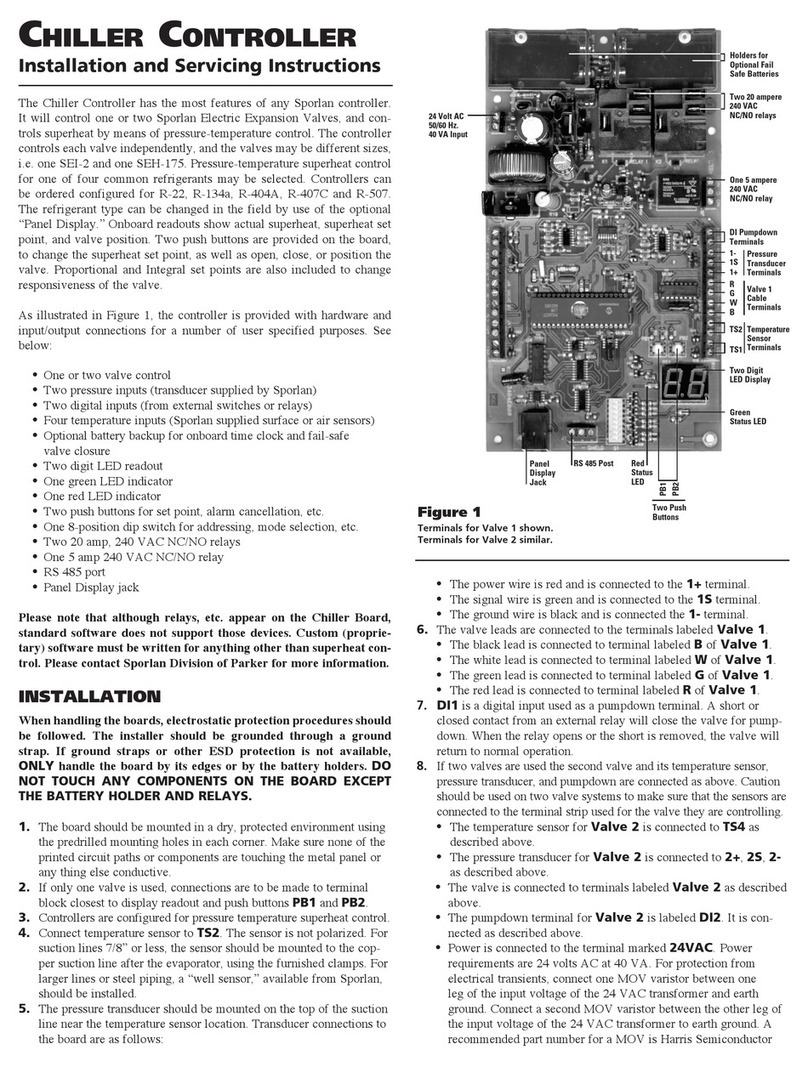

Image Procedure to be adopted

To access the parameter menu, first press the SET key and

browse through by means of the arrow keys up to "Heating Set".

Then, to set the COOLING SET value, just press the screwdriver

key and enter into the modification of the set involved.

At this stage, by increasing or decreasing its value, the parameter

can be changed by means of the arrows (+ and -). Once the desired

temperature is decided, just confirm the operation by pressing

again the screwdriver key.

SET

C1

C2

R

LR

SETTING

Hot Set +50.0"C

SET

C1

C2

R

LRSETTING ADJUST

Hot Set +50.0"C

SET

C1

C2

R

LR

SETTING ADJUST

Hot Set +49.9"C

COOLING SET POINT SETTING

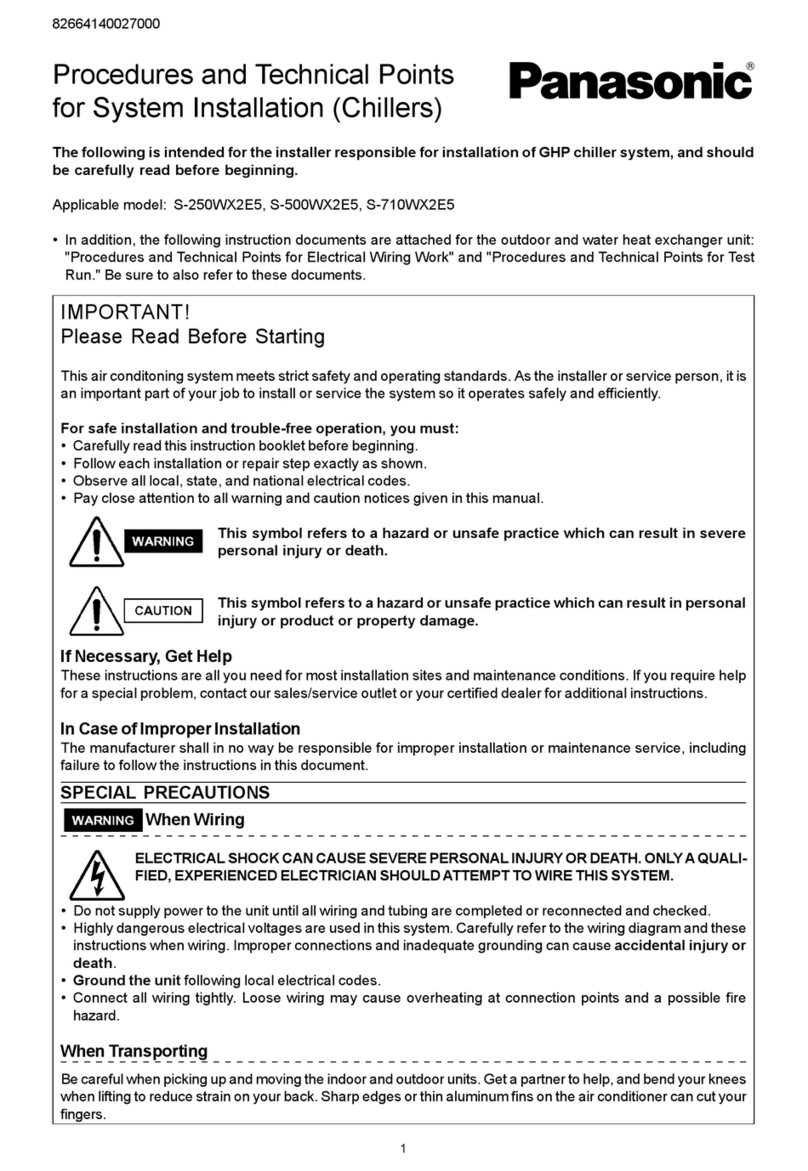

Image Procedure to be adopted

To access the parameter menu, first press the SET key and

browse through by means of the arrow keys up to "Cooling Set".

Then, to set the COOLING SET value, just press the screwdriver

key and enter into the modification of the set involved.

At this stage, by increasing or decreasing its value, the parameter

can be changed by means of the arrows (+ and -). Once the desired

temperature is decided, just confirm the operation by pressing

again the screwdriver key.

SET

C1

C2

R

LR

SETTING

Cold Set +20.0"C

SET

C1

C2

R

LRSETTING ADJUST

Cold Set +20.0"C

SET

C1

C2

R

LR

SETTING ADJUST

Cold Set +19.9"C

N.B.

There is a second cooling operation set point (parameter: 2nd C.

set). and a second heating working set point (parameter: 2nd H.

set). Both parameters (2nd C. set - 2nd H. set) can be operated

when the digital input (M11 3-4) is closed. For further information,

consult the installer or the Technical After Sales Service.

Cooling set

point values

Minimum -10 °C

Maximum 20°C

Heating set

point values

Minimum 30°C

Maximum 50°C