Page 7

Chapter

4

DATA MODIFICATION

4-1 Data Modification Menu.............................................................................. 4-2

4-2 PCB Data ................................................................................................... 4-3

4-3 Board Recognition Data ............................................................................. 4-4

4-3-1 Selecting REF .....................................................................................................4-5

4-3-2 Evolution Data.....................................................................................................4-6

4-4 Dispensing Code Data ............................................................................... 4-7

4-4-1 Multi-point Data...................................................................................................4-8

4-5 Head Data .................................................................................................. 4-9

4-5-1 Priming Shot Data.............................................................................................4-10

4-6 Block Attribute Data.................................................................................. 4-11

4-7 Mount Data............................................................................................... 4-12

4-8 Function Switch ........................................................................................ 4-13

4-9 Data Check............................................................................................... 4-14

4-10 Form Print................................................................................................. 4-15

Chapter

5

TEACHING

5-1 Before Teaching.......................................................................................... 5-2

5-1-1 Recognition .........................................................................................................5-2

5-1-2 Lighting ...............................................................................................................5-3

5-2 Board Recognition Teaching ...................................................................... 5-4

5-2-1 Board Recognition ..............................................................................................5-4

5-2-2 Flowchart of Board Recognition Teaching...........................................................5-4

5-2-3 Teaching Procedures ..........................................................................................5-5

5-3 Bad Mark Recognition Teaching................................................................. 5-9

5-3-1 Bad Mark Recognition.........................................................................................5-9

5-3-2 Flowchart of Bad Mark Recognition Teaching.....................................................5-9

5-3-3 Creating Procedures .........................................................................................5-10

5-4 Dot Recognition Teaching ........................................................................ 5-15

5-4-1 Dot Recognition.................................................................................................5-15

5-4-2 Flowchart of Dot Recognition Teaching.............................................................5-15

5-4-3 Creating Procedures .........................................................................................5-16

Chapter

6

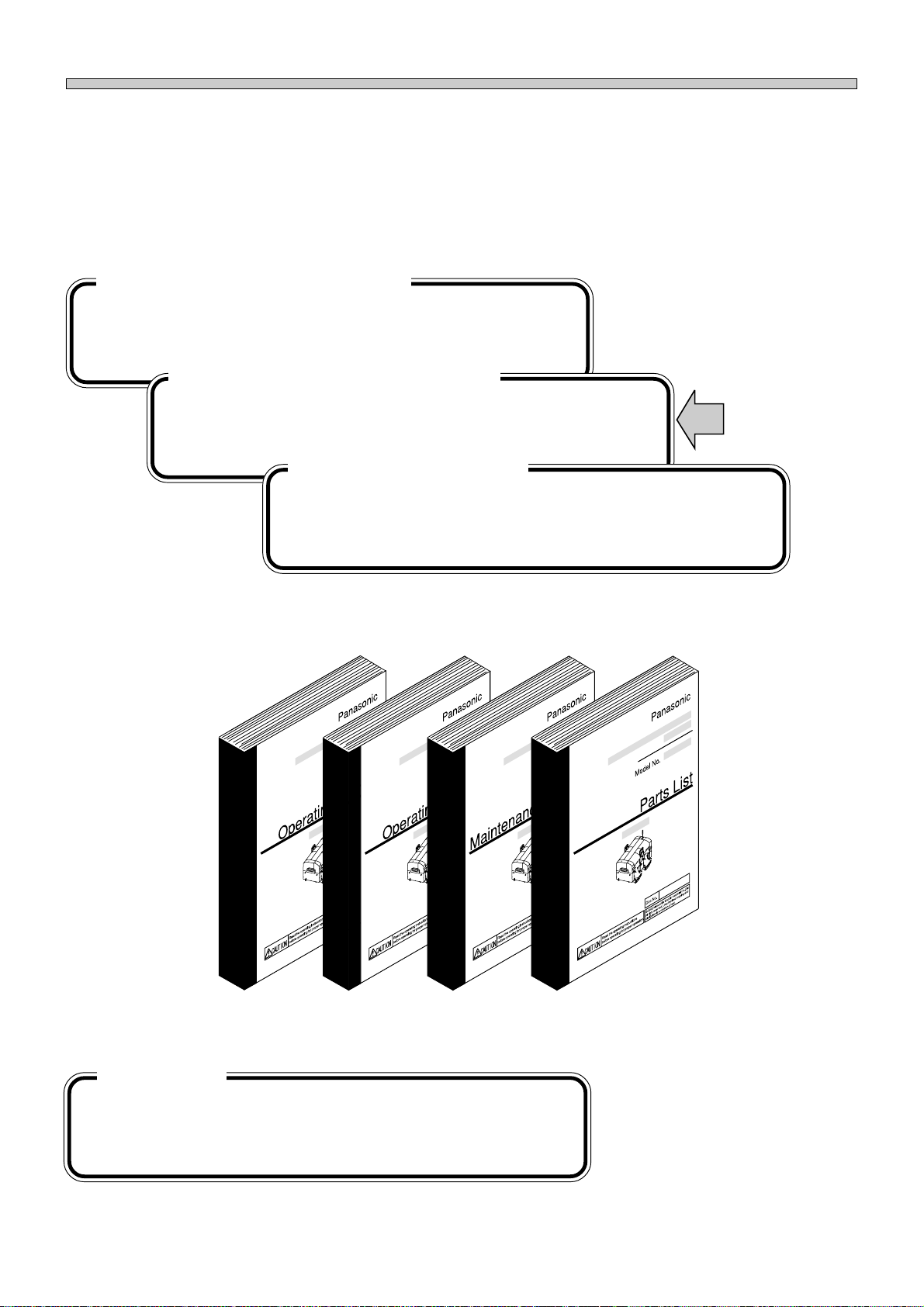

FILE OPERATION

6-1 File Operation of PT ................................................................................... 6-2

6-1-1 Loading Data.......................................................................................................6-3

6-2 File Operation of Floppy Disk ..................................................................... 6-5

6-2-1 Loading Data.......................................................................................................6-6

6-2-2 Saving Data ........................................................................................................6-8

6-2-3 Loading and Saving the Machine Parameter....................................................6-11

6-2-4 Loading the Coordinate Data ............................................................................6-13

293C-E-EMA00-A02-01